Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

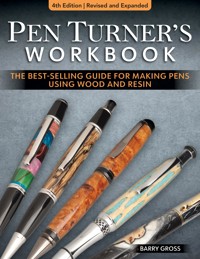

Learn to turn and sell custom-made pens that are both practical and beautiful! In this newly revised 4th edition, author and expert pen turner, Barry Gross, provides new pen kits and mechanisms with up-to-date techniques, along with in-depth instruction and creative ideas for both the novice and the experienced turner looking for new ideas. From choosing a lathe to pen turning basics and even selling your work, no detail has been left out! Also included is a section on casting your own acrylic pen bodies, so you can customize by embedding your own artwork and memorabilia. Instructions for turning pens made from resin, Corian, InLace, antler, and other materials is included. New to this edition is expanded information on what makes a good pen, selecting materials, and tool maintenance, as well as 7 new projects and an updated gallery featuring gorgeous pens made by master pen makers.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 215

Veröffentlichungsjahr: 2025

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Dedication

This book is dedicated to Lenora—my best friend in life, my partner, my wife—who always keeps encouraging and inspiring me to reach higher by trying different methods and techniques while never looking back. For over 40 years, she has been a pillar of strength for me. Analogous to the tree above with deep roots, she keeps me grounded and without her unwavering support, this seventh book would not be possible.

Acknowledgments

You hear horror stories of deadlines and editors that are demanding—maybe that is the way it is with other publishers, but the organization that Alan Giagnocavo has assembled is top shelf. From my editors to the sales team, the “family” at Fox Chapel makes it a pleasure to write books for them. I want to thank them for putting up with my hectic schedule and working around my needs.

My friend Ed Ryan continues to be my mentor through this process. Ed is still unselfishly teaching students turning, and his “ABC’s of tool techniques” is still the gold standard for students learning to turn. I want to thank Ed for showing me this technique and allowing me to pass it on to all of you.

—Barry Gross

Cover Photography: Mike Mihalo

Gallery Photography: Scott Kriner, Greg Heisey, and Mike Mihalo

Interior Photography: Barry and Lenora Gross, Scott Kriner

© 2003, 2006, 2013, 2025 by Barry Gross and Fox

Chapel Publishing Company, Inc., 903 Square Street, Mount Joy, PA 17552.

Pen Turner’s Workbook is an original work, first published in 2003, revised in 2006, and revised and expanded in 2013 and 2025 by Fox Chapel Publishing Company, Inc. The revisions include new photographs, information about new materials, and new projects. No part of this book may be duplicated for resale or distribution under any circumstances. Any such copying is a violation of copyright law.

ISBN: 978-1-4971-0354-2

eISBN 978-1-63741-218-3

Library of Congress Control Number: 2025933558

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free at 800-457-9112 or visit us at www.FoxChapelPublishing.com.

You can also send mail to:

903 Square Street

Mount Joy, PA 17552

We are always looking for talented authors.

To submit an idea, please send a brief inquiry to [email protected].

Because turning wood and other materials inherently includes the risk of injury and damage, this book cannot guarantee that creating the projects in this book is safe for everyone. For this reason, this book is sold without warranties or guarantees of any kind, expressed or implied, and the publisher and the author disclaim any liability for any injuries, losses, or damages caused in any way by the content of this book or the reader’s use of the tools needed to complete the projects presented here. The publisher and the author urge all readers to thoroughly review each project and to understand the use of all tools before beginning any project.

Contents

Introduction

PART 1 Gallery of Pens

PART 2 Pen Turning Basics

Chapter 1: Setting Up Shop

Chapter 2: Selecting Materials

Chapter 3: Pen Plating and Styles

Chapter 4: Pen Blank Preparation

Chapter 5: Pen Turning Tool Techniques

Chapter 6: Finishing Your Work

PART 3 Turning Basic Pens

Project 1: Timeline Twist Pen—A Perfect First Pen

Project 2: Wire-Burned-Band Slimline Pen

Project 3: Corian Center-Banded Slimline Pen

Project 4: Double-Dyed Buckeye Burl Comfort Pen

Project 5: Hybrid Baron Chrome Fountain Pen

Project 6: Fidget Spinner Pen

Project 7: Lacewood Cigar Pen

PART 4 Turning Pieces from Other Materials

Project 1: Steampunk Watch Parts Pen

Project 2: Majestic Trustone Rollerball Pen

Project 3: Elegant Sierra Alumilite Pasta Pen Turned Between Centers (TBC)

Project 4: Corncob Pipe

Project 5: Deer Antler Lever Action Pen

Project 6: Mechanical Pencil

Project 7: Creating Turned Rings

PART 5 Turning Advanced Pens

Project 1: Segmented Pen

Project 2: Acrylic Closed-End Ballpoint Pen

Project 3: Single Cross Pen

Project 4: Laser Inlay Lighthouse Pen with Light

Project 5: Kitless Fountain Pen

PART 6 FAQs and Troubleshooting

PART 7 Marketing

Introduction

Creating the Pen of Your Dreams!

Pen Turner’s Workbook has been a huge success over the past twenty years, and it is all thanks to you, the turning community. Travelling and demonstrating pen turning all over the country has given me the opportunity to meet and educate thousands, and it is because of your thirst for more knowledge that this fourth edition is coming to life. You have named me “The Pen Turning Teacher,” and I appreciate the moniker. Whether you have used my books as a reference guide to learn pen making or used some of the ideas to earn extra income, you have turned (no pun intended) to Pen Turner’s Workbook, and I want to personally thank you.

My objective for this book, as well as for all my books, is to approach the subject from the mind of the individual asking the question, “how do they do that?” This book will guide you step by step through your journey to creating the pen (or fine writing instrument) you want to make by using alternative materials, casting your own blanks, or using a Mother-Nature-inspired piece of wood. This instructional book will be the definitive state-of-the-art guide in your quest to learn the skills necessary to make a better product for yourself and your customer.

This guide will discuss the fundamental skills needed to turn pens, as well as the techniques used to create your own pen blanks using burl caps and acrylic. I will show you how to assemble a laser cut pen, how to glue up the material necessary to make a segmented pen, how to work with biological materials (such as antler and snakeskin), and many other tips and tricks to make your life easier when creating your masterpieces.

I will assist and guide the individual who has not decided which lathe to purchase and which turning tools are best suited for your particular skill set. I’ll demonstrate a variety of tool techniques—for example, how to avoid the dreaded “dig in” with a skew—and discuss the various pieces of shop equipment, including safety equipment and dust collectors, needed for turning a pen.

We’ll cover casting pen blanks with or without a pressure pot and go over what pen platings work best for the different pen blanks Additionally, we will investigate wood dyes, coloring your wooden pen blanks, and alternate ways of preparing the same wooden pen blank to obtain three very distinct outcomes.

An expanded troubleshooting, or “oops,” section will show you how to correct some of the common mistakes that everyone (myself included) makes.

My favorite section is the marketing section. It will provide you with some ideas for marketing and displaying your work to maximize your efforts. A gallery section will inspire you as it showcases other very talented pen makers’ favorite masterpieces that they have created.

As I have stated in the past, life is too short to carry an ugly pen, so let’s get busy creating that one-of-a-kind fine writing instrument that you will be proud to use and display!

You’ll learn how to make terrific pens like these by following the instructions SCOTT KRINER in this book.

PART 1

Gallery of Pens

There are many very talented and skillful artisans who create wonderful, handmade, one-of-a-kind fine writing instruments. The pens that you will see in this gallery show the work of some of these “master pen makers.” The artists include Brian Gisi, Anthony Turchetta, Mark Gisi, Seamus Rooney, Glenn McCullough, Dan Symonds, Hugh Scher, Jason Rose, Steve Wohlgemuth, and myself—all of whom are members of the prestigious Pen Makers Guild. However, the gallery is just a sampling of work. There are many more very talented pen makers who are part of this organization, and everyone in the guild shares their experience and knowledge so that each member’s skill can progress.

As your ability improves with each pen, the challenge will be to seek out other pen makers who could offer a different approach to pen making and to see if that method could be adapted to your individual style. The internet is a great tool to research and discover other skilled craftsman. Observe them and absorb the information they offer on pen making because that will increase your ability to manufacture one-of-a-kind pens. I hope you enjoy these fine writing instruments!

This amazing array of pens is featured on the gallery pages.

GLENN MCCULLOUGH

Glenn McCullough is an independent pen maker who incorporates exotic woods, antler, and resins into his pens. The accents he uses are precious metals such as rhodium, platinum, titanium, and sterling silver. Glenn is a member of the Pen Makers Guild.

McCullough’s Junior Retro rhodium rollerball is made from Trustone, Corian, acrylic, and guitar pick guard material.

Glenn McCullough presents a gentleman’s rhodium fountain pen in curly koa and alternative casein.

McCullough’s Platinum El Presidente curly ash and black acrylic pen incorporates guitar pick guard material and sterling silver wire accents.

SEAMUS ROONEY

Seamus Rooney is a member of the Pen Makers Guild who uses a scroll saw to cut his coins and casts them in clear resin to create these wonderful pens. Seamus has been casting pens for over sixteen years and has developed his own special style.

Seamus Rooney’s Titanic pen (top) is an Emperor Rollerball. He replaced the cap with a liquid-filled compass and layered the barrel with three coins in clear-cast acrylic. Australian pen (middle) is an Atrax fountain pen with a coin pierced and clear casted. At bottom, the pen barrel is a 30-06 Upshaw bullet with a pierced Texas quarter and clear cast in polyresin.

ANTHONY TURCHETTA

Anthony Turchetta has been making pens for over twenty years and creates a number of fascinating pieces using many acrylic type materials. Anthony is also a member of the Pen Makers Guild as well as other pen making groups. You can find more of his work at www.penchetta.com.

Amber Ripple, a closed-end fountain pen, is made from Italian Lucite with a 14-karat solid gold nib.

This statesman fountain pen is made from orange and black swirl ebonite with a 14-karat solid gold nib. The rope pattern was cut on a legacy mill and then hand sanded.

JASON ROSE

Jason and his wife own Speakeasy Pen Emporium, and he has been making pens for over twelve years. He incorporates historic pieces of wood and other materials to create his unique fine writing instruments. You can find more of his work at www.speakeasypen.com.

This rollerball pen features pieces of wood from the USS Arizona and a metal piece of a Japanese Zero fighter plane over images of the ship and plane encased in acrylic. Jason made this pen to be placed on display for the World War II Valor in the Pacific National Monument.

The Iwo Jima antique brass rollerball pen contains a piece of volcanic ash sourced by the Iwo Jima Association of America that is embedded into the cap of the pen. The lower barrel is made from leather and black acrylic.

Titanic “The Queen of the Ocean” antique silver rollerball pen is made from a piece of wood and coal from the Titanic. Images of the Titanic and newspaper articles are placed over the pen tubes and then coated in resin for lasting protection.

BRIAN AND MARK GISI

Brian and Mark Gisi are a father-and-son team who are both members of the Pen Makers Guild. They started with a pen turning class at a local woodworking store over twenty years ago, and they have advanced pen making to another level. Brian calls this latest series his “exoskeleton” series, and Mark still uses very complicated segmented pieces to create his works of art.

Carbon Torpedo pen by Brian Gisi features integrated handcarved aluminum support structures with titanium rod accents. Brian has incorporated woven carbon fiber tubes and support beams with an intricate fin system of plate titanium.

Mark Gisi accents green-dyed buckeye and acrylics with color grain in vee and straight line patterns. The fine lines are made from green and white Gisi Designs accenting material with a custom carbon fiber clip.

Brian Gisi’s Black Widow pen features hand-cut titanium plates fitted over a carbon fiber tube with hand-turned acrylic and aluminum frame components assembled with more than 50 brass screws.

Mark Gisi combines rosewood cylinders and titanium bars with amboyna and buckeye burls in random angle patterns, accented with orange and black Gisi Designs with a custom carbon fiber clip.

DAN SYMONDS

Dan is a member of the Pen Makers Guild, and you can clearly see why. Each pen is custom designed and then crafted from the finest materials. Dan carves each piece with meticulous care—these are not overlays; they are carved from the original pen blank. All his pieces are unique functional pieces of art and are enjoyed by the people who purchase them. You can find more of his work at www.artcarvedpens.com.

This junior statesman closed-end fountain pen was Dan’s submission to the Pen Makers Guild. It is made from holly with carved rosewood, mesquite, and ebony.

A bespoke teal acrylic fountain pen accented on the cap and lower barrel with mottled ebonite. Hand-carved interlaced accents also adorn the center band and lower barrel.

This junior statesman closed-end fountain pen features carved musical notes that are the opening lines of Bach’s Partita in D minor for solo violin, BWV 1004. The body of the pen is purple-dyed maple burl with carved holly.

This slimline pen was upgraded by hand carving and dying mesquite wood to form a beautiful fine writing instrument.

Dan’s Safety Pen is made from acrylic, and its design is extremely difficult to master. The nib retracts into the body of the pen, and the body of the pen acts as an ink reservoir with the cap sealing the ink inside.

HUGH SCHER

Hugh, of Kanilea Pen Co., started making pens after reading the revised and expanded 3rd edition of Pen Turner’s Workbook. He and his wife have turned his love for pen making into one of the most successful pen companies in world. Their writing instruments are inspired by Hawaiian locations that enable them to recharge their spirit and connect with nature’s elements. You can find more of their work at www.kanileapenco.com.

Maui’s winding road to Hana takes you past a small, sheltered bay called Honokalani, which means “harbor of the chief.” This Honokalani fountain pen echoes the clear blue water that swirls in beautiful contrast to the glistening black sand.

On the slopes of Hualalai and Mauna Loa, rich, volcanic soil nurtures the coffee planted there. This Kona Cherry fountain pen represents those reddest and ripest cherries (red, ripe coffee beans) that are handpicked for roasting.

The Kilauea Kai fountain pen recalls rivers of fiery, molten lava that scorched a path across the land and flowed into the sea, sending up a thick, gray haze. Kilauea, home to Pele—creator and destroyer—expands the Big Island even as it lays waste. Hugh customizes the proportions of orange and gray for each customer.

The color of the Kona Snow ballpoint pen represents the snow that appears on the Big Island for a few days every spring, blanketing Kona’s coffee plants in fragrant, white blossoms. Soon, flowers turn to green berries, hinting at the delicious promise to come.

Every evening, the manta rays arrive, drawn to the lights at Kauna’oa Beach. The gentle giants glide past silently, glowing in the luminous green water. This Manta Maile Lei fountain pen also features a wide argentium silver band with a lei of maile leaves. A lei made of maile leaves expresses many meanings and is used to celebrate important life events or is given as a sign of friendship. This maile lei band represents an unbroken circle of love, respect, peace, and friendship.

STEVE WOHLGEMUTH

As a retired surgeon, Steve employs the tactile and creative skills required by his former profession to create finely detailed and imaginative functional art. He has spent countless hours training to perfect his pen making skills. Steve’s main priority is to make custom products that are special for each customer. To see more of his work, visit www.woogworks.com.

This black titanium majestic rollerball pen has fly-fishing lures on top of carbon fiber mesh with Fordite, acrylic, and steel accents cast with Liquid Diamonds clear epoxy resin.

This gold majestic junior rollerball pen is made from Fordite. Fordite is a man-made material that is polished from layers and layers of hardened paint that was built up on the floor of automobile factories. Sometimes, it is called Detroit agate.

This majestic rollerball pen is an orthodontist’s dream. Orthodontic ligature ties are adhered to carbon fiber tubes and accented with Fordite. The pen tubes are placed into a mold, and Liquid Diamonds is the resin used.

Orthopedic plates and screws are glued to white carbon fiber mesh. Fordite and metal are used as accents cast in Liquid Diamonds for this gold majestic rollerball pen.

BARRY GROSS

You can find more of Barry’s work at www.bgartforms.com.

Elegant Beauty and Tycoon pens feature real snakeskin cast into acrylic resin.

Tycoon Stars & Stripes, El Presidente green-dyed buckeye burl, closed-end Statesman amboyna burl with cigar label.

These pens feature Gatsby-style pen kits with Kallenshaan Woods laser-cut kits.

These pens are made using my techniques for casting acrylic resin (see here). From left, Captain Morgan Original Spiced Rum label pen, watch pieces pen, and clear-cast Sierra Vista fly-fishing lures.

The top pen is made from a shotgun shell with pheasant feathers and antler. The pen on the right is made from walrus oosik with a Gatsby pen kit.

These closed-end pens feature clear-cast cigar bands, with a custom cigar box to match the cigar bands.

PART 2

Pen Turning Basics

Creating and turning pens is an exciting hobby that will afford you hours of enjoyment and relaxation. The thrill of creating something useful and beautiful with your own hands from the variety of materials available to pen turners will keep you engaged for quite a long time. Stunning pens can be turned using everything from man-made materials to wood and acrylics you cast yourself. This section will show you the particulars of mini lathes and turning tools, materials for pens, and basic turning techniques from the perspective and the goal of turning great pens.

The skew chisel cuts a smooth and clean surface on the pen blank.

CHAPTER 1

Setting Up Shop

The heart of your workshop will be your lathe. If you have yet to purchase one or if you are looking to purchase a new one, I have included some guidelines to aid you in your decision-making process. We’ll also take a look at some of the other tools that are useful when making pens.

Choosing a lathe

Purchasing a lathe is a personal choice, and one that cannot be made solely on the recommendations of others! When considering the purchase of a lathe, take time to ask yourself the following questions.

What Type of Turning Will You Want to Accomplish?

Lathes come in a variety of sizes and styles, and it is important to identify the type of turning you would like to do before you make a purchase. Investing in the wrong type of lathe can limit the number and variety of pieces that you can create. And, if you are a beginner, the wrong type of lathe purchase can make your first turning experience less than wonderful!

For this book, I used both a mini and midi variable-speed lathe to make the pens you will see in the coming pages As their names suggest, mini and midi lathes are smaller than regular full-size lathes and are particularly well suited to smaller projects, such as pens, pencils, bottle stoppers, ornaments, boxes, smaller bowls, and vessels.

A mini lathe (see Figure 1.1) can turn an object up to 10 inches in diameter. A midi lathe (see Figure 1.2) can turn an object up to fourteen inches in diameter, and a full-size lathe (see Figure 1.3) can turn larger heavier objects up to 24 inches in diameter. See the chart on here for current manufactures of lathes. This is not a complete list of manufacturers, but it is a good starting point.

Will You Concentrate your Energies Strictly on Pens?

Turning is a great hobby and, even if you only turn pens, there will be more than enough pens to keep you very busy. Pens come in all shapes and sizes and can be made from a variety of materials including, but not limited to, all sorts of domestic and exotic hardwoods, stabilized woods, dyed and double-dyed woods, wood and acrylic combinations (acrywoods), antler, plastics, acrylics, and solid surface material, such as Corian.

In this book, you will learn how to turn many different pen styles. You will also learn to turn a sampling of some of the most common materials used in turning pens. Using your imagination to combine different styles and materials will keep you busy with a neverending array of projects for your new hobby.

Figure 1.1. Mini lathes, like this Turncrafter lathe, are smaller than regular-size lathes and are well suited to smaller projects.

Figure 1.2. Like the mini lathe, the midi Robust lathe is well suited to smaller projects, including pens. Its maximum diameter for projects is 14 inches, as opposed to the mini lathe’s 10 inches.

Are You Interested in Turning Smaller Bowls or Vessels Now or Possibly in the Future?

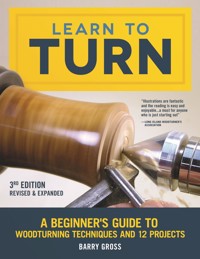

As mentioned before, both the mini and midi lathes are great tools for a variety of additional small projects, including bowls, back scratchers, shoehorns, lidded boxes, small spindles, and much more. (These additional items are not addressed in this book but are available in my other book, Learn To Turn.) If you are even remotely interested in expanding your hobby to include more than pens, you’ll want to take that interest into consideration when choosing a lathe.

How Much Money Are You Willing to Commit to your Purchase?

Lathes vary greatly in price depending on the manufacturer and the accessories included. General pricing for a mini lathe can run anywhere from around $300 to several hundreds of dollars. Again, think long and hard about how you want to use your lathe. Buying a more expensive lathe now may make better use of your resources than buying an inexpensive lathe now and then a second more expensive lathe shortly thereafter.

Figure 1.3. A full-size benchtop lathe is a good choice if you have ample room in your workshop, and you plan to make larger projects in addition to pens.

How Much Room Do You Have to Devote to your Lathe?

Mini lathes are just that: miniature lathes. They measure approximately three feet across and about one foot wide. They are perfectly suited to smaller workshop areas, such as those in a garage or a corner of a basement. My mini lathe fits comfortably in my one-car garage, and it shares that space with a dust collector, a band saw, a contractor’s table saw, a scroll saw, a wide variety of shop tools, and uncounted blocks and boards of wood that will soon turn into beautiful lathe projects.

Figure 1.4. A floor-mounted lathe, like this 14″ Jet lathe, will work well for a variety of projects if you have the necessary space for it in your workshop.

Are You Interested in a Floor-Mounted Lathe or a Benchtop Lathe?

Your choice of a floor-mounted lathe or a benchtop lathe is determined by the amount of workspace you have (see Figures 1.1 and 1.2). Choose a benchtop lathe if space is limited. If you choose a benchtop lathe, make sure that the bench is positioned correctly so that you aren’t turning on a lathe that’s too low or too high. Make sure that your lathe is bolted to your bench top to avoid vibration. A floor-mounted lathe should have a sturdy base, preferably one specifically designed for the lathe (see Figure 1.4).

Do You Want a Belt-Driven Lathe or One with a Variable Speed Control?

Switching belts can take time out of your schedule, and, if you are someone who has a limited amount of time to turn, you may opt for the variable speed control (see Figure 1.5). Since the first edition of The Pen Turner’s Workbook was written, I have switched over to a variable-speed mini lathe for both the convenience of not having to change belts and the ease of use when applying my finishes.

What Important Features Are a Must for Your Lathe?

Two items that I personally feel are very important are variable speed and a digital readout. Let’s discuss each feature.

It’s important to recognize that adjustable speed is not the same as variable speed. When a lathe is marked as an adjustable-speed lathe, it means you must physically change the belt onto another pulley to change to a higher or lower speed. In a variable-speed lathe, you simply turn a knob, and the speed goes up or down within a range without you physically changing the belt. However, even with a variable-speed lathe, you will sometimes need to change the belt depending on how many pulleys you have and their speed ranges. For example, one pulley may have a range of 500 to 1,500 rpm, and the other pulley may have a range from 1,500 to 3,000 rpm (see Figure 1.6). You’ll need to change the belt to change speed ranges. Even with needing to change the belt sometimes, variable-speed lathes offer more versatility than a strictly belt-driven lathe.

Figure 1.5. A lathe that requires switching belts to change speeds can be very inefficient if time is limited. Lathes with variable-speed controls (inset) change speeds with the simple turn of a knob.

Figure 1.6.