Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

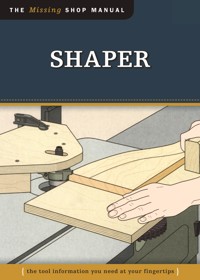

This handy pocket sized guide offers all the tips, tricks, and ideas a woodworker needs to get the most out of their shaper.

Das E-Book Shaper (Missing Shop Manual) wird angeboten von Fox Chapel Publishing und wurde mit folgenden Begriffen kategorisiert:

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 52

Veröffentlichungsjahr: 2011

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

© 2011 by Skills Institute Press LLC

“Missing Shop Manual” series trademark of Skills Institute Press

Published and distributed in North America by Fox Chapel Publishing Company, Inc.

Shaper is an original work, first published in 2011.

Portions of text and art previously published by and reproduced under license with Direct Holdings Americas Inc.

Print ISBN 978-1-56523-494-9eISBN 978-1-63741-555-9

Library of Congress Cataloging-in-Publication Data

Shaper.

p. cm. -- (The missing shop manual)

Includes index.

1. Woodworking tools. I. Fox Chapel Publishing.

TT186.S448 2011

684’.082--dc22

2010017536

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free 800-457-9112 or visit us at www.FoxChapelPublishing.com.

Note to Authors: We are always looking for talented authors to write new books in our area of woodworking, design, and related crafts. Please send a brief letter describing your idea to Acquisition Editor, 1970 Broad Street, East Petersburg, PA 17520.

Because working with wood and other materials inherently includes the risk of injury and damage, this book cannot guarantee that creating the projects in this book is safe for everyone. For this reason, this book is sold without warranties or guarantees of any kind, expressed or implied, and the publisher and the author disclaim any liability for any injuries, losses, or damages caused in any way by the content of this book or the reader’s use of the tools needed to complete the projects presented here. The publisher and the author urge all woodworkers to thoroughly review each project and to understand the use of all tools before beginning any project.

Contents

Chapter 1:The Shaper

Chapter 2:Cutters and Accessories

Chapter 3:Setup and Safety

Chapter 4:Basic Cuts

Chapter 5:Vacuum Jigs

Chapter 6:Frame-and-Panel Doors

Chapter 7:Windows

Chapter 8:Entry Doors

Chapter 9:Handrails

WHAT YOU WILL LEARN

Chapter 1The Shaper

Chapter 2Cutters and Accessories

Chapter 3Setup and Safety

Chapter 4Basic Cuts

Chapter 5Vacuum Jigs

Chapter 6Frame-and-Panel Doors

Chapter 7Windows

Chapter 8Entry Doors

Chapter 9Handrails

CHAPTER 1 :

The Shaper

The shaper and the router share a common heritage. In the mid-19th century an inventor in Ohio produced a prototype for a machine with a vertical spindle projecting out of a horizontal table. This machine, known as a spindle router, was virtually identical to the present-day shaper. Another model from the same era, employing an overhead spindle to raise panels and cut grooves and recesses, evolved into today’s router.

Similar origins notwithstanding, the router and shaper have since followed different paths. The router is often considered the most useful and versatile woodworking power tool; the shaper, on the other hand, is frequently the last machine added to the woodworking shop, a fact that belies its usefulness to the craftsman.

If you frequently cut decorative moldings in the edges of curved workpieces, or if you build many doors and drawers, the shaper is an ideal tool for your shop. Basically, the machine is a bigger, stronger, and more stable version of a table-mounted router, with a much wider range of available cutters. Shaper cutters (here) vary from simple, single profile cutters to complex combination systems that produce the contours of a host of individual blades. Relatively safe and easy to work with, solid cutters with carbide teeth are the preferred choice, though many woodworkers still opt for the versatility of grinding their own knives to whatever profile they desire.

The shaper is a common sight in production shops, where it is unequaled for constructing cabinet doors. The panel-raising jig shown above allows arched top rails and arched raised panels to be shaped quickly, safely, and accurately.

With its large cutter exposed above the table, the shaper requires special attention to safety; the tool is often considered to be the most dangerous machine in the shop. Key concerns are the rotation of the spindle, the direction of feed, and the location of the cutter with regard to the workpiece. Most shaper spindles and cutters are designed to rotate either clockwise or counterclockwise; each direction offers its own advantages and disadvantages. Most cutters are designed to cut from above a workpiece while spinning counterclockwise (as seen from above). This offers a better view of the cut and, because of the direction of the threads on the spindle, ensures that the nut securing the cutter in place remains tight throughout the operation. By reversing spindle rotation and inverting the cutter so that it lies mostly below table level, you can shape the underside of the workpiece. This is often a safer setup for freehand shaping or for working with extra-wide or very long stock. If the workpiece lifts up, the cutter will not gouge it and kick the board back.

Read your owner’s manual carefully and follow the setup and cutting guidelines discussed here, starting here. Take the time to build the guards and fence shown here; they will make your machine much safer to use.

ANATOMY OF A SHAPER

The shaper works very much like a table-mounted router, but it is larger, heavier, and generally more powerful. The heart of the machine is its spindle, a threaded ½- to 1¼-inch-diameter assembly that typically turns a cutter from 7,000 to 10,000 rpm. The spindle, in turn, is driven by a belt- or direct-drive mechanism connected to a ½- to 5-horsepower motor. Some models offer variable speeds.

Shapers are sized by spindle diameter. Machines with larger-diameter spindles require more powerful motors, but these tools vibrate less, produce cleaner cuts, and can be used with a wider assortment of cutters. Many shapers feature interchangeable spindles.

Shaper cutters and accessories are secured to the spindle with a nut and lock washer. The spindle normally turns counterclockwise. On many machines, spindle rotation can be reversed by flicking a switch located on the motor junction box. This is a valuable feature, allowing stock to be fed from either side of the table.

Depending on the model, the height of the spindle can be adjusted from 2 to 6 inches.