28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

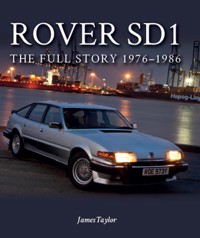

Rover's big hatchback saloon of the 1970s and 1980s had all the elements of a superb motor car. It was the work of long-standing Rover engineers, with substantial input from their colleagues at Triumph. The SD1's top models even shared their V8 engines with earlier and much-loved classics from Rover. It was stunningly attractive, cleverly derived from Italian supercar styling and still extraordinarily practical thanks to its large hatchback configuration. In this new book, Rover historian James Taylor tells the full story of the SD1, warts and all, from initial concept to final production model. The oft-criticized early models and the more successful later variants are discussed as well as the exclusive Vitesse and Vanden Plas models and overseas and police variants. Finally, for those inspired enough to seek one out today, there is guidance on purchase and ownership.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 386

Veröffentlichungsjahr: 2016

Ähnliche

ROVER SD1

THE FULL STORY 1976–1986

James Taylor

THE CROWOOD PRESS

First published in 2016 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2016

© James Taylor 2016

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 192 5

Disclaimer

Every reasonable effort has been made to trace and credit illustration copyright holders. If you own the copyright to an image appearing in this book and have not been credited, please contact the publisher, who will be pleased to add a credit in any future edition.

CONTENTS

Introduction and Acknowledgements

CHAPTER 1 EARLY DEVELOPMENT, 1969–1972

CHAPTER 2 FINAL DEVELOPMENT

CHAPTER 3 THE FIRST CARS, 1976–1979

CHAPTER 4 THE 1980 AND 1981 MODELS

CHAPTER 5 THE FACELIFT MODELS, 1982–1986

CHAPTER 6 INJECTED AND EXCLUSIVE – VITESSE AND VANDEN PLAS EFi

CHAPTER 7 THE SD1 IN POLICE SERVICE

CHAPTER 8 THE SD1 OVERSEAS

CHAPTER 9 THE SD1 IN MOTOR SPORT

CHAPTER 10 THE SD1 AFTERMARKET

CHAPTER 11 BUYING AND OWNING AN SD1

Appendix I Car and Major Component Identification

Appendix II Production Figures

Index

INTRODUCTION AND ACKNOWLEDGEMENTS

The Rover SD1 was the new kid on the block when I first became interested in the products of the Rover Company. By that time, of course, there was no Rover Company any more, and Rover was just a name used for the car that fitted into a certain bracket within the British Leyland range hierarchy. However, the SD1 had been largely designed by the old Rover team, and was built at the old Rover factory in Solihull. So it felt like a real Rover, and I joined many others in hoping that it would become a success.

As we now know, the multiple problems that beset British Leyland in the 1970s meant that the SD1 never really fulfilled its true potential. Quality was so variable that buying one in the first five or so years of its life was a calculated risk. I have owned four of them, and one of them (a late model 2600) was a really good car. That says it all, really.

Yet the SD1 was fundamentally an excellent design. I followed its progress throughout its production life, and was lucky enough to meet and interview several people involved with it. So I owe a major debt of gratitude to Gordon Bashford, Spen King and David Bache, all of whom enlightened me about the background to the design. There were many others, too, some of them acknowledged in the narrative.

In putting this book together, I also drew on the knowledge and enthusiasm of several other people. In particular, I must single out Ian Elliott, who had the unenviable task of preparing most of the UK press releases about the car, and who saw much of the story from the inside. On the enthusiast side, thanks go to Chris Powell, historian of the Rover SD1 Club, whose research provided valuable information that was not available elsewhere. I am very grateful also to Paddy Carpenter, of the Police Vehicle Enthusiasts’ Club, for providing a number of photographs relating to his specialism. Several overseas enthusiasts added their knowledge of SD1 sales outside the UK, so thanks go to Rob Turner and Tony Cope in Australia, John Miller in New Zealand, Rob Hafkamp in the Netherlands and to João Peres and José Almeida in Portugal. Others have certainly added to my knowledge over the years, and I’m sorry I can’t remember and list every one of them here.

Most of the photographs and illustrations have come from my own collection. However, I must add special thanks to photographer Craig Pusey for the photographs of his Vitesse and to Lisa Stevens at the British Motor Industry Heritage Trust in Gaydon. Please note that all publicity material and photographs originally produced for or by the British Leyland Motor Corporation and British Leyland Ltd, including all its subsidiary companies, is now the copyright of the British Motor Industry Heritage Trust; anyone wishing to reuse this material should contact BMIHT for permission to do so. Finally, in quoting VINs I have gone for additional clarity by inserting a hyphen between the prefix code and the serial number (eg SARRRWVF3AA-000803). This hyphen does not appear on the identification plates or on documents associated with the cars.

James Taylor

Oxfordshire

October 2015

The oldest-known Rover SD 1. Wearing chassis number five and registration number JYF 227N, the car was built in 1975 as a pre-production model.

CHAPTER ONE

EARLY DEVELOPMENT, 1969–1972

THE ROVER STORY

Although the Rover name remained constant during the production life of the SD1, the Rover identity was in an almost constant state of change. To document those changes in detail as they occurred would unnecessarily complicate the story of the car, so they are explained here as a way of providing some context for the story that follows.

Rover began making cars in 1904, and before that had been involved in the bicycle and sewing machine industries in Coventry. However, it was not until the 1930s that the company really made its name, under the guidance of brothers Spencer Wilks as managing director and Maurice Wilks as chief engineer. Rover became makers of ‘One of Britain’s Fine Cars’, as their publicity material put it, building discreet and elegant cars of high quality that were largely aimed at the professional middle classes.

This business continued after the Second World War when Rover moved to Solihull, to the south-east of Birmingham. The company was still guided by the Wilks brothers, and a younger generation of the Wilks family now joined as well. From 1948, car sales were supplemented by the light commercial Land Rover, which was a worldwide success and generated the profits that allowed the Rover Company to remain a viable, if small, independent car manufacturer.

Mergers – Rover within BLMC, 1967–1974

Rover’s days of independence were over by the time the Rover SD1 was launched in 1976. Prompted by mergers elsewhere in the British motor industry that threatened their body supplies, in early 1967 Rover sought refuge within the Leyland bus and truck group, which already owned car maker Standard-Triumph. During 1968, Leyland then merged with the other major British car combine, the British Motor Corporation (BMC), to become the British Leyland Motor Corporation (BLMC). Although little changed in the way Rover was run for a few years, it was inevitable that belonging to a larger combine, which united several formerly rival British car makers, would have an effect.

The first effects became apparent around the turn of the decade. In 1969, Rover’s planned new sports car (known as the P9 and due to be built under the Alvis name) was cancelled because of a clash with Jaguar. A further clash with Jaguar saw the new Rover P8 saloon cancelled in 1971. In 1972, Rover and Triumph were effectively merged when it became clear that their planned new executive-class saloons would compete against one another – and out of this merger came the car that would become the SD1.

Meanwhile, Rover’s management was changing, too, as the Wilks family lost its hold on the remains of the company and British Leyland began to hire professional managers to run its various businesses. The enormous and varied problems that would beset British Leyland over the next two decades made the subsequent history of Rover and its identity both complex and hard to follow.

In 1972, Rover ceased to exist as a separate business and became part of the merged Rover Triumph, which was a business within the British Leyland combine that now became known as the Specialist Division. The Specialist Division was headed by Bill Davis between 1972 and 1973, although other key management figures were former Rover men: Bernard Jackman became managing director and Spen King (a nephew of the Wilks brothers) became chief engineer. Former Rover man A. B. Smith became chairman in 1973, and then in 1974 former Triumph engineer John Lloyd became chief engineer when Spen King was moved to take overall charge of car engineering for British Leyland.

Nationalization – the British Leyland and BL Years, 1975–1986

BLMC’s losses had been mounting and at the end of 1974 the company turned to the British government for financial support to remain open and safeguard jobs. As a result, the company was nationalized; the last BLMC board meeting was on 24 April 1975 and the company was renamed British Leyland Ltd. Within that renamed company, the plan was for the individual car marques to be suppressed and for their operations to be united as Leyland Cars, which was run by Derek Whittaker. Within Leyland Cars, the former Rover, Triumph and Jaguar marques were to be united as the Large Cars division, which was run by Tony Thompson. This was the position when the SD1 was launched in 1976; formally, it was the new Rover from Leyland Cars, and all the publicity at the time of the launch made that very clear.

The years 1976 and 1977 saw some changes in top management, of which the most far-reaching was the appointment of Michael Edwardes (a highly competent professional manager rather than a car man) as chairman and CEO of British Leyland. Edwardes inherited a company that was once again on the verge of collapse, thanks to falling overseas sales and an epidemic of strikes within the workforce, and from July 1978 he made further changes.

British Leyland Ltd now became BL Ltd, and its Leyland Cars division became BL Cars Ltd. Jaguar Rover Triumph (JRT) was formed as a division of BL Cars, and Land Rover Ltd was created as a separate company. Head of BL Cars was Ray Horrocks, William Pratt Thompson was appointed head of JRT and Jeff Herbert became head of Rover Triumph. Jaguar was separately managed, and the plans to suppress the old marque names were abandoned. From 1980, JRT was split up yet again, and the Rover marque became part of the Light-Medium Cars division.

This arrangement lasted for two more years. Michael Edwardes, by now knighted for his achievement in keeping the company afloat, left in 1982 and a further reorganization ensued. Under Sir Austin Bide as chairman of BL Ltd, all the car marques except Jaguar and Land Rover were united as Austin Rover, with Harold Musgrove as its chairman. So it was as part of this group that the Rover name survived to the end of SD1 production in 1986. Yet, although the Rover Company had long since ceased to exist, the Rover name and what it stood for remained valuable business assets. As a result, in 1986, when there was yet another reorganization of what had begun as BLMC, the entire company was renamed the Rover Group under its new chairman, Graham Day.

FROM P10 TO SD1 VIA RD1

The chain of events that led to the introduction of the Rover SD1 in 1976 was immensely complicated, and was affected from the beginning by the twists and turns in the saga of British Leyland outlined above. Even though it carried the hugely respected name of Rover, the car was not purely a Rover design but a hybrid of Rover and Triumph design and components. Legend has it that there was a suggestion at one stage that it should not be a Rover at all but should instead carry Leyland badges.

Despite its excellent reputation for building well-made quality cars, Rover in the early 1960s was still a small independent manufacturer. Profits from booming Land Rover sales had enabled the company to move at the end of the 1950s from a single model range (coded P4) to two model ranges (P4 and P5), and then in 1963 to replace the older of those ranges with a very advanced new design (P6). However, this left the company with the problem of replacing both the P5 and the P6 ranges in the first half of the 1970s. Design and engineering resources were finite, so Rover planned to replace both model ranges with a single design. Work on what was known internally as the P8 began in 1964, making use of design and engineering resources freed up after the P6 had entered production in 1963.

However, the Rover plans were disrupted by corporate changes in the middle of the decade. Early in 1967, Rover merged with the Leyland truck and bus combine, which already owned Standard-Triumph and now planned to enlarge its car interests to rival the large BMC group, which owned Austin and Morris. BMC had also acquired Jaguar in 1966, and Leyland now planned to use Rover to counter the big Jaguar saloons.

One result of this was that Leyland instructed Rover to abandon work on the smaller-engined versions of the P8 and to focus on it as a large car that would compete with the Jaguars. This move left Rover with no replacement in prospect for its P6 range, so the company aimed to begin work on such a car as soon as designers and engineers could be spared from the P8 project.

As things were to turn out, the P8 never became a production model. After the Leyland-BMC merger that created BLMC in 1968, Rover found itself part of the same group as Jaguar. Belatedly recognizing the danger of competition between the two marques, the British Leyland board gave priority to Jaguar as a maker of large luxury saloons, and the P8 project was cancelled in 1971, a matter of weeks before the first pre-production cars were to be built.

The Rover people were not to know that back in 1969, by which time the bulk of the design and development had been completed on P8, and resources began to free up again. So they turned to the next new project, which was to design the replacement for the smaller Rover, the P6.

ROVER CAR PROJECTS, 1945–1976

The P code appears in Rover documents for the first time in 1945. There is no documented evidence for its significance, but a strong possibility is that it stood for Post-war.

PModel P was a series of mock-ups designed to modernize the appearance of the pre-war Rovers for post-war use. It was abandoned.

P2The P2 name has been applied to the revived pre-war models produced between December 1945 and early 1948.

P3An interim model, using pre-war styling on a new chassis with a new engine. It lasted in production from 1948 to 1949.

P4A completely restyled car, introduced in 1949 and built until 1964. Its chassis and engine were both developments of the P3 type.

P5Built alongside the P4 from 1958, this car was Rover’s first monocoque design and sold at a higher price. From 1967, it was re-engined with the ex-Buick V8 to become P5B, and remained in production until 1973.

P6Built from 1963 to 1977, P6 was an advanced design that replaced P4 as the ‘junior’ Rover. From 1968, the V8-engined 3500 became available alongside the original 4-cylinder car.

P7Originally planned as a re-engined P6, P7 became a series of development prototypes that fed into both P8 and P10 projects.

P8Planned as the replacement for the P5B with a 1971 start to production, P8 was cancelled at the last minute because of a feared clash with the Jaguar XJ6; the makers of both cars were by this stage united under British Leyland.

P9This was a short-lived plan to productionize the BS (also known as P6BS), an experimental mid-engined sports coupé designed within Rover. It was swiftly cancelled because of a feared clash with the Jaguar E-type.

P10The last of the P-series Rover projects, P10 was intended as the replacement for the ‘junior’ Rover, the P6. It later became RT1 and then SD1 soon afterwards.

Preliminary Ideas

The replacement for the P6 gained the internal code name P10. Several of the Rover designers had already had some informal preliminary thoughts about such a car, including Gordon Bashford, whose responsibility was chassis design and overall packaging, and David Bache, who ran the styling studio. However, the first formal briefing about P10 was not held until March 1969.

For the next twelve months, as P8 progressed towards production and work associated with aspects of its design diminished, the key players at Rover developed their preliminary ideas about P10. Then, in March 1970, the scope of the programme was formally outlined. P10 was to have two basic models, one being a four-door saloon with seating for four or five people, the other being a two-door sports saloon that used the same mechanical elements and the same structural elements as far as possible.

A full-size buck of the gull-wing body centre section was built from wood in the styling studio, and some work was done on interior layout as well. This photograph was taken in January 1971.

Not all the early sketches for P10 showed gull-wing designs; this one is clearly a four-door saloon, but it does have the fastback design that Bache wanted. Although undated, this sketch certainly existed by mid-1970.

Rover’s David Bache was keen from the start to make the new Rover saloon a hatchback design. He was also keen on the idea of gull-wing doors. Both ideas are incorporated in this early sketch by Ian Beech, a member of the Rover styling studio.

The project now began to gather pace. In June 1970, Gordon Bashford’s package drawings, which provided the basic dimensions for the car, were passed to David Bache’s styling studios so that work on the car’s shape could begin. That same month, Rover’s chief engine designer, Jack Swaine, was asked to begin work on the engines for the new car. At the top of the range would be the existing 3.5-litre V8 type, below which would be a 4-cylinder based on the existing P6 engine and available in two different states of tune; some later handwritten notes by Gordon Bashford show that a 2.8-litre version of the V8 engine (known as the Redcap type, but never built) was also under consideration as the companion engine to the 4-cylinders. According to the minutes of the Rover board meeting held on 1 June 1970, P10 was expected to replace P6 in autumn 1974.

Gordon Bashford remembered that his team was attracted to the idea of front-wheel drive in the early stages of P10. Rex Marvin, who then ran development at Rover, told Karen Pender (Rover SD1: The Complete Story) that some feasibility work was done on braking for such a design, using a front-wheel-drive BMC 1800 car. However, the designers reasoned that the space-saving advantages in a car of P10’s size were minimal and a poor trade-off against the known handling qualities of a rear-wheel-drive layout. So rear-wheel drive was chosen.

There were also discussions in the second half of 1970 about the actual construction of P10. Rover had used base-unit construction for the P6, where unstressed outer panels were hung on a stressed inner structure. This brought the advantage that a facelift could be achieved relatively cheaply – although no major change was in fact ever made to the P6 panels during the car’s production life. Discussions with Pressed Steel Fisher at Cowley, who were Rover’s existing body suppliers, showed that a monocoque would be more expensive than a base unit; the actual figures were £6 per unit more on a production of 600 bodies per week. This issue seems not to have been resolved before the P10 project moved into its next phase during 1971.

Dated October 1970, this was an early P10 interior mock-up. It was clear that the dashboard was always going to be very different from earlier Rover designs.

By December 1970, the most promising of the initial P10 design themes had been turned into a number of 3/10 scale models. This one had different treatments of the theme on each side.

These pictures show the other side of the 3/10 scale model. A first reaction from today’s perspective is that the shape resembles a Citroën CX – although that car would not reach the market until five years later and cannot have been an inspiration. The ‘flying buttress’ shape at the rear gives the appearance of a fastback, although the design is actually for a three-box saloon!

Meanwhile, David Bache was coming up with his first ideas for the new car. He had been keen for some time on the idea of a large hatchback design, inspired no doubt by the practicality of cars such as the Renault 16 and the Austin Maxi, the latter to be released during 1969. So his first thoughts were of fastback designs, and early design sketches showed how he wanted to combine these with smooth, flowing lines. By the standards of the late 1960s, they were remarkably advanced shapes.

Bache was also keen on the idea of gull-wing doors, which were hinged in the roof panel and opened upwards. Theoretically these offered greater ease of access than conventional side-hinged doors, and such doors could be fully opened in tight parking spaces where a conventional door can not. It was also true that gull-wing doors still brought the wow factor to a design, thanks mainly to their pioneering use on the legendary Mercedes-Benz 300SL coupé of 1954. Bache was so convinced of the idea’s merits that he had a full-size gull-wing buck built in the styling studio. Combining these doors with a hatchback on a saloon car such as the P10 was to be would certainly have given the car an image of advanced design, and that fitted well with the image of Rover at the time.

THE SKELETAL ROVER BADGE

The design for a new Rover badge, with a skeletal style replacing the traditional Viking ship image, seems to have entered the picture towards the end of 1969. It was in evidence on the full-size P8 saloon mock-up photographed in early December that year and appeared again on the full-size mock-up for the P9 sports car photographed in March 1970.

The original design was done by Ian Beech in the styling department and it was approved and promoted by David Bache. It seems to have been unaltered when it was adopted for the production SD1 in 1976. However, traditionalists regretted the loss of the familiar Viking ship emblem and from 1979 Rover reinstated a version of this on the nose of the SD1.

The infamous ‘skeletal’ Rover badge pre-dated the SD1 by several years but never appeared on any other production Rover.

The Engine that Never Was – Rover’s dohc Slant-4

Rover’s plan for P10 was to have three models, with the existing 3.5-litre V8 engine in the top model and the two cheaper models having a new 4-cylinder engine in two different states of tune. This new engine was to be a twin-cam, 16-valve derivative of the 4-cylinder ohc used in the Rover 2000. Work began on it in June 1970, when Jack Swaine entrusted the project to Dave Wall. At that stage, engine production for sales was scheduled to start in May 1974.

Dave Wall reflected on the design of the engine in a 1987 interview with the author, which was subsequently published in the February 1988 issue of Thoroughbred & Classic Cars magazine.

Working with Wall were Ray Cobley, who was responsible for the detail design of the cylinder block, and Jack Read, who dealt with the cylinder head. There was a tight design brief, which included using the existing P6 2000 engine transfer line tooling in order to save costs and ensuring that the engine would meet the known and likely future requirements of exhaust emissions control regulations, particularly in the USA.

With the basic parameters of the cylinder block already defined by the need to use P6 tooling, Wall decided to go for more power by using a twin-ohc cylinder head with 4 valves per cylinder. The 16-valve head was also expected to convey an image of high performance and technical sophistication at a time when the 4-valve configuration was still largely exclusive to racing engines. Although the requirement was for 145bhp in the more powerful version of the engine (and 120bhp in the entry-level version), Wall’s team aimed for 170bhp in the prototypes in order to give an adequate margin for further development and, of course, for losses caused by changes to meet future exhaust emissions regulations.

Although the 16-valve head was clearly going to be the key feature of the new engine, some significant alterations were also made to the block. The bore was enlarged from 85.7mm to 90.5mm, partly as a way of making room for more valve area in the combustion chambers, and this took the capacity up to 2204cc from the original 1978cc. This was the origin of the enlarged bore adopted when the 2000 engine was uprated for the P6 2200 models in 1973, which had that same 2204cc capacity.

The block was also redeveloped in conjunction with the Wolverhampton-based C & B Smith Foundry, using thin-wall castings to save weight and solid sides in place of the leak-prone side cover plates of the P6 engine. The P10 was being planned with a low bonnet line, so the engine was designed to be installed with a slant of 35 degrees to the vertical, which in turn demanded a new sump design.

Around £10,000 was invested in pattern equipment to manufacture the revised block, which was both lighter and more rigid than the original. However, the open sides of the P6 block had allowed the water jacket to be cast into a design without core holes, and the new solid-side design required another way to achieve this. So Wall’s team redesigned the block to use wet liners, so that the water jacket could be supported during casting through the top of the block; the liners would then be inserted later. The plan was to hold them in position with Loctite, a feature that was tested on a number of modified Land Rover engines and proved very effective.

A chain drive was chosen for the camshafts because of the need to keep as close as possible to the original P6 engine design. The camshafts themselves ran directly in cast housings, which had cast weirs to ensure adequate cam lubrication on start-up. One great advantage of the new engine was that it was possible to change both inlet and exhaust timing by simply rotating the camshafts relative to one another, which gave great flexibility in tuning for control of exhaust emissions.

Taper-seat spark plugs were positioned centrally in the classic twin-cam tradition and the inlet ports were completely separated, while the exhausts were siamesed just before the outlet facing and a phased exhaust manifold was designed. Rover sought advice on gas flow from Walter Hassan and Harry Mundy at Jaguar (who were of course colleagues under British Leyland), and the inlet tract shape incorporated on the prototype engines derived from Mundy’s suggestions.

The valves themselves had an included angle of 44 degrees and single, high-rate springs. Actuation was through bucket tappets with shim adjustment, similar to the P6 design. Tappet clearance adjustment was simpler than on the parent engine, however, because the camshafts on the dohc engine could be removed without undoing the head bolts. The light weight of the valve gear allowed the engine to rev hard, and the target 170bhp was eventually achieved at 7,000rpm. This gave the new engine a very different character from its P6 parent, which achieved its peak power at 5,000rpm or 5,500rpm, according to tune.

P10 was intended to have a 16-valve derivative of the Rover 2000’s 4-cylinder engine. This was prototype no. 3, which survived with large intake trumpets. These would not have been fitted in production as they negated the saving in height achieved by canting the block over to one side.

The slant-4 engine under renovation in the British Motor Industry Heritage Trust (BMIHT) workshops during 1980. The engine is lying on its left side.

Wall and his team spent several months on the design of the P10 engine before the prototypes were commissioned and bench-testing began. By then, it had been agreed that there would be a twin-carburettor version for the mid-range car, and a single-carburettor version for the entry-level model. Prototype work started with the more powerful variant because this would be subjected to greater stresses, and it soon became clear that the SU carburettors traditionally favoured by Rover were not up to the task. Some consideration was given to using Webers, but the final choice fell on a pair of twin-choke Dellortos, largely because the supplier could offer the necessary technical back-up immediately.

On the bench, top-end power turned out to be poor while bottom-end torque was much better than expected. This imbalance was traced to overlong inlet tracts resulting from a miscalculation in the design of the water-heated manifold. Rather than hold things up while the manifold was redesigned and remanufactured, Wall’s team decided to try the engine out with fuel injection, which looked like a particularly good idea because it would also save the under-bonnet space otherwise taken up by the manifold. It was with a Bosch L-Jetronic system that the engine achieved its design target of 170bhp. Note, by way of comparison, that the 3.5-litre V8 would have just 155bhp in carburettor form for the first production SD1 models.

The cylinder head of the slant-4 engine clearly shows the sixteen valve ports and eight exhaust ports.

However, decisions made outside the engine development section now affected the outcome. Before the 16-valve engine had clocked up 200 hours on the test bed, British Leyland management had decided that the two lower-level engines in the new Rover would be developments of the existing Triumph 6-cylinder type. So the new Rover engine – by this stage described in some documents as the RT1 engine – was axed in May 1971 before it had ever run in a car.

Dave Wall believed that five or six prototype engines had been built. At least seven cylinder heads were cast, in line with Rover’s usual policy of making about 25 per cent spares, and all of these had the twin-carburettor manifold; the single-carburettor version never progressed beyond the drawing board. Only one engine ever ran on a test bed and that, still with its fuel injection system, now belongs to the museum collection at the Heritage Motor Centre in Gaydon after being restored in 1980. The other engines went to Dr Weaving at Jaguar in connection with his work on exhaust emissions control; cylinder head no. 5 still existed in 1987 when it was owned by Land Rover; and Wall himself bought no. 7 as a memento.

Changes within the structure of British Leyland and its constituent companies in the early 1970s meant that the dohc slant-4 engine commissioned for the P10 became the last engine ever to be designed by the old Rover Company.

The Triumph Dimension

While Rover were forging ahead with their P10 design and its new slant-4 engine, Triumph were also working on a new saloon design. The Rover 2000 and Triumph 2000 had been introduced at the same time in 1963 and had always been rivals in the executive-car market sector. The Rover had a staid but efficient 4-cylinder engine; the Triumph had a 6-cylinder engine and a rather more sporting demeanour. It was no surprise at all that Triumph should be thinking of replacing their saloon at about the same time as Rover.

At this stage, British Leyland had not fully got to grips with the variety of marques now under their control, and in most cases the formerly independent companies continued to behave as if they were still independent. So it was some time before top management dealt with the ridiculous situation of having two of its brands designing new cars to be launched at the same time in the same sector of the market. Whether each company knew of the other’s plans is a moot point, but if they had it is highly unlikely that they would have done anything to resolve the situation; the old rivalries died hard.

Triumph’s new executive saloon was code-named Puma, and some of its engineering was to be shared with other planned new Triumph models. However, by all accounts its design was running behind that of the Rover. The full story is unclear, but it looks as if Triumph had drawn up their own design, apparently with the aid of freelance designer William Towns, who had once worked at Rover. From some time in 1970, Triumph had also started work on a new 6-cylinder engine that was intended to power this car and others; the top model of the Puma range would meanwhile have a version of the Triumph V8, which would first be seen later that year in the Triumph Stag grand tourer.

This was the Triumph Puma proposal that lost out to David Bache’s P10 themes at the design contest held in February 1971. The large glass area was striking, but the rear treatment looks a little odd in this picture.

RT1 – the Compromise Solution

By late 1970, top management had realized what was happening. Triumph were told that Rover would have priority in the executive-saloon class and that they could not continue with the Puma project. This may not have been too upsetting to Triumph’s chief engineer, Spen King, who was fundamentally a Rover man and had been transferred to the rival marque in 1968, when BLMC made its first attempts to reorganize the multiple companies now under its control. The message probably got through to Rover fairly quickly, too, because Rover’s technical director Peter Wilks was actually Spen King’s cousin and the two had worked closely together on many Rover projects, including the P6 saloon.

Nevertheless, Triumph were not completely shut out of the new project. An internal design competition between the two divisions was arranged culminating in a presentation in February 1971 at which chairman Sir Donald Stokes and finance director John Barber made their choice between the styling models for the Rover P10 and the Triumph Puma. Triumph’s proposal was the rather elegant but somewhat conventional three-box saloon design drawn up by William Towns; David Bache at Rover prepared at least six scale models, five of them hatchbacks and one a three-box saloon. There seems to have been no major disagreement between Barber and Stokes, who decided that Leyland’s new executive car should be based on Bache’s more advanced-looking hatchback designs.

More changes followed swiftly. The British Leyland board decided on a classic compromise for the powertrains of the two cars, which would see the top model powered by Rover’s V8 and the mid-range and entry-level cars powered by the new Triumph 6-cylinder engine. Triumph were also working on a new five-speed gearbox and would be allowed to continue with that, not least because it could have future applications in cars throughout the British Leyland organization. From this point on, the new executive-car project was renamed RT1 to reflect the co-operation between the two divisions.

Further down the line, Rover and Triumph would be subsumed into a single business unit, the Specialist Division, while Austin and Morris would form the Volume Cars Division. Although this reorganization would not take place until early 1972, from April 1971 – in anticipation of the merger – the new executive-car project was renamed SD1.

In practice, there was considerable bitterness about the British Leyland changes on both the Rover and Triumph sides of the house. Although the engineers of the Specialist Division were theoretically united under a single banner, the reality was that they were very far from united. The old rivalries between the two marques would cause tensions and problems throughout the design phase of SD1.

It is interesting that the Rover V8 engine was only mildly revised for the new car. In its post-1973 production form, it developed 143bhp, which was increased to 155bhp for the SD1. (Note that earlier output figures quoted in Rover literature were to SAE standards rather than the stricter DIN figures used from 1973 and cannot be used for comparison.) The main changes were to the inlet valves and ports, and to the hydraulic tappets, which allowed the engine to rev higher than before. A Lucas Opus electronic ignition system, representing the latest technology, gave more reliable firing than older contact-breaker systems and demanded less maintenance.

As for the gearbox, this was an all-new design that was intended to be produced with both four and five speeds. The basic unit was a four-speed type, with the fifth or overdrive top gear being located in a bolt-on rear housing. The design would become known in both four-speed and five-speed forms as the 77mm type, 77mm being the distance between the axes of the mainshaft and the layshaft. Some years later it would take on the name LT77, the LT standing for Leyland Transmissions.

SD1 Takes Shape

The SD1 project now went forward with Spen King, as technical director of Rover Triumph, in charge. (Rover’s Peter Wilks had chosen to take early retirement from the top engineering position there during 1971. This was not as a result of the Rover Triumph reorganization; he was indeed ill, with a heart problem, and died a year later.) The rest of the team now gathered. David Bache was still in charge of styling, and Gordon Bashford remained responsible for the engineering package. British Leyland now saw the SD1 project as extremely important and were prepared to commit extensive resources to it. The job of chief programme engineer was entrusted to Mike Lewis, a Rover man. He had far greater responsibilities and a far larger team than had been the norm under Rover, when new cars were developed to production readiness by a project engineer, an assistant project engineer and one or two technical assistants, who were typically young engineers fresh from an apprenticeship. The development testing was done by teams of drivers working for Rex Marvin.

This full-size clay buck was prepared at the start of the SD1 period and shows the way the design was going by May 1971, when Lord Stokes reviewed progress. The styling studio staff were positioned to help give an impression of relative size.

Further refined by July 1971, the initial SD1 design was not really progressing well (for further details, see Chapter 2). The design somehow lacked presence, but would nevertheless be used for the A-body prototype cars.

After more detail work, this was the September 1971 scale model for the car that had become the SD1 in April that year. It reflected Bache’s overall outline and incorporated a hatchback.

There was strict control of costs from the very beginning, which – as Gordon Bashford recalled – encouraged the team to abandon any thoughts of independent rear suspension and to go for a cheaper ‘live’ rear axle. This would be manufactured by Triumph, who would also use it later in their TR7 sports car. The initial trials of the beam axle concept were done on a ‘mule’ prototype (known as a P7F), a Rover P6B prototype registered JXC 820D that had been fitted with the rear axle of a Vauxhall Ventora. Most of its trim was removed to simulate the target weight of the SD1, and the car was nicknamed the ‘Lightweight Bomber’ by the test engineers. It was tested both in the UK and on the Stelvio Pass in Italy.

Spen King wanted to separate the links counteracting axle wind-up from those providing longitudinal location, and so Gordon Bashford drew up a design that combined a torque tube (to resist wind-up) with radius rods and a Watt’s linkage. King was also a believer in ride-levelling systems, having used one successfully on the Range Rover a few years earlier, and to maintain ride height and handling in an SD1 with a fully laden boot he specified twin Boge Nivomat self-levellers on the rear axle.

Rigid cost-control procedures were new to British Leyland. They had been brought in by the large numbers of former Ford people who had been headhunted to help make the organization lean and efficient. An August 1972 document from the Rover Triumph Vehicle Cost Control Department shows their effect. It analyses the projected manufacturing costs of the SD1 in minute detail, comparing them with those for the Rover P6 and Triumph 6-cylinder saloons that the new car was destined to replace. This comment, from a comparison of the new rear suspension with that of the Rover 2000TC, is typical:

SD1 uses more expensive springs £(0.20) and dampers £(0.29) but saves £15.67 on the De-Dion tube and all the associated links. A further saving of £0.14 is made on spring insulation.

Further evidence of cost control was clear in the decision to fit drum brakes at the rear, even though the Rover P6 that the car would replace had featured disc brakes all round. There would of course be discs at the front; no credible new high-performance car could do without them in the mid-1970s. As for David Bache’s gull-wing doors, they were always going to be expensive and complicated to manufacture and disappeared from the specification.

Quite a lot of the SD1 design was influenced by Triumph practice, too. There was now no question of base-unit construction, and the new car was to have a monocoque body-shell with a subframe at the front, much like the existing Triumph 6-cylinder saloons. The front suspension followed Triumph practice in using space-efficient MacPherson struts, not least because neither the complex design for the Rover P8 nor that for the P6 – dictated by optimistic plans for a derivative with a gas turbine engine – was suitable for SD1. New for SD1, though, was that the rack-and-pinion steering gear would be mounted rigidly to the subframe, ahead of the transverse arms, one advantage of this arrangement being that any lateral deflection of the bushes would give safe understeer. To keep cost and weight to the minimum, the anti-roll bar was made an integral part of the transverse link. For safety, the steering was designed to incorporate a collapsible column.

Most of the basic engineering design for the SD1 was in place by mid-1972, and much of it was tested on some ‘slave’ prototypes based on other cars. The plan was to progress to two prototype stages, which were to be called the A-batch and B-batch cars. The A-batch cars were assembled in late 1972 at Solihull, and the very first one was slammed into a concrete block at the Motor Industry Research Association (MIRA) during 1972 to test the crashworthiness of the structure; the box overleaf gives details of the others and their uses.

SD1 PROTOTYPES – SDS AND A-BATCH

There were three groups of SD1 prototypes. These were the SDS (S for ‘Slave’) prototypes, the A-batch cars and the B-batch cars. The first two groups had varying degrees of resemblance to the eventual production models; details of the B-batch cars, which closely resembled the production types, are given in the next chapter.

SDS cars

The SDS prototypes were ‘mules’, built during 1972 and created by building elements of the proposed SD1 into existing cars. The known details are as follows:

SDS1Triumph 2000 automatic registered RDU 479H. Fitted with SD1 front and rear suspensions, probably in early 1972. The car was used to test 6-cylinder engine mountings and the proposed fuel tank. In September 1972 the Stress Office and the Vehicle Safety Section ran a joint test using SDS1 for low-speed impact tests with sprung bumper mountings; photographs from these tests suggest that the bodyshell had been heavily modified both front and rear.SDS2Used for prototype rear-axle tests.SDS4Rover 3.5-litre (P5B) with SD1-type rear suspension and weight reduction to simulate SD1.SDS5Rover P8 with 3.5-litre V8 engine, registered BXC 760K. First registered on 7 June 1972; went to Boge at Eitdorf, West Germany, for work with the Nivomat ride-levelling system.SDS6Rover P8 with 3.5-litre V8 engine, registered HXC 800H on 10 October 1972. Use not known.SDS7Rover P8 with V8 engine, registered OXC 811E on 1 February 1972. Used for barrier crash test on 19 April 1973.A-batch cars

The A-batch cars were first-stage prototypes and were built in late 1972. They had the original body design. Engineering documents reveal the following:

SD1-A1Used for barrier crash test at MIRA (no. L69), for side intrusion tests and for roof intrusion tests.SD1-A2/BIn July 1973 this car was put through a 1,000-mile pavé durability test. The designation suggests it may have incorporated certain elements of the B-batch cars by that stage.SD1-A3This was the first fully running prototype and was described as having a ‘2.5-litre’ Triumph 6-cylinder engine. It was used for interior noise tests (the Jaguar XJ6 was used as the benchmark), for engine shake tests and for road noise tests.SD1-A4Probably a V8-engined car, as it was compared with a Rover P6B V8 in cooling tests during November 1972.Company registration records reveal details of two A-batch cars, one of which may be the car identified as SD1-A2/B above. Both were recorded as ‘Cilroen’ types (the spelling is correct; no doubt Rover planned to take advantage of the outline similarity between the new Rover and the Citroën CX saloon under development at the same time).

SD1-A-002Registered on 1 November 1972 as MLY 375L. This was a blue V8-engined car with engine number 218227, which may be a mis-recording of ‘215/227’; the V8 engine was often identified as the ‘215’ type (i.e. 215cu in, in its original Buick form), and 227 would be the engineering serial number. The car was tested on the roads using a canvas ‘van’ back to disguise the hatchback shape. However, later in life it was somewhat crudely converted to a three-box shape. It is likely that this was the car that survived into the 1980s as part of the Rover historic vehicle collection. Sadly, it was not retained when that collection was passed to BMIHT.SD1-A-005Registered on 16 November 1972 as MMV 110L. The engine number was 3.5 P8/7, which indicates a 3.5-litre V8; the ‘P8/7’ suggests this was a spare engine from the cancelled P8 programme.An A-batch mock-up built by the research department was used in May 1972 for ventilation and heater defrost tests.

One of the A-body prototypes was slammed into a concrete block at MI RA to test the crashworthiness of the design. Test cars of all makes were given identifying numbers in the same sequence, and the initial letter corresponded to the registration letter then in force. The L-prefix therefore identifies this test as taking place between mid-1972 and mid-1973.