Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

This handy pocket sized guide offers all the tips, tricks, and ideas a woodworker or furniture maker needs to get the most out of this indispensable tool.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 77

Veröffentlichungsjahr: 2011

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

THEMissingSHOP MANUAL

BAND SAW

THEMissingSHOP MANUAL

BAND SAW

{the tool information you need at your fingertips}

© 2010 by Skills Institute Press LLC

“Missing Shop Manual” series trademark of Skills Institute Press

Published and distributed in North America by Fox Chapel Publishing Company, Inc.

Band Saw is an original work, first published in 2010.

Portions of text and art previously published by and reproduced under license with Direct Holdings Americas Inc.

ISBN 978-1-56523-492-5

eISBN 978-1-60765-009-6

Library of Congress Cataloging-in-Publication Data

Band Saw.

p. cm. -- (The missing shop manual)

Includes index.

ISBN 978-1-56523-492-5

1. Band saws. I. Fox Chapel Publishing.

TT186.B287 2010

684’.083--dc22

2010016958

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free 800-457-9112 or visit us at www.FoxChapelPublishing.com.

Note to Authors: We are always looking for talented authors to write new books in our area of woodworking, design, and related crafts. Please send a brief letter describing your idea to Acquisition Editor, 1970 Broad Street, East Petersburg, PA 17520.

Printed in China

First printing: November 2010

ePub Version 1.0

Because working with wood and other materials inherently includes the risk of injury and damage, this book cannot guarantee that creating the projects in this book is safe for everyone. For this reason, this book is sold without warranties or guarantees of any kind, expressed or implied, and the publisher and the author disclaim any liability for any injuries, losses, or damages caused in any way by the content of this book or the reader’s use of the tools needed to complete the projects presented here. The publisher and the author urge all woodworkers to thoroughly review each project and to understand the use of all tools before beginning any project.

Contents

Chapter 1:Band Saw

Chapter 2:Band Saw Blades

Chapter 3:Cutting Curves

Chapter 4:Straight Cuts

Chapter 5:Cutting Duplicate Pieces

Chapter 6:Band Saw Joinery

Chapter 7:Cabriole Legs

Index

WHAT YOU WILL LEARN

Chapter 1:Band Saw, page 8

Chapter 2:Band Saw Blades, page 32

Chapter 3:Cutting Curves, page 46

Chapter 4:Straight Cuts, page 60

Chapter 5:Cutting Duplicate Pieces, page 74

Chapter 6:Band Saw Joinery, page 88

Chapter 7:Cabriole Legs, page 100

CHAPTER 1:

Band Saw

For ease of operation and wide-ranging utility, the band saw is hard to beat. It is the only woodworking machine capable of making both straight and contour cuts. In addition to crosscutting and ripping, it is well suited for cutting curves and circles, enabling the woodworker to produce anything from a dovetail joint to a cabriole leg.

Both rough and delicate work fall within its domain. Fitted with a ½-inch blade—the widest size available for most consumer-grade machines—a band saw can resaw 6-inch-thick lumber into two thinner pieces in a single pass. And with a 1⁄16-inch blade, a band saw can zigzag its way through a board at virtually any angle, even making 90° turns during a cut. Many cuts can be made freehand by simply pivoting the workpiece around the blade. With the cutting techniques and shop-made jigs presented in this chapter, you will be able to turn out intricate curves, cut perfect circles, and produce uniformly square-edged rip cuts and crosscuts.

This quarter-circle-cutting jig is an ideal time-saver for rounding corners for tabletops. The jig pivots around a fixed point, taking the guesswork out of cutting perfect arcs.

A ¼-inch band saw blade weaves its way along a curved cutting line, paring away a block of mahogany to form a graceful cabriole leg.

Compared to the radial arm saw or table saw, the band saw is a quiet machine, so noise-related fatigue is rarely a problem. Moreover, very little of the blade—usually only ⅛ inch—is ever exposed while it is running. And since the cutting action of the blade bears down on the workpiece, pushing it against the table instead of back toward the operator, kickback cannot occur. For this reason, the band saw is the tool of choice for ripping short or narrow stock.

Band saws are classified according to their throat width, which supports the machine’s upper wheel. Band saws for home workshops fall in the 10- to 14-inch range. Saws are also categorized according to their depth-of-cut capacity, which corresponds to the maximum gap between the table and the upper guide assembly. In choosing a band saw, look for one with a sturdy table that can tilt 45° in one direction and at least 10° in the other. In addition, consider spending a little more for a ¾-horsepower motor.

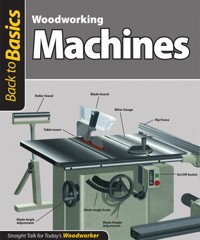

ANATOMY OF A BAND SAW

1.Wheel cover

Protects operator from wheel and blade; may be removable or hinged to provide access to wheel.

2.Wheel

Rimmed by a rubber tire that cushions the blade and keeps it from slipping.

3.Throat column

Supports blade between wheels and protects operator from blade.

4.Table lock knob

Allows table to be tilted for bevel or compound cuts; a second knob is located on opposite side of table.

5.Tension handle

Raises and lowers upper wheel to adjust blade tension.

6.Blade guard

Protects operator from blade; moved up and down with guide assembly.

7.Upper guide assembly

Raised and lowered depending on thickness of workpiece; includes blade guard, thrust bearing and guide blocks. Setscrews release guide blocks for lateral adjustment; thumbscrews release bearing and blocks for front-to-back adjustment by means of adjusting knobs. (A fixed guide assembly with thrust bearing and guide blocks is located under table insert.)

8.Miter gauge

Guides workpiece across table for crosscuts or miter cuts.

9.Rip fence

Guides workpiece across table for rip cuts, crosscuts and resawing.

10.Table leveling pin

Adjustable to keep miter gauge slot properly aligned.

11.Table insert

Prevents wood pieces from falling into table and supports workpiece when close to blade; usually made of aluminum.

12.Dust spout

For dust collection system.

13.On/Off switch

Can be padlocked in off position for safety.

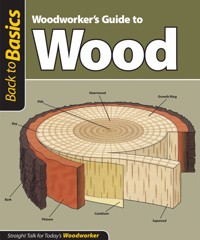

As the name suggests, a band saw blade is a continuous steel band. Varying in length from roughly 72 inches to 104 inches depending on the size of the machine, the blade runs around rubber-rimmed wheels and passes through an opening in the saw table. One of the wheels—typically the lower one—is the drive wheel, which is turned by a motor. The blade is not fastened to the wheels but is held in place by tension and turns through its elliptical path at roughly 3,000 feet per minute—the average cutting speed for a 14-inch saw.

The three-wheel band saw’s wide throat capacity—typically 20 inches, rather than the 10 to 14 inches available on most two-wheel models—makes it more convenient for working with particularly large workpieces.

The blade is kept taut by means of a tension handle, which raises and lowers the upper wheel. A tilt knob that cants the upper wheel is used to keep the blade centered on the wheels. The blade is kept steady on its path by thrust bearings located behind the blade above and below the table, and by guide blocks, which prevent lateral movement. Although some cuts can be made freehand, a rip fence and miter gauge are available with many models to guide workpieces across the table.

SETTING UP

The band saw has a reputation among some woodworkers as a relatively imprecise cutting tool. And yet, band saws are routinely used in industry to cut very hard materials such as metal to very close tolerances. The fact remains, however, that the tool can only be made to cut straight edges and precise curves if it is kept finely tuned.

The ideal is for the blade to cut squarely into the workpiece, producing a smooth, accurate result. But the peculiarities of band saw geometry can make this ideal difficult to achieve. After bending around the machine’s wheels at 35 miles per hour, a section of the blade must straighten out by the time it reaches the saw table a split second later.

For this to happen, the adjustable parts of the saw must be kept in proper alignment so the blade runs smoothly and square to the table. Particular attention should be paid to the wheels, the guide assembly and the saw table itself.

To tune your band saw, unplug it, install and tension the blade you plan to use (page 23), then follow the setup steps detailed on the following pages. Take the time to do it right. Adjusting the band saw may be more time-consuming than learning how to operate the tool. But the advantages of a well-tuned machine will be noticeable not only in the quality of the results but also in the longevity of your blades and of the band saw itself. Misaligned wheels or poorly adjusted guide blocks can lead to premature blade wear or breakage.

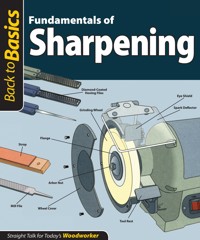

Installing nonmetallic guide blocks on a band saw can reduce wear and tear appreciably (page 27)