39,49 €

Mehr erfahren.

- Herausgeber: The Crowood Press

- Kategorie: Lebensstil

- Sprache: Englisch

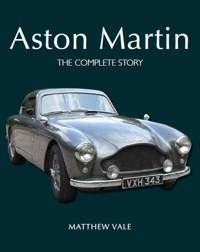

Aston Martin is a marque that holds a special place in the British motor industry. As a manufacturer of cars for over 100 years, its history is tied up with the British psyche, and the marque holds a special place in the hearts of all motoring enthusiasts. This book charts the history of Aston Martin from its early days in central London, as Banford and Martin, through the Bertelli years in Feltham and the post-war David Brown years at Newport Pagnell to the current day with its purpose-built, state-of-the-art factory in Gaydon, Warwickshire. Now seen as an iconic luxury British sports car manufacturer, Aston Martin has been designing, manufacturing and racing cars for over 100 years, almost continuously. Known for combining quality, style and performance in its products, the company has often struggled to balance these attributes with financial success. Fortunately, over the years generous investors who recognize the potential in the company have always been on hand to rescue and perpetuate the brand. Looking at the engines, the cars, the people, the business and car owners, this book tells the story of a quintessentially British marque.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 542

Veröffentlichungsjahr: 2022

Ähnliche

First published in 2022 byThe Crowood Press LtdRamsbury, MarlboroughWiltshire SN8 2HR

www.crowood.com

This e-book first published in 2022

© Matthew Vale 2022

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication DataA catalogue record for this book is available from the British Library.

ISBN 978 0 7198 4119 4

Cover design by Blue Sunflower Creative

CONTENTS

Acknowledgements

Preface

CHAPTER 1THE HISTORY OF ASTON MARTIN

CHAPTER 2THE FORMATIVE YEARS: 1913–1925

CHAPTER 3RESCUE AND THE BERTELLI YEARS: 1925–1946

CHAPTER 4THE START OF THE DAVID BROWN YEARS: 1946–1956

CHAPTER 5CONSOLIDATION AND EXPANSION: 1957–1965

CHAPTER 6THE DBS YEARS: 1966–1975

CHAPTER 7TURBULENT TIMES: 1975–1987

CHAPTER 8THE FORD YEARS: 1987–2000

CHAPTER 9THE START OF THE GAYDON ERA: 2000–2014

CHAPTER 10ASTON MARTIN 2014–2021

Index

ACKNOWLEDGEMENTS

This book would not have been possible without the assistance of many people, including private owners, the Aston Martin Heritage Trust (AMHT), the Aston Martin Owners Club (AMOC) and Aston Martin, as well as well regarded experts including Ecurie Bertelli and Chicane.

The owners of the cars I write about are always a great source of information. I’d like to thank Chris Bland, Jeff Sears, Rob Smith, Richard Loveys, Zara and Jerry Doughty, Tim Slow, Edward Hollaway, Mark Seligman, Phil Taylor, Chris Youell, James Bevin, Rodney McMahon, Roland Long, Mark Holmes and Alan Cambridge for giving me access to their cars and allowing me to tell their stories.

So a special thanks to John Watson, the managing director of Chicane (Ford Lane, Bramshill, Hook, RG27 0RH, see chicane.am) and Robert Blakemore, the managing director of Écurie Bertelli (53 Stilebrook Road, Yardley Road Industrial Estate, Olney, Bucks MK46 5EA, seeecuriebertelli.com) for allowing me to visit their premises and take many photos.

From the Owners Club I’d like to thank Jeff Sears, the Area 10 representative for his help and assistance in meeting owners and for running such a friendly branch.

Rob Smith of the AMHT deserves a special thanks for his assistance with the Aston Martin Heritage Trust and for showing me his fine collection of Astons, as well as the AMHT members Sophie Anderson, who facilitated the pictures from the trust, and Tim Cottingham for data on production numbers.

Steve Waddington, the official Aston Martin historian gave a great deal of help during a busy time at Aston Martin, providing answers to my questions and sorting out various photos used in the book.

Finally thanks to my wife Julia and daughter Elizabeth and her husband Simon for putting up with me writing yet another motoring book.

PICTURE CREDITS

The pictures on the following pages are courtesy of the Aston Martin Heritage Trust: 19, 19, 22 (left), 23, 26, 28, 31, 32 (top left and right), 38, 39 (top), 45, 46, 57 (right), 58, 62, 72, 93 (bottom), 95, 104 (bottom left), 113 (bottom left and right), 116, 122 (all), 123 (left), 126, 146 (bottom), 157 (bottom) and 174.

The pictures on the following pages are courtesy of Aston Martin Lagonda: 177 (bottom left), 179 (bottom), 180, 196 (both), 198 (bottom two) and 203 (both).

PREFACE

In the automotive world the combination of quality and performance is not cheap and it is a tricky path for a company to pursue and remain solvent. Aston Martin is one company that has followed this path, and suffered mixed fortunes as a result. However, the emphasis on quality and performance meant – and means – that with Aston Martin it is all about the cars. From Lionel Martin’s ambition to produce the perfect light car in the formative years of the twentieth century through to today’s range, Aston Martin cars always gave great performance underpinned with engineering integrity and style – but it all came with a cost. And of course Aston Martin has always been bedevilled with the classic British industry malaise: not enough money to realize the dream. In over 100 years of its existence, Aston Martin’s fortunes have fluctuated from being modestly successful to being on the brink of bankruptcy – indeed, it has gone over the edge on more than one occasion, only to be dragged back from the brink by generous investors who saw the potential in the company.

The V8 Vantage was the Aston Martin of the 1970s and 1980s. A combination of brute force and suave good looks made it the ‘poster car’ for many a teenage boy of the time.

But despite these vicissitudes throughout the decades, Aston Martin has held a special place in the hearts of the owners and enthusiasts who recognize the marque’s almost unique combination of price, performance, quality and style, and are prepared to put their hands in their pockets and pay the premium price that those characteristics demand.

CHAPTER 1

THE HISTORY OF ASTON MARTIN

Aston Martin’s history can be traced back to 1913, and since then has been almost continuous – with only a few pauses while new finance was organized – up to the present day, albeit having a rollercoaster ride for much of that time. The fact that the company has survived is in many ways surprising, but the strength of its product and its ethos, along with a certain mystique that has pervaded the brand since its earliest days, have been enough to carry it through wars, depressions and financial calamity.

The DB2 started the line of ‘DB’ Aston Martins. This DB2/4 Mark III is a good-looking and high-performance Grand Tourer from the mid-1950s.

So what is it that has made the brand so strong and appealing? Is it its strong presence in automotive competition, its successes at Brooklands in the 1920s and 1930s, its record of winning at Le Mans in the 1950s, its racing sports cars dicing with Ferraris throughout the 1950s and 1960s, endurance racing in the 2000s, or its recent return to Formula 1 in 2021? Or is it the Bond effect, which since starting in the 1960s has been a lasting element of the brand since the DB5 first appeared cruising through Europe in pursuit of Goldfinger? Or is it the road cars the company produced – high performance, competitive, lightweight, stripped-down sports cars in the 1920s, more road-oriented and better equipped sports cars for the 1930s ‘man about town’, followed by sophisticated GT cars in the post World War II era, designed to transport a gentleman and his lady from London to the French Riviera at maximum speed and in maximum comfort?

Perhaps it is the image of the company keeping the lamp burning for the last of the British performance cars during the 1980s, with the plucky V8 Vantage fighting a rearguard action against the massed hoards of foreign mid-engined supercars trying to wrest the performance crown from Aston Martin’s increasingly aged hands. Finally, what about the essential elements of hand-built luxury cars built using the highest standards of traditional British metalworking, coach building, trimming and engineering skills – the hand-crafted bodyshells, the state-of-the-art engine with the plaque telling you who built it, and the hand-stitched leather-lined interior?

All these factors make up the DNA of Aston Martin. The cars are more than the sum of their parts: they are an amalgam of exceptional mechanical elements with a dash of nostalgia and magic mixed in, and a big dollop of tradition to make what is a unique product in today’s asinine and sanitized world. Any Aston Martin is a car that has character, backed up with an unbroken line of tradition and heritage stretching back to when Lionel Martin was competing at the Aston Clinton hill climb in his modified Singer in those halcyon days before the devastation of World War I.

By the late 1960s the DB6 was Aston Martin’s flagship model. A fine, high-performance, four-seat GT that was capable of extended high-speed continental journeys.

In many ways it is a miracle that Aston Martin has survived, but its very existence is a result of the strength of the things that make the brand great, and a testimony to the many people who have been prepared to back their faith in the name with their own money. Today Aston Martin appears to be more financially secure than it has been for many years, and has a range of products that make it well placed to weather any future storms. Let us hope that the brand has many more successful years ahead of it, because the world would be a smaller place without it.

The rest of this book tells the story of Aston Martin, the cars and the men who made it all possible. It is a relatively complex story, littered with successes and failures, financial stability and ruin, and many forceful personalities. So it is useful to have a potted history of the company, which will put the rest of the book in context and give the reader an overview of the major events in the company’s commercial history.

COMPANY TIMELINE

1913–1926: Bamford and Martin, formed and run by Lionel Martin and Robert Bamford to 1920; Bamford was then replaced by Martin’s wife Kate Martin as director.

A number of prototype cars built and competed in various events, but production cars only trickled on to the market from 1923 as Sports and Supersports models. Production cars were mainly powered by a side-valve 1500cc motor.

1926: On 12 October Aston Martin Motors was formed. Directors of the new company were Lord Charnwood and his son (John Benson), Bill Renwick and Bert Bertelli. The new Bertelli-designed, overhead-camshaft 1500cc engine was produced.

1929: The company was reformed as Aston Martin Ltd: Bertelli stayed, fresh finance came from S.C. Whitehouse, a garage proprietor from Harrow, as well as Nigel Holder and Reginald Straker of Kensington-Moir, and Straker, the then current Aston Martin distributors; then additional finance came from P.C. ‘Percy’ Kidnet, an old friend of Bertelli and previously joint managing director of Vauxhall before the General Motors takeover of 1925.

1931: Aston Martin Ltd acquired new finance from H.J. Aldington of Frazer Nash, then Lance Prideaux-Brune invested capital to buy out Aldington and restore control to Bertelli. Prideaux-Brune gained distribution rights at his Winter Garden Garage in Holborn, London.

1932: Late on in the year shipping magnate Sir Arthur Sutherland bought out all the company and put in his son, R. Gordon Sutherland, as joint managing director with Bertelli. In 1936 the 1500cc ohc engine was developed into a 2-litre ohc unit.

The first Aston Martins, built by Bamford and Martin, had a simple circular badge with the initials ‘AM’ superimposed on each other.

Typical of the early Bamford and Martin-era cars, this is the famous ‘Green Pea’ racing car, pictured in 1923 just before the Grand Prix de Boulogne.

During the Bertelli era, Aston Martins had this winged badge.

This 1934 1500cc example is typical of cars built by Aston Martin in the 1930s.

The ‘modern’ Aston Martin badge, seen here on ex-works car ‘LM1’, was designed by S.C.H. ‘Sammy’ Davis, the famous racing driver, journalist and team manager who owned LM1 as his daily driver in the 1930s.

1937: Bertelli left, and Claude Hill was appointed chief engineer. Hill started to look at new designs for Aston Martin cars, moving away from the traditional ladder chassis to more sophisticated designs.

1938–1945: Most car production halted for the duration of World War II. The factory turned over to manufacturing parts for the war effort, concentrating mainly on aircraft parts. The Atom prototype continues in development. Hill’s new 4-cylinder engine was designed, and the prototype was put into Atom.

1948: The Aston Martin and Lagonda companies were bought by David Brown, and Aston Martin Lagonda Ltd was created. Lagonda and Aston Martin relocated to another site on the Hanworth aero park. The first Aston Martin model under David Brown was the 1948–1950 2-litre Sports model. There was limited Lagonda car production. The Lagonda straight-six, dohc engine was adopted. Claude Hill left the company.

1950: DB2 was announced, powered by Lagonda’s straight-six 2580cc dohc engine.

Post war the cars were fitted with the Sammy Davis-designed badge, seen here on the Aston Martin 2-litre Sports, the first model to go into production after World War II.

1952: The DB3 sports racer was developed by Robert Eberan von Eberhorst, to compete at Le Mans.

1953: The DB3S was developed by Willie Watson from the DB3. It was lighter and smaller.

1958: The definitive ‘DB’ model was introduced, the DB4, powered by the Tadek Marek-designed, all-new alloy 3670cc dohc straight six.

1959: The all-new, space-framed DBR1 won Le Mans and the World Sportscar championship. Aston Martin withdrew from racing.

1961: The Lagonda Rapide was introduced – four doors based on the DB chassis, powered by a 3995cc dohc straight six. Production ended in 1966 with just fifty-five cars produced.

The DB4 came to epitomize the David Brown-era cars: smart Italian styling combined with great mechanicals and a strong engine to make a fine GT car.

David Brown amended the badge to include his name during the 1950s. This original patinated example is from Chris Bland’s DB5.

1963: The DB5 was introduced with a larger 3995cc dohc straight six; it stars in the 1965 James Bond film Goldfinger.

1965: The DB6 was introduced, still obviously based on the DB4, but longer and with a restyled tail, and more interior room for rear passengers.

1967: The William Towns-designed DBS was introduced; it was still powered by the 3995cc straight six.

1970: The DBS finally received the all-new Tadek Marek-designed quad cam all-alloy 5340cc V8 engine; it was named the DBS V8.

1972: Aston Martin Lagonda was sold by David Brown to Company Developments, chaired by William Willson. The DB initials on cars were dropped.

After the DB6 came the DBS. Launched in 1967, the basic shape would be in production until the late 1980s.

1974: The Aston Martin Lagonda Series 1 was introduced, a four-door derivative of the Towns-designed DBS.

1974: The receiver was brought in in December 1974; the production of cars stopped, but the service department continued running.

1975: In August, Aston Martin Lagonda (1975) Ltd was set up, with directors Peter Sprague (North American CEO of National Semiconductors), George Minden (Canadian Toronto-based hotelier and car dealer), Alan Curtis (British property developer) and George Flather (retired Sheffield Steel magnate). Production of the Aston Martin V8 resumed.

1978: The Lagonda Series II was introduced – the incredibly futuristic wedge-shaped four-door saloon designed by William Towns, which is now indelibly associated with the Lagonda name.

1980: Victor Gauntlett bought a 12.5 per cent stake in the company. Tim Hearley of CH Industrials (CHI) also took out a 12.5 per cent stake in 1980.

1981: Aston Martin Lagonda was sold to Victor Gauntlett and Tim Hearley, with Gauntlett taking over as executive chairman. Tickford set up as a subsidiary, providing engineering services to the motor industry.

1983: Gauntlett sold his share to Greek shipping magnate Peter Livanos; Livanos’ share was invested through a joint venture between Livanos and fellow Greeks Nick and John Papanicolaou called ‘ALL Inc’. While Gauntlett remain executive chairman, 55 per cent of Aston Martin Lagonda was owned by ALL Inc, with Tickford owned 50/50 by All Inc and CHI. CHI’s shares in Aston Martin Lagonda were exchanged for ALL Inc’s 50 per cent share of Tickford, and Tickford was separated from Aston Martin Lagonda, although it retained the responsibility for the development of existing models.

1984: Livanos’ father George bought out ALL Inc’s share, and Gauntlett bought a 25 per cent share in Aston Martin Lagonda.

1986: The limited edition V8 Zagato model was introduced.

1987: Ford took a 75 per cent shareholding in Aston Martin in September, then took over the company in 1991.

1989: The new Virage was introduced as a replacement for the V8.

1991: The remaining shares in Aston Martin Lagonda were bought by the Ford Motor Company, giving it 100 per cent of the company. Aston Martin Lagonda was placed in Ford’s Premium Automotive Group (PAG). Development of the ‘base’ model DB7 started to give the marque a lower priced model to stimulate demand and give the company the volume of sales it needed to survive.

1994: The new DB7 was introduced, the new ‘base’ model of the Aston Martin range. It was built in the ex-Jaguar/TWR factory at Bloxham. It was priced below the hand-built ‘V’ cars.

1999: The new V12 engine was introduced, initially fitted in the DB7 Vantage. To begin with the engine was assembled by Cosworth.

2000: Ford appointed Dr Ulrich Bez as CEO of Aston Martin Lagonda.

2001: The Virage range was dropped in favour of the all-new Vanquish with its all-new chassis made from extruded alloy with glue and riveted construction, and new V12 engine. Vanquish slotted into the range above the DB7; it was produced at Newport Pagnell.

The car that arguably saved Aston Martin in the 1990s was the DB7. This is Richard Lovey’s Volante example.

The current Aston Martin badge is still the traditional design, and is made in the old-fashioned way, with glass enamel applied over a heavily chromed casting. This is from the author’s 2007 DB9.

2004: The DB7 was dropped, and the all-new DB9 with VH platform chassis and V12 engine was introduced. DB9 was produced at the all-new factory at Gaydon. An engine manufacturing facility was set up at Ford’s Cologne plant, allowing all engines to be built ‘in house’. The new V8 engine was unveiled.

2005: The second VH platform car was introduced, the V8 Vantage. It was designed as a sports car to compete with the Porsche 911.

2007: A consortium headed up by Prodrive chairman David Richards bought Aston Martin Lagonda from Ford for £475,000,000.

2013: Daimler AG bought a 5 per cent share in Aston Martin Lagonda with the intention of increasing it up to 20 per cent. Daimler would supply engines and electronics to AM.

2014: Andy Palmer was appointed CEO, replacing Dr Bez, and instigated a major development programme.

2018: Aston Matin Lagonda Global Holdings IPO was held on the London Stock Exchange Listing, making Aston Martin a publicly listed company.

2020: Canadian investor Lawrence Stroll led a consortium – which included Ernesto Bertarelli and Toto Wolff – that bought a 25 per cent share in the company. Tobias Moers from Mercedes AMG took over from Andy Palmer as CEO. Aston Martin re-entered Formula 1 motor racing, renaming Stroll’s Racing Point team as Aston Martin. The DBX SUV joined the company’s line-up.

The first of the Gaydon era cars, the DB9. With its ‘VH’ aluminium chassis and Aston Martin V12 engine, it is every bit an Aston Martin Grand Tourer.

The second model to be produced at Gaydon was the two-seat sports car, the Vantage. This is Jeff Sear’s V12 S model.

PRODUCTION NUMBERS

Year

Cars Produced

1914

1

1915

0

1916

0

1917

0

1918

0

1919

0

1920

2

1921

4

1922

3

1923

8

1924

25

1925

26

1926

0

1927

3

1928

13

1929

13

1930

69

1931

35

1932

30

1933

106

1934

104

1935

69

1936

15

1937

140

1938

14

1939

6

1940

1

1947

0

1948

7

1949

57

1950

191

1951

221

1952

351

1953

242

1954

324

1955

294

1956

199

1957

208

1958

308

1959

221

1960

358

1961

369

1962

245

1963

241

1964

590

1965

487

1966

591

1967

370

1968

488

1969

550

1970

467

1971

317

1972

245

1973

296

1974

256

1975

21

1976

175

1977

257

1978

276

1979

271

1980

193

1981

158

1982

135

1983

196

1984

204

1985

163

1986

193

1987

214

1988

193

1989

208

1990

201

1991

168

1992

46

1993

88

1994

169

1995

719

1996

653

1997

662

1998

625

1999

622

2000

1,029

2001

1,461

2002

1,465

2003

1,511

2004

2,069

2005

4,459

2006

7,052

2007

7,393

2008

6,487

2009

2,649

2010

4,500

2011

6,200

2012

3,500

2013

4,200

2014

3,661

2015

3,615

2016

3,687

2017

5,117

2018

6,441

2019

5,862

2020

4,150

CARS PRODUCED BY ASTON MARTIN ON A YEARLY BASIS

This section gives an overview of the number of cars produced by Aston Martin on a year by year basis. The actual number of Aston Martins built, especially in the times before World War II, is still the subject of research and exploration, and numbers from different sources do vary. However, the object of this section is to give an idea of the relative volumes of cars produced over the company’s existence, so the exact numbers are not as important as the overall pattern exhibited by the data. The data are broken up into the significant eras of the company: the Bamford and Martin years, the Bertelli and Sutherland years, the David Brown years, the Company Developments through to Gauntlett years the Ford years, the Ulrich Bez years (2000–2014) and finally the Andy Palmer era (2015–2020). While the graphs speak for themselves, there is some brief text to put the numbers in context.

The Bamford and Martin Years (1913–1926)

In its early days Bamford and Martin produced only just over sixty cars in total, with a lot of the initial models being prototypes and works racing cars. While the market for cars was obviously smaller than today, the numbers produced were still low, and in some ways it is surprising that the company survived as long as it did – it was reliant on regular injections of cash just to keep going. The company only really got going in 1924 and 1925, with twenty-five and twenty-six cars produced – just before it finally ran out of cash.

The Bertelli and Sutherland Years (1927–1946)

Rescued from obscurity by Bertelli and his all-new design of light car based on the ‘Buzzbox’, Aston Martin restarted production in 1927. Based in their new factory in Feltham, the company now had the space and facilities to start to produce cars in serious numbers. However, in their first year of operations (1927) only three cars were produced, and the increase in production was painfully slow, with only thirteen cars produced in 1928 and 1929. But 1930 was a bumper year, with sixty-nine cars produced, and while the next couple of years saw production fall back, 1933 was the company’s first year of producing over 100 cars, a feat repeated in 1934 and 1937. Car production then inevitably tailed off as the factory turned its hand to more important war work.

The DBS is the current flagship of the range. This is a 2019 example.

The DB5’s Italian styling, GT credentials and of course the ‘Bond’ effect epitomized Aston Martin in the David Brown era. Here is Chris Bland’s beautiful example basking in the sunshine.

The David Brown Years (1947–1972)

After World War II, with David Brown at the helm, Aston Martin started off the era slowly, with the 2-litre Sports model selling modestly. However, the introduction of the DB2 in 1950 saw demand and sales soar to unprecedented levels, with yearly production ranging between 199 and 324 up to the introduction of the DB4 in 1958. Production levels peaked at 590 in 1964 after the DB5 was introduced in 1963, and again in 1966 at 591 after the DB6’s introduction in 1965. The DBS led to another peak in 1969 – but then production dropped off, with just 245 cars produced in 1972.

The Company Developments/Curtis/Gauntlett Years (1973–1987)

With the sale of Aston Martin to Company Developments in 1973, production continued at 1972 levels for the first two years; but the company went into receivership in 1975, and production plummeted to a mere twenty-one cars as the factory was closed down. Sales recovered when the company was sold to the Alan Curtis consortium in 1975, with 257 cars sold in 1977. This set the scene for the following decade, during which sales were fairly steady at between 190 and 210 (with a bad year in 1982 with only 135 cars produced); this seems to have been just enough to keep the company afloat.

The Ford Years (1987–1999)

The purchase of Aston Martin by Ford led to the DB7 – arguably the car that saved Aston Martin by demonstrating there was a market for a luxuriously appointed, well engineered GT car in the Aston Martin tradition. The introduction of the DB7 in 1995 which was produced in the old TWR/Jaguar factory at Bloxham, gave a massive boost to the sales figures of the company: sales of the expensive hand-built Newport Pagnell car slumped to a mere forty-six in 1992, as compared to 719 cars sold in 1995 – mostly DB7s, and the highest ever yearly production figure to date for Aston Martin. Sales of the cars remained over 600 through to 1999, when Dr Ulrich Bez took over.

The Dr Ulrich Bez Years (2000–2014)

The turn of the century saw great changes at Aston Martin, with Dr Ulrich Bez at the helm and an all-new factory being built to produce a pair of brand new mainstream cars, the DB9 and the Vantage. Production of the DB7 continued at Bloxham until 2003, while the new factory at Gaydon was being built; then in 2004 car production at Gaydon took off with 1,608 DB9s being built, and was further boosted in 2005 as Vantage production started. The hand-built, top-of-the-range Vanquish also made a contribution, with over 500 units being built per year in 2002 and 2003; production dropped to just under 400 cars for 2004 and 2005. In 2006 and 2007 production built up to over 7,000 cars per year, but this was too much for the market, and led to oversupply. From 2008 production was dropped to more sustainable levels, but it was built back up from 2,649 units in 2009 to a steady level of around 3,500–4,000 units between 2010 and 2014.

The Andy Palmer Years (2016–2020)

From 2015 to date, car production has fluctuated, thanks in part to the global shutdown caused by the Covid 19 pandemic. In the first years of Palmer’s leadership production mirrored that of 2010–2014 at just over 3,500 cars, picking up to 5,117 cars in 2017, and peaking at 6,441 in 2018; it then dropped back a little in 2019 at 5,862, and then dropped to 4,150 in 2020 thanks mainly to the pandemic. The introduction of the DBX added another model line to the range for 2020, and hopefully the following years will see a sustainable increase in production numbers.

Production Numbers: Conclusion

As can be seen from the figures, Aston Martin has never been a mass producer of cars. While this has helped the marque’s exclusivity, it has not assisted in the company’s liquidity, and most of the financial crises the company has gone through have been caused by failing to build and sell enough cars. It was only when Ford appeared on the scene that Aston Martin received the financial stability and commitment it needed to become the company that we see today – a resurgent Aston Martin with a relatively wide and up-to-date range of models that it is to be hoped will enable the company to trade successfully into the 2020s and onwards.

BOND AND ASTON MARTIN

When writing about Aston Martin in general, and the David Brown cars in particular, there is no escaping one aspect of the car’s life. Never mind Aston Martin winning Le Mans in 1959, it was another event that gave Aston Martin what was probably the company’s best advertising ever, which extended from 1964 through to the present day: the appearance of the gadget-laden DB5 in the 1964 Bond film Goldfinger alongside Sean Connery as Bond. While it was probably the first ‘product placement’ in the film industry that made a lasting impression on viewers, it was not your average ‘product placement’, as the car with its extras devised by ‘Q’ was an integral part of the story told by the movie, and made Aston Martin the car of choice for all secret (or not so secret) agents. The author remembers seeing and being inspired by the car in Goldfinger, and of course owned (and still owns) the original Corgi model.

The reappearance of the Bond DB5 (or a replica, but it did retain the original Goldfinger car’s registration number, BMT 216A) in the 2012 Bond film Skyfall was a master stroke. When the author watched the film shortly after it was released, the appearance of the car as Bond opened the warehouse doors elicited an auditable gasp from the audience in the cinema – and there were many groans when the ‘baddies’ shot the car to pieces later on! From the marque’s first appearance in Goldfinger, Aston Martins have featured in many of the later Bond films, and are now firmly entrenched in the myth that is Bond.

The first Bond movie was 1962’s Dr No, when Bond had a brief but exciting car chase driving a standard Sunbeam Alpine pursued by an enormous LaSalle hearse, albeit with a lot of studio footage using back projections with Bond see-sawing furiously on the Alpine’s wheel! The second film, 1963’s From Russia With Love, featured Bond in a 1935 Bentley 3.5 drop-head coupé fitted with a car phone, albeit only briefly – the action then moved to Turkey, where cars played a subsidiary role to the action. It was in the third Bond film, 1965’s Goldfinger – still starring Sean Connery – that the first real Bond car made its debut. Fleming’s novel, written in 1958 and published in 1959, had placed Bond in the driving seat of an Aston Martin Mark III – assumed now to be a DB2/4 Mark III – so the obvious choice for the film was the then current Aston Martin product, the DB5.

And so was born a cinematic legend, as the iconic Silver Birch DB5, used by Bond to track Auric Goldfinger’s Rolls-Royce across Europe, was introduced to the public. It wasn’t just the car’s looks that caught the public’s imagination: the DB5 was fitted with lots of gadgets, including a pair of Browning machine guns in the front wings, the famous ejector seat, telescopic overriders, extendable tyre-chewing rear spinners, a rear bullet-proof screen, rotating number plates, and oil and tack dispensers in the rear lights – a fine collection of nefarious equipment well suited to Bond’s role. Of course it all ends in tears at Goldfinger’s factory when Bond is dazzled by searchlights and crashes the car, coming round to find himself strapped to the laser table – and of course Goldfinger’s classic retort to Bond’s question ‘Do you expect me to talk?’ – ‘No Mr Bond, I expect you to die!’

The car was further immortalized by die-cast model car makers Corgi, whose 1:43 scale DB5, with most of the gadgets incorporated, was a massive hit with the fans. There must have been hundreds or thousands of tiny Goldfinger henchmen scattered and lost in suburban homes after too enthusiastic a use of the model’s tiny ejector seat!

From the front the Bond DB5 shows the telescopic over-riders and the two Browning machine guns concealed behind the indicator lights.

This view of the Bond DB5 shows the ejector seat’s offset panel in the roof, the extending spinners, the bullet-proof rear screen, telescopic over-riders and the ports in the rear lights to dispense oil, water and tacks.

After the brief appearance of the DB5 in the starting sequence of 1965’s Thunderball, where Bond chucks his jet pack into the boot before using more gadgetry – water cannons – to discourage the baddies before roaring off, the next appearance of an Aston Martin in a Bond film came with the 1969 film On Her Majesty’s Secret Service. In this production Australian actor George Lazenby was in the starring role, along with a largely gadget-free olive green DBS, registration number GKX 8G. The car’s appearance started with the lead girl Contessa Teresa ‘Tracy’ di Vicenzo (played by Diana Rigg) briefly stealing it, and ended with the unforgettable scene on the side of the motorway, bullet holes in the windscreen and Tracy dead beside Bond after their marriage.

The next appearance of an Aston Martin was in 1971’s Diamonds Are Forever, when there was a brief glimpse of a DBS in Q’s workshop. Aston Martin was then absent from the first Roger Moore-era Bond film, as Lotus, that other British sports-car company, provided cars for the next films. The Lotus Esprit that becomes a submarine appeared in the 1977 film, The Spy Who Loved Me, starring Roger Moore; Moore had of course starred in the early 1970s ITC television series The Persuaders as Lord Brett Sinclair, in which he drove a yellow DBS dressed up to look like a V8, alongside Tony Curtis playing playboy Danny Wilde and driving a Ferrari Dino. The Esprit featured in one other Roger Moore-era Bond film: 1981’s For Your Eyes Only, although arguably the co-starring Citroen 2CV was given a better role!

The franchise finally returned to Aston Martin after lobbying in 1987 by company executive chairman Victor Gauntlett, with The Living Daylights, when Timothy Dalton took over from Moore as Bond and drove a new gadget-laden Aston Martin V8, registration number B549 WUU. Equipped with missiles, side-mounted retractable skis, a jet engine in the rear and laser side cutters – a modern update on the original DB5’s extending spinners – along with bulletproof glass, the V8 reverted to the form that most Bond fans loved. The car endured an eventful chase with Communist border guards, which as usual resulted in the unfortunate car being blown up as Bond and the girl escaped by tobogganing over the border into the West in a cello case. There was also a cameo appearance from Gauntlett’s personal V8 Volante, which Dalton drove early on in the film.

The next film in the franchise, 1989’s Licence to Kill, had no Astons in it, and there was then a long hiatus in their appearance in Bond films; this only ended in 1995 with the release of Goldeneye, starring Pierce Brosnan. Although the producers had signed up BMW to supply the main cars for the franchise, DB5 BMT 214A made a welcome (if slightly unconvincing) appearance in Goldeneye, in a chase sequence where the DB5 outruns a modern Ferrari F355 GTS. In 1999 the DB5 made another brief appearance in The World is Not Enough, again starring Pierce Brosnan – but Aston Martin were firmly back in the running in the last Brosnan film, Die Another Day. In this 2002 production the brand new Aston Martin Vanquish was the real star – that is, when you could see it, as one of its gadgets was an invisibility cloak. The offensive side of the gadgets was not forgotten, with four missile launchers hidden behind the grille, heavy machine guns in the nose, and a pair of multi-barrelled Gatling gun-style miniguns mounted on swivels on the front wings. All in all a fitting return to the franchise for the new Gaydon era of Aston Martin – even if the Vanquish was build at Newport Pagnell!

In the year 2006 the Bond film returned after a four-year hiatus, with a new lead actor and a grittier, more down-to-earth approach to the story, albeit with the plots placed firmly in the twenty-first century. In Casino Royale Daniel Craig played a more flawed but ruthless character rooted in the current geopolitical scene, whilst the storyline stayed quite close to the original plot penned by Ian Fleming in 1953.

The main car that Craig drove in Casino Royale was a Gaydon-era DBS, although there is a cameo role for a silver DB5, which Craig wins in a card game in the Bahamas. Aston Martin had not launched the DBS when the film was released, but had supplied two prototypes for filming. Gadgets were limited to a defibrillator and a gun stowed in a sliding draw in the glovebox – the defibrillator maybe being a sensible item that Aston Martin should consider offering as an extra to its older customers? The car’s main role in the film was to be sacrificed in a spectacular sequence when Bond wrenches the steering wheel over at speed to avoid running over the female lead, double agent Vesper Lynd (played by Eva Green), who had been dumped in the middle of the road by the villains. The DBS perished in a spectacular sequence of seven complete rolls – a sequence that has been recorded in The Guinness Book of Records as a new world record.

The DBS does return briefly in the next film, the 2008 Quantum of Solace, participating in a destructive car chase around Lake Garda, with Bond being pursued by a posse of black Alfa Romeo 159s – but otherwise the car is absent. The next Daniel Craig film was 2012’s Skyfall, in which (as recounted above) the classic silver DB5 makes its appearance, much to the delight of the audience – although it, too, meets its doom.

The next film, Spectre, came out in 2015, and again, as in the 2006 Casino Royale, featured an Aston Martin that was produced exclusively for the film. The DB10, while obviously a development of the Casino Royale/Quantum of Solace DBS, was futuristic and unique. Powered by the V8 engine and designed by Marek Reichman, the DB10’s styling was amazing – but the gadgetry was limited to a flame-thrower in the tail, put to use in a duel in Rome with the ‘bad guy’ in a Jaguar C-X75 concept car – another that never made it into production.

The latest Bond film, No Time to Die, was supposed to be released in 2020, but Covid put paid to that, and at the time of writing (February 2021) the film had not been released. There were tasters though – the film features the classic silver DB5, in both the pre-credits scenes filmed in Italy and in the film itself. Eight new DB5s were made for the film, using laser scanning to perfect the carbon-fibre bodywork, with modern underpinnings for the stunt drivers to play with. Gadgets had been brought up to date, with multi-barrelled miniguns replacing the front Brownings to devastating effect, while the ejector seat was primed and ready. The classic V8 last seen in Timothy Dalton’s The Living Daylights also makes an appearance, along with a right up-to-date DBS Superleggera. All in all the film promises to be a real treat for any Aston Martin aficionado, and hopefully is well worth waiting for!

The Bond franchise has been of immense value to Aston Martin. Obviously from a marketing point of view the cars were popularized virtually every time a Bond film was made or screened, and this exposure has brought the marque into the public eye worldwide. It has also placed it precisely where it needs to be: as an exclusive product that is expensive but not so out of reach that ownership is unattainable. Furthermore it has generated a great deal of goodwill for the brand, which is instantly recognizable to most people thanks to the films – and people are usually genuinely pleased to see an Aston Martin on the road. All in all the placement of that first DB5 in Goldfinger was of inestimable value to Aston Martin and the Bond franchise, and long may the relationship endure.

CHAPTER 2

THE FORMATIVE YEARS: 1913–1925

Aston Martin’s early products were very different to those produced by the company after World War II up until the present day, with its product line of large capacity, high performance GT cars. When it was formed, the company was dedicated to extracting the maximum performance from the then current crop of ‘light’ cars, which featured lightweight bodies and engines of less than 1500cc, eschewing the large capacity behemoths – or ‘Chittys’ – that had dominated the performance arena at the turn of the century. Aston Martin’s founders, Robert Bamford and Lionel Martin, were determined to produce small, light, beautifully engineered cars that could take on and beat their rivals on the road and track, and this was the successful philosophy that would dominate the company for its first decades.

ESTABLISHMENT OF THE COMPANY

The story of Aston Martin started in 1913 with the establishment of a motor company by engineer Robert Bamford and old Etonian Lionel Martin. The company was called Bamford and Martin Ltd, and was initially based in Callow Street in Fulham, West London. The company was set up not only to sell and tune light cars, such as Singer, Calthorpe and GWK, but also to crystallize and refine Martin’s emerging ideas of a perfect lightweight sporting car, and to manufacture it.

Two of the oldest surviving Aston Martins, ‘A3’ and ‘Razor Blade’, reunited and pictured on the Brooklands banking in May 2021.

The company had arranged a sub-agency for Singer through Percy Lambert, Singer dealer and motor racer, and Martin had personally bought a Singer 10hp from Singer at the London Motor Show at Olympia in 1912, which he had been using in various competitions, including speed trials and hill climbs. The company quickly moved to larger premises in Henniker Place in South Kensington – and this relocation also brought along a new employee, Jack Addis.

The company specialized in buying and selling all light cars, as well as tuning customers’ cars and competing in various events with Martin’s tuned Singer 10. The origin of the Aston Martin name is obscure, but there are various theories that it was as a result of Martin competing at the Aston Clinton hill climb in his Singer 10-based Special, along with the need to get the company’s name at the top of the alphabetical listings in the press of the day.

Brooklands in 1921 with Aston Martins at the start of the JCC 200-mile race. The Coal Scuttle is no. 20, ‘Bunny’ is no. 40 and Count Zborowski in the ‘track car’ is no. 66.

In 1914 the company used the name ‘Aston Martin’ on the first car produced by Bamford and Martin; this car is now known as the ‘Hybrid’ and was based on an Isotta-Fraschini chassis and a Coventry Simplex motor. It was designed to test Martin’s ideas of the perfect light car, and was built while the company waited for a chassis of their own design to be produced. Very little is known about this first product of the infant company, and the car no longer exists.

With the outbreak of war, activity at Bamford and Martin slowed, and the machinery at Henniker Place was eventually sold to the Sopwith Aviation Company for war work. Bamford, who was a member of one of the London cyclist reserve battalions, was commissioned into the Army Service Corps. During the war period extensive testing work was carried out by Martin using the second car the company produced. This car was nicknamed the ‘Coal Scuttle’ and was based on a new chassis, and powered by an engine based on the Coventry Simplex design used in the Hybrid, but likely to have been built specifically for Bamford and Martin.

In 1918 the company reconvened in the pre-war premises in Henniker Place. During 1919 and 1920 the company’s activities concentrated on developing their product, and racing was the medium used to test and advance these developments. The various prototype cars produced were raced extensively, giving the company results that could be channelled back into ever-improving designs. However, development work was expensive, and with little or no money coming in from car sales the company was reliant on Martin’s personal wealth. Bamford left the company in 1920 for reasons unknown – perhaps because he considered that any chance of advancement in Bamford and Martin as a producer of cars for actual customers seemed a long way off.

Just after he left, in May 1920 the company moved and set up home in new premises at what was originally No. 51 Abingdon Road (now renumbered No. 53) in Kensington. While the company was not renamed to reflect Bamford’s leaving, Bamford himself was replaced on the board by Martin’s wife Kate. Kate was not, and never had been, a sleeping partner in the company – she had already thrown herself into the racing programme with some enthusiasm, and was often pictured alongside Martin at various sporting events. She was no mean competitor herself, acting as a passenger for Martin in many of the events he competed in, and she also competed in her own right. As an example, she won the Junior Car Club’s Ladies Race at Brooklands in 1920 driving the venerable ‘Coal Scuttle’ (AM4656) at an average speed of 63mph (101km/h).

In 1922 Count Louis Zborowski invested in the company, financing the construction of two cars to compete in that year’s French Grand Prix at Strasburg; he also had a seat on the board until his untimely death while racing his Mercedes at the Monza track in Italy in 1924. As a result of his investment of some £10,000, the two cars were fitted with the new dohc ‘Gremillion’ engine; however, both cars failed to finish.

A typical Brooklands scene with Kate Martin driving the Coal Scuttle at the JCC Spring Meeting in May 1921.

During this time Martin was cultivating many young and enthusiastic motoring enthusiasts, recognizing that the job of racing Bamford and Martin cars competitively needed more talent than he himself, his wife Kate or works foreman Jack Addis had. Racer and engineer H. Kensington-Moir, a name that would be synonymous with Aston Martin cars during the early 1920s, joined the firm in mid-1921, coming from a post as engineer at Zenith Carburettors after completing his apprenticeship at ABC cars. While much of the success of the company in competition was the result of Kensington-Moir’s fine driving, he was destined to move to Bentley, having met with the famous W.O. Bentley himself on the ferry coming back from the abortive trip to compete in the Isle of Man TT race.

Although by 1922 the company had seen a great deal of success in competition, it was still not actually producing any cars. In early 1922 Martin, accompanied by Zborowski, made a trip to Bristol to visit ‘an aeroplane firm’ to see if they could raise sufficient funds to start producing cars; however, the trip was fruitless, and the company continued to just limp along.

Actual production of road cars for customers eventually started in early 1923, when the first customer car was delivered to a W.G. Barlow. This car was chassis number 1916, and featured front brakes based on the Perrot system. Perrot brakes operating on the front wheels became a fixture on Bamford and Martin production cars from the early 1920s, and were often retrofitted to older cars. The Perrot brake system was devised by Frenchman Henri Perrot while he was working for vehicle manufacturer Argyll in Alexandrea in West Dumbartonshire, Scotland. The system was registered on 18 March 1910 at the British patent office as patent number 6807. It allowed the fitment of mechanically operated brakes to the steered wheels, using a system of universal joints and shafts to connect the movable brake-drum backplate to the chassis-mounted operating cables or rods. The Perrot system eventually led to the formation of the Bendix Corporation by Vincent Bendix in South Bend, Indiana, in 1924. Martin gained a licence to manufacture Perrot-type brakes from the original manufacturers in December 1923.

In fact the ‘production’ of cars at 51 Abingdon Road was in reality more of an assembly operation, with the twenty or so workers who made up the company payroll assembling bought-in components: chassis frames from Rubery Owen, engine blocks from Rowland Hill and Sons of Coventry, crankshafts from Ambrose Shardlow, and gearboxes from E.G. Wrigley. Other minor components would be bought in as required. Most of the engine components and other parts that needed machining were worked on by Weybridge Engineering at Brooklands and Giusti Patents of Euston Road, so very little actual manufacturing was carried out on site. This is confirmed by the limited amount of machine tools discovered when the premises were inspected by Bert Bertelli after the sale of the company in 1926.

There was no bodyshop at the Abingdon Road premises, so bodies for the racing and production cars were produced by external but relatively nearby coach builders; these included local firms Jarvis of Wimbledon, Compton and Hermon of Thames Ditton, Albany of Hanwell and Moss of the Fulham Road. The cars came in all sorts of body style, including open-topped two- or four-seaters, four-seat saloons, and the then popular ‘clover-leaf’ three-seaters. Production of the Martin-era Aston Martin cars was small, with just eight cars produced in 1923, twenty-five in 1924 and twenty-seven in 1925; production ceased in November of that year.

John Benson was taken on in May 1924 to perform the role of chief engineer. Benson was the son and heir of the first Lord Charnwood, and like Martin had been at Eton before going up to Oxford to study engineering. Although he left without a degree he was by all accounts a talented engineer, and his appointment was no doubt helped by the prospect of his mother, Lady Charnwood, putting £5,000 into the business.

This 1924 car fitted with a ‘clover-leaf’ three-seater body is typical of the early Bamford and Martin cars.

The Bamford and Martin company of 53 Abingdon Road ran out of money and called in the official receiver on 11 November 1925; Lionel Martin left the company two days later. The family of John Benson, then chief engineer and designer of the Aston Martin engine, purchased the goodwill and assets of Aston Martin, and then approached the Birmingham firm of Renwick and Bertelli with the intention of forming an alliance to rekindle the ashes of Aston Martin.

BAMFORD AND MARTIN ENGINES

While the Hybrid, Bamford and Martin’s first complete car, was powered by a proprietary 4-cylinder side-valve Coventry Simplex engine, all the cars produced after the Hybrid were powered by engines designed and built either for or by Bamford and Martin. All these early engines were 4-cylinder in-line units of varying capacities, but all were just under the 1499cc capacity limit required for the RAC Light Car racing class. Engine configurations reflected the rapid development of engine technology of the time, and Bamford and Martin’s thirst for innovation. They ranged from simple side-valve units with combined cylinder head and block, to 4-valve-per-cylinder units, with the valves operated by double overhead camshafts, as well as single overhead camshaft 8-valve and 16-valve units, giving a range that covered most possible combinations of valve operating gear that could be used on a straight-four engine. Oddly the company in these early days did not produce a simple pushrod-operated overhead valve unit – although this would be in keeping with its sporting profile.

The oldest surviving Aston Martin, A3, is preserved by the AMHT.

The Side-Valve 4-Cylinder Engine

Based closely on the Coventry Simplex unit used in the Hybrid, Bamford and Martin’s first engine was a 4-cylinder, side-valve, 1486cc unit, with a bore and stoke of 66.5 × 107mm (giving an RAC rating of 11.6hp and still qualifying for the RAC Light Car class limit of 1500cc), a three-bearing crankshaft and a combined cast-iron cylinder block and head – usually described as a ‘monobloc’. The combined block and head was used to avoid head-gasket problems, which were common at the time with separate head and block designs. The combined head and cylinder block was bolted on to a light alloy crankcase, which had cast-in ‘bearer arms’ on each side that were used to mount the engine directly on the chassis. The crankshaft was carried on three main bearings.

The engine was designed with two aims in mind, reliability with power, and to this end a great deal of thought was given to keeping the engine oil clean. This meant that a considerable amount of time and effort was given to the design of the lubrication system, both in terms of the use of the system and the filtration of the oil. The filler was placed in a prominent position on the right-hand side of the crankcase, and when the cap was swung open sideways it also operated a small level tap – when the oil reached the correct level, it would dribble from the tap indicating that the sump was filled to the correct level. A second, larger tap was used to drain the oil from the sump, and a dipstick was also fitted. Oil was pumped from the sump under pressure to all the engine bearings, and a pressure release valve diverted excess oil to the timing gear in the side of the crankcase.

The Aston Martin 1486cc side-valve engine was the first production engine made by Aston. Note the one-piece cylinder block and head, and how the lower crankcase bearer arms are bolted directly into the chassis members.

The oil filtration system comprised three distinct filters. First, a gauze filter was placed in the filler tube to stop debris getting into the engine in the first place; then there was a gauze tray fitted above the sump to catch any large particles from falling from the engine into the sump; and finally there was a patented nest of three gauze filters on the pressure side of the oil pump, through which the oil was forced before it got to the oilways in the crankcase that served the engine bearings.

The Robb Single-Overhead Camshaft Engine

While the 4-cylinder side valve was producing some relatively high power outputs, the company recognized the advantages of the increased efficiency of overhead-valve designs. So Aston Martin’s first overhead-valve engine design was commissioned, with engineer S. Robb, formerly of Coventry Simplex, employed to produce a new engine with the intention of fitting it to at least one of the ‘works’ race cars. The result was a new unit with a single shaft-driven overhead camshaft operating 16 valves (4 per cylinder) using a complex system of rockers and pushrods.

The camshaft was carried in five bearings and had the rocker shaft mounted above it, which was also carried in five bearings. The rocker shaft carried eight forked rockers, each one operated from the camshaft by a roller, and each of which was connected to two valves using short rods. The valves were all positioned vertically in the casting, and had relatively long bronze guides to allow for the high side thrust generated by the rocker mechanism.

The iron cylinder block and head were cast in one piece, and there were large plates fitted on the sides of the engine to give access to the rocker gear. The water jacket covered the upper part of the cylinders and the head, while the lower half of each cylinder was exposed to the air; there was also an air gap between each cylinder to aid cooling. The cast-alloy crankcase was, like the side-valve unit, a large aluminium casting with cast-in bearer arms or webs to fix it to the chassis frame. The positions of the webs were identical to those seen on the side-valve engine, so making the units interchangeable. The crankshaft was carried on three shell main bearings.

At the front of the engine the camshaft driving shaft was gear-driven from the nose of the crankshaft, and the shaft also drove a horizontal geartrain located in a rectangular alloy casing. This geartrain was used to drive a vertically positioned magneto, the water pump and the oil pump, all mounted on the left-hand side of the engine. With a bore and stroke of 65 × 112mm, the engine displaced 1486cc.

The engine was not particularly successful, mainly because although it was reliable, it showed little if any power increase over the side-valve unit, contemporary reports stating it gave a mere 40bhp. The engine design was therefore recognized as being a dead end from a developmental point of view, so the unit was eventually scrapped.

The Double-Overhead Camshaft ‘Gremillion’ Engine

When Bamford and Martin realized that the first Robb-designed 16-valve engine was not particularly powerful, they still recognized the advantages of overhead valves, and so with financial help from Count Zborowski they decided to commission a new racing unit to replace the side-valve engine. The question was how to avoid another dud like the Robb-designed single overhead camshaft unit. Luckily one of the ‘works’ drivers, Clive Gallop, had served his apprenticeship at Peugeot, and knew talented engine engineer Marcel Gremillion, who had designed the successful straight-eight 3-litre Ballot engine. The company approached him, and apparently for the sum of £50, Gremillion arranged for drawings of a scaled-down version of the Ballot engine’s cylinder block and head to be made available to Bamford and Martin.

The company used the new design to modify the original Robb-designed overhead cam engine, replacing the combined head and barrels of the original engine with the new design. The intention was to use the new engine to compete in the 1922 French Grand Prix – the first international event for a factory-entered Aston-Martin car.

The new top end was designed around the bottom end of the rejected single camshaft engine designed by Robb, keeping that engine’s bore centres and retaining its bore and stoke of 65 × 112mm, giving a capacity of 1487cc. The 4-valve engine had a pair of separate alloy camshaft carriers that were bolted to an integral head and barrel assembly. Inlet valves of 31mm diameter and exhaust valves of 29mm were fitted, also twin valve springs, and the valve angle was 60 degrees. The valves were operated directly from the cam lobes using bucket tappets, and the two camshafts were carried on three large-diameter roller bearings. As on the previous engine the camshafts were driven from the crank by a vertical shaft. Each camshaft had a gear attached to its end, and these meshed with a central gear, which was driven from the vertical shaft using a bevel gear.

Retaining the existing engine’s bore centres meant that the valves were placed asymmetrically, and the valve pockets in the head were relatively large, which constrained the engine’s breathing; but despite this design compromise, the new unit was reported to produce 55bhp and revved up to 4,200rpm, a significant improvement over the 40bhp given by the side-valve unit and the Robb sohc engine. This gave the Strasbourg cars a top speed of around 95mph (153km/h).

The exhaust side of the 1924 1.5-litre dohc engine.

The carburettor side of the 1924 Bamford and Martin 1.5-litre dohc engine.

While the new top end and barrels endowed the engine with a significant performance boost, the engine’s Achilles heel turned out to be the magneto drive. The drive was by a laminated spring coupling, which often failed, the problem causing both the cars in the French race not to finish. The problem reoccurred at a later 200-mile race, but the substitution of