39,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

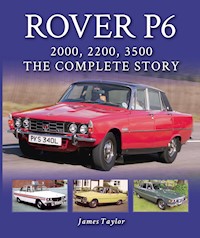

The Rover P6 was unquestionably one of the best saloon cars to come out of Britain in the 1960s and was winner of the first-ever European Car of the Year award. It combined a wealth of technical innovation with a distinctive appearance that incorporated exactly the right degree of Italianate sharp-suited appearance for its time. It was, and remains, a great car to drive, and all these qualities were combined with the space and practicality of a four-seat family saloon. Rover P6: 2000, 2200, 3500 - The Complete Story documents its evolution from the earliest ideas in the 1950s to the end of production in 1977. It describes all the models with specification tables and paint and trim options, including NADA and Federal cars and remembers the motorsport successes and failures. It records the manufacturing process at Solihull and CKD overseas and includes a useful chapter on buying and owning a Rover P6.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 525

Veröffentlichungsjahr: 2020

Ähnliche

ROVER P6

2000, 2200, 3500

THE COMPLETE STORY

OTHER TITLES IN THE CROWOOD AUTOCLASSICS SERIES

Alfa Romeo 916 GTV and Spider

Alfa Romeo Spider

Aston Martin DB4, DB5 & DB6

Aston Martin DB7

Aston Martin V8

Audi quattro

Austin Healey 100 & 3000 Series

BMW M3

BMW M5

BMW Classic Coupés 1965–1989

BMW Z3 and Z4

Citroen DS Series

Classic Jaguar XK: The 6-Cylinder Cars 1948–1970

Classic Mini Specials and Moke

Ferrari 308, 328 & 348

Ford Consul, Zephyr and Zodiac

Frogeye Sprite

Ginetta Road and Track Cars

Jaguar E-Type

Jaguar Mks 1 and 2, S-Type and 420

Jaguar XK8

Jaguar XJ-S

Jensen V8

Jowett Javelin and Jupiter

Lamborghini Countach

Land Rover Defender

Land Rover Discovery: 25 Years of the Family 4×4

Land Rover Freelander

Lotus Elan

MGA

MGB

MGF and TF

MG T-Series

Mazda MX-5

Mercedes-Benz Cars of the 1990s

Mercedes-Benz ‘Fintail’ Models

Mercedes-Benz S-Class

Mercedes-Benz W113

Mercedes-Benz W123

Mercedes-Benz W124

Mercedes-Benz W126

Mercedes SL Series

Mercedes SL & SLC 107 Series 1971–2013

Mercedes-Benz W113

Morgan 4/4: The First 75 Years

Peugeot 205

Porsche 924/928/944/968

Porsche Boxster and Cayman

Porsche Carrera: The Air-Cooled Era

Porsche Carrera: The Water-Cooled Era

Range Rover: The First Generation

Range Rover: The Second Generation

Reliant Three-Wheelers

Riley: The Legendary RMs

Rover 75 and MG ZT

Rover 800

Rover P4

Rover P5 & P5B

Rover SD1

Saab 99 & 900

Shelby and AC Cobra

Subaru Impreza WRX and WRX STI

Sunbeam Alpine & Tiger

Toyota MR2

Triumph Spitfire & GT6

Triumph TR6

Triumph TR7

VW Karmann Ghias and Cabriolets

Volvo 1800

Volvo Amazon

ROVER P6

2000, 2200, 3500

THE COMPLETE STORY

James Taylor

First published in 2020 byThe Crowood Press LtdRamsbury, MarlboroughWiltshire SN8 2HR

www.crowood.com

This e-book first published in 2020

© James Taylor 2020

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication DataA catalogue record for this book is available from the British Library.

ISBN 978 1 78500 722 4

CONTENTS

Introduction and Acknowledgements

Timeline

CHAPTER 1

DESIGN AND DEVELOPMENT, 1956–1963

CHAPTER 2

THE ‘SHARK’S-TOOTH’ 2000, 1963–1966

CHAPTER 3

TC, SC AND AUTOMATIC, 1966–1970

CHAPTER 4

THE P7 INTERLUDE

CHAPTER 5

ROVER P6 IN MOTOR SPORT

CHAPTER 6

THE NEW V8

CHAPTER 7

THREE THOUSAND FIVE, 1968–1970

CHAPTER 8

GREAT IDEAS, 1964–1971

CHAPTER 9

THE NADA AND FEDERAL CARS

CHAPTER 10

NEW LOOK OR ‘SERIES II’ MODELS, 1970–1973

CHAPTER 11

2200s AND REVISED V8s, 1973–1977

CHAPTER 12

P6s IN POLICE SERVICE

CHAPTER 13

HOME AND ABROAD: BUILDING THE P6

CHAPTER 14

BUYING AND OWNING A ROVER P6

Appendix I: Identification Numbers and Statistics

Appendix II: Factory Registration Numbers

Index

INTRODUCTION AND ACKNOWLEDGEMENTS

The Rover P6 was unquestionably one of the best saloon cars to come out of Britain in the 1960s. It combined a wealth of technical innovation with a distinctive appearance that incorporated exactly the right degree of Italianate sharp-suited appearance for its time. It was, and remains, a great car to drive, and all these qualities were combined with the space and practicality of a four-seat family saloon. All right, legroom in the rear was a little tight, but it was fine while the children were still young…

For anyone new to the car, it is worth briefly running through its innovative aspects. It used base-unit construction, a type seen elsewhere only on the revolutionary Citroën DS. It had all-round independent suspension, with a De Dion rear end, and disc brakes all round with the rear pair mounted inboard. Its four seats provided the style and comfort previously known only to owners of saloons in the 3-litre class. It delivered 100mph (160km/h) performance with fuel economy that was excellent for the time – and it held a promise of the future, as Rover made their intention to produce a gas turbine-powered version very clear from early on. Sadly, that intention never became reality, but instead owners were treated to the superb performance of a model powered by a lightweight V8 engine.

My interest in the P6 was triggered in 1981, when I bought the Panelcraft convertible prototype. As I had already been interested in Rovers more generally for five years or so by then, I soon began to appreciate just what an excellent car the P6 really was. I went on to have my share of P6s over the years. In date order, they have been the 1965 convertible, a 1968 2000SC Automatic, a 1970 2000SC Automatic (spares only), a 1972 2000SC, a 1975 2200SC and a 1975 3500S.

For most of the 1980s, the P6 was still a cheap old car, but by the early 1990s the late John Blunsden at Motor Racing Publications reckoned there was sufficient enthusiast interest to merit a book on the subject. So he asked me to write Rover P6, 1963–1977, which was published in 1993. Nearly twenty years later, there was still no other book on the subject, but enthusiasts had discovered a good deal of new information and some colleagues encouraged me to prepare a new edition. With help from three of them, Nick Dunning, Al Worsfold and Chris York, a revised edition appeared in 2012, this time published by Brooklands Books.

There was still more information coming out of the woodwork, however, and it was clear that the time was right for a new book. So here it is, and I will say right now that it incorporates a lot of new research, both by me and by Chris Wilson and Andries Griede. I will also say that rewriting some of the original was more than a little difficult – pointless, even, where there was nothing new to say – and so if any sentences or even whole paragraphs seem familiar to readers of the original 1993 book, the reason is that I could see no reason to change them.

It is customary to add a list of acknowledgements at this point. As I know this book is tight for space, I will simply scoop up all the P6 enthusiasts who have provided valuable information or pictures into a single big thank you. They know who they are. But there have also been many former Rover people who have helped, and I think it is important to record who they have been. Sadly, many of them are now no longer with us.

So, for the record, these are the Rover people to whom I have spoken directly about the P6 story over a period of some forty years:

David Bache

Chief styling engineer

Gordon Bashford

Design engineer

Gerry Boucher

V8 engines team

Chris Bramley

Gas turbine engineer

Eric Branson

Research Department

John Carter

Engine development

Lou Chaffey

Rally team mechanic

Dan Clayton

Competitions Department

Roger Crathorne

Land Rover engineer

Maureen Hill

PA to David Bache

Spen King

Advanced design and gas turbine work

Bruce McWilliams

Head of RCNA

Jimmy McWilliams

Public relations at RCNA

William Martin-Hurst

Managing director

Tony Poole

Styling Department

Gordon Reed

P6 project engineer

Frank Shaw

Head of Transmissions Department

Jim Shaw

Brakes specialist

Brian Terry

Engine Test Department

Lyn Thomas

Suspension and NVH engineer

Richard Twist

Engine development

Dave Wall

V8 engines team

I have also corresponded with:

Tony Cleminson

Triplex

Richard Fishwick

NVH engineer

‘Nobby’ Fry

FLM Panelcraft

Ted Gawronski

P6 project engineer

Mike Green

Son of RCNA engineer Dick Green

Roger Harding

New Zealand Motor Corporation

A. Lowe

AE Brico, fuel injection development

David McMullan

Crayford

A. B. Smith

Managing director

Jack Swaine

Head of the Engines Department

Finally, through the efforts of others, I have been able to tap into the memories of:

Gerry Beddoes

AE Brico, fuel injection development

Anne Hall

‘Works’ competition driver

Colin Elmer

P6 inspection superintendent

Roger Clark

‘Works’ competition driver

Rob Lyall

Rover steering specialist

Peter Willmer

Rover transmissions engineer

Obviously, steering a way through sometimes conflicting memories has been my responsibility, and I hope the result is an accurate reflection of what really happened. But I would never think of describing what is in this book as definitive, and I hope that any reader who can add to the story or correct what I have said will feel free to let me know by contacting the publishers.

One final thing: if you get half as much fun out of reading this book as I have done in writing it, then my publisher should have charged you at least twice as much when you bought it…

James TaylorOxfordshire, September 2019

TIMELINE

September 1956

First meeting to discuss the specification of the future Rover P6 model

October 1963

P6 introduced as the Rover 2000

March 1966

2000TC model introduced (initially for export)

October 1966

2000 Automatic introduced

April 1968

Three Thousand Five introduced

October 1969

North American 3500S introduced

October 1970

New Look range introduced

October 1971

3500S (manual) model introduced

October 1973

2200SC, 2200SC Automatic and 2200TC replaced equivalent 2000 models for most markets

June 1976

First Rover SD1 variants (3500) introduced to replace P6 range

February 1977

End of Rover P6 production

CHAPTER ONE

DESIGN AND DEVELOPMENT, 1956 –1963

Although the start of work on what would become the Rover P6 can be traced quite accurately to a meeting held on 21 September 1956, Rover’s first ideas about such a car were actually discussed at least three years earlier. A central factor was the success of the Land Rover, introduced in 1948 as a product primarily for export that was intended to tide the company over until the difficult trading conditions of the post-1945 period came to an end. In practice, the new vehicle had been such a success that it had become Rover’s primary product by 1951.

With it had come increasing profits, and these had encouraged the Rover board to consider bringing out a second range of cars alongside the P4 models that had been introduced in 1949. They envisaged a smaller and cheaper car to be built in larger volumes, one equivalent in size to cars like the contemporary Vauxhall Velox.

In the post-war period, Rovers had been deliberately conservative and were aimed at the well-to-do professional classes. This is a 1964 110, the last of the well-loved P4 range.AUTHOR

However, as those discussions progressed and the first scale models of the new car were produced in the styling studio, it became clear that the plan had a flaw. Once again, the Land Rover was the cause: booming demand and the need for extra assembly facilities meant that Rover could not satisfy that demand and create the assembly plant needed for a brand-new high-volume car as well. So the plan for a second car range was radically rethought during 1955. What was already known as the P5 model changed from a mediumsized, high-volume car to a larger, low-volume luxury model – and in that guise it entered production as the Rover 3-litre in 1958.

Above the P4 in the Rover range was the P5 3-litre, a more modern luxury saloon that nevertheless maintained the Rover traditions of conservatism and discretion. This 1959 model is typical of the breed.WIKIMEDIA COMMONS

However, the idea of a smaller Rover that would be built in higher volumes did not go away. By 1957, with Land Rover sales still booming and providing much of the necessary finance, the Rover board were prepared to look again at the possibility of such a car. Not the least of their concerns was the medium-term need to prepare a replacement for the P4 model, which was already beginning to look old-fashioned next to some of its rivals from other makers. If Rover could combine the two ideas and replace the P4 with a smaller, high-volume model, that would make perfect sense.

Along with all this came the idea that the new Rover should incorporate the very latest technology. Although Rover’s mid-1950s cars made the company appear staid and traditional, behind the scenes it was highly innovative. It was Rover who had led experiments with gas turbine propulsion for road cars, developing its first experimental car in 1950 and using it to claim a world speed record in 1952. Since then, further development had led to a quite remarkable prototype of a small gas turbine coupé in 1956, which combined a rear-mounted gas turbine engine with an advanced structure and drive to all four wheels.

Other development work, initially in connection with the aborted volume-car project, had focused on chassis-less construction with a steel skeleton structure and unstressed skin panels – an idea put forward by manufacturing director Olaf Poppe. So it was not surprising that some of these new ideas should be submitted when discussions began in earnest about the new high-volume Rover in 1957.

Most importantly, although the thought was not recorded in any contemporary documents, Rover knew that it faced a major challenge with its new car. What were high volumes to Rover were low volumes to the established makers of high-volume saloons like Vauxhall and Ford, and so the new car would have to offer something very different in order to establish a place for itself in the market. Advanced technology seemed like the ideal answer: it would give the Rover what is today called a unique selling point (USP).

IN THE BEGINNING

In the mid-1950s, the two outstanding figures at Rover were the brothers Spencer and Maurice Wilks, who had guided the company’s fortunes since the early 1930s. Spencer Wilks, the older brother, had been managing director since 1933, while Maurice Wilks had run the Engineering Department since 1931. However, times were changing. On the one hand, the success of the Land Rover and Rover’s consequent expansion demanded changes in the way the company was managed; and on the other hand, it was time to give some of Rover’s very able younger engineers the opportunity to influence the company’s future.

Maurice Wilks was Rover’s technical director in the 1950s, and became its managing director. He oversaw the early thinking on the P6 project.ROVER CO. LTD

So in a series of top management reshuffles during 1956, Maurice Wilks was appointed joint managing director with his brother. Although he would continue to keep a fatherly eye on Engineering, he appointed as Rover’s new chief engineer his deputy, Robert Boyle. Below Boyle he also appointed two new senior engineering managers. These were Dick Oxley, whose task was to oversee Rover car engineering, and Tom Barton, whose job focused on Land Rovers.

Meanwhile, there remained a number of separately managed departments within Rover Engineering – notably Engines, under Jack Swaine; Transmissions, under Frank Shaw; Research, under Brian Silvester; Gas Turbines, under Spen King; Styling, under David Bache; and Design Research, under Gordon Bashford. These positions remained unchanged when Spencer Wilks became chairman in 1957 and finance man George Farmer was appointed as joint managing director alongside Maurice Wilks.

Robert Boyle was Maurice Wilks’ deputy, and was appointed Rover’s chief engineer when Wilks became joint managing director in 1956. He initiated the P6 project.ROVER CO. LTD

Spen King was a nephew of the Wilks brothers and was involved with gas turbine experiments in the 1950s, later becoming head of Rover’s future products think-tank. He had a substantial input to P6 – initially because there were thoughts of making a gas turbine-powered version available.ROVER CO. LTD

Gordon Bashford had designed the ‘package’ for every post-war Rover and became Spen King’s deputy in the department that became New Vehicle Projects. He was responsible for the overall layout of the P6.ROVER CO. LTD

Thus it was Robert Boyle who called that meeting on 21 September 1956, which was intended to initiate thinking about a new Rover car, to be known as the P6. Present were Peter Wilks (Boyle’s deputy and a nephew of the two senior Wilks brothers), Gordon Bashford, David Bache, Jack Swaine, and Olaf Poppe, who was still running Rover Manufacturing. Spen King did not attend the meeting, but received a copy of the minutes and became fully involved in all subsequent planning meetings.

Peter Wilks was another nephew of the Wilks brothers and a cousin of Spen King. He held a senior position in the Engineering Department, and later took over as its director.ROVER CO. LTD

Boyle told his colleagues that Rover needed to start work on a new car, and that ‘in broad outline this had to be a vehicle substantially cheaper as regards both tooling cost and selling price than the P5’ – the 3-litre saloon that would not reach the showrooms for another two years. The meeting agreed a target weight of 24cwt (2,866lb or 1,219kg) with alloy panels and 25cwt (2,800lb or 1,270kg) with steel panels, and that the new car’s cost before purchase tax should be no more than £800. This would make it a direct rival for the Austin A105 (£799 in October 1956), Wolsley 6/90 (£806) and Standard Vanguard Sportsman (£820). These were all relatively expensive and prestigious saloon cars, although none was quite in the Rover price bracket, which at the time ranged from £865 for the cheapest 60 saloon up to £1,130 for the most expensive 105R De Luxe.

With the record of the September meeting came an outline specification that contained some quite radical proposals. There was to be base-unit construction, a De Dion rear suspension, and an engine of between 2 and 2.5 litres – ideally a 4-cylinder but ‘silence and smoothness are primary considerations’. All these ideas survived into the production model. Those that did not included front-wheel drive with a two-speed automatic gearbox, rack-and-pinion steering, 13in wheels, the possibility of plastic body panels and ‘doors possibly partly in the roof for access’.

That initial meeting was not precise about the size of the proposed new car, but for the next meeting – on 1 October – Boyle had prepared a document that described it as ‘possibly similar in general proportions to the Ford Consul’. He specified a 105in (2,667mm) wheelbase, actually 5in (127mm) longer than that of a Mk 1 Consul but still one size down from the 111in (2,819mm) of the P4’s wheelbase and the 110.5in (2,807mm) of the planned P5’s wheelbase.

Through this meeting and a number of others in November, December and the early part of January 1957, Boyle and his colleagues discussed the initial proposals on the table and more. At the third meeting, on 19 November, Boyle asked for future meetings to be referred to as PX meetings rather than as P6 meetings. Perhaps this was to restrict speculation within the company about what might be happening, because to anyone who worked at Rover, the P6 name immediately suggested a new product destined to follow the P5.

During this period, Boyle asked for a number of studies to be made. Engine designer Jack Swaine, for example, was to investigate three engine configurations – a V6 and in-line engines of both 4 and 6 cylinders. Specifically, Boyle wanted him to re-examine the experimental 2-litre V6 that had been drawn up for P5 in the days when it was envisaged as a smaller car than P4, and he wanted Swaine to think about developing a lightweight aluminium alloy version of it. He also wanted him to look at the 4-cylinder Mercedes-Benz 190 engine (an ohc type of 1897cc with 75bhp) as ‘a good example of about the best that can be done’. Other subjects of study were to be the 6-cylinder Mercedes-Benz 220S engine (ohc, 2195cc, 100bhp) and the 6-cylinder Mays-head Ford Zephyr engine (ohv, 2553cc, 127bhp).

WHY CALL IT P6?

In late 1945, Maurice Wilks began work on the design of a new post-war Rover, which he called Model P. This was a completely new type of name for Rover – the pre-war cars had simply been called 10hp, 12hp, and so on – and the most likely theory is that the P stood for post-war. (Wilks seems to have liked these single-letter codes. He used M for a proposed post-war miniature car, T for the gas turbine models and J for a mule prototype based on the Jeep that eventually developed into the Land Rover.)

Model P did not materialize, but the one that followed it logically became model P2, even though it was actually a very limited update of the last pre-war Rovers. Next came P3 in 1948, marrying a new engine and chassis to what was essentially still pre-war styling with separate wings and running boards.

The P3 was a short-lived model, and the proper post-war model arrived in 1949 as the P4. Engine and chassis were both further developments of those pioneered in the P3, but the new full-width, three-box body styling was completely new to Rover – and upset many traditionalists.

The P5 was initially intended to be a smaller, higher-volume car positioned below the P4, but actually became a more upmarket, lower-volume model released in 1958. It was still being developed when Rover started work on their new high-volume model, which logically took the next code name of P6.

The P-series of code names continued until the end of Rover’s days as an independent company. P7 was a further development of P6, which is described in Chapter 4; P8 was intended to replace P5 but was cancelled by British Leyland because it would have been a direct rival for the Jaguar XJ6. Then there was the P9, a sports car developed from the P6BS (seeChapter 8), which was cancelled because it was another direct threat to Jaguar; and finally the P10, which started life as the replacement for the P6 and became SD1 under British Leyland.

1957: A SLOW START

The start of serious thinking about Rover’s new model had coincided with the early days of a major international crisis. In July 1956, President Nasser of Egypt nationalized the Suez Canal, and Israel, Britain and France responded by sending invasion forces to ‘liberate’ this critical international waterway. Nasser then sank blockade ships in it to prevent trading vessels passing through, and although the United Nations then intervened to restore peace in the region, oil supplies were seriously disrupted.

In Britain, petrol prices rose sharply and rationing was introduced in mid-December, the ordinary car user being limited to enough for 200 miles (320km) a month. Sales of new cars slowed dramatically; Ford and Vauxhall reduced production and introduced a four-day working week, and Rover sales inevitably suffered. Clearly there was not much point in planning for a new model if the Suez Crisis was going to have long-term effects. On 23 January, Peter Wilks wrote a memo to say that all PX planning would be suspended until further notice. He asked for any ideas to be forwarded to Gordon Bashford, who would bring them to Maurice Wilks’ notice when the time was right.

Fortunately, the crisis began to ease, and the ban seems to have been lifted fairly quickly. Within a couple of months, Robert Boyle had drawn up a ‘Suggested Specification for P6’. There was no more talk of PX. He now expected the car to have rear-wheel drive, still with a two-speed torque converter transmission. He expected Rover to manufacture the base-unit in house as a ‘composite structure using steel, light alloy and other material such as waterproof plywood… as dictated by cost, weight and performance’. Its bolt-on skin panels were to be of light alloy.

Boyle envisaged 4-cylinder and 6-cylinder derivatives of the P6, with engines that shared common bore and stroke dimensions, a chain-driven overhead camshaft and a die-cast light-alloy cylinder block. The 4-cylinder was to have 80bhp, five main bearings and a 1.8-litre swept volume, while the 6-cylinder was to be a 2.7-litre engine with seven main bearings and 120bhp.

This was the outline specification that he put to an engineering policy meeting on 19 April, no doubt seizing the opportunity created by the end of petrol rationing, which followed the reopening of the Suez Canal that month. Chairman Spencer Wilks and the two recently appointed joint managing directors, George Farmer and Maurice Wilks, agreed that he should go ahead with what he had in mind. That meeting also agreed that Boyle should find a new office for Gordon Bashford – whom he had made responsible for the layout of the new car – close to Spen King in the Gas Turbine Department to allow maximum co-operation between them.

This was a new and exciting development, and it marked the formal start of a plan to develop a gas turbine-powered variant of the P6 saloon. Rover had already built a number of successful gas turbine cars, but all had been engineering test-beds. Pressing his department’s interests, King now wanted to build a new gas turbine car that would be a viable production possibility. The cost of developing a purposedesigned model would be too great, and so King wanted to get a gas turbine engine adopted as a production option for the new P6 saloon. This was why he needed to work closely with Bashford, whose overall design for the base unit was to leave room for the 2S/140 gas turbine engine that King’s team were already developing.

The idea that there should be both 4-cylinder and 6-cylinder models now became more firmly embedded in the plan, and on 13 May a document outlining Rover’s ‘suggested future car programme’ envisaged a 4-cylinder P6/A model and a 6-cylinder P6/B model. The first P6/A prototype was to be on the road by March 1959 and cars were expected to be on sale from October 1960. The P6/B programme was undated, and was presumably expected to follow at a later date.

This was all well and good, but there was still no agreed specification for P6, and paperwork from the first half of 1957 reflects this confusion. The 6-cylinder engine, for example, is called a 3L7 in some papers – but that was actually the P5 3-litre IOE engine and not the planned new ohc type at all. By June, the idea of a two-speed torque converter gearbox had been dropped, but some papers refer to a conventional four-speed manual box as standard while others suggest that a new three-speed type then being developed might be fitted. Expected options were the P5’s overdrive and Borg Warner automatic gearboxes. Frank Shaw’s transmission engineers probably breathed a sigh of relief when they were finally asked to focus on a new four-speed all-synchromesh gearbox for the P6.

Gordon Bashford, frustrated by this lack of clear direction from his management, spoke to Robert Boyle and Peter Wilks on 12 June in an attempt to pin down a specification for the P6, but all he got was another set of different ideas! So P6 remained undefined until the autumn, when Bashford, Wilks and Boyle met in Boyle’s office on 30 September and established ‘certain terms of reference for P6’. They agreed a number of actions, and Peter Wilks drew up a dated engineering programme on 11 October, which was adopted with minor changes and issued to relevant people at Rover on 29 October.

At last, things were getting under way. Rover management now agreed to aim for an October 1961 Earls Court show launch for the new car. The company advertised for a project engineer and recruited Ted (Tadeusz) Gawronski from Ford specifically to lead development of the new car; his experience with cars produced in much higher volumes than Rover was used to was no doubt expected to be invaluable. Gordon Reed became his deputy as Assistant Project Engineer, and a pair of more junior Technical Assistants completed the development team.

Robert Boyle had already concluded that Rover could not manufacture the base units in house after all, and so he and Gordon Bashford visited Pressed Steel in November to arrange for that company to supply base units and panels in quantity by July 1961. By the end of the year, Gordon Bashford had completed the preliminary mock-up and layout work, although there were still some stray ideas around. Among these were an air suspension system, which Brian Silvester’s Research Department engineers investigated as an eventual alternative to the steel springs planned for the first production cars.

The Base Unit

Base-unit construction, in which the mechanical components and unstressed skin panels are bolted to a stressed steel skeleton, had first been proposed at Rover in 1951 by Olaf Poppe – four years before Citroën had announced it on their revolutionary DS model. It was ideally suited to the long model life for which a small company like Rover had to plan, because styling facelifts to the unstressed skin panels would be cheap and simple to make.

This method of construction also appealed to Gordon Bashford, because it both saved the weight of a separate chassis and offered the torsional rigidity that he considered so important in car design. Following Poppe’s suggestion, he built a first experimental base unit in 1952 using the dimensions of the then-current P4 saloon so that direct comparisons could be made. By mid-1954 he had built one up into a mobile test rig, using P4 60 running gear and an experimental strut suspension.

Base-unit construction had been part of the specification for the original ‘small’ P5, but a monocoque was chosen when that car became larger and heavier. Nevertheless, Bashford remained convinced of the soundness of the base-unit principle, and he championed it for P6.

For Pressed Steel, the Rover base unit was a new challenge. Not only was it the first base-unit structure they had been asked to build, but Rover also demanded very tight manufacturing tolerances because they wanted to minimize the amount of hand-fitting necessary on the assembly lines. To achieve the necessary ‘first time’ panel fit, Pressed Steel planned to put every base unit through a large automated drilling jig that ensured all the bolt holes for the outer skin panels would be in exactly the same place every time. Pressed Steel engineers kept in close touch with Rover designers as details of the base unit evolved during the P6’s development.

This is the very first full-size base unit, which would be built up as P6/1. The unusual front suspension design can be clearly seen. The tyres are tubeless crossply types on 13in steel disc wheels.ROVER CO. LTD

This schematic drawing shows the unstressed skin panels that bolted to the P6 base unit.

From this policy of easy panel fitting came the idea of easy panel replacement, and Rover decided to provide readypainted P6 skin panels from the factory that could be bolted straight on to reduce the cost of accident repair work. This system continued in use until the late 1960s and perhaps longer, but brought with it additional complications for stocking the panels as the number of colour options increased.

1958: P6 TAKES SHAPE

The issue of a preliminary specification for the P6 on New Year’s Day 1958 was almost symbolic of a new beginning. Some fifteen months after that first discussion about the P6 in Robert Boyle’s office, the car was formally expected to be a high-performance lightweight four-seater of advanced design on a 103in (2,616mm) wheelbase. It was to sacrifice none of the traditional Rover engineering quality or ride comfort, but it would be lighter and cheaper to run than the P4 that it would replace.

Work on the P6 during 1958 was aimed at just two targets. By July, all information needed to build a base unit and suspension units for static tests was to be available. By December, the main styling features were to be established and enough information available to permit manufacture of a set of body panels for the first running prototype. That put much of the onus onto David Bache’s Styling Department because the base unit could not be finalized until certain elements of the styling had been determined.

David Bache ran the Styling Department. He had been responsible for the P5, for various P4 facelifts, and would lead the styling for the P6.ROVER CO. LTD

In fact, Bache had put down his first thoughts on P6 styling in a memo dated 12 December 1957. These show how much emphasis he placed on simplicity: ‘In view of the very nature of the P6 specification,’ he wrote, ‘it lends itself ideally to be a simple classical form, devoid of all superfluous ornament.’ In the longer term, such a style would be ‘most helpful for a future revision (facelift) policy’. Bache envisaged ‘a clean elegant form with all character lines expressed by the medium of sculpture in the basic panels, with no external rubbing strips. The general form flows forward creating vivid movement with a new and unused character.’

Bache’s ideas for the shape of the P6 were translated into a series of scale models. The dart-like shape of early proposals is clear on the one nearer the camera.AUTHOR’S COLLECTION

With simplicity went good aerodynamics, which Bache reasoned would improve both performance and stability. Good high-speed handling would be important in the coming age of the motorway, and Bache’s designs for the P6 therefore all aimed to get the centre of air pressure far enough rearwards to ensure straight-line running at high speeds. Aerodynamics also influenced the design, and from the start the bonnet and windscreen planes were designed to provide optimum pressure at the base of the windscreen, where the air intake for the heating and ventilating system would be located.

Sketches and photographs from Bache’s styling studios show that there was a good deal of American influence on the early P6 proposals – unsurprising at a time when American car design was in the ascendant. Several had pronounced tail fins, and some of the bold tail-light designs proposed were wholly unlike anything seen in the European motor industry. The dimensions, though, were firmly European, and there was European influence in the shapes of the roof line and the nose, both of which clearly took their inspiration from Citroën’s 1955 DS saloon.

By the middle of January 1958, Bache’s team were making quarter-scale models of various styling proposals; by the end of March these were ready for formal viewing and selection of a theme; and by the middle of July, the favoured theme had been turned into the first full-size P6 clay styling model. As a next stage, this was handed over to the jig shop, where a team led by Cyril Nicholls had hand-built a prototype base unit by the end of October. This was then put through a series of static tests, mainly to determine its torsional rigidity.

Those scale models showed a different proposal on each side. This is side A of model no. 2; some of the differences on the side B proposal (otherwise 2B) can be seen.ROVER CO. LTD

THE CITROËN INFLUENCE

The Citroën DS represented the cutting edge of automotive design at the time Rover began thinking seriously about the new model that would become the P6, and so it should be no surprise that it had a considerable influence on the new car from Solihull. Introduced at the Paris Salon in October 1955, the DS pioneered base-unit construction, and featured all-round disc brakes with a full-power hydraulic system, together with a revolutionary interlinked suspension that was operated from the same high-pressure hydraulic circuit as the brakes. High-pressure hydraulics were also used for the steering and clutch.

The Citroën had a 4-cylinder, 2-litre engine, which was an elderly design that was the car’s only major disappointment, but it did drive the front wheels rather than the rear wheels, and this was still seen as quite avant-garde even though Citroën had espoused front-wheel drive as long ago as 1934. One result of this layout was that the passenger cabin was quite remarkably spacious for the size of the car.

The Citroën DS had some important influences on the design of the P6.KLUGSCHNACKER/WIKIMEDIA COMMONS

Rover certainly considered using front-wheel drive for their new car, although they abandoned the idea quite early on. They enthusiastically followed Citroën’s lead by using base-unit construction (which they had been looking at independently for some years), and they also chose to use an all-disc braking system. The high-pressure hydraulic system was a step too far, although Rover certainly did experiment with full-power brakes, testing them on a pair of P4 105R saloons during 1957. The Citroën’s famed ‘magic carpet ride’ almost certainly persuaded Rover to pay careful attention to the suspension of their new car, choosing a De Dion rear axle to give most of the benefits of an all-round independent layout.

Then there was of course the influence of the Citroën’s shape on David Bache’s styling for the P6. His original design had a low, sloping nose that recalled the Citroën (although the Rover always had a conventional boot instead of a sloping rear like the French car). The shape of the Rover’s roof and glass area was also undeniably influenced by the DS, and a comparison of the bright trim around the top corners of the windscreen on the two cars is further confirmation of the Citroën influence.

It is again no surprise that Rover should have bought a Citroën to study, although of course they had a fleet of competitor cars of all types. Their Citroën was not in fact a DS but the cheaper and less complex ID19 model, which lacked some of the highpressure hydraulic systems. The car was registered to Rover as XUE 431 on 5 February 1958; for the record, it had commission number 9-560085 and engine 20701225, and was sold on through Stratton Motors on 11 August 1960.

1959: THE FIRST PROTOTYPES

Skin panels, gearbox and engine all became available in the closing months of 1958, and the first running prototype of the P6 was on the road by the end of February 1959. To the Engineering Department it was known as P6/1, but in terms of the overall P6 programme it was known as a Phase I prototype. The plan was to build four Phase I cars to the 1958 specification, to incorporate the lessons learned from these into the Phase II prototypes, and then for the Phase III prototypes to have the final modifications before production began. At least, that was what the Rover engineers hoped. In practice, there would also be a Phase IIIA, a Phase IV and a Phase IVA before the P6 entered production, and along the way there would be plans for a radical future redevelopment that became known as Phase X!

Here is P6/1 during early testing. No wind tunnel was available, so the aerodynamic performance was measured by means of tufts of wool attached to the car.ROVER CO. LTD

The construction of the first P6 prototype should have signalled the end of Gordon Bashford’s involvement with the project. His job, after all, was to develop new concepts and no more. However, Maurice Wilks wanted to ensure that the radically new engineering that would go into the P6 should lose nothing in the transition from drawing board to production line, so he asked Bashford to remain in close touch with the project right up to the pre-production stage. As a result, the P6 would always be very much Gordon Bashford’s baby.

The four Phase I prototype cars were built in the first nine months of 1959 and were numbered P6/1 to P6/4. They all had a sloping nose with frog-eye headlamps, a pillarless passenger cabin with frameless door windows, a 100in (2,540mm) wheelbase and a ‘box’ boot with full-depth tail panel for rigidity. All of them had the new 2-litre 4-cylinder ohc engine and all-synchromesh gearbox that would be carried through to production, but they had disc front brakes and inboard rear drums because a satisfactory all-disc system was not yet available. Suspension and steering were generally similar to the eventual production designs, although the Phase I cars had crossply tyres on 13in wheels instead of radials on 14in wheels. It was probably one of these cars that achieved 109mph (175km/h) at the new MIRA test track near Nuneaton.

The early base unit design was pillarless, with a deep panel at the rear that added strength and formed a box-like boot. This is base unit no. 4 undergoing torsional testing at Pressed Steel. It would never be built into a complete car.PRESSED STEEL CO.

By the time of the fifth prototype in late 1959, Rover had greater confidence in the strength of the base unit and the depth of the rear panel was reduced. This appears to have been the only car built with twin headlamps on the original sloping nose.ROVER CO. LTD

Inevitably, there were problems. ‘When we put the first car on the road, it was a shocker… terrible!’ Gordon Bashford told the author. ‘It vibrated, it was noisy, and tyres were a problem. You’ve got to remember it was a lot of new ideas incorporated into one vehicle.’ Pavé testing revealed structural problems, too: the weight of the full fuel tank, located under the boot floor, caused the joint between the A-post and the cantrail to flex and crack because the pillarless construction failed to absorb the stress loading. The frameless side windows also gave trouble.

Then there were objections to the Phase I car’s appearance, especially to its futuristic sloping nose design. ‘Maurice Wilks thought the public wouldn’t like it,’ Spen King told the author. As a result, David Bache was asked to draw up a ‘proper’ front end, and as early as July 1959 he was working on the squared-off, twin-headlamp nose that would lend the production P6 such distinction. Even that was a bit radical for some tastes, as all earlier Rovers had incorporated a recognizable old-style radiator grille.

Not all of these problems had been rectified by the time of the first Phase II prototype, which was probably built in 1959. The sloping nose remained, although it now incorporated the four frog-eye headlamps that had been tried on a full-size mock-up in April. The passenger cabin was still pillarless and the door glasses were still frameless, and the fuel tank was still under the boot floor. However, the clumsy rear end shape of the Phase I cars had been refined, the roof had been redesigned with a more pronounced rearward curve, and the interior trim had been extended to leave none of the bare metal in the passenger compartment that had characterized the first four cars.

Interior Design

David Bache’s Styling Department began work on a full-size model of the P6’s passenger compartment early in 1958. The driver’s compartment (seat, facia and controls) was initially developed on a separate model, and the finished details were then transferred to the full passenger compartment buck.

This interior proposal is a full-size model, and shows the early design of lightweight seats and the twin-nacelle proposal for the instruments; in this case, the dials have been taken from a P5. The ‘shin bins’ and central grouping of the switchgear are already in the plan.ROVER CO. LTD

Bache’s aim was to allow the driver maximum comfort and convenience to give him or her the best chance of retaining full control of the car at all times. He was a pioneer in applying the science of ergonomics to car design, and this was reflected in some of his design solutions. For example, he made the steering column adjustable to suit drivers of different sizes; he set the speedometer as far from the driver’s eyes as possible because most people have difficulty in changing focus from road to instruments quickly; he sited cold-air vents carefully to prevent drowsiness; he used modern ‘idiot lights’ instead of gauges because they were impossible to ignore; and he used different designs for different dashboard switches to make them easier to distinguish in the dark.

The P6 interior was also designed to simplify production of both left-hand-drive and right-hand-drive cars. The handbrake, gear lever, radio and switches were all mounted centrally. Bache reversed the traditional positions of glove box and parcel shelf to give a full-width parcel shelf onto which the instrument pod could be mounted on either side. The original design had all the instruments contained in two large circular pods ahead of the driver, and both mock-ups and prototypes had P5 dials. However, the production layout with its ribbon speedometer was settled in December 1960, and the first car to have it was probably P6/12, ten months later.

Bache’s design also took account of the trend towards safety features, with rounded or soft edges to interior components to minimize injury in an impact. Below the parcel shelf he sited angled drop-down ‘shin bins’, which were padded and would collapse under impact to reduce leg injuries. At the same time, he designed most of the P6 dashboard to be made from injection-moulded plastic, a relatively new medium in the motor industry. These large mouldings reduced the amount of hand assembly typical on car production lines, so lowering costs. He designed injection-moulded plastic retainers for the wood finishers on the doors, reducing the amount of hand fitting traditional to Rovers. And, of course, all the plastic components contributed to weight saving.

Rover owners expected leather upholstery, but Bache’s team developed a new lightweight seat design that was half the weight of a traditional P4 or P5 seat. They began by sculpting the seat in clay to ensure its form was physiologically correct, and then designed the mechanical details within the agreed contours. A new patented frame was created to absorb impact loads in a collision and so minimize injuries, and it incorporated infinite rake adjustment for the first time in a Rover. The first lightweight seat prototype was ready in March 1959, and seats of this design went into many of the early P6 prototypes. They can still be seen in the surviving gas turbine prototype, T4. Unfortunately, they were not carried through to production. No details are known, but it seems that the visually more luxurious production design was called for some time around 1962.

1960: MORE DELAYS

For the second time in its short history, political problems now had an impact on the P6 programme. The British government were pursuing a policy of creating employment in depressed areas of the country by encouraging manufacturers to build new factories there and refusing planning permission for new factories in existing prosperous areas. The Midlands was a prosperous area, and Rover were denied permission to build the new factory at Solihull that they had always seen as essential to the P6 project.

Rover moved rapidly to resolve the problem. The company acquired a 120-acre (48ha) site on the former airport at Pengam, near Cardiff – a choice probably influenced by their new production director, William Martin-Hurst, who was also chairman of the Welsh Development Board. By October 1960, they had gained planning permission for a satellite plant there and for an extension to some existing buildings on the north of the Solihull site.

Building the new factories from scratch meant that the P6’s launch would be delayed by two years from its original target of October 1961. While Rover management were probably less than happy, the engineers were more positive. As Gordon Bashford remembered, ‘We were under some pressure because of some development problems on P6 relating to structure and vibration, so in my opinion a delay was a godsend.’ One consequence was that any plans for further Phase II prototypes were cancelled, and Rover moved straight to Phase III for the next cars.

Spen King also believed that this delay allowed Rover to take a second look at the P6 project. King had now become much more directly involved with P6 after a management reshuffle in 1960, which had put him in charge of what was now called New Vehicle Projects. This was in fact Gordon Bashford’s old design research team, now supervised directly by King instead of reporting both to Robert Boyle as chief engineer and to Roland Seale as head of the drawing office.

‘We now had time for a rethink,’ he told the author. ‘I was keen on looking at front-wheel drive, so I asked Gordon to draw up some layouts for me.’ This second look probably began in December 1960 and became known as Phase X. Like the main programme, it allowed for both 4-cylinder and 6-cylinder derivatives of the car, but it did not go beyond the drawing board. The main reason was that the delay caused by the new factory allowed Rover to develop out the problems that had shown up on the prototypes and to make the P6 much more refined in its existing rear-wheel-drive form.

Much of this refinement work was carried out on the next pair of prototypes. Planning for the Phase III cars had begun in the early autumn of 1959, before the Phase II car was on the road, and they were to have some major differences. Their fuel tanks were to be repositioned over the rear axle to overcome the stress problems at the front of the base unit, and they were to have a conventional full centre body pillar with framed door tops and the new squared-off front end. At some stage during the design process, their wheelbase was lengthened from the original 100in (2,540mm) to a nominal 103.5in (2,629mm), probably to restore passenger cabin space taken up by the relocated fuel tank. With this redesign, Phase III became Phase IIIA, and in practice no Phase III cars were ever built. Both P6/6 and P6/7 were put on the road in July 1960 as 103.5in wheelbase Phase IIIA cars.

After Maurice Wilks had vetoed the sloping nose design as too radical, David Bache redesigned the front end. This is the full-size mock-up, pictured on the roof of the Styling Department in May 1960. There are quarter-bumpers at the front, and there is still a kick-up at the waistline on the rear window, although the pillarless design has been abandoned.ROVER CO. LTD

The visual redesign required a redesign of the base unit, too, and here a scale model is being prepared.AUTHOR’S COLLECTION

The next stage in the P6 test programme was high-mileage endurance testing, and much of this would be done on public roads. Keen to keep their new car secret for as long as possible (in order to protect sales of the existing models), Rover chose an elaborate disguise. It was not enough to register the cars away from Solihull, as had been done with the earlier prototypes, because the cars still carried the Rover name on the licence discs in their windscreens. This time, they set up an entirely fictitious car company that would register the cars, and developed badges to go with it. The company was called Talago, a name thought up by project engineer Ted Gawronski and based on his initials of TLG.

Special Talago badges were made up to disguise the prototypes when they went out on road test. It appears that each car had only two, one on the rear and one on the left-hand front wing. This one was kept as a memento by deputy project engineer Gordon Reed (who later took over as project engineer).AUTHOR

Ted Gawronski checks the tyres by the roadside during the 1960 Continental test. The half-height rear panel and a proposed design of rear overriders are both very clear here.TED GAWRONSKI

Over the summer of 1960, P6/7 went on a long continental road test with Peter Wilks and Ted Gawronski. Closer to home, it achieved a best speed of 107.8mph (173.5km/h) for the flying quarter-mile and a mean of 104.8mph (168.7km/h) during maximum speed runs on the M1 motorway, where the police used to allow testing early in the morning before traffic had built up. These were good figures: although an earlier prototype had reached 109mph (175km/h), P6/7 was heavier, thanks to those extra 3.5in (89mm) in its wheelbase, and it had a less aerodynamic front-end design. Besides, 100mph (162km/h) was still a magic figure that was unattainable by most family saloons in the early 1960s.

Prototype number P6/7 was taken on a Continental proving trip by Peter Wilks (left) and Ted Gawronski (right) during 1960. Note how the design of the rear door windows has been changed to incorporate a quarter-light. This picture was probably taken in Spain.TED GAWRONSKI

Meanwhile, the older prototypes remained in use for some types of development work. Under Phase III of the P6 programme, for example, P6/3, P6/4 and P6/5 were to be fitted with Delaney-Gallay heater-demister units to see if these were a viable alternative to the Smith’s type. But Phase IIIA did not last for long. Phase IV began on 18 November 1960.

COMPARING NOTES

In 1960 Rover became aware that Standard-Triumph were developing a new 2-litre saloon for release at about the same time as their own. After what was probably some high-level negotiation, the two companies got together to compare notes, probably to determine the risks involved in putting two essentially similar models onto the market at the same time.

Rover discovered that the new Triumph 2000 was going to have a 6-cylinder engine and that it would be far more conventional than their P6. What neither company realized was that they were both working on cars that would start a new market trend – the so-called ‘executive saloon’ market that would become important during the 1960s.

The Engine and Gearbox

Jack Swaine’s brief for the new Rover engine called for a 4-cylinder type of between 1700cc and 2000cc. The performance target for P6 was 100mph (162km/h), and this had to be allied to good fuel economy. Swaine calculated that the new engine needed about 90bhp in view of the overall weight target for the P6. Minimum weight was a given, along with a low overall height so that David Bache could have his sloping nose design.

Engine and gearbox viewed from the left-hand side; this one was taken from an early (suffix B) production car. The forward exit of the exhaust outlet probably restricted power a little.NICK DUNNING

That low overall height was not going to be easy to achieve with the modern ohc design that Swaine wanted to use. He had to argue his case for this with Maurice Wilks, who was initially strongly opposed to the idea, probably thinking of the long timing chain that would be needed when he insisted that such an engine would be noisy. Swaine got his way in the end, designing a two-stage chain drive with double roller chains in each one and a tensioner to take up wear. He also pointed out that wide-throated valves in an ohc design would give good breathing, with low reciprocating weight and light valve spring loadings.

The height issue also limited the length of the pistons’ stroke. An oversquare design would have limited low- and mid-speed performance, so Swaine chose an equal bore and stroke of 85.7mm, which gave an overall displacement of 1978cc. Steeply inclined inlet ports and vertical inlet valves would have given the best gas flow, but this would also have given overall height problems. So Swaine chose to cast the inlet manifold into the cylinder head in the form of an open gallery, with its top face closed by a bolted plate.

Cost ruled out an all-alloy engine, although an alloy cylinder head was affordable and followed existing Rover practice. An aluminium sump was affordable, too, and Swaine made it as deep as he could, meeting the block along the crankcase centreline. Bolting the sump through to the base of the gearbox maintained rigidity of the engine-and-transmission assembly, while a steel sandwich plate sealed off the rear of the block and sump from the clutch housing.

Working with his assistant, Norman Bryden, Swaine reduced the weight of the iron block by designing it with two large ‘windows’ in the sides, where strength was less critical. These were then covered with 16-gauge blanking plates. The timing cover was also cast in one with the block, access being through holes filled by blanking plugs with rubber seals. Swaine had no hesitation in choosing a five-bearing crankshaft (three-bearing types were more common in 1958) to ensure smooth running. When torsional vibration problems showed up at 5,200rpm on test during 1960, Norman Bryden sought advice from Stewart Tressilian at Bristol Siddeley Engines in Coventry. However, in the end Rover did not adopt his suggestion of a four-bearing crankshaft with counter-weights in place of a centre main bearing; instead, they used a Holset rubber damper on the nose of the five-bearing crankshaft.

Combustion chamber design was influenced by the need for compactness, with the whole squish area within the bore. The ohc design with in-line valves ruled out a conventional hemispherical chamber in the cylinder head, and Swaine told the author that ‘bathtub’ designs proved unsatisfactory. So Rover used a Heron-head design, with the combustion chamber in the piston crown and a flat cylinder head face. Early fears of high piston operating temperatures proved unfounded, but a cutaway piston top was designed after tests on a single-cylinder development rig showed that the valves would hit the pistons at TDC if the engine was over-revved to the point of valve bounce.

With a single SU carburettor and a 9:1 compression ratio, the new 2-litre engine developed 90bhp gross at 5,000rpm – almost as much as the 6-cylinder Rover 90 engine produced from 2.6 litres. The engine was a viable concern by the end of 1958, although considerable detail refinement followed before production – such as using a nylon adjusting arm to cut out secondary vibrations from the rubber-mounted dynamo.

From the other side, the high-mounted oil filter is a notable feature. It simplified servicing – and had been tried before on the early Rover P4 engines.

This engine drove the rear wheels of the P6 through a new four-speed all-synchromesh gearbox drawn up by Frank Shaw in the Transmission Department, who reported to Roland Seale, the head of the Rover drawing office. Despite the good fuel economy that was a P6 design target, the additional weight and cost of a bolt-on overdrive (as used in existing P4 and P5 Rovers) probably prevented one from being specified for the new car. Nevertheless, experiments with an overdrive did follow during the early 1960s (seeChapter 8).

1961: PHASE IV

It was on 24 October 1960 that Maurice Wilks formally proposed to the Rover board that the P6 should be put into production. His fellow directors agreed and set a new launch target date of October 1963 – just two years after that originally planned. And in December 1960, the New Vehicle Projects team turned their thoughts to the next stage of the P6 programme, which was the 6-cylinder derivative that had been planned since the beginning. In practice, it became the P7, and its story is told in Chapter 4 of this book.

Nearly there! P6/9, built in 1961, still had front quarter-bumpers but was very recognizably the car that would enter production less than two years later.ROVER CO. LTD

There was, however, still plenty of development work still to be done on the 4-cylinder P6. Five more base units were sanctioned under Phase IV, but only four of them were built up as P6 prototypes. These were numbered P6/8, P6/9, P6/11 and P6/12, the missing number 10 becoming Spen King’s gas turbine-engined prototype and being renumbered as T4/10 (there is more about this car in Chapter 8). All of them were built up during 1961, and all of them had a new rear end with a bootlid that opened down to bumper height: it was by now clear that the P6 base unit was strong enough without the additional transverse panel at the rear. To counter the extra weight introduced when the wheelbase had been extended under Phase IIIA, the Phase IV cars had lower first, second and third gear ratios that improved acceleration. That 104mph (167km/h) top speed achieved in 1960 was going to be enough.

It was during this stage of the programme that the P6 made the important switch from crossply tyres to radials. Spen King recalled radial tyres being suggested to Rover by Dunlop, with whom the company had long-standing links:

Rex Marvin [Rover’s chief development engineer] and I looked at radials for the P6, but they increased road noise enormously – and the P6 was already a noisy car. So we examined a Peugeot, which was the best there was then for low road-noise on radials. That had compliance built into its suspension, and so I designed some compliance into the P6’s suspension and we standardized on radials. The handling was much better after that.

One of the last changes before production was that the ventilation outlets on the rear pillars were deleted. Here is one, on the car that survives as P6/16.AUTHOR