Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Wissenschaft und neue Technologien

- Sprache: Englisch

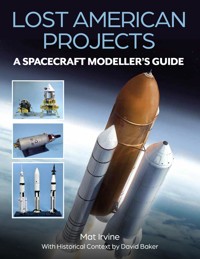

Bring to life America's most amazing space projects that never were, using highly illustrated step-by-step guides. The major American space programmes that carried crews are well known. From Mercury, Gemini and Apollo in the 1960s and into the 1970s, through to the 1980s Space Shuttle, which made its final flight in 2011, they have all made their mark – even the North American X-15 rocket plane that earned many of its pilots their Astronaut Wings, owing to its high-altitude capability. All these involved a lot of new hardware, including the Saturn rockets, the Apollo craft and the Shuttle Orbiter with its solid-fuel rocket boosters and giant external tank. During this time of actual missions, space scientists and engineers were also looking at how all these new techniques and hardware could be put to even greater use. Many plans were devised, artwork drawn and technical models produced to illustrate the proposals. However, none were ever built and certainly none ever flew. This book looks at what could have been and how they can be built as models to display alongside those that did actually fly. Lost American Projects – A Spacecraft Modeller's Guide is a follow-on to Mat Irvine's earlier book, Scale Spacecraft Modelling.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 264

Veröffentlichungsjahr: 2024

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

CONTENTS

Introduction

1 The Mercury Observatory

2 The Original Apollo Spacecraft

3 Two Men to the Moon

4 An Air Force Gemini

5 X-15 Piggyback on a Valkyrie

6 How the Saturn IB Grew Bigger

7 Heavy Lift Saturn V

8 Shuttle on a Saturn

9 Fly-Back Boosters for the Shuttle

10 Shuttle-C for Cargo

11 Heavy Lift Shuttle

12 The Lost Constellations

Appendix: the model companies

Index

INTRODUCTION

This book is intended to be a follow-on to my original book published by The Crowood Press Ltd, Scale Spacecraft Modelling, but this time there are detailed descriptions of what could have been built, from my colleague David Baker. It is intended for modellers who have at least a passing knowledge of model building. Scale Spacecraft Modelling featured in detail many aspects of building models of spacecraft and rockets, including information on the types of tools and paint required, working environments and other aspects such as spray painting, applying decals and scratch-building additional parts. Consequently these minutiae are not repeated here – the recommendation, somewhat obviously, is to please read the earlier book!

However, there are some aspects that come up fairly frequently in this book, that perhaps do need a little further explanation.

As this book features spacecraft that were planned, but not built, there are no commercial model kits of them. But all were based around craft that had been designed, built and launched, and for which commercial model kits have been made. So the starting point for many of the builds included here can start with an existing kit.

Because of the subject matter, the numbers of the kits used here do get repeated, but most should be reasonably easily to obtain, if not from one manufacturer, then maybe from another. Plus many modellers still have stashes of unbuilt kits tucked away (invariably referred to as ‘loft insulation’), so these can finally have a use! It could also be a time to dig out old, already built kits that maybe have seen better days and perhaps should have been consigned to the dustbin or garbage can. But recycling is all the rage, and anyway most modellers are extremely reluctant to throw anything away – ‘You never know, it might come in useful…’ – and these conversions may indeed be the chance to prove that point.

Of course the model kit industry does not stand still, and although all the model kits in these conversions have been available at some time or another, and may even still be widely available when this book is published, it does not mean that they will be forever. But new kits of the same subject get issued, and old kits frequently get reissued. And local model clubs still run shows and swap-meets, where modellers have tables full of their old stock of kits that they will ‘never get round to building’, so sell them off (then invariably spend the cash on buying yet more kits from fellow modellers on other stands, so the stock never really diminishes…). In addition there is the joy (or otherwise) of those on-line auction sites where obsolete kits can be obtained, some still at amazingly reasonable prices.

Here is a short list of the main kits used in these conversions, and where there are alternatives.

MODEL KIT CONVERSIONS

Saturn V

In the 1:144 scale used here for the conversions, the two mainly available kits of the Apollo Saturn V are from Airfix and Monogram. (The latter is now under the Revell name, but it is the same kit.) In more recent years 4D issued a ‘visible’ 1:144-scale Saturn V, though the Airfix and Monogram/Revell are going to be easier to find and cheaper, even at today’s prices.

Airfix 1:144-scale Apollo Saturn V – early box.

Monogram 1:144 Apollo Saturn V – first box.

Revell 1:144-scale Apollo Saturn V. This is the reboxing of the Monogram kit.

Airfix 1:144-scale Skylab Saturn V.

But if you wish to adapt the scales of the builds using the Saturn V, there is one from AMT that is down in scale to 1:200, and up in scale there is the 1:96 example from Revell. Even larger is the newest kit from Dragon, in 1:72 scale. Airfix also makes the Skylab Saturn V in 1:144, and Dragon makes it in 1:72, where most of the parts are the same as the Apollo version.

Saturn IB

The main kit here is the Airfix one in 1:144 scale, but AMT makes one in 1:200 scale in its ‘Man in Space’ five-rocket set, and Dragon makes one in 1:72. There are also resin versions in 1:144, from RealSpace Models and New Ware.

Airfix 1:144-scale Saturn IB – box for the third issue.

Space Shuttle

The conversions here use 1:144 scale, and most use the Airfix kit. However, Revell also makes a similar 1:144 kit. Both companies make this as the Full Stack set-up, so with Solid Rocket Boosters (SRBs), External Tank (ET) and the Orbiter itself. In fact Airfix only makes this set-up, while Revell makes separate Orbiter and full stack kits. A full stack kit is also made by Minicraft. (This started life as a G-Mark kit, then Entex, now Minicraft, but the kits are identical, though the moulding colours can vary.) A 1:144-scale Shuttle Orbiter has been made by Bandai (now a rare kit), and Dragon makes an Orbiter by itself, and also with the Boeing 747 SCA (Shuttle Carrier Aircraft).

Airfix 1:144-scale Full Stack Space Shuttle – first box (with some technical issues – these are corrected in later box-art).

Revell 1:144-scale Full Stack Space Shuttle – one of a number of issues.

Revell 1:144-scale Space Shuttle Orbiter – one of a number of issues.

1:72-scale kits of the Orbiter have been made by both Revell and Monogram, which were different as they were then separate companies. More recently 4-D makes a ‘visible’ 1:72-scale Orbiter. Monogram also makes a full stack 1:72 Shuttle – it is likely that this is the largest commercial ‘space kit’ ever made, or ever likely to be made.

Tamiya made an Orbiter in 1:100, but there was no matching Booster section. In smaller scales Hasegawa and Lindberg make full stack Shuttles in 1:200 scale; the latter was also available under the AMT name. (As AMT also makes the 1:200 ‘Man in Space’ set, it makes this transfer of name somewhat logical.) Then there are even smaller-scale Shuttle full stack kits in 1:288 scale, originating from Union and Academy. The Union kits have also been issued under other names, such as Revell and Doyusha. These have been available as full stack, Orbiter only, and with a 747 as the SCA. (If you are wondering as to the ‘oddness’ of this scale, it came about as it is half of 1:144, itself half of the traditional aircraft scale of 1:72.)

Apollo

Revell has made the most of Apollo over the years, with kits in 1:96 and 1:48 scales. The 1:48 especially is used a great deal in these conversions, as although from very early years, and based on ‘boiler-plate’ mock-ups, it does still look the part, and has many useful parts for these conversions. Monogram and Dragon have also made good use of Apollo, and the Monogram 1:48-scale Lunar Module and the 1:32 Command Service Module (CSM) find their way into these pages. The 1:72- scale Airfix Apollo Lunar Module is also a source of parts.

Revell 1:48-scale Apollo Spacecraft – 25th anniversary issue.

Revell 1:48-scale Apollo Lunar Module – 40th anniversary issue.

Airfix 1:72-scale Apollo Lunar Module – the most recent issue.

Monogram 1:48-scale Apollo Lunar Module – one of a number of issues.

Monogram 1:32-scale Apollo Command-Service Module – one of a number of issues.

The X-15

The X-15 is available as a true 1:72-scale kit from Monogram and MPM. The oft-quoted ‘1:72’ Revell kit that dates as far back as 1958 is not, in fact, 1:72, but 1:65 – close, but not 1:72. However, recently the original Monogram kit has moved under the Revell name, so care must be taken to ensure that you have the ‘1:72’-scale kit and not the older 1:65. There are other scales of the X-15, but the conversion included here relies on a similar scaled XB-70, and for that there is really only one kit, the AMT version. (This is now under the Italeri name, but it is the same kit.) There are 1:48-scale X-15 kits, even one in 1:32, but a similar scale XB-70 would be impressive, though extremely impractical.

Monogram 1:72 North American X-15 – one of the two original boxes.

MPM 1:72-scale North American X-15.

AMT 1:72-scale North American XB-70 Valkyrie – limited edition box.

Gemini

Most Gemini conversions will use one of the two scales made by Revell, namely 1:24 and 1:48. Other kits have been available: Imai, also issued by Bandai, made one in 1:28 scale and Dragon has one in 1:72. There have been several in resin in 1:32 scale, especially from Collect-Aire and Raccoon, but firstly these were produced in small numbers and are consequently rare and expensive (if they can be found at all), and although they could be used in conversions, here we stay with conventional styrene. There are other Gemini spacecraft models, but they are far smaller and will be the payload for a Gemini-Titan II launcher vehicle.

Revell 1:48-scale Mercury and Gemini – first box.

Revell 1:24-scale Gemini – one of several boxes.

Mercury

The Revell 1:48-scale Gemini was made as a double kit with America’s first craft to carry an astronaut, Mercury. Unfortunately Revell never made a 1:24-scale Mercury kit to match the 1:24-scale Gemini, only the 1:48 (and 1:110 scales to go with its two launch rockets). Different kits from Horizon Models and Dragon come in 1:72, with launch rockets, but they are really too small for the conversions here. There are some resin kits in 1:32 scale, similar to the 1:32 Gemini, and there is one 1:24 scale from Sheri’s Hot Rockets (and yes, ‘Sheri’ did exist!). It was designed to be launched on a flying model Mercury Redstone and was produced in injection styrene and resin, but is long out of production. Consequently the Mercury spacecraft conversion here is really restricted to the MRC/Atomic City kit, which is in 1:12 scale.

Atomic City/MRC 1:12-scale Mercury.

Others

The Heller 1:125-scale Ariane 4 launcher is useful as it provides booster rockets, used in several conversions, and the MPC futuristic Pilgrim Observer space station can also supply some parts.

Heller 1:125-scale Ariane 4 launcher.

MPC 1:100-scale Pilgrim Observer: the second box.

MATERIALS

You will also see the name of ‘EMA’ mentioned through the chapters. EMA stands for Engineering Model Associates, an American company that makes injection-moulded parts originally intended for professional model makers building models of industrial complexes, such as power stations, chemical plants and the like. These parts were soon discovered by the special effects industry (including this author), as they were ideal raw materials for building special effects miniatures and props.

Unfortunately for the general model maker, as a result of the growth of CAD-CAM, 3D printing and CGI for both the commercial model maker and special effects industries, the use of EMA parts has reduced, and these days many parts are difficult to obtain. However, EMA did branch out and start a ‘hobby modeller’ division, called Plastruct. This used the smallest scales of EMA parts, and introduced new shapes and sizes, primarily as tubes, rods and ‘girder’ shapes – I beams, T beams, L beams and the like. These can usually be found displayed in their own special rotating display on the counters of many model shops, or they are available online.

A very small selection of EMA parts with various catalogues.

MEASUREMENTS AND SCALES

‘EMA’ also brings in units of measurement, and how they are used throughout the book. The world works almost entirely in metric as the vast majority of countries use the metric system. However, the modern commercial model kit industry started – or at least was vastly expanded upon – in the UK and the USA. As both at that point used the British imperial system of measurements (and America still mainly does), the model kit industry followed suit. Hence the vast majority of scales are based on imperial units – so 1:72 and 1:48 scale for aircraft, 1:32 and 1:24 for cars, and 1:144 for space rockets. This applies even with the model companies based in ‘metric’ countries, which also predominantly follow these scales.

Plastic sheet, including plain and embossed.

Spare parts can be kept in their own kit boxes, large card boxes and specialist card storage trays.

Imperial measurement especially applies to EMA as it is an American company, so all its sizing is listed in inches and feet. To EMA its 6in-diameter tube is just that – 6in – and it has the code VT600. In many countries, however, it will be listed as the somewhat ungainly ‘152mm’. As EMA parts come into many of the builds in this book, the imperial measurement will come first in inches, followed, if necessary, with the equivalent in millimetres.

‘Plastic sheet’ will also be mentioned throughout the book. As its name implies, these are flat sheets of ‘stock’ polystyrene, usually in white (though black and other colours are made). It is made in various thicknesses, from 0.5mm up to several millimetres. Most hobby stores will sell it in small sheets, usually 8 × 12in, which is convenient, but expensive. Commercial plastic suppliers will usually have similar sheets in much larger sizes, such as 4 × 6ft, which, if you can source them (and transport and store them!), will be much cheaper. Cutting them down to working sizes requires a straight-edge and a suitable cutting tool.

However, note that a standard ‘sharp-edged blade’ is not really suitable for these sheets, nor for cutting styrene sheet in general. Special cutting knives/ blades are made that have a V-shaped edge that scores the styrene, allowing it to be ‘snapped’. Model stores should have such knives, and they are available as extra blades for many ‘Stanley’-type knives.

Plastic sheets are also available ‘embossed’ with patterns to reproduce ‘full size’ objects. Perhaps ‘bricks’ are the best known example here, though probably not much use for models of spacecraft (even for the ‘tiles’ on the Space Shuttle Orbiter!). However, other patterns include corrugated, and this can be useful for rolls around rocket sections – as seen, for example, on the Saturn V.

Other than that, most modellers, especially those who have been working at it for some years, will have acquired a well-stocked spares box, otherwise known colloquially as the ‘bits and pieces’ box (or more likely ‘boxes’). These will – should – have all those, well, ‘bits and pieces’ that you will invariably find useful with such conversions as are found within these pages. You will be constantly diving down into them and rummaging around in them, and emerging with that small part and the exclamation ‘Yes, that will do nicely…’.

TOOLS, PAINT AND CEMENT

If you are contemplating any of the builds in this book, you will almost certainly have a well-stocked model toolbox, with knives, files, sanding materials, clamps, modelling saws and hand-held ‘pin-vice’ drills, maybe even a small electric drill.

‘Plastic cement’, the type that came in tubes, is still available, and can still be used for standard ‘plastic kits’ moulded in polystyrene. However, most plastic gluing these days is of the liquid variety, based around some hydrocarbon solvent. Most of these are unpleasant to inhale, if not actually poisonous, so the advice is always to work in well-ventilated surroundings, and if you are particularly worried, to use suitable masks. Most liquid cements will glue polystyrene, but they will also glue other plastics, such as ABS (acrylonitrile butadiene styrene). As most of the EMA parts mentioned throughout this book are moulded in ABS, this is the only way to glue them.

Superglue – the common name for cyano-acrylate, or CA – is also very useful these days as it will glue – virtually – anything to anything else. With many kits being multi-material (that is, they are built up from more than one type of material) and with a predominantly polystyrene kit – with parts that can be resin, photo-etched and white metal, let alone any other materials you add yourself – superglue is indispensable. Sometimes even contact adhesive will have its uses, and spray glue in an aerosol is vital for applying gold foil, as again will be found throughout this book.

A selection of modelling tools, including knives, scalpels, files, saws and clamps.

A selection of modelling glues, decal softener, fillers and – old – brushes used for applying them.

A selection of masking tapes – general masking (left); standard adhesive tape (right); and specialist model masking tape (centre).

Paints used for model making have also changed, especially over recent years. Originally virtually all paints made for model makers were enamel based. This applied to both those in bottles or tinlets, and to spray paints. However, the vast majority of paints for modellers – and spray paint especially – have been reformulated to acrylics. This also applies to brush-on paints, though some companies, and in particular Humbrol, still make their traditional enamel paints in their traditional tinlets, supplemented by a similar range that is indeed acrylic.

CHAPTER 1

THE MERCURY OBSERVATORY

The Mercury capsule was small, with a maximum weight in space of around 3,000lb (1,376kg). It had an attitude control system enabling manual or automated controls to point it in a desired orientation, essentially rotating around its roll, pitch and yaw axes. Built by McDonnell, and wanting to see further development and more orders for its little Mercury capsule, the company funded a wide range of proposals for other uses.

Little was known about the space environment, but one problem that troubled NASA was the destructive effect of tiny micrometeoroid particles. With the potential risk to human life should the walls of a pressurised spacecraft be punctured, these threats had to be measured and quantified.

The tiny Mercury capsule was NASA’s first major project, with several possibilities beyond its limited role carrying America’s first astronauts.

The proposed layout for collecting micrometeoroid impact data involved rolled-out sheets of material to register hits.

To get this information, one proposal was to equip an unmanned Mercury capsule with rolls of aluminium-covered Mylar that would unfold in space and test its suitability for protecting future manned vehicles. The ultra-thin aluminium foil would act as a recuperable capacitance gauge when connected to the terminals of on-board batteries, providing information through the electrical current about the size of impacting micrometeoroids and their frequency, together with the ability of the coated Mylar to resist being fractured by the collisions.

Another potentially more attractive application emerged after astronaut Gordon Cooper enthused over detail he could see from space on the surface of the Earth during his 22-orbit mission in May 1963. That year, the Central Intelligence Agency (CIA) and the National Reconnaissance Office (NRO) were already working on highly complex spy satellites for broad area surveillance and close-look reconnaissance.

McDonnell saw a potential application for an unmanned Mercury variant outside the range of non-military programmes. They approached the Air Force to propose the use of an unmanned Mercury capsule suitably modified for high-resolution imaging from space. Support came from specialist consultants, but having examined the capabilities of the Mercury spacecraft, the Air Force concluded that the limited weight-carrying capacity was too small for the kind of optical devices required for an orbital spy satellite.

Recoverable spacecraft were in their infancy, and Mercury was a ready-built solution to the problem of expensive equipment launched once and left in orbit. It was this potential for recoverability that championed the use of the Mercury spacecraft and offered a production-line vehicle to do that for a variety of applications.

It appeared logical on paper, but there were drawbacks with using the Mercury capsule. Electrical power was stored in batteries, and in Mercury there was no way of producing power from solar cells or small nuclear isotope generators. It would have negated the advantages in using an existing spacecraft if that had to be built. This meant that the operating life of a Mercury capsule was only a few days at most, and many of the potential applications proposed would have used large amounts of power, further reducing its operating life.

Put together as an orbiting astronomical observatory, this unmanned version of Mercury was outcompeted by more sophisticated designs.

Nevertheless, the potential in Mercury’s ability to return expensive pieces of equipment such as telescopic lenses, complex photographic instrumentation and even rolls of high-grade film for immediate processing, was attractive. McDonnell saw potential in fitting whole camera systems inside a Mercury capsule, and worked on a proposed observatory in space. The desire to place a telescope above the atmosphere predated the space age, and in 1964 NASA’s Langley Research Center carried out a study to see whether Mercury could be adapted for this purpose.

All the internal life-support equipment would have been removed and replaced with this telescope, while the upper section of the spacecraft, which on a manned mission carried the forward recovery section, would be replaced with the optical tube, bringing light down the telescope to the camera. A separate toroidal recovery section would replace the original, with a parachute housing to either side of the forward section. To achieve all the desired advantages, Mercury’s attitude-control equipment would be replaced with an equivalent, but much more accurate, stabilisation platform to achieve a pointing accuracy of 0.08 arc-sec during film exposure, which could last from seconds to several hours.

MODELLING THE MERCURY OBSERVATORY

If there is one thing optical astronomers hate, it’s the Earth’s atmosphere. To the human eye the sky looks clear, but viewing the skies through an optical telescope is invariably likened to viewing it from the bottom of a pond. To most astronomical instruments the Earth’s atmosphere appears just as wavy and distorted as would the view to the human eye peering upwards through the water in the pond. Consequently, when space satellites became a reality, the idea of placing a telescope in orbit above the atmosphere must have been on the minds of many scientists and space engineers.

The Atomic City/MRC 1:12-scale Mercury spacecraft as used in this build. The main parts to be used are on the left and are black, except the hatch, which is supplied on the red runner – though this will end up black.

The hatch will be filled in place, but the window also needed filling in. The kit supplies the window in clear, and this can be used as a template.

Here, sheet styrene plastic is cut (it is going to be thin, so scissors will probably be adequate) and glued into place. Odd gaps can be filled in with model putty and sanded smooth, but the general idea is that the UNITED STATES decal will eventually be applied over the top, so will hide any imperfections.

And given that the USA had launched a successful series of crewed spacecraft with one person on board – Project Mercury – it wasn’t long before the idea of replacing the astronaut with a telescope came into being – hence this conversion. In effect this is a very early design for the Hubble Space Telescope, using the Mercury craft as the container for a reflecting telescope with a 30in (760mm) diameter mirror.

The basis for this conversion is the Atomic City/ MRC kit of the Mercury spacecraft in 1:12 scale. Unfortunately, although Revell made a 1:24-scale Gemini, a scale that may perhaps have been a more logical starting point, it never made a similarly scaled Mercury. The only Mercury spacecraft that Revell made was a 1:48-scale double kit, with a matching Gemini. This could be used, but it would make a rather small final result. There have been 1:32-scale resin kits of Mercury from Racoon, CollectAire and Crows Nest, and there was actually one 1:24. However, the last was intended as the payload for a flying 1:24-scale Mercury Redstone, made by Sheri’s Hot Rockets. But that company is out of production, so here the Atomic City/MRC kit is really the only kit that can be used.

You only need the outer structure for this conversion, as the interior is now purely the Cassegrain reflecting telescope – all traces of the human crew have been removed.

The Mercury has a hatch without a window, so here it can be simply cemented in place. Because of the way the parts are positioned on their runners, the main spacecraft is moulded in black, while the hatch is on the red runner (with the Launch Escape System). But as it is usual to paint the whole model, this will be turned black, along with the rest of the craft.

The Window

Slightly more of a problem is the window, as the telescope would have no need for one in this position, and if this version had even been built, one assumes it would never have been fitted in the first place – this area would be the ‘shingles’, as used for the rest of the exterior. The ideal solution would be to use another kit and cut out an appropriate area, but this would be somewhat wasteful and, needless to say, expensive. Alternatively, a section of the exterior could be moulded and a recast cast and used as a replacement.

But, given that the interior in this version doesn’t need to be pressurised, the window opening would probably simply have been covered, which was done here. The kit instructions supply a template to cut the outer window from the supplied sheet of acetate, so here it is purely used as a template to cut sheet styrene to fill the gap. A small amount of filler may be necessary to fill the odd gap, but that should be it. It is also helpful to apply the UNITED STATES decal in the kit, over this section, so that will help hide the irregularities.

The Nose Section

The nose section of the telemetry and parachute compartments of the original Mercury are now all reserved for the parachutes, two drogue and two main, and as this is now split into two halves, the first task is to glue the two main parts together. Then when thoroughly dry, these combined parts are cut down the centre. It is easiest to use the vertical moulding on the lower section to cut along, continuing into the upper section, to get two (more or less) identical halves. There are no illustrations to show what the new ‘inner panels’ would be. One assumes they would be closed in to protect the ‘chutes during manoeuvres, so embossed plastic sheet, with a ribbed pattern, was used to block off both the inner areas and the lower.

The ‘nose’ section of the Mercury. The parts for the nose were first cemented together, and then sawn down the centre. Both halves have their edges ‘cleaned up’ by using a sanding board – simply a sheet of sanding paper spray-glued to a sheet of plywood or MDF.

A selection of tubing that could be used as the telescope tube. On the left is a length of EMA tube; in the centre is a cut section of a Saturn V; on the right is a part of an old build, using more EMA tubing, with an ‘end’ in place. Note that the main Mercury spacecraft – far left – has the hatch in place, and the window is filled and sanded.

Filling the inner surfaces of the modified nose cone with sheet styrene. Here the hinges are made from EMA parts – these are number KBC-10, and are intended to join girders together for architecture models, but bent wire could be used, fixed into drilled holes.

Assuming the model is being built with this section folded back to reveal the telescope tube, they need some method to hold them at 90 degrees from the main body. They could be hinged, and small hinges are available from hobby suppliers, but here it was felt that it would be more suitable to fix them in place, otherwise nothing of the interior can be seen. For this, small EMA parts, with the reference KBS-10 or KBC-10 (they are intended to join girders), were used. KBS-10 can be used ‘as is’, while KBC-10 needs one end cut off. Then the U-shaped section of either fits neatly over the top of the spacecraft body. Alternatively, thin wire, bent at 90 degrees, could be used, fitted into drilled holes.

Sorting out the telescope tube. A section from a Saturn V rocket was used. All the interior surfaces – including the spider – will be spray-painted matt black. The interior surfaces of all optical telescopes need to be as ‘matt – or flat – black’ as possible.

Making the primary mirror. This is the top of a Saturn V S-IC stage tank, using the inside surface. The hole in the centre needs to be carefully drilled accurately in the centre. (This is where the light passes through, bounced off the secondary mirror, to instruments that would be located behind the main mirror.)

The Interior: ‘All’ Telescope

As far as the interior is concerned, this is ‘all’ telescope. This consists of three parts – the telescope tube, the primary mirror and the secondary mirror and spider. The last is positioned at the top of the tube, the ‘spider’ being the structure that holds this secondary mirror in place. From the information available, this does indicate that a ‘second’ secondary mirror is positioned further down the tubes, but details are sketchy, so this is omitted.

The main components for the build, left to right: the Mercury spacecraft; the primary mirror; the telescope tube; the heat shield, with the mirror support in place; the spider, with the secondary mirror; and the two halves of the opening nose.

Fitting the telescope tube in place, and fitting the tube – the grey object on the right – that will take the rod for the stand.

The tube could be sourced from a variety of places. It needs to be approximately 2¾in (70mm) in diameter, and EMA makes suitable tubes (VT-275), though these are increasingly difficult to get hold of, are not cheap, and have to be bought in 36in (90cm) lengths. But given that it is purely a tube, maybe a card tube could be sourced, then lined with thin plastic sheet. Alternatively, a tube could be made from flat plastic, rolled into a tube shape and cemented at the edges.

More components, and the completed retro-rocket pack – bottom right – which is the same as fitted to the craft with an astronaut.

However, and by coincidence, the 1:144-scale Saturn V kit’s S-II stage is 2¾in (70mm) in diameter and an almost perfect fit; a section was found in the ‘bits and pieces’ box, and was used here. The Saturn V kit will also supply a ‘mirror’ using the ‘inside’ one of the tank tops. This should strictly speaking be a parabolic section, which the tank top isn’t, but at the end of the tube, the wrong cross-section is hardly noticeable. This needs a hole approximately 3/8in (10mm) drilled in the centre, as this is a Cassegrain set-up – the light enters the top opening, hits the primary mirror, is reflected back up the tube to the secondary mirror, is refocused and then sent back down to the primary, but this time through the hole in the centre. Behind, a variety of instruments do the ‘viewing’. (As this viewing is not being done by a human eye, technically the set-up is a Schmitt camera, but the telescope itself is still a Cassegrain.)

The secondary mirror is only seen from the back, and because the Saturn V kit is already being cannibalised, the heat shield part from the Apollo Command Module (CM) was used. The spider was