The Big Nuri Sardine Cookbook E-Book

Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Brandstätter Verlag

- Kategorie: Lebensstil

- Sprache: Englisch

These sardines are iconic! They are freshly caught in the Atlantic off the coast of Porto every morning. After being treated with lots of love and processed entirely manually, they find their way into smart yellow tins before the day is out. This guarantees the unique quality and outstanding taste of these legendary fish. This is a book full of stories about and recipes for these silvery ocean inhabitants. The picturesque port of Matosinhos and the impressive architecture of the Nuri factory are lovingly presented via descriptions and pictures. Diverse and sophisticated recipes deliver the taste of the sea directly onto our plates. Pasteis de sardinhas, pao de frigideira with sardines and salsa, fish soup with sauce rouille and pizza de batata … Enjoy trying out all the recipe ideas!

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 149

Veröffentlichungsjahr: 2022

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

THE BIGNURI SARDINECOOKBOOK

HOW THE FISHGOT INTO THE TIN ANDTHEN OUT ONTO OUR PLATES

EDITED BY JAKOB GLATZ

With texts by Anna Burghardt &recipes by Andres Stirn

THE TINNED SARDINE PRODUCED BY HAND

Preface by Jakob Glatz

THE ROUTE OF NURI SARDINES

From Portugal out to the world

THE NATURE OF THE SARDINE

Sardines love company

A good catch

Only the seagulls don’t make a bid

A fighting spirit is needed – fish buying is a tough business

TIME FOR THE FINISHING TOUCHES

The stars of the show arrive

Making the difference – typical Nuri spices

How the sardine becomes canned

THE HISTORY OF THE “FÁBRICA DE CONSERVAS PINHAIS”

Work for generations

MEALTIME

Why write a cookbook on tinned sardines?

TAPAS

From kohlrabi salad to grilled spring onions

COLD DISHES

From blood orange salad to celery vichyssoise

HOT DISHES

From leek pockets to pizza da batata

BASICS

From Nuri butter to port wine onions

Index of recipes

PREFACE

Every tin of Nuri is part of a living tradition. A production process which has simply refused to change for a 100 years. The same factory, the same marble tables, the same recipe day in and day out.

— JAKOB GLATZ —

I’ll never forget my first visit to Portugal. It was the autumn of 2002. I was just 24 years old and was on a business trip to Matosinhos in order to meet one of my family’s most important and longest standing partners. My father had been tragically killed in an accident a few months previously, and responsibility for our family company now rested on my shoulders. On the evening of my arrival, I wanted to explore Porto and took a taxi into the center of the city. I was, however, unaware that the old quarter was the most dangerous part of the city. Sinister figures seeking to accost and rob guileless visitors were not the problem. There weren’t any such shady characters there. The key risk for any passer-by was being crushed under pieces of masonry falling from façades. I saw entire streets lined with hundred-year old buildings that were in a serious state of dilapidation. They had been braced with makeshift supports and then boarded up. Pieces of rubble which had obviously broken off recently lay around on the sidewalk. The heart of the city, which had once been so magnificent, had practically died out and had been left to decay for decades. Porto was a sad and bleak city on the edge of Europe. The state of the city was a legacy of Salazar, whose long period of dictatorial control in Portugal had isolated his country and sucked it dry.

These initial impressions left me in a somber mood early the next day as I set out for Matosinhos, one of Porto’s suburbs. Matosinhos has a population of almost 300,000. At the start of the 20th century, a scheme was devised to establish an industrial area in the southern part of the town, right behind Portugal’s second largest port. These plans were implemented exactly as they had been conceived on the drawing board. The main focus at the time was on the canned sardine industry, a sector which was undergoing strong growth. Immediately after the Second World War, the orthogonal streets of Matosinhos Sul were home to more than 50 fish factories, of which only two remain today. The ruins of dozens of former factories lined my route both to the right and the left as I progressed along the straight, wide thoroughfares. I glimpsed collapsed roof trusses and piles of debris through the window openings. Many of these skeletal structures even had trees growing out of the windows and along the edges of their façades.

Suddenly, in the midst of this apocalyptic setting and seemingly unaffected by the surrounding dereliction, the “Conserveria Pinhais” loomed up before me. Its factory building was patinated, but not shabby or rundown. The appearance was like an elegant, elderly lady who is able to keep her composure despite all the tribulations of life. This ornamental building dates back to a time when functionality and efficiency were not the be all and end all. There was a place too for external beauty which showcased the quality of the product and the manufacturing process.

I was greeted almost as soon as I got out of the car and was led through the magnificently tiled entrance hall, up a broad, curved staircase and into a wood-paneled office, where I waited for Senhor António Pinhal, the primary owner and Managing Director at the time. After a few minutes, a gaunt 83-year old man entered the room. Despite being barely five feet tall, he radiated an imposing presence and authority. Senhor Pinhal had already guided the fortunes of the company for 55 years and was to continue in this role until his death seven years later.

As Senhor Pinhal didn’t speak any English, we conversed in French as best we could. Every few minutes, he announced in a tremulous voice that quality was the primary concern. “La qualité, la qualité, la qualité, Monsieur Glatz!” He explained to me that quality was behind his firm’s conscious choice to do without modern machinery. Everything was still done by hand, just as was the case back in 1920. Quality was also the reason why the company survived, unlike the other 50 canned sardine factories. After a tour of the factory and a bite to eat, I was hooked. I lost my heart to “NURI” once I had seen how this unique place operates in accordance with an immutable tradition to wrap tins of sardines in yellow paper adorned with a flowery logo. I asked myself what makes the brand so popular all around the world?

Some say that Nuri is an iconic product. Others are simply taken by the yellow tin, which they have known since childhood. Nuri is a product which was always in their parents’ or grandparents’ pantry and which is somehow an integral part of the kitchen. Virtually everyone in Austria is familiar with Nuri, the hand-produced tinned sardine from Portugal. People of all age groups and social origins have embraced its taste. It can be found on the kitchen shelves of construction workers and museum directors alike. In Curaçao, the annual arrival of a container of tins of Nuri even precipitates a public festival including radio announcements and events staged all over the island.

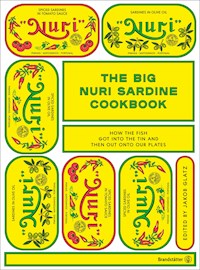

Some people regard Nuri as a lifestyle. Its Portuguese origins are clearly visible from the packaging of the tin which features a richly decorative design in a friendly yellow hue. This design has remained almost unchanged for a century and exudes a lighthearted appearance like the azulejos which adorn the façades of the buildings in Porto. It awakens a saudade, a yearning and a sense of nostalgia for an era in which everything was easier, slower and perhaps better. Every tin of Nuri preserves a piece of the past and encapsulates a living tradition. A production process which has stubbornly refused to change for a century. The same factory, the same marble tables, the same recipe year in and year out. An island of calm in a sea of food products which is always evolving. The proud counterpart to innovation – semper idem.

My family has been associated with the Nuri brand, with the Conserveria Pinhais and with the Pinhals for three generations. These many decades of close collaboration and partnership have also enabled us to rescue the company in Matosinhos from its impending demise and to continue the history of the factory. After the centenary celebrations of 2020 and the opening of our “Nuri Museum”, which allows visitors to tour the shop floor and experience production first hand, we have now decided to publish a cookbook. The Big Nuri Sardine Cookbook is aimed at die-hard Nuri fans who would always have a supply of tins at home. It is also aimed at cookery enthusiasts of all abilities who are keen to find out about the qualities these small fish can offer. Our aim is to show the multitude of opportunities offered by Nuri in the kitchen. Our aim is to feature recipes with Nuri that can add brand new flavor dimensions.

Coming home on a Sunday evening and enjoying a tin of Nuri with a slice of wholesome bread and a glass of wine will always remain one of life’s small pleasures. But Nuri sardines are capable of far more. They are suitable for use in a wide range of hot and cold dishes. Their complex intensity makes them an ideal option for spicing up and enhancing many a long-familiar recipe. Both Nuri mayonnaise and Nuri butter are unbeatable and I can heartily recommend the various tapas, cold dishes and delicious salads described here. Nuri quiche and beef tartare with added Nuri are also well worth trying out. Our hot dishes are all based on a generous portion of Nuri. You will find quick pasta recipes, a “frango Nuri” and a Nuri fish soup which is amazingly quick to make. This is one of my absolute favorite recipes!

There are two prerequisites for anyone wishing to dedicate a cookbook to a single food brand. Firstly, both the manufacturer and the publisher must be fully on board with the idea. The book’s audience also needs to trust that the nature and quality of the product will not change. This would mean that the book and its recipes don’t lose relevance over time. I’m totally convinced of the product and I’m confident that all those who know and love the brand will feel the same way. Our aim is for this book to stand the test of time, just like our sardine factory, enabling the artisanal knowledge contained in the recipes to live on. Nuri sardines themselves are a craft trade product. They aren’t like the kinds of industrial food products which are churned out by the highly efficient and automated machinery operated by major manufacturers. Nuri is an example of the preservation of cultural skills. Our aim is to provide you with at least the same pleasure as is derived from eating the sardines straight out of the tin.

So much has happened since my first visit to the factory twenty years ago. The center of Porto has been almost completely renovated and is teeming with tourists, shops and small, trendy cafés. The ruins of Matosinhos Sul have given way to parks or else have been redeveloped into residential buildings and hotels. This small suburb, which has its own beach, has blossomed into one of the most popular places to live in the region. The Nuri factory has also been fully refurbished and has opened its doors to international visitors, who are now able to observe how the staff – comprising around 100 women and a significantly smaller number of men – work every day to prepare the world’s best sardines.

The route of Nuri Sardines

FROM PORTUGAL OUT TO THE WHOLE WORLD

In the inter-war period, who could have imagined that Nuri fan merchandise would be produced one day?

The canned sardine bug is all too easy to catch. The Viennese entrepreneur Konrad Glatz fell hopelessly in love with the tinned sardine whilst on a trip to Portugal during the inter-war period. He was smitten by the sense of eager anticipation associated with the ritual of opening the tin, by the tidiness of small fish lying next to one another, by the full-bodied flavor and by the juicy flesh full of healthy fats. He was unable to shake off the bug and took the selfless decision that he would attempt to convert as many of his compatriots as possible. And so it came to pass that the company Glatz GmbH und Co KG, founded in 1892 in Vienna to “trade in milled products”, started to import cans of Nuri sardines to Austria in the 1950s, as it has continued to do to this day. Nuri canned sardines are packaged in a striking form of cellophane bearing an iconic logo (complete with the novel addition of inverted commas on either side of the brand name). Ever since their market launch, Austrians have always considered Nuri sardines to be something special.

In 1960, both Austria and Portugal became founder members of the European Free Trade Association alongside a number of other countries. Portugal still possessed numerous colonies at this point in history. These included Macau (now a Special Administrative Region of the People‘s Republic of China), Mozambique and Angola in Africa and Goa, which went on to become one of the federal states of India. Writing about “Portugal as a trade partner” in a special supplement to the Austrian daily newspaper Die Presse, Julius Raab, the Federal Chancellor of the day, was on hand to extol the enhanced economic links that now existed between the two countries. Raab made explicit mention of Portugal’s luxury food products. The same supplement also contains an advertisement by Nuri, where it is written, “The delicious speciality!” and “Spicy flavorings!” while also promoting Matosinhos as the place of origin. Portuguese provenance was a key element of Nuri’s brand identity at the time, as it still does today.

Nuri enjoyed success for several decades before its producer, the company Pinhais based in the cannery district of Matosinhos, was affected by a severe crisis caused by the introduction of a fishing ban in Portugal in 2015. Both senior managers and numerous local families feared for their jobs. Some employees had been making their living from the tinning factory for generations. Mothers and daughters dealt with the tail fins, spices, oil and cans, while fathers and sons handled the steam ovens and griddles. The factory employed around 120 staff (mostly women) who often began as teenagers and would remain loyal to Pinhais until they retired.

Numerous hand movements are required in order to get the sardines into their tins.

Nuri celebrated its centenary by opening a shop in Vienna.

In 2016, the Vienna-based entrepreneur Jakob Glatz acquired the Pinhais company together with its listed factory building, thus ensuring that the tradition of canned sardines could continue.

The shortage of sardine stocks off the coast of Portugal even started to jeopardize the future existence of the factory. The workforce now had major concerns regarding their future. Jakob Glatz, the fourth generation representative of the Vienna-based entrepreneurial family was prepared to step in to save the day. After all, close business and personal ties had existed with the production facilities in Portugal for many decades. In 2016, Jakob Glatz made a relatively spontaneous decision to acquire Pinhais in its entirety, including the listed factory building. By this time Pinhais was one of the very few remaining canned sardine producers in a port which had once buzzed with activity. He was thus able to ensure that skilled sardine production work would continue in Avenida Menéres and that a company that was steeped in history would not fall into the hands of property investors.

The new owner from Vienna made only a few interventions to improve the appearance of the factory which was more than a century old. The entrance area complete with its sweeping staircase and curved banister remained intact, as did the ordering hatch on the ground floor. The latter still provides a quirky feature. In the production hall itself, Jakob Glatz introduced a few modernizing measures where necessary and did not affect staff numbers. One of the key arguments for buying the factory in its entirety had been to continue to work by hand.

Transportation of the fish from the tables where the tins were filled to the can sealing machine was the only step which became automatized. Previously, the open cans of sardines had been artistically stacked before being carried over on foot (by female members of staff who sometimes looked like midwives taking care of newly born babies). Today the cans are sent to the next work station by conveyor belt to have the oil added and to be sealed. Ultimately, not even the most sensitive of palates will notice how the end product happened to be transported from point A to point B. And this approach also means that more staff can be deployed to fill the tins.

The centenary of the Fábrica de Conservas Pinhais in 2020 was also marked by celebrations at Nuri. To mark the occasion, a small Nuri shop was also opened in the Herrengasse in Vienna. Its stylish design by Atelier Karasinski in Portuguese tiles, marble and wood makes reference to the materials of the historic canning factory on the Atlantic. Alongside classic Nuri tins of sardines, stocks also include special varieties such as horse mackerel in spicy tomato. Hardcore fans can also opt for a range of yellow clothing bearing the Nuri logo. Everything from socks to umbrellas are available. If Nike, then why not Nuri?

The various faces of tins from the Fábrica de Conservas Pinhais.

A collection of vintage sardine lifters from past decades shows how the fish can be stylishly extracted from their carriage once they have made the journey from Portugal. The sardine lifters on display come in various designs, but all have a broad “ship” (the specialist terminology preferred by table culture experts). This is deployed to lift out the contents of the can in an elegant fashion avoiding the necessity to poke around clumsily.

The top floor at the Fábrica de Conservas Pinhais