28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

Land Rover Defender, 90 and 110 Range - 30 Years of the Coil-Spring 4x4 Models charts the evolution of the coil-sprung Defender vehicles. When Land Rover switched from leaf springs to coil springs for their utility models in 1983, it was a major step forward. The first coil-sprung model, the One Ten, replaced the Series III 109s. The short-wheelbase Ninety replaced the Series III 88s in 1984. From 1990, the models were all re-branded as Land Rover Defenders - 90, 110 and 140 - as the Land Rover range expanded and the marketing teams wanted a new name.Topics covered include: Origins of the Defender and early Ninety and One Ten Models; Development and use of the long-wheelbase models; Special conversions and Defenders built outside the UK, including in Australia and South Africa; Military and emergency service use of the Defender; Detailed examinations of engines and engineering, and the focus on diesel power; The future of the Defender. Charts the evolution of the coil-sprung Defender vehicles - the early 90 and 110 models from 1983 to present day. A must buy for all Land Rover enthusiasts. Superbly illustrated with 300 colour photographs. James Taylor is a well-known writer on classic motoring and a specialist on the Land Rover marque.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 404

Veröffentlichungsjahr: 2013

Ähnliche

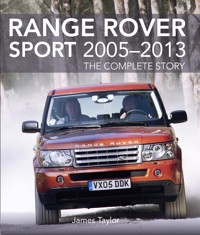

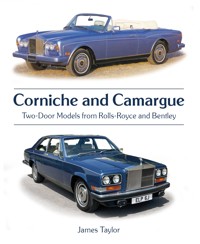

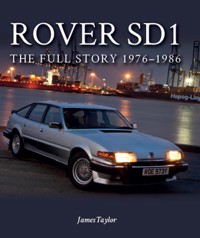

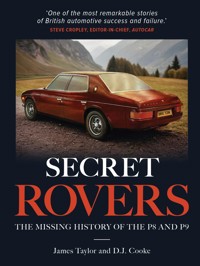

OTHER TITLES IN THE CROWOOD AUTOCLASSICS SERIES

AC COBRA Brian Laban

ALFA ROMEO 916 GTV AND SPIDER Robert Foskett

ALFA ROMEO COUPÉS 1954–1989 Graham Robson

ALFA ROMEO SPIDER John Tipler

ASTON MARTIN DB4, DB5 & DB6 Jonathan Wood

ASTON MARTIN DB7 Andrew Noakes

ASTON MARTIN V8 William Presland

AUDI QUATTRO Laurence Meredith

AUSTIN HEALEY Graham Robson

BMW 3 SERIES James Taylor

BMW 5 SERIES James Taylor

CITROËN DS SERIES John Pressnell

FORD CAPRI Graham Robson

FORD ESCORT RS Graham Robson

JAGUAR E-TYPE Jonathan Wood

JAGUAR XJ-S Graham Robson

JAGUAR XK8 Graham Robson

JENSEN INTERCEPTOR John Tipler

JOWETT JAVELIN AND JUPITER Geoff McAuley & Edmund Nankivell

LAMBORGHINI COUNTACH Peter Dron

LANCIA INTEGRALE Peter Collins

LANCIA SPORTING COUPÉS Brian Long

LOTUS & CATERHAM SEVEN John Tipler

LOTUS ELISE John Tipler

LOTUS ESPRIT Jeremy Walton

MGA David G. Styles

MGB Brian Laban

MGF AND TF David Knowles

MG T-SERIES Graham Robson

MASERATI ROAD CARS John Price-Williams

MERCEDES-BENZ CARS OF THE 1990S James Taylor

MERCEDES-BENZ SALOONS OF THE 1960S AND 70S Laurence Meredith

MERCEDES SL SERIES Andrew Noakes

MORGAN THREE-WHEELER Peter Miller

MORGAN 4-4 Michael Palmer

ROVER P5 & P5B James Taylor

SAAB 99 & 900 Lance Cole

SUBARU IMPREZA WRX AND WRX STI James Taylor

SUNBEAM ALPINE AND TIGER Graham Robson

TRIUMPH SPITFIRE & GT6 Janes Taylor

TRIUMPH TR7 David Knowles

VOLKSWAGEN TRANSPORTER Laurence Meredith

VOLKSWAGEN GOLF GTI James Richardson

VOLVO P1800 David G. Styles

Copyright

First published in 2013 by The Crowood Press Ltd, Ramsbury, Marlborough, Wiltshire, SN8 2HR

www.crowood.com

This e-book edition first published in 2013

© James Taylor 2013

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

ISBN 978 1 84797 518 8

CONTENTS

ACKNOWLEDGEMENTS

Anybody who thinks that all of the coil-sprung Land Rovers are pretty much of a muchness will be surprised by the story contained within this book. When I came to pull it all together, it surprised me, too. In thirty years, the coil-sprung models have embraced an astonishing number of variants – and that is without considering the specialist conversions, which are varied enough to deserve a book of their own one day.

The essence of this book has come from my own collection of material, filed away over a period of more than thirty years in the belief that it would eventually amount to something. However, dozens, possibly hundreds, of people have added little snippets of information – and sometimes very large ones – to make the story hang together. A great deal of it has come in through my work for various Land Rover magazines: Land Rover Owner from 1989 to 1999; Land Rover Monthly from 1999 to 2000; Land Rover Enthusiast (as Editor and, latterly, co-owner) from 2000 to 2010; Land Rover Monthly again from 2010 to 2012; and, most recently, Land Rover Owner again. I’m grateful to all those who sent material for my long-running Roverphile column that has found its way into this book, and also to my colleagues on those magazines who have added their own information to the sum of my knowledge.

I have also drawn on the memories of very many Land Rover engineers and other employees, who have patiently put up with my questions or dug out ancient photographs to illustrate a point. So special thanks here must go to George Adams, Colin Andrews, Bill Baker, Tom Barton, John Bilton, Keith Bird, Mike Broadhead, Roger Conway, Larry Court, Mike Gould, Ian Jones, Geof Miller, Bill Morris, Tony Poole, Dave Saddington, Bob Seager and Les Wilkins. Equal thanks go to a smaller number of people who have asked for their names not to appear in print – and of course to anybody I should have acknowledged but have omitted from this list.

I have been very fortunate to have extensive access to the legendary Dunsfold Collection of Land Rovers, established by Brian Bashall and now run by his son Philip. Jan Valentino and Richard Bacchus in the BMIHT archives at Gaydon have been enormously helpful, and I am particularly pleased to say a public thank you to my friend Roger Crathorne, who has helped out in all kinds of ways on this project.

JAMES TAYLOROxfordshire, June 2012

CHAPTER ONE

LIFE AND TIMES OF THE COIL-SPRUNG LAND ROVERS

By 1983, when the One Ten was introduced as the first coil-sprung Land Rover, the Land Rover marque had existed for thirty-five years. In all that time, its suspension had resolutely depended on leaf springs and the crucial novelty of the new model was that it had all-round coil springs. That was far from its only new feature of course, but it represented a defining moment in the history of the Land Rover.

During those thirty-five years, the Land Rover had made a place for itself in the motoring world. It had started out as a light commercial vehicle and despite the introduction of personnel-carrying station-wagon variants, it had remained essentially a light commercial. No matter that enthusiasts were wont to buy time-expired examples and turn them into competitive vehicles for off-road motor sport. No matter that Land Rovers were the first choice of pioneers and explorers from all round the world. In an August 1982 feature on buying second-hand examples, the magazine What Car? summed the position up quite simply: ‘The Land Rover,’ it said, ‘is first and foremost a workhorse.’

Thirty years later, the Land Rover, renamed a Land Rover Defender in 1990 to give it a clearer identity within an expanding product range, is still primarily a workhorse. But that definition has become considerably more blurred as the people-carrying Station Wagon models have taken an increasing share of the business. A Land Rover Defender is now also a vehicle that symbolizes adventure and personal freedom. It can even be chic and it most definitely reflects the owner’s view of his or her own image. Whereas the mainstream motoring press only rarely mentioned Land Rover developments in the early 1980s, by 2010 they were hot news, worthy of as many column inches as developments on everyday saloon cars.

These changes in public perception had their own effect on the development of the Land Rover; a manufacturer, after all, has to deliver products that people actually want to buy. Yet public perception was far from the only influence behind the changes to the Land Rover after 1983.

During the 1980s, four-wheel-drive models suddenly became fashionable as family transport, resulting in more and more manufacturers introducing products that threatened Land Rover sales. So Land Rover developments were driven by the need to keep ahead of the game, or, at the very least, up with it. Then there were changing regulations in the myriad world markets where the vehicles were sold – changes that affected such things as lighting, exhaust emissions and safety. Development was also affected by the backlash against four-wheel drives in general, engendered by those with environmental concerns who believed that the heavy fuel consumption typical of Land Rovers and their ilk was contrary to the best interests of the planet.

Yet some things did not change in the period of the coil-sprung models. Military demand worldwide for Land Rovers as light front-line vehicles barely fluctuated, despite the increasing popularity of purpose-built multirole machines like the Humvee. Police, ambulance and fire services continued to buy Land Rovers for special-duty tasks. Explorers, adventurers, conservationists and environmentalists all continued to buy Land Rovers to take them to places that would otherwise be inaccessible. Off-road driving enthusiasts still bought older models to turn into off-road competition or adventure machines – and often spent very large sums of money converting and equipping brand-new examples as well.

Ironically, as the new One Ten was announced in 1983, so one of its key overseas markets had started to collapse. Sub-Saharan Africa had always been a big market for Land Rovers, in particular because large fleets were bought by Government agencies and these fleets were renewed on a regular basis. Changes in UK Government subsidies at the start of the 1980s severely undermined this market, with Japanese competitors being quick to move in.

Land Rover responded in two main ways. First, it switched its focus from developing markets like these to the developed markets of the West – in particular continental Europe and North America. Then, to keep the Land Rover marque alive in Africa in the hope that better times would come, it established a number of reconditioning plants where older Land Rovers could be rebuilt to as-new condition for less than the cost of a new Japanese vehicle. Gradually, sales returned to sensible levels, although they never did regain the volumes seen in the 1960s and 1970s.

These were the company’s successes in the face of adversity, but Land Rover did not always get things right. A pigheaded refusal to accept that larger and more powerful engines, most notably a diesel, were an absolute necessity in some markets allowed competitors to make major inroads into long-standing Land Rover markets in the early 1980s. Without what amounted to unilateral action by some of the marque’s overseas branches, the situation would have been worse.

There is also no doubt that development of the workhorse models was neglected to an extent in the 1990s. The new focus on developed markets certainly diverted resources from developing a new Defender. The models that Land Rover developed instead – the Discovery, the Freelander and the Range Rover Sport – undoubtedly did the marque a power of good, but the constant deferment of a new model to some indeterminate point in the future meant that the task of developing one became ever more difficult. When it became clear, in 2011, that work really had begun on a Defender replacement, it also became apparent that the new model would have to be very different from the old in very many ways. The world, quite simply, had moved on.

Changes of Ownership

Yet the coil-sprung Land Rovers did provide a form of reassuring continuity through all the changes of ownership that their manufacturer went through at the end of the twentieth century and the start of the twenty-first. Owners came and owners went, but the Land Rover, a Defender by then, remained a constant.

When the One Ten was announced in 1983, Land Rovers were made by Land Rover Ltd, which was a standalone operating division of the much-reviled British Leyland (BL). That change to its status had occurred as recently as 1978, when Land Rover had been established as a separate company. Before then, it had sat uncomfortably alongside Rover, Triumph and Jaguar cars in the specialist cars division of the company, because before being absorbed into BL at the end of 1966, Land Rovers had been built by the old Rover Company.

However, it was Government money that had made the One Tens possible. Their design and development was funded by a £200 million grant provided as Stage 2 of an investment scheme agreed in 1978 – and as a result these models were initially known within Land Rover as Stage 2 types.

Arguably, this was good use of the British taxpayer’s money. However, the burden could not be borne forever and in 1986 the Government made moves to sell British Leyland. At that stage, the most likely buyers for Land Rover were General Motors and Ford, but public protests made the sale impossible. A management buyout attempt in 1987 was rejected; negotiations for British Aerospace to take over the whole of the Rover Group were announced in March 1988 and the deal was ratified by shareholders on 11 August. Only a nominal purchase price was paid (and this was the subject of later condemnation by European bodies), as the deal was as much a political move as anything else. The Rover cars and Land Rover sides of the company had been swiftly integrated so that no buyer could easily close down the loss-making car business and focus on the profit-making Land Rovers. That safeguarded jobs at Rover – which was important for the Government.

Nevertheless, British Aerospace ownership had been planned as a five-year caretaker arrangement; thus by late 1993 the company was looking for somebody to take over the burden of the Rover Group. Although there was a long-standing relationship between the Rover Cars side of the business and Honda in Japan, that was not exploited. Instead, British Aerospace was receptive to an approach from the German BMW company, whose interest was primarily in Land Rover. The introduction of the Discovery in 1989 had persuaded BMW to sit up and take notice, then in 1991 the German company had agreed to supply diesel engines for the forthcoming new Range Rover, due in 1994. Things became more serious towards the end of 1993 and in January 1994 the deal was done. The whole of the Rover Group became a BMW subsidiary.

BMW entered its period of ownership with enthusiasm. Over the next few years, it invested heavily in Land Rover, although most of that investment bypassed the workhorse models. Unfortunately, part of the deal with BAe had been that the German maker should also take on Rover Cars, the car-making business which was the mortal remains of all the marques once united under BL. This division made big losses, with things coming to a head in 2000 when the BMW Board refused to continue supporting it. Rover Cars and Land Rover were sold separately, Land Rover going to Ford in the summer of that year.

Ford, too, invested heavily in Land Rover, although once again the major investment bypassed the Defender range. An important change during this period was that Land Rover was amalgamated with car-maker Jaguar, also then under Ford ownership, to create a new company called Jaguar Land Rover (JLR). Then Ford’s core business in the USA ran into trouble and the company chose to slim down by selling off some of its peripheral businesses. Jaguar Land Rover was among them, and was bought in 2008 by the giant Indian Tata Group. Ironically, at the time Land Rover was celebrating its sixtieth anniversary since the very first production models in 1948.

Tony Gilroy did sterling work as Land Rover’s Managing Director in the 1980s.

The Men in Charge: Corporate Management

Individuals at the top of the Land Rover corporate organization had an important influence on the company’s products and well-being over the years. When the One Ten was brought to market in 1983, Land Rover’s Managing Director was Mike Hodgkinson, who had held that position since the company’s foundation in 1978. But his successor had already been appointed and from later in 1983 it was Tony Gilroy at the helm. Gilroy was notoriously forthright, but laid the foundations for Land Rover’s resurgence during the 1980s, in particular overseeing the reduction in ‘satellite’ manufacturing plants, which had been foreseen under Hodgkinson, and the reorientation towards developed markets.

Gilroy was still at the helm of Land Rover when the Rover Cars and Land Rover businesses were reorganized as the Rover Group under Sir Graham Day. In 1987, he led a management buyout attempt, but that was rejected. When Day appointed George Simpson as Group Managing Director with the job of integrating the cars and Land Rover sides of the company into a single operation, Gilroy left. A new streamlined management structure was announced in January 1989 and, under the new regime, Land Rover’s most senior figure was its Commercial Director, Chris Woodwark.

The merged Rover Cars and Land Rover operations remained so when BMW took over, but the German company put in its own top management. From early 1994, Land Rover was directly managed from Germany as part of the Rover Group, initially by Wolfgang Reitzle, then by Walter Hasselkuss, and finally by Werner Sämann as Chairman and CEO. The company did not have its own Managing Director, but had separate MDs for Land Rover Vehicles and Land Rover UK sales. Peter Kinnaird became the Managing Director for Land Rover’s UK sales company and was succeeded in 1999 by Mike Wright. Between 1994 and 1999, Ian Robertson was MD of Land Rover Vehicles; he was succeeded by Dieter Udelhoven.

The situation was different under Ford, with an extra layer of management being introduced because Land Rover belonged to Ford’s Premier Automotive Group. This had its own Chief Executive Officer, initially Wolfgang Reitzle (who had left BMW for Ford), then Mark Fields and subsequently Lewis Booth.

Jaguar Land Rover also had its own Chairman under Ford. The first one was Bob Dover, a former Land Rover Director of Manufacturing. Joe Greenwell took over in 2003, then Geoff Polites had the job from September 2005, now with the title of Chief Executive Officer for Jaguar Land Rover. He retired through ill health in 2008 and David Smith took over, steering JLR through the Tata takeover. Smith stood down in early 2010 and his replacement was Dr Ralf Speth, who had been Vice-President of Land Rover during the BMW period.

In 2003, a new post of Land Rover Managing Director was created. Matthew Taylor was the first appointee, handing over the reins to Phil Popham in 2006. Reorganization under Tata ownership saw the individual National Sales Companies given their own Managing Directors; in the UK, the job went initially to John Edwards, in 2010 to Colin Green and in 2011 to Jeremy Hicks.

Phil Popham became Land Rover Managing Director in 2006, and subsequently Director of JLR Group Sales Operations.

The Men in Charge: Engineering and Design

Traditionally, Land Rover had been run by its engineers, but by the time of the One Ten there had been some important changes. Heavily influenced by the example of Ford, Land Rover had established a new Product Planning division in 1978.

This had the responsibility of collating information about customer requirements and engineering developments outside the company, identifying market trends and opportunities, and proposing new products for the company to manufacture. The new division reported directly to top management, but in effect its function was to tell the designers and engineers what they would have to come up with next. Many engineers saw this as unwarranted interference and Product Planning was not universally liked in its early years.

Within Product Planning came another new group of people, united under the title of Brand Management. This was a group whose job it was to ensure that proposed changes to the products would not compromise their image or usefulness and so harm sales. Once again, Brand Management was not universally popular in the beginning, but by the time of the Defender in 1990 it was guiding the important move towards leisure-market derivatives.

Meanwhile, the Chief Engineer remained the man in charge of engineering and associated development. Though his title changed more than once during the coil-sprung era, and his precise sphere of influence was also redefined more than once, he remained the key figure.

During the development phase of the Stage 2 models in the late 1970s, Land Rover’s Chief Engineer had been Tom Barton. Barton had worked in a very junior capacity on the development of the original Land Rover in 1948, had gained a huge wealth of invaluable experience of the brand over the years, and had risen through the ranks until he reached the top job. But he had initially been opposed to the use of coil springs on Land Rovers and, perhaps reluctantly, allowed himself to be converted when it became obvious that this was the way forwards.

His successor in 1981 was Mike Broadhead, who had been his assistant and took over as Chief Engineer when Barton retired. Broadhead had already had a major influence on the design of the coil-sprung range, in particular leaving his mark on the short-wheelbase derivative, the Ninety. He oversaw the launch of the One Ten in 1983 and of the Ninety a year later, but he did not get on with Land Rover’s then Managing Director, Tony Gilroy, so chose to leave the company in 1984.

Mike Broadhead’s successor, with the title of Director of Product Engineering, was Bill Morris, another long-serving Land Rover engineer who oversaw the move into turbocharged diesel engines during the 1980s. However, the change to a merged Rover Cars and Land Rover under British Aerospace also brought another layer of management and Stan Manton was put in as overall Engineering Director for the Rover Group. As the group was restructured, Manton left and Steve Schlemmer briefly took over as head of Land Rover vehicle engineering. By summer 1990, Alex Stephenson had come in from Perkins Diesels to assume the post of overall Director of Engineering.

When BMW took over in 1994, it put Burkhard Goeschel in as Land Rover Chief Engineer. Under Ford, the top engineering job at Land Rover went to Steve Ross, an American who had overseen that company’s very successful Explorer Sport Utility Vehicle (SUV) programme. Then, when Tata took over in 2008, Land Rover brought in Murray Dietsch, a former Ford employee who, although Australian by birth, had been strongly influential within Land Rover’s South African operation.

The styling of the original One Ten was overseen by David Bache, the former Rover styling chief who had become British Leyland’s Director of Corporate Styling Services. However, more directly responsible for the One Ten styling was Tony Poole, who remained with the company after Bache left in 1981 following a row with Harold Musgrove, then Director of Manufacturing and later Chairman of the Austin Rover Group.

From 1985, Land Rover styling took place under the supervision of Dave Evans, who had joined the company from Chrysler UK when that company had closed down. He remained in charge of styling – by then called Design – under BMW. When Ford took over, the top job went to Geoff Upex; from 2007 he handed over the reins to Gerry McGovern, who had worked on the original Freelander. However, the man with direct responsibility for Defender in this period was Studio Director Dave Saddington.

Bill Morris was in charge of Land Rover engineeringin the late 1980s.

Murray Dietsch took charge of Land Rover engineering under Tata.

Dave Saddington became Studio Director for Defender in the Ford era.

Defenders on the assembly line at Solihull in 1990.

This was Land Rover’s V8 engine assembly line at the end of the 1980s.

The assembly line at Solihull has always depended heavily on people rather than machines. This was it in the early 1980s.

The Manufacturing Plants

When the One Ten entered production, Land Rover’s headquarters was at the old Rover Company plant in Lode Lane, Solihull, in the West Midlands. Rover car production had ended there in the last months of December 1981, being transferred to the old Morris plant at Cowley; meanwhile, production of the Triumph sports cars built there from 1979 had also come to an end. Solihull was, and remains today, completely dedicated to Land Rover manufacture.

At the start of the One Ten era, Solihull was primarily an assembly site, depending on a number of ‘feeder’ or ‘satellite’ factories in the surrounding area that manufactured subassemblies. So diesel engines and V8 petrol engines were brought in from Acocks Green, while 4-cylinder petrol engines came from Tyseley. Transmissions came from Percy Road, axles from Perry Bar, suspension and bell-housings and gearbox casings from Tyburn Road in Erdington. Clay Lane in Coventry provided cabs and hardtops. All these items reached Solihull by road because the site did not have – and still does not have – its own rail terminal.

All the ‘satellite’ factories were progressively closed in 1984–5, with their functions redistributed around the Solihull site. Outside suppliers continued to provide some major items, however, and notable among them was John Thompson Pressings in Wolverhampton, which manufactured all the chassis frames. From 2006, Defender engine supply arrangements changed, as Ford diesel engines began to arrive from the Ford plant at Dagenham.

Still dependent on people, these were the Defender production lines in 2007.

Defenders on the assembly line in South Africa at the Ford-owned assembly plant in Silverton.

The Overseas Assembly Plants

A proportion of coil-sprung Land Rovers has always been assembled abroad, usually to avoid prohibitive import duties on fully built vehicles. The figures have varied considerably over the years, but during the period of the coil-sprung Land Rovers have usually been between 3,000 and 5,000. Coil-sprung models were initially exported in knock-down kit form through Export Packing in Banbury, but from the mid-1980s the operation was taken back in-house and based at Solihull. The number of overseas assembly operations also dwindled from the mid-1980s, mainly as a result of a changing political climate, although global complete knock-down (CKD) figures were on the rise during the 1990s.

These overseas assembly operations typically added a proportion of locally manufactured content to the material sent out from Solihull, although the proportions varied from one plant to another. Two overseas assembly plants, in Australia and South Africa, depended heavily on locally manufactured items and were able during the coil-sprung Land Rover period to develop distinctive models of their own.

The major overseas assembly operations were in Australia, Brazil, South Africa and Turkey. The Australian operation was based at Moorebank in the suburbs of Sydney and was run by Jaguar Rover Australia (JRA). Though relatively new in this location, it continued a tradition of building Land Rovers in Australia that stretched back to the start of the 1950s. One Ten assembly began there in the third quarter of 1984 and continued right through until JRA ran into difficulties in 1992, by which time the models were Defenders. The Australian operation also developed its own vehicles – notably the 120in chassis and the special Perentie 4×4 and 6×6 military vehicles. Land Rover sales in Australia after 1984 mixed locally assembled and completely built-up (CBU) imports from Britain up to 1992, as well as South African-assembled models from 2003. Between 1996 and 1998, a further batch of military models was also assembled at the British Aerospace plant in Adelaide.

The Brazilian operation opened in 1998 at the Karmann plant in São Paulo, assembling primarily civilian models for the local market. When Ford bought Land Rover from BMW in 2000, Land Rover do Brasil merged with the Brazilian Ford operation, but CKD assembly remained at São Paulo. The Brazilian plant handled a large military contract for the Brazilian armed forces in 2003–4 and was much respected for the quality of its products. By mid-2004, it was assembling around 1,500 Defenders every year, while some 500 units of Land Rover’s other models were imported as fully built vehicles from Solihull. However, the Brazilian assembly operation was closed at the end of 2005 as part of a rationalization scheme under Ford.

The South African assembly operation was also closed in 2005 under the same scheme. Land Rovers had been assembled in South Africa since October 1963. Assembly of coil-sprung models was initially at Blackheath in Cape Province, but was moved to the BMW plant at Rosslyn, Pretoria, in 1998, then moved again to the Ford-owned assembly plant at Silverton in mid-2001. It assembled about 1,500 Defenders a year. Like the Australian operation, the South African one developed a number of its own special models. Notable among them were the Defender 130 Game Viewer and the Defender 147.

The Otokar CKD operation in Turkey was established on the back of military and other Government requirements, but it also built civilian models. This is a One Ten Station Wagon, distinguishable from the Solihull product in this view only by the small Otokar decals behind the front wheels.

The Turkish CKD operation was carried out by Otokar, initially in Istanbul and later in Arifeye. One Ten assembly began in 1987 and was primarily for the military and for Government agencies in Turkey. Otokar developed a number of its own special body variants and by the turn of the new century, Defender build volumes were around 2,000 a year.

There were several smaller operations. In Jordan, a CKD operation was established at Ma’an in the south of the country in mid-2005, as a joint venture with the Olé Automotive Trading Company of Amman. Build volumes were claimed to be as high as 2,000 a year, but this was probably a short-term operation to deal with a specific military contract. The initial plan was to build 5,000 vehicles, all Defender 110s, and these seem to have included pick-up, Station Wagon and window hardtop variants.

In Kenya, the Cooper Motor Corporation of Nairobi oversaw a small-volume operation assembling around thirty-five Defenders a year. This was actually carried out by Kenya Vehicle Manufacturing, which also assembled Mazda and Nissan trucks, and its main function was to deliver special derivatives for local use. The best known was the 135in chassis intended for safari tour buses. There was a slightly larger operation in Malaysia, where 200 to 300 Defenders were assembled each year by the Ford-owned Associated Motor Industries in Shaha Alam, Selangor; the operation later moved to the Inokom plant in Kulim.

Considerably larger was the CKD operation in Pakistan, which began in 2003 and assembled around 1,500 Defenders a year. Assembly was at the Ghandara Nissan plant in Karachi and the vehicles were for both civilian and military use. Assembly of Defenders in Thailand began in 2011. Then there was another low-volume operation, building around twenty to twenty-five Defenders a year, in Zimbabwe. Land Rover’s CKD partner was latterly the Quest Motor Corporation, which took over the operation from Leyland in 1993.

This was one of SVO’s first products, a Quadtec 2 body on the One Two Seven Crew Cab.

Special Vehicles

In the very earliest days of the One Ten, Land Rover still operated its Approval system for conversions and adaptations of the vehicle. This had been established as long ago as 1957 – the department responsible for ‘approving’ conversions was the Special Projects Department. Its function was to act as a central point where aftermarket specialists who wanted to market a conversion or adaptation for the Land Rover could get their work tested. If it did not compromise the integrity of the vehicle, it would be awarded Land Rover Approval, which meant that Land Rover would honour their standard warranty on a conversion. They would also help to promote its availability through their showrooms and by displaying demonstrator vehicles at the ‘field days’ held regularly in most countries to attract customers.

However, the founder of the Special Projects Department, George Mackie, retired in 1981 and the department seemed to drift for a while. It was probably late in 1984 that a member of the Product Planning Department, Roland Maturi, put together a plan for reorganizing Special Projects. He presented it to Land Rover MD Tony Gilroy, who liked Maturi’s vision and the additional profits it promised. Maturi was duly appointed to head the reorganized department, which from July 1985 was formally known as Special Vehicle Operations.

Special Vehicle Operations took over the functions of the department it replaced, but to them it added the development of its own conversions. Its longer-term aim, which became clearer towards the end of the 1980s, was to bring as much as possible of the conversions business in-house. Though this would create greater profits for Land Rover, it did not please some of the converters, who saw their market slipping away from them.

SVO’s new product range was spearheaded in April 1985 by the backhoe conversion, made in conjunction with Polymark Beaver Ltd. However, the main focus of the new division’s work was on a modular series of box bodies marketed under the name of Quadtec and designed to exploit the possibilities of the One Two Seven range. These were built in-house and could be fitted with all kinds of specialist equipment, some of which was of course sourced from outside the company. Quadtec 1 was a low-roof box with a crew-cab chassis; Quadtec 2 was a high-roof box with a crew-cab chassis; Quadtec 3 was a low-roof box with a standard cab; and Quadtec 4 was a high-roof box with a standard cab. Doors could be fitted more or less anywhere the buyer wanted.

Roland Maturi’s declared plan was to make Special Vehicles into Land Rover’s ‘fourth marque’ alongside the Defender, Discovery and Range Rover, but he left the company in 1992. SVO was reorganized yet again, this time as Land Rover Special Vehicles (LRSV). It added the old Special Installations Division (responsible for such things as winch installation) to its empire, then expanded further to embrace another new area of special conversions. This became apparent during 1993 when Land Rover announced the Autobiography custom-finishing scheme for Range Rovers, but in fact LRSV had also built the slightly earlier SV90 special-edition Defender.

Special Vehicles (as it is usually called) went on to take responsibility for all the UK-originated volume-build special derivatives of Defender, adding the special features to part-finished vehicles taken from the assembly lines. The North American Specification models (see Chapters 6 and 7) were also completed by Special Vehicles. The division was responsible for equipping those Defenders used as support vehicles on the Camel Trophy and G4 Challenge adventure events. It has continued to act as a focal point for aftermarket conversions, advising and assisting specialist converters where appropriate, and coordinating manufacture in cases where several specialists have made individual contributions to a single vehicle. However, the volume of commercial conversions has diminished over the years, largely because of the cost associated with testing and individual vehicle approval.

LRSV had its own distinctive logo, which it applied to the Defenders with which it had been involved.

A Special Vehicles commercial vehicle normally carries identifying badges on the front wings. Initially, these were decals, but from 1998 they were three-dimensional aluminium items. All Defenders built by Special Vehicles, including the special-edition models, have an identifying plate under the bonnet with the contract number and date of build.

There was yet another reorganization in March 2012, when LRSV expanded to take on custom-building duties for Jaguar Cars as well, which of course had been Land Rover’s close partner ever since the Ford takeover had brought them under common ownership in 2000. Under Tata ownership after 2008, when the company had been renamed Jaguar Land Rover, this closeness was further emphasized. The new name for the division was ETO – Engineered To Order.

Production Figures

Land Rover quotes its production figures by calendar year, not by model year, so it is impossible to separate out individual model year build figures. The figures for 1983–5 also include a proportion of Series III models, which were on their production run-out. These figures were the best available at the time of publication, but should not be considered definitive: Land Rover has a habit of recalculating its production figures from time to time.

¹ Plus 4,824 KD.

² Plus 1,200 KD.

³ Plus 1,740 KD.

CHAPTER TWO

GETTING THERE: THE HYBRID PROTOTYPES

The critical factor in the further development of the Land Rover was actually the huge success of the Range Rover, which was introduced in 1970. This had three major technological advances over the contemporary Land Rovers. First, it had permanent four-wheel drive, which not only provided it with the traditional Land Rover rough-terrain ability, but also improved handling on the road. It also did away with the need for heavy-duty axles with powerful engines, so reducing unsprung weight and permitting a more car-like ride.

The second of the Range Rover’s major advances was vastly improved stopping power, brought about by an all-disc braking system in place of the all-drum system still used on Land Rovers. The third was its reliance on coil-spring suspension, which gave a comfortable ride both on and off the road.

At Solihull, the potential advantages for future Land Rovers of permanent four-wheel drive and disc brakes were obvious. The sticking point, however, was coil springs. Land Rover’s somewhat autocratic Technical Director, Tom Barton, was implacably opposed to coil springs on future models. His view was that the rough ride given by leaf springs inhibited the driver from driving too fast over rough terrain and so damaging the vehicle. Coil springs, he was convinced, would give a ride that was too comfortable, so putting the vehicle at risk from a driver who lacked mechanical sympathy.

In the normal course of events, some preliminary work on an eventual successor follows almost immediately on the launch of a new model, partly so that the good ideas that went unused for that vehicle do not get lost. So it was with the Land Rover, with the result that after the Series III models had entered production in autumn 1971, some work was done on a possible Series IV model. The fact that it would have leaf-sprung suspension seems not to have been questioned.

Series IV looked at a number of other new ideas, though, and by 1974 had evolved into a new project that attracted the code name of SD5. This reflected the fact that Land Rover now belonged to the Specialist Division of British Leyland and it was that division’s technical chief, Spen King, who allocated the code name; it was simply the fifth new vehicle project since the Specialist Division had been established in 1971.

By this stage, the Range Rover had demonstrated beyond reasonable doubt that the additional comfort of coil-spring suspension did not lead to excessive damage in off-road driving. It was also true that Spen King was the man who had originally proposed using coil springs for the Range Rover and it may be that he encouraged the Land Rover engineers to look again at their use on future utility models. Tom Barton, perhaps sensing that he was now fighting a losing battle, asked his deputy Mike Broadhead to oversee the SD5 project – and coil springs found their way into the specification.

They were only used on the front wheels of the ‘mule’ prototypes that were built by converting Series IIIs, perhaps because leaf springs seemed like a cheaper option for the rear. The issue was that the Range Rover incorporated a self-levelling strut which pumped itself up to keep the vehicle level when there was a heavy load in the back. Land Rovers, designed to carry such loads all the time, would certainly need one – and the additional expense and complication may have been seen as undesirable.

However, the whole way in which Land Rover approached new products was changing in the early 1970s. Traditionally, ideas for new products had come from the engineers or the management, perhaps, after discussion, being built into prototypes for testing. If they worked, they would then become part of a formal engineering project, which might eventually result in a new product. However, one way in which British Leyland was trying to streamline its operations at this time was by borrowing ideas from Ford, which led the market in Britain. Ford had for many years had a department that was dedicated to examining future product opportunities, so at Land Rover a similar department was established with the name of Product Planning. At its head was Roland Maturi, a former Ford employee.

The raw material: the Series III and the Range Rover were Land Rover’s products in the mid-1970s, and the new Land Rover combined elements of the two vehicles.

So the SD5 project, promising as it was, was halted in 1975 as Product Planning turned their attention to future Land Rovers. A major document – the Assumptions Document – was drawn up within Product Planning, with the idea that this should be the basis of future work on new Land Rovers. Many of the ideas that went into this came out of a world survey of Land Rover’s markets that had been done between 1972 and 1974. Unfortunately, no copy of this vital Assumptions Document has yet come to light. However, Roger Crathorne, who worked on it during a spell in the Product Planning department, remembers that it envisaged Land Rover product development taking place in two stages.

Despite calls for a larger diesel engine from several markets around the world, the focus of Stage 1 was on replacing the old 6-cylinder petrol engine. Land Rover had just been taken off the Arab embargo list and was keen to get back into the Gulf markets, so this became the top priority. Stage 1 envisaged uprating the existing Series III models by fitting the 3.5-litre V8 engine from the Range Rover, together with its gearbox and permanent four-wheel-drive system. Stage 2 envisaged a further upgrade, this time by fitting coil springs to what was in effect the existing Land Rover. As there was very limited funding available, Mike Broadhead endorsed the ‘minimum change’ approach that the Product Planners were recommending.

Work began quite quickly on the Stage 1 proposal, which actually retained that name when it entered production in 1979. Stage 2 was of course further in the future and it was not until 1976 that work began on that. The change to coil springs was going to need considerable additional development, so Mike Broadhead asked Bill Morris, then Chief Engineer in charge of the product development teams, to take the project on.

In the meantime, Roger Crathorne had moved out of Product Planning and back into the Vehicle Development side of the Engineering Department, where he was working on a variety of trouble-shooting projects. It was during 1975 that he had idly used up some spare time at his drawing board by sketching up a coil-sprung Land Rover. In effect, he had simply amalgamated the relevant parts of the General Arrangement drawings of a long-wheelbase Land Rover and a Range Rover. The idea seemed logical to him, as he knew the benefits of coil springs from working on the original Range Rover project in the late 1960s. However, Technical Director Tom Barton caught sight of what he had done and was very definitely not impressed. Roger was given a disciplinary interview and was told not to waste company time by drawing up a vehicle that was not part of company policy.

So when he was asked to take the idea of a coil-sprung Land Rover further, Bill Morris remembered this incident, and suggested that Roger should be given the job of building the ‘mule’ prototypes that would have to be the first stage of the new project. By the autumn of 1976, Roger had been given the job of building four prototypes. They had to be completed quite quickly, because they would be needed in early 1977 to demonstrate to the British Leyland (BL) Board what Land Rover had in mind for the future. Only after that, and only if they liked what they saw, would the BL Board approve the funding for a full development programme of the Stage 2 vehicle.

The Stage 1 V8 was the first stage in upgrading the basic Land Rover.

The Range Rover chassis was the starting point for the new coil-sprung Land Rovers.

Driven by Product Planning’s Assumptions Document, the plan was for two different sizes of Land Rover, as had been the case ever since 1953. But the short-wheelbase models, then with an 88in (2,235mm) wheelbase, were generally seen as too small. Tom Barton in particular favoured an intermediate wheelbase of 100in (2,540mm) – the same size as the Range Rover’s – with a long-wheelbase model broadly similar to the existing 109in (2,769mm) of the Series III Land Rover. As the Range Rover chassis had already been stretched to 110in (2,794mm) for some special applications, 110in (2,794mm) became the long-wheelbase size. However, the idea of a short-wheelbase model had not been completely excluded, and the wheelbase dimension for this was set somewhat arbitrarily at 90in (2,286mm) – very slightly larger than the 88in that was considered too small.

As a result, the four ‘mules’, or hybrid prototypes, were to consist of two with a 100in wheelbase because this was the major new development, one with a 110in wheelbase and one with a 90in wheelbase. Of the 100in models, one had to be a Station Wagon, to see whether the new dimension would give enough passenger space and comfort.

As Roger remembered it for the July 2003 issue of LAND ROVER enthusiast magazine:

Off I went to see Maurice Hanson, who was our Production Director, and I asked him for four Range Rover rolling chassis and four body ‘kits’ for Land Rovers. I told him what I was doing and Maurice said, ‘It won’t fit!’ but he let me have what I wanted.

I came in on a Saturday morning and I remember watching a fork-lift bringing four sets of painted Land Rover panels into the Experimental Shop. They were just as they’d come out of the Paint Shop, on their trollies, and they were all grey because they’d been doing a run of grey vehicles that week!

All the work was done in the Experimental Department and Roger had a team of fitters to carry out his instructions. As a first stage, the Land Rover bodies were assembled; a photograph taken on 14 October 1976 shows one of these resting on the chassis of a Range Rover, to give a clearer idea of where the necessary cutting and shutting would have to take place. Among other things, it was already clear that the tyres would project beyond the body sides because the Range Rover axles were wider than the Land Rover ones for which the body had been designed. In keeping with the philosophy of ‘minimum change’, the solution was not to cut the body down the middle and widen it, but rather to fit wheel-arch extensions to cover the tyres. The job of drawing these up was given to Tony Poole, then in charge of Land Rover work in the Styling Department. Surviving photographs from late November 1976 show both simple and more elaborate proposals, in each case using aluminium alloy.

The 90in (2,286mm) hybrid was built up as a soft-top, while the 110in (2,794mm) model was a pick-up-bodied truck cab. Both had standard Range Rover V8 power trains. Of the two 100in (2,540mm) vehicles, one was built up as a four-door Station Wagon, although it had a canvas roof which saved the time and cost of modifying standard production panels. This also had a Range Rover V8 power train. The second 100in was built as a two-door soft-top, but this had an experimental power train with a Land Rover 2.25-litre petrol engine and remotely mounted gearbox, at Mike Broadhead’s request. All four hybrids had right-hand drive and all four had single-line braking systems plumbed into the Range Rover’s twin-piston front calipers; more details of the individual vehicles are shown below.

The basic principle was to fit a Land Rover body to a Range Rover chassis. The Land Rover body was designed for a 109in (2,769mm) wheelbase and the Range Rover chassis had a 100in (2,540mm) wheelbase, so the body had to be cut down. This is one of the four ‘hybrid’ prototypes at the very early build stage: the Series III body has been lowered onto the Range Rover chassis and the next stage is to mark up where sections will be removed. The picture was taken on 14 October 1976 and the vehicle probably became the 100in soft-top.