Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: CompanionHouse Books

- Kategorie: Lebensstil

- Sprache: Englisch

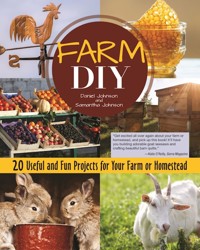

Roll Up Your Sleeves and Build a Better Farm! Loaded with complete plans and easy-to-follow construction tips, this book offers a creative mix of both practical and decorative projects for working and hobby farms. Veteran family farmers and 4-H alumni Samantha and Daniel Johnson present 20 essential projects for aspiring homesteaders. From log jacks, rabbit hutches, and milking stools to a goat see-saw and a barn quilt, clear step-by-step color photographs guide the reader through each hands-on project. An introduction to the DIY mindset explains the positive benefits and satisfaction of building things yourself, and provides an overview of the basic tools and skills needed to complete each task. Farm DIY also includes a background discussion of farming today, and instructions for building an effective farmer's market display stand for selling your products. Inside Farm DIY · 20 step-by-step, do-it-yourself projects for creating the farm of your dreams. · Build practical items like gates, bee houses, log jacks, rabbit hutches, and milking stools. · Make fun items like a barn quilt and a goat see-saw. · Create an attractive display stand for selling your products at farmer's markets. · Easy-to-complete projects all feature inexpensive materials and basic techniques.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 144

Veröffentlichungsjahr: 2019

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Farm DIY

CompanionHouse Books™ is an imprint of Fox Chapel Publishers International Ltd.

Project Team

Vice President–Content: Christopher Reggio

Acquisition Editor: Bud Sperry

Editor: Jeremy Hauck

Copy Editor: Laura Taylor

Design: David Fisk

Index: Jay Kreider

Copyright © 2019 by Samantha Johnson and Daniel Johnson and Fox Chapel Publishing International Ltd.

All rights reserved. No part of this book may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Fox Chapel Publishers, except for the inclusion of brief quotations in an acknowledged review.

ISBN 978-1-62008-332-1

The Cataloging-in-Publication Data is on file with the Library of Congress.

This book has been published with the intent to provide accurate and authoritative information in regard to the subject matter within. While every precaution has been taken in the preparation of this book, the author and publisher expressly disclaim any responsibility for any errors, omissions, or adverse effects arising from the use or application of the information contained herein. The techniques and suggestions are used at the reader’s discretion and are not to be considered a substitute for veterinary care. If you suspect a medical problem, consult your veterinarian.

Fox Chapel Publishing

Fox Chapel Publishers International Ltd.

903 Square Street

7 Danefield Road, Selsey (Chichester)

Mount Joy, PA 17552

West Sussex PO20 9DA, U.K.

www.facebook.com/companionhousebooks

We are always looking for talented authors. To submit an idea, please send a brief inquiry to [email protected].

Printed and bound in Singapore

22 21 20 19 2 4 6 8 10 9 7 5 3 1

CONTENTS

Introduction

Tools: What You’ll Need

Projects

Build a Bee House

Make a Candy Board for Honey Bees

Extract and Bottle Honey

Build a Goat Seesaw

Build a Log Jack

Paint a Barn

Plant a Fruit Tree

Protect a Fruit Tree

Build a Rabbit Nest Box

Build Sawhorses

Build a Stone Boat

Build a Stone Crib

Build a Beehive

Build a Goat Stand

Build a Farmers’ Market Display Stand

Build a Rabbit Tractor

Make Cottage Cheese

Build a Barn Quilt

Graft a Fruit Tree

Build a Barn/Stable Medicine Cabinet

Index

About the Authors

INTRODUCTION

Hello, DIYers! We’re glad you’re here to join us on what we hope is a fun and productive journey through twenty do-it-yourself farm projects.

Farmers through the centuries have proven themselves to be nothing if not self-reliant. The true farmer—whether farming as a full-time occupation, or simply as a hobby to add some self-sufficiency to life—is a jack-of-all-trades. Farmers rely on themselves to hammer, screw, saw, dig, weld, and paint their way through farm life, happily and effectively repairing, improvising, and building the items and infrastructure they need to get the job done.

And that’s where this book comes in. We’ll introduce you to twenty farm projects, outline the concepts involved, and demonstrate at least one potential method for getting the job done. In some cases, you might want to follow our ideas exactly, using the measurements, tools, and steps as we outline them. Other times, you might want to improvise on the basic concept—as a DIYer, you’re certainly entitled to do so! What we’d really like is for the book to be an inspiration, or motivation, something to give you a few ideas that might make you say, “Hey, I could do something like that!”

Something for Everyone

We tried to include variety in the projects, both in purpose and scope. Some of the projects—the barn quilt, for instance—are large and somewhat complex. Others—like the old-fashioned log jack or the goat seesaw—can probably be completed in an afternoon. We aimed for diversity in the skill levels and time required, so there is something for everyone here.

Why DIY?

But hang on a minute—why even DIY at all? As we said, self-reliance is almost a part of the farmer’s job description, but if anyone reading this is still asking, we’ll offer a few more reasons:

1. IT SAVES MONEY

There’s no question that building and constructing items from your own materials is usually a money-saver. Sure, you might be able to purchase a set of sawhorses, or a rabbit nest box, or even a beehive from a catalog or at the local home improvement store, but it’s almost certainly cheaper to build these items yourself, particularly if you already have the lumber or materials on hand. Putting materials that you might already own (maybe scraps from other projects around the farm!) to use not only gets them out of the barn or shed, it turns them into a useful product in exchange for a little effort. (Farmers tend to hang on to odds and ends and scraps of lumber. We’re not saying we have any experience with this, of course …)

2. UNIQUENESS

While you might be able to find a goat milking stand for sale, it’s a large item that will likely be expensive, especially if you have to ship it. But you’d be hard-pressed to find a fence post stone crib for sale, or a stone boat, in the local classifieds. Building your own projects—like rabbit tractors, livestock medicine cabinets, or display stands for your farmers’ market produce—allows you to construct items for your farm that you probably won’t easily find anywhere else. Plus, it allows you to customize the projects and put your own spin on them, tweaking the dimensions or functions to suit your farm’s specific needs.

3. FUN AND SATISFACTION

Finally, we think there’s a lot of satisfaction to be had in building for yourself. It’s that self-reliance again—there’s just something to be said for being able to meet a need on your own. Also, these projects can be fun! We truly enjoyed designing and building these items, and we hope you do, too. Take your time, and stay safe.

Now then—off to work!

How to Read the Cut List

About Metric Conversions

Lengths of lumber are sold, in North America, by their nominal dimensions, which are usually different from their actual dimensions. For example, a 2×4 actually measures 1½ × 3½ inches. For lumber like this, the metric conversions reflect the nominal rather than the actual dimensions.

TOOLS: WHAT YOU’LL NEED

While this is not an exhaustive listing of all the tools you may require for these projects, here’s a quick rundown of the basic tools needed for many of the projects, as well as a few thoughts about using them.

Carpentry Tools

Electric Drill

Modern lithium-ion battery-powered electric drills are wonderfully versatile tools. In addition to their usefulness in drilling holes through wood, electric drills also double as fantastic electric screwdrivers, making short work of framing tasks and chores that involve fastening larger pieces of lumber, like 2×4s and the like. In fact, we’d go so far as to say that quickly fastening screws is really what cordless drills are most useful for.

Choosing an electric drill is a matter of power vs. weight/size. A smaller, lighter cordless drill might be nicer to carry and easier to handle, but may not possess the power of a larger drill (although this isn’t necessarily true). Likewise, a robust drill will probably be stronger, but possibly more expensive, too. Generally speaking, a drill lighter than about 12 volts might be a little too weak for the workload required by some of these projects.

Whatever type of cordless drill you choose, you might consider obtaining two batteries for it. That way, when one of them runs low, you don’t have to stop working—you can charge one battery while you continue to work with the other one. Also, be sure to pick up a good selection of screw bits in various sizes, including Phillips, square, and torque bits, as well as various sizes of holedrilling bits.

Circular Saw

No true DIYer should be without one. The circular saw is often the workhorse of many garages, workshops, and jobsites, and you’ll definitely want one on hand for the projects in this book. Circular saws are available in both traditional plug-in varieties that generally have more power, and smaller portable battery-powered kinds. These battery-powered versions can be handy indeed, but may not have the power you need to accomplish some tasks quickly enough. Circular saws have small round blades—7¼ in. (184 mm) is a common diameter—that are capable of most crosscutting straight and miter cuts, and they can make rip cuts, too.

Miter Saw

Need to make many short crosscuts in a hurry? Are you looking for a quick way to cut multiple long pieces of lumber into shorter sections? Or perhaps you need to make a few precise angled (mitered) cuts? A miter saw might be just what you need for your woodworking setup. While not always specifically essential—you can probably get away with using your circular saw for the same jobs—a miter saw will definitely speed up your workflow and make these tasks easier.

Jigsaw

Not used all that often for basic construction work, a jigsaw is nevertheless essential for certain specific tasks, when making a very precise cut—particularly a curved cut—is what’s needed. It’s definitely a tool that is worth having around in the workshop for projects like those in this book. Besides wood, some jigsaws can be used for cutting mild steel, aluminum, or plastics. Naturally, a more powerful jigsaw—one over five amps—will have an easier time cutting through heavy materials, and may also have extra features. When shopping, consider purchasing a jigsaw with orbital action (this helps the blade cut more effectively) and variable speed so that you can speed up or slow down the blade as needed while making turns. Cordless battery-powered jigsaws are available, but may be less powerful than corded versions and weigh more.

Table Saw

When it comes to cutting wood, most people are probably more familiar with circular saws, miter saws, or even handsaws. Even though they work in different ways, these saws all have one thing in common: they work by crosscutting, that is, by cutting the wood across the grain, usually in fairly short distances. To take a very simple cut, for example, imagine cutting an 8 ft. (244 mm) 2×4 down to 6’. To do this only requires a fairly short cut across the short end of the 2×4. This cut goes across the wood’s grain (a crosscut), and is easily and quickly accomplished by a circular saw, chop saw, or handsaw.

Now consider the table saw, which works under a different concept. Instead of being used to make relatively short cuts across the grain, a table saw is capable of making long rip cuts—cuts parallel to the grain of the wood. For example, a table saw could be used to modify an 8 ft. (244 mm) 2×4 into two 8 ft. (244 mm) 2×2s, or some similar type of cut, and it can do this very quickly and effectively, providing pro-quality results with minimal effort on the part of woodworker. However, a table saw is a large, expensive tool, so you may or may not have easy access to one. Luckily, in a pinch, your circular saw can also make rip cuts with the use of a rip guide, but this isn’t as easy to do and your cuts might not be quite as straight as they would be with a table saw. If you do need to perform a lot of rip cuts, a table saw is definitely the way to go.

Performing a rip cut with the table saw

Squares

A ruler-like tool that is quite un-squarelike itself, a square is an invaluable carpentry tool that can be used for a variety of purposes, but it’s especially good at keeping your construction projects, well, square. There are two types of squares we suggest you have on hand: framing squares and triangle squares. Framing squares are “L”-shaped and very useful for keeping right angles perfectly at 90°, especially when constructing larger items out of long pieces of lumber. Triangle squares are very helpful as simple quick rulers for making cut lines, but they also help you easily mark angled cut lines for angles other than 90°. Triangle squares are light and compact, and easily fit in a pocket or tool belt while you work.

Framing square

Triangle square

Tape Measure

One tool that is absolutely necessary for proper construction of almost all the projects in this book is a good tape measure. Because you’ll be using it so often, we recommend looking for a quality tape measure that will hold up to frequent use and is easy to use. Find one with a locking mechanism that you like; different tapes use different types of levers or buttons to lock the tape and you’ll want one that you find intuitive. Also, if you’re not already a frequent carpenter, take a minute or two to familiarize yourself with the inch fraction markings on the tape. There are different-sized lines to make different-sized fractions easy to find at a glance, including half inch, quarter inch, eighth inch, and sixteenth inch. It might not seem like an eighth or a sixteenth inch might make much of a difference, but you would be surprised how critical these small amounts can be in the world of carpentry. Finally, select a tape that is the length you like best: 25 ft. (7.62 meters) is a fairly standard size, but you can also find smaller 16 ft. (4.87 meter) tapes that should also be sufficient for the projects in this book.

Essential marking tools that work together: tape measure, triangle square, pencil

Hammer

For many basic construction tasks, we will often recommend a cordless drill and screws for assembly, just because it makes the job so easy. Still, a good hammer is an essential tool to have around for several reasons. Besides its basic use as a nailer—a job which a good hammer and a practiced arm can make quick work of—hammers are constantly needed for the gentle tapping or positioning of tight joints, or for carefully pulling out bent or misplaced nails or staples. Hey—mistakes happen!

For basic construction and for the projects outlined in this book, our advice is to select a standard claw hammer—perfect for nailing and occasional pulling or prying. Try a 16-ounce (453 gram) hammer as an excellent balance of weight and performance.

Wood Glue and Wood Clamps

Some carpentry projects will benefit from the addition of wood glue to help secure joints. The additional bond provided by the glue, in addition to the standard screws or nails, can help make your project extra strong. Along with glue, you’ll also find that wood clamps are handy to hold wood in place while you fasten it, or to hold something down while the wood glue dries. Having a few different sizes and lengths of wood clamps on hand is probably a good idea.

Applying wood glue

Holding glued surfaces together with clamps

Finish Nailer

Some of the projects will be sped up considerably with the use of a pneumatic finish nailer. These nailers can fasten wood extremely quickly and make it look great at the same time. Obviously, the use of a finish nailer also demands that you obtain an air compressor to go with it. We understand that not everyone will have access to a finish nailer, but if you do, this is a good way to go.

Pencil

While you can of course use any basic pencil for marking measurements on your lumber, you’ll find that a pencil made specifically for carpentry is a benefit. These pencils are generally thicker than regular pencils, so they have the ability to make bolder marks on lumber. Also, you might find that using a flat pencil rather than a round one is beneficial in keeping the pencil from constantly rolling off your worktable or sawhorses.

Razor Knife

Razor knives are one of those construction tools that are just convenient to have around. You can’t ever be sure exactly when you’ll want one, but when the need arises, it’s a tool that’s very handy to have on hand. Obviously, razor knives are extremely sharp and care must be taken whenever handling them.

Level (Spirit Level)

Whether you select a longer 3 or 4 foot (91 or 122 cm) version, or you stick with a simple (and inexpensive) 1 or 2 foot (30 or 60 cm) style, a good level is a highly valuable tool to keep in your carpentry toolbox. Levels couldn’t be simpler to use—simply lay the level down against a flat surface on the project you’re working on, and the convenient small bubble inside the glass window will show you precisely how accurate—or inaccurate!—your level surface is. Levels can also be utilized vertically, to verify if something is plumb—the vertical equivalent of level.

Sawhorses

Trust us—you’ll want a set of sawhorses for all your carpentry work. In fact, you’ll want several sets—they’re just so convenient, whether you’re cutting wood or simply in need of a table-like workspace for all of your project materials. Luckily, we show you how to make your own sawhorses (on pages 92–97), so you can build as many sets as you need!

GENERAL SAFETY WARNING