Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Ullmann Medien

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

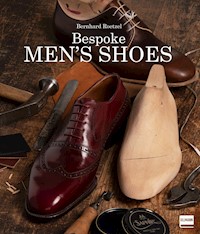

Shoes are the basis for a good appearance. Handmade bespoke shoes guarantee well-being with every step and are at the same time a perfect example of a sustainable product. Because bespoke shoes are still made exclusively in handicraft businesses today. No matter where and how big the workshop is, the working techniques, tools and raw materials are the same everywhere. Every craftsman has only one goal: the perfect shoe for his customer - whether boots, patent leather shoes or slippers. "Bespoke Men's Shoes" shows how a pair of shoes are made in the workshop of the Berlin bespoke shoemaker Korbinian Ludwig Hess is created - in all details, from raw lasts to finished polished shoes. In addition, the book offers a lot of interesting facts about shoe topics, fit and shoe care and provides important information and addresses for everyone who dreams of bespoke shoes.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 218

Veröffentlichungsjahr: 2022

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

MEN’S SHOES

Bespoke

© Ullmann Medien GmbH

Project management: Daniel Fischer

Design, layout & ebook production: Erill Fritz, Berlin

Editorial: Kirsten Lehmann

Technical advice: Korbinian Ludwig Heß

Cover design: Beate Lennartz and Dirk Diederich

Cover photos: Martin Josef Smolka and Tommi Aittala

Translation from German: Rebecca DeWald

English editorial: Elizabeth Gilbert

Photographic assistant / styling: Lilli Charlotte Liebchen

Overall responsibility for production: Ullmann Medien GmbH,

Rolandsecker Weg 30, 53619 Rheinbreitbach, Germany

ISBN 978-3-7415-2686-2

10 9 8 7 6 5 4 3 2 1

www.ullmannmedien.com

Imprint

Bernhard Roetzel

Photography by Martin Josef Smolka and Tommi Aittala

taken in the workshop of Korbinian Ludwig Heß

MEN’S SHOES

Bespoke

4

Contents

6 Foreword | 8 Introduction

10 History

12 A Short History of Shoe Styles | 16 Bespoke Shoes: Past and Present

20 Makes

23 Welted | 24 Stormwelted | 25 Wood-Pegged

26 The Fit

30 Shoe Size Systems | 32 The Dream of the Perfect Fit

34 Men Wearing Bespoke: Marcus Schramek

36 Shoemakers

39 Selected Workshops

46 Measurements

48 Wanted: Maker of Dream Shoes | 50 The Consultation | 52 Measuring the Foot

56 A Reproduction of the Foot | 58 Shoemakers: Benjamin Kleman

60 Lastmaking

62 The Wood | 64 Constructing a Last | 68 Shoemakers: Alexandru and Lucian Maftei

70 The Upper

72 From Measurements to Style | 74 From Style to Uppers | 76 The Pattern

78 The Paper Form | 80 Clicking the Uppers | 82 Stitching the Uppers

88 The Trial Shoe: Pros and Cons | 90 Building the Trial Shoe | 92 Trial Shoe Fitting

94 After the Fitting | 96 Men Wearing Bespoke: Andrej Kupetz

Contents

5

Contents

98 Raw Materials

100 From Hide to Leather | 102 Leather A to Z | 104 Cordovan | 105 Exotic Leathers

108 Leather Soles from the Pit | 112 Rubber and Plastic Soles

114 Further Upper Materials | 116 Men Wearing Bespoke: Maximilian Mogg

118 Shoe Styles

120 Shoe Components | 122 The Oxford | 124 The Brogue | 126 The Wholecut

128 The Derby | 130 The Norwegian | 132 Buckled Shoes | 134 Slip-Ons

136 Ankle Boots | 138 Boots | 140 Mountain and Hiking Boots | 142 Evening Shoes

144 Summer Styles | 146 Shoemakers: Saskia Wittmer | 148 House Shoes

150 Men Wearing Bespoke: Torsten Grunwald

152 Construction

154 Upper, Insole and Welt Are Stitched Together | 166 Constructing the Lower Parts:

Sole and Heel | 176 The Shoe Is Completed | 186 Men Wearing Bespoke: Martin Purwin

188 Care & Repairs

192 Folding the Cloth | 193 Polishing | 196 Oiling the Sole

197 Suede Care | 198 Repairs | 200 Men Wearing Bespoke: Alexander Kouril

202 Appendix

204 Which Shoe Goes with which Outfit? | 206 Men Wearing Bespoke: Jörg Woltmann

208 Glossary | 210 Index | 214 Photo Credits

Images with a red last icon are directly linked to the respective shoemaker.

6

Foreword

Foreword

Can someone who has never worn bespoke shoes truly write about them? That depends first of all on the nature of the text to be written and on the writer’s approach to the subject. A jour-nalist wearing sneakers can certainly write a readable account on Bespoke shoes, the crafts-people making them and the people wearing them. Equally, an essay on bespoke shoes as em-blematic of a particular way of life does not re-quire the author’s personal experience either. However, for anyone wanting to communicate to their readers the advantages and disadvan-tages of bespoke shoes, and what distinguishes them from ready-to-wear designs, it is vital to have tried them on and out – not only once, but several times, and this applies to shoes created by different shoemakers. Above all, the author needs to be a regular customer of shoemakers rather than someone only visiting a workshop with the aim of learning about construction methods purely to write about them.

I had my first bespoke experience in London in 1999. My tailor back then knew I was toying with the idea of commissioning bespoke shoes. He recommended Larson & Jehan, two craftspeople working in a basement workshop around the corner from him. When I went to pay them a visit, I noticed a last with the inscrip-tion “R. Lauren”. I asked: “You make shoes for Ralph Lauren?” The way they looked at me with a nonchalant shrug made me realize: neither of them knew who that was. And of course, they had never heard of my book The Gentlemanei-ther, which had been published in English only a short while earlier. I was a customer like any other. And, by the way: the shoes turned out very nicely and I still wear them today.

Bespoke shoes are not about boasting or showing off well-known labels. And even the most renowned bespoke shoemakers in the world have to start from scratch with every new

foot. If the shoe does not fit, even the most fa-mous name cannot fix that – so neither the shoe-maker nor the customer stands to gain anything from that. From this point of view, bespoke shoe-making might be even more difficult a profes-sion than men’s tailoring. In any case, their work brings bespoke shoemakers closer to the cus-tomer than any other craftsperson. Having one’s feet in socks measured, observed and examined is a completely different procedure from the one you would undergo at a tailor’s or a shirtmaker’s.

The pictures in this book, taken by photog-rapher Martin Smolka and Tommi Aittala in the workshop of Berlin-based custom shoemaker Korbinian Ludwig Heß, clearly show the prox-imity during the consultation, when taking mea-surements, and when fitting the shoe. Another kind of proximity develops between the crafts-people and the shoes they are building: taking into account the process of lastmaking, taking measurements and multiple fittings, Korbinian Ludwig Heß spends around 100 hours on every customer’s first pair of shoes. That is a long time – not only in relation to the price the customer pays for their bespoke shoes but especially considering the many years they will be able to wear them.

Bernhard Roetzel, 2019

Bespoke Oxfords for the author by Vickermann & Stoya.

7

Foreword

8

Introduction

Walk a Mile in My Shoes: what sounds like an idiom is the title of a Joe South (1940–2012) song from 1968. In it, the US-American singer calls on people to put themselves in other people’s shoes, as it were, instead of criticising them too soon. Here, the image of the shoe rep-resents much more than the well-known adage asking people to look at the world through an-other person’s eyes. However, shoes are neither a part of the body nor a sensory organ, but simply something we wear on our feet. They differ from other clothes in that they literally “ground” us: through their soles, we are connected to the face

of the earth, while this protective barrier simul-taneously separates us from it. And yet, shoes are very close to us, because we stand in them with all our weight and load. If they get too close to us in the wrong places, we get sores and the shoes can become a torment. A well fitted, worn-in shoe, on the other hand, is extremely pleasant. It is often considered to be the epitome of famil-iarity, of something old we prefer over some-

A black Oxford with toe cap, handmade in the workshop of Korbinian Ludwig Heß in Berlin. We will follow the making of this particular shoe in detail throughout this book.

9

Introduction

thing new, even if the latter may look more at-tractive at first glance. If someone was to walk in our shoes, they would partially perceive the world the same way we do – their sensory im-pression would either be pleasant or unpleasant, depending on how well the shoes fit.

Almost everyone is interested in shoes since only very few people walk barefoot in their daily lives. And a lot more people are interested in bespoke shoes than in custom-made suits be-cause many are tempted to try out the former, at least once in their lives. Those of us who do not exclusively wear sneakers – which softly cushion the foot all round due to their thickly padded soles and their soft upper material – will have experienced, more than once, the discom-fort or even pain an ill-fitting, constricting shoe can cause. Nevertheless, for most people, be-spoke shoes remain an object of another world, a mere fantasy or pipe-dream, ostensibly because of their price tag, but often because people have other financial priorities: cars, kitchens, holidays or smartphones are considered more important. Another reason may be that people are afraid of entering another world. Are custom-made shoes not something for, quite literally, well-heeled managers or millionaires? Or just something for people with real foot issues or problematic feet? The present book aims to alleviate this fear since more people can and should be able to af-ford themselves bespoke shoes! For comparison: a pair of bespoke handmade leather shoes costs about as much as a good electric guitar, a decent ride-on lawnmower or a digital SLR camera, de-pending on the manufacturer.

The bespoke shoemaking industry is un-dergoing radical change – this is something of a permanent state of affairs for this craft, which has had to react to competitors since its begin-nings in the Middle Ages. Nevertheless, the chal-lenges of today are particularly great. When it

comes to footwear nowadays, the majority of people’s first choice is sneakers and casual shoes made from various materials. Leather shoes are chosen less and less often, and some people never wear them at all. On the other hand, young men are rediscovering custom-made shoes. There are countless instructions online on how to make your own DIY shoes, students are in-vesting their savings in their first bespoke pair made by affordable shoemakers in Hungary or Romania – and some secondary-school gradu-ates even choose a shoemaker’s apprenticeship over a university degree. Thanks to numerous customers from the USA, Asia and continental Europe, London still boasts several legendary workshops. From a design point of view, how-ever, Italy and France, but also Vienna and Japan, above all, are playing centre-stage. Some of the best bespoke shoemakers in the world today are based in these locations, yet China and Korea have also produced many talented craftspeople. In addition, new trends raise fundamental ques-tions for the craft: What shoes do I wear if I’m vegetarian or vegan? Is tanning harmful to the environment? What kind of toxins are in the adhesives and plastics, and are there alternative materials for uppers and soles?

Customers commissioning leather shoes from independent shoemakers at least know with relative certainty that the craftsperson experiences a sense of achievement through their work – that was the impression I gained repeatedly when researching and taking photo-graphs for this book. Constructing well-fitting, beautiful and long-lasting shoes from naturally grown materials formed on wooden lasts pro-vides the maker with a sense of satisfaction. In return for their money, the customer receives a pair of shoes that suit them in every way and help them walk and stand on this earth in a more conscious way!

Introduction

History

It is unclear when our ancestors began wearing shoes. We can only speculate on their footwear from depictions in art. These can be found in Palaeolithic cave paintings as well as in Ancient Egyptian reliefs and statues from An-tiquity. Whether people wore anything on their feet at all depended not only on their evolu-tion but also on the climate and environment in which they lived. Towards the end of the Stone Age, hunters began to wrap animal hides around their feet. The “original” shoe, however, in its de-sign as footwear with a firm sole, was the sandal – and its basic construction has remained the same ever since: a sole produced with varying manufacturing styles is fastened onto the foot through straps. These straps could either wrap around the foot in different ways or run between

the toes. Not everyone wore sandals, of course, as they were often reserved for higher-ranking groups of people. During the time of the New Kingdom of Egypt (1551–1071 BCE), sandals were regarded as luxury items, usually made from papyrus, palm leaves or leather. The Pha-raoh even wore sandals made from rolled silver or sheet gold. The soles of sandals were even-tually bent upwards at the front to protect the wearer’s toes, which led to mixed styles halfway between a sandal and a closed shoe. The Assyr-ians extended the heel seat to the instep, which provided more support and better protection for the foot. The Syrians, Medes, Phoenicians, Persians and Hebrews all wore covered shoes as well. These were generally made by wrapping a piece of leather around the ankle and fastening it

Shoe illustrations in the catalogue of an English manufacturer, dated 1905. Shoe styles today differ only slightly from those of the early 20th century.

12

History

at the front with hooks, laces or loops. Persians also had boots and half-boots, which were later adopted by many peoples of Asia Minor.

In Greece, the cradle of European culture, sandals were the footwear of choice. But people also wore carbatinae, a type of one-piece tied shoe, as well as fur-lined and felt shoes, in ad-dition to a halfway form between a sandal and a closed shoe, the crepida, which had tacks nailed onto its sole. Overall, people in Ancient Greece wore a vast array of different sandals and shoes. The shoe culture of Ancient Rome was equally rich, if not richer: the Romans integrated even more shoe styles borrowed from other peoples into their wardrobes than the Greeks, such as the Tyrrhenian sandal worn by the Etruscans. This sandal featured a wooden sole, nailed to the bottom of the shoe, and was covered with bronze sheet along the sides of the foot. At times, the thick wooden soles featured hinges to make them more flexible. The Romans generally con-

sidered footwear as a symbol of identification of the wearer’s social status. For example, city dwellers wore closed calceus shoes, while magis-trates donned their purple mulleus. Rural people and slaves, on the other hand, walked around wearing the sandalium, a wooden sole with a strap; soldiers wore the famous caligae. From the 6th century CE, shoes increasingly featured toe and heel caps. The feet of rulers were adorned with shoes covered in precious stones and pearls, their design resembling opanci, the European counterpart to moccasins. Bishops adopted this type of shoe, and even the German emperors’ coronation shoe bore this shape. Wooden shoes were still widely worn as well, in the shape of ga-loshes or pattens. Both were shoes designed to be worn above and underneath the actual shoe, re-spectively, to protect it from dirt or water. North of the Alps, the men of the early Bronze Age usu-ally wore foot and leg wraps, as well as one-piece tied shoes from the Middle Bronze Age onwards. These resembled moccasins in that the upper ex-tends from the sole and is closed above the in-step, that is, the upper material is the same as the outer sole. From the 4th century onwards, Roman shoe styles were adopted. Until the 11th century, sock shoes extending up to the calf were common, a variation of the Roman caligae with its crossed straps.

In the Middle Ages, shoes started to be in-fluenced by Coptic and Oriental styles. Shoes became more sophisticated, with upper and sole made from different types of leather, held to-gether by a welt. At that time, distinct lasts for the left and right foot were already in use, and

A Short History of Shoe Styles

Sandals were the most important Roman footwear style. The statue of Roman Emperor Antoninus Pius (86–161 CE) in front of a reconstructed Roman camp in Saalburg near Bad Homburg shows his calf-high sandals.

13

History

Three types of medieval shoes: all three styles have a long, pointed toe in common, yet are otherwise very different. The shoe at the top shows that different lasts were used for the right and left foot, while the most striking feature of the two styles below is the decorated upper.

the cordwainers’ profession split from other leather trades, such as tanners and bag makers, and formed guilds. Peasants carried on wearing traditional one-piece tied shoes made from tex-tiles, fur or leather until the 17th century, as well as half-boots, into which they tugged the trouser legs. Shoes and footwear for members of the upper estates became even more distinct in the 12th and 13th centuries: there were slip-on shoes with clasps and buckle closures, san-dals made from plaited material or leg wraps with reinforced soles. In the 14th century, cra-kows became fashionable: their exaggerated long toe was sometimes stuffed and, towards the end of the century, it was bent upwards and deco-rated with bells. As a guard against faeces in the streets, pattens were worn underneath crakows. In the 15th century, the crakow returned to a less extreme form and was eventually worn by the urban bourgeoisie as well as by craftsmen and peasants. The length of the toe cap, however, was regulated in official dress codes: at court, for ex-ample, the tips were about two feet long and had to be fastened to the wearer’s leg with chains. At

the end of the 15th century, the crakow fell out of fashion; it was replaced by the cow-mouth shoe. For reasons unknown, the distinction between the right and left shoe was abandoned again in the 16th century, perhaps due to the wide shape of newly fashionable styles. Around 1600, the heel first made an appearance. Throughout the Middle Ages, it had remained entirely unknown. During the Thirty Years’ War (1618–1648), men’s shoes were replaced with boots; only in areas that had been spared by the war did men of the upper classes wear heeled court shoes. From the mid-17th century onwards, the buckle became the shoe’s most important decorative element. Small and oval-shaped at first, it grew in size from the mid-18th century onwards and was then often square or rectangular. The heel was stacked by layering pieces of leather; red heels were the re-serve of the nobility. Boots then were only worn for hunting or as part of one’s professional cos-tume, such as by postilions. It was not until the 1770s that light boots became fashionable again among pedestrians. In terms of shoe fashion, the escarpin with its wide opening gained in popu-

14

larity, while its heel gradually disappeared over time. By the end of the 18th century, lower jockey boots had become the most desirable footwear.

In the 19th century, industrialized footwear production made significant progress thanks to important inventions and developments. From 1821 onwards, lasts were produced in a pro-duction line on a lathe; in 1856, the first leather sewing machine came on the market, which ac-celerated the production of uppers. For the con-struction of soles, the McKay stitching machine from 1869 was of great importance. It was fur-ther improved through patented inventions by US-American entrepreneur Charles Goodyear Jr. and made it possible to stitch the upper onto the welt and insole – a strenuous and labour-in-tensive step in the manufacturing process until then. Goodyear later developed another ma-chine that stormwelted the outsole onto the welt. Both machines revolutionized the production of welted shoes and are in use to this day by manu-facturers of these types of shoes; bespoke shoe-makers, however, still stitch by hand. From then

on, shoes became asymmetrical again, distinctly fitting the left and the right foot. Ankle boots be-came the most important men’s shoe and were fastened either with laces or buttons, at the side or down the centre. Thanks to the invention of vulcanization, the pull-on ankle boot with elas-ticated gusset came into fashion from 1839 on-wards; it made the cumbersome act of lacing or buttoning-up superfluous. In the last two de-cades of the 19th century, three English shoe styles still considered to be classics began their rise to popularity: the Oxford, the Derby and the brogue. The escarpin as a day-time shoe fell completely out of fashion – with the exception of its rare use as part of ceremonial dress or at court – and only survived in the context of evening at-tire. Variations on these basic shapes have en-riched the range of styles since 1900; in addition, buckled shoes and various ankle boots with elas-ticated gusset or lacing have survived. New kinds

Right: This illustration from 1877 shows various styles from the 16th and 17th centuries, including numerous riding boots, women‘s shoes and children‘s shoes.

Left: Two men in 17th-century clothing. Illustration in the Münchner Bilderbogen, a magazine published from 1861 to 1880. Noteworthy are their high-heeled shoes, which were already welted constructions then.

History

15

of sports required new materials, such as tennis shoe uppers made from canvas. In the US of the 1930s, slip-ons became fashionable as smart weekend shoes; in Europe, these only slowly be-came popularized after the Second World War. In the 1950s, the footwear industry increasingly began to use a cemented manufacturing style for mass-market shoes. Welted shoes were increas-ingly pushed into an upmarket corner, and in the 1970s, most shoe factories stopped manufac-turing welted shoes altogether. Only in England, Spain, France and the USA did some manufac-turers hold onto this type of production, which began to pay off again a decade later, starting in the 1980s. The demand for bespoke shoes had declined sharply since the 1970s, and handmadeshoes became either luxury products for the rich or the only option for customers with ortho-paedic requirements. Even wealthy customers

lost interest in bespoke and instead opted for fashionable, quickly available mass-produced shoes. At the end of the 1980s, a slow revival of custom-made shoes set in, as a new genera-tion of customers found interest in high-quality, traditionally made footwear. People who were in their 20s then and developed an interest in welted shoes often have children of their own now, who are beginning to discover the world of bespoke shoemaking for themselves. Thanks to the internet and social media, they are able to learn more about this craft than any genera-tion before them – and perhaps they will keep the trade alive.

An insight into the workshop of bespoke shoemaker John Lobb in London: the photograph was probably taken in the 1950s. It shows Eric Lobb, the director at the time, who restored the company to its former glory after the war.

History

16

When we talk about bespoke shoes today, we think first and foremost of perfectly fitting footwear. Many men who might not otherwise be interested in high-quality clothing dream of shoes with exceptional fit. However, one must not conclude from this desire that bespoke shoes have always been particularly comfort-able. Up until the 18th century, during the Ba-roque and Rococo periods – when there was no shoemaking industry – every pair of shoes was specifically made for each individual. How well these custom-made shoes fitted is difficult to say. Simple rope-soled shoes or wooden clogs worn by peasants must have had a very different feel

from the sophisticated welted shoes with buckle worn by a prince. The boot of a craftsman, who would be on his feet all day long, differed from that of a professional horseman or the country gentleman, who mostly travelled by horse; the servant’s boot was different from that of a high ecclesiastical church dignitary, who would be carried around in a sedan chair.

Although the Greeks and Romans had al-ready produced differently shaped sandals for the left and right foot, in Europe of the 17th to the 19th centuries, shoes for both feet were pre-dominantly made on the same last. There was no distinction between the shape of the left and that of the right shoe, as it were. It was only in the mid-19th century that two lasts were used again to make a pair. It remains unclear why shoemakers would squeeze both feet into sym-metrical uniform models – though one theory is that it was because travelling cordwainers only carried one last per size with them. Shoe design might have also played a role in it. Sandals in ancient times were worn on bare feet, so it may have been obvious for the sole to trace the shape of the wearer’s footprint. In contrast, the cow-mouth shoe with its wide toe did not require any adjustment to fit either the left or right foot.

The new middle classes benefited from an emerging shoe industry towards the end of the 19th century. Yet, bespoke shoes remained the first choice of wealthy people until the early 20th century. Fashion was the be-all and end-

Bespoke Shoes: Past and Present

A framed sign testifies to the Viennese bespoke shoemaker R. Scheer & sons’ status as “Purveyor to the Imperial and Royal Court”. At the time of the Austrian monarchy, this designation was considered a seal of approval and therefore constituted the best kind of advertisement – above all, the court dictated what was fashionable. Even today, the term “purveyor to the court” serves to impress customers.

History

17

Time seems to stand still in the workshops of some bespoke shoemakers. This applies to techniques and tools as well