Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Lebensstil

- Sprache: Englisch

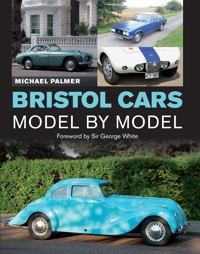

The Bristol badge sat proudly on a succession of fast, reliable and expensive 6-, 8- and 10- cylinder cars since 1946. Though it was initially revered by the motoring press, an air of mystery descended over the marque throughout the 1980s and 1990s. Now under new ownership, Bristol is to be reborn with new state of the art models proposed. As a compliment to the revival, this book celebrates the rich diversity of each model from Bristol Cars' production catalogue. Bristol Cars Model by Model provides a history of the development and production of each of the cars, including coachbuilt and racing models, and full specifications. It is richly illustrated with over 400 photographs.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 538

Veröffentlichungsjahr: 2015

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

BRISTOL CARS

MODEL BY MODEL

MICHAEL PALMER

THE CROWOOD PRESS

First published in 2015 by The Crowood Press Ltd Ramsbury, Marlborough Wiltshire SN8 2HR

www.crowood.com

© Michael Palmer 2015

This e-book first published in 2015

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication DataA catalogue record for this book is available from the British Library.

ISBN 978 1 78500 077 5

CONTENTS

Foreword by Sir George White, Bt

Dedication and Acknowledgements

Introduction

CHAPTER ONE

THE 400, 1946–1950

CHAPTER TWO

THE AERODYNES – THE 401 AND 403

CHAPTER THREE

THE 405, 1954–1958

CHAPTER FOUR

THE 406, 1957–1961

CHAPTER FIVE

THE DROPHEADS – THE 400, 402, 404 DROPHEAD COUPÉ, 405 DROPHEAD COUPÉ, THE BEAUFORT AND BLENHEIM SPEEDSTER

CHAPTER SIX

SHORT-CHASSIS CARS – THE 404, ARNOLT AND 406S

CHAPTER SEVEN

THE 412 AND BEAUFIGHTER

CHAPTER EIGHT

THE 450, 1953–1955

CHAPTER NINE

THE CAROZZERIA, CAROSSERIE AND SPECIAL-BODIED CARS

CHAPTER TEN

THE 407, 1961–1963

CHAPTER ELEVEN

THE 408 TO 410, 1963–1969

CHAPTER TWELVE

THE 411 SERIES 1–5, 1968–1976

CHAPTER THIRTEEN

THE 603, BRITANNIA AND BRIGAND

CHAPTER FOURTEEN

THE BLENHEIM, 1994–2011

CHAPTER FIFTEEN

THE FIGHTER, 2004–2011

AFTERWORD: Project Pinnacle – The Future

Index

FOREWORD

GEORGE S.M. WHITE, my father, was responsible for the Bristol Aeroplane Company’s entry into motor car production. He began work on the project around 1941 and saw it come to fruition in 1945. The Aeroplane Company itself had been founded by his grandfather and managed by his father since 1911. It was by then an industrial giant, with subsidiaries and agents throughout the world.

The Bristol publicity and photographic departments went into overdrive as the first cars were produced, encouraging universal interest from motoring journalists. Knowing that all their products were built to exacting aircraft standards and having complete confidence in their quality and design, there was nothing to hold them back. The company’s forays into motor sport, from the Mille Miglia to Le Mans, attracted worldwide attention. The era of the 2-litre cars, built to my father’s exacting standards, was a golden age.

So great was the Bristol Aeroplane Company’s size, that when the British Government forced mergers throughout the aircraft industry in the late 1950s, the company was split up. Its airframe business became part of the British Aircraft Corporation and its engine works became part of Bristol Siddeley and later Rolls-Royce. My father bought Bristol Cars in October 1960, bringing into partnership the company’s principal agent, Anthony Crook. The support of the aircraft company had gone, but the quality and widespread reputation of the products remained. My father retained management of the company and control over design, and perfection was his obsession. I well remember as a young man walking through the factory with him, watching him sending back cars for refinishing, because he had spotted the merest ripple in their paintwork. ‘Understated’, ‘elegance’ and ‘quality’ were the watchwords of those years.

My father retired reluctantly in 1973, following a serious motoring accident, and Anthony Crook bought out his controlling interest to become sole proprietor. As a young man and a Bristol agent, Anthony Crook had exploited his remarkable abilities as a showman to court publicity for the marque. He changed tack, however, as the years passed, favouring the creation of a wall of mystery and exclusivity around the company. By this means he built up a coterie of loyal customers for the cars he produced, but the marque itself slipped quietly from the general consciousness.

New ownership from 2011 onwards has, however, brought a new awakening. Kamkorp, through its subsidiary Frazer Nash Research, promises new models and advanced technology. Interest in the company has returned. The prices of classic Bristol care are climbing relentlessly. The forgotten legacy is being rediscovered. The Bristol marque is back.

This book is an extremely welcome part of that rebirth. Packed with technical information and exhaustively researched, it cannot but be a worthy and timely addition to every motoring library.

SIR GEORGE WHITE, Bt

Sir George White (nearside) with his son Philip (offside) with Sir George’s 1947 Bristol 400. SMG 117 was the first 400 to be sold to a member of the public. Car No. 400/A/103, engine No. 1017 was delivered to Colonel Aldington at AFN, to be sold on 16 May 1947.

DEDICATION

FOR MY SONS TOM AND HARRY. WE’VE LEARNED LOTS FROM EACH OTHER.

ACKNOWLEDGEMENTS

THANK YOU TO THE Bristol Owners Club and Bristol Owners and Drivers Association for help, advice and information, and to the Bristol Owners Club Heritage Trust for photographs.

My grateful thanks to the following BOC (Bristol Owners Club) and BODA (Bristol Owners and Drivers Association) members and individuals for their contributions, assistance and advice in writing this book:

Anatoly Arutunof

Marc Atkinson

Christopher Balfour

CLH Ball

Michael Barton

David and Philippa Bensley

Mark Berger

Adrian Berry

David Billington

Rodney Bisker

Alan Blackwood

Andrew Blow

Jonathan Bradburn

Clive Burton

Peter Campbell

Dr Stefan Cembrowicz

John Charlton

Gavin Coulthard

Tony Crook

David and Cathy Crownshaw

Dr David Dale

Ian Dalton

Peter Darby

Adrian Davis

Jamie & Susie Doggart

Andrew Dooley

Simon Draper

Andrew Dredge

John Dyson

Guy Ferrington

David Firth

Sam Frost

Charles Gallanaugh

Philip Goëzinger

Russell Gournay

Professor Vaughan Grylls

John and Gillie Hamshere

Geoff Hawkins

Jochen Hempel

Philip Herbert

Martin J Höermann

Leigh Hogben

Richard Howell

John Huntingford

Richard Katz

Richard Kemp

Edward Vincent King Jr

Hugh Knox

Lt Col (retd) Spencer Lane-Jones

Dr Richard Levine

John Manley

Justin Marozzi

Brian May

Peter McGough

Adrian Miller

Hugh Miller

Andrew Mitchell

Charles Nelson

Stefano Pasini

Andrew Passer

Richard Phillips

Philip Redfern

Stuart Risebrow

Mike Say

Dr Norman Shirlaw

Toby Silverton

John Sparkes

Hugh Stebbing

Ian Tonkin

Neil Turnbull

Richard Vaughan

Brian Wadsworth

Sarah and Richard Weale

Sir George White

Philip White

Thomas Wiggett

The following publications and publishers generously gave permission to use or reference their material:

Brooklands Books: BristolCars, Brooklands Portfolio

Car magazine

Classic Cars magazine

Classic and Thoroughbred Cars magazine

Evo magazine

Guernsey Press

Haymarket Publishing

Haynes Publishing: BristolCars. A Very British Story by Christopher Balfour

Octane magazine

Osprey Publishing: Bentley.Cricklewood to Crewe by Michael Frostick

Osprey Publishing: Historyof the Bristol Car by GC Oxley-Siddey

Palawan Press: A Private Car by LJK Setright

The following companies kindly supplied material or information:

Albion Classic and Sports Cars

American Car Centre

Bristol Cars

Chrysler Motor Corporation

Classic Automobiles Worldwide

Justin Banks Classic Cars

Mitchell Motors

Spencer Lane-Jones Ltd

Material was also sourced from the following internet sites:

Allpar

Bristol Owners Club

Automobile catalog

Carfolio

Wikipedia

Sharp, simple and unpretentious 407 Viotti styling was in line with Bristol philosophy.

INTRODUCTION

WITH A COMPANY SUCH as Bristol Cars, it is not easy to separate the product from the producer, particularly with individuals such as Sir George White, Tony Crook or Toby Silverton at the helm. However, rightly or wrongly, that is what I have tried to do here. Other authors have eloquently described the history of this exclusive marque, and I reference their works in this book, but I deal primarily with the cars, what the motoring press thought of them and the change in the relationship between the media and the motor company over Bristol Cars’ sixty-five-year history.

In the early days, the press were supplied with and enthusiastically reported on the products that emerged from the Bristol Aeroplane Company (Car Division) Ltd. As time passed, and developments in the motor industry moved forwards in leaps and bounds, Bristol Cars ceased to be a trend setter or a bench mark. More criticism began to be levelled at a succession of upgraded models, and as a result the cars ceased to be made available to the gentlemen or ladies of the press.

A high price always kept the cars exclusive and elusive. Those who could afford it got a road-going product developed and built to aircraft standards in terms of precision and workmanship. In the early days, Bristol made many of the components themselves, such as steering, gearbox and shock absorbers, contracting out only as supplier’s standards met their own. And of course, there was the engine: a six-cylinder gem of only 2 litres that performed as well on the track as it did on the road. Testament to its ability came from the legion of small manufacturers that installed it as their power plant of choice, either in their road cars or their racing vehicles. AC, Frazer-Nash, Lotus, Lister and Tojero, to name but a few, all used Bristol power.

From the first 400, through the 401 and 403, Bristol quickly carved a niche as a maker of comfortable, high-quality machines, capable of transporting four people and their luggage quickly and in total comfort. The 404 introduced the idea of a short-chassis sports car, while the 405 represented the firm’s one and only foray into the four-door saloon market. A return to the two-door format came with the 406, the last car to use the much-respected Bristol six-cylinder engine. In between were a variety of convertible and coachbuilt models, all based on their saloon counterparts, or, in the case of the Arnolt, a short-chassis derivation.

Plans for a bigger engine paired to an automatic gearbox had to be shelved due to the wider problems experienced in the British aircraft industry in the late 1950s. In order to survive, the Bristol Aeroplane Company was split into three divisions, with ultimate government intervention almost signalling the end of the Car Division. It was only the determination of George White to protect what he had started, and his subsequent partnership with Tony Crook, that kept the company afloat as the 1960s dawned.

Although the Bristol Six was highly respected, the company recognized that a new engine was needed. The new decade brought the power that the cars required. Launched to a fanfare of positive publicity, the 407 hid Chrysler’s 5.1-litre (313ci) V8 under its bonnet, transforming the ‘gentleman’s express’ into the gentleman’s ballistic and instantly rekindling the love between the motoring press and the marque. Progress was evolutionary, with styling changes for the 408, mechanical developments for the 409 and a mix of the two for the 410.

Funds were always tight but, throughout the 1960s, a series of imaginative and progressive developments, guided by Sir George White (who became third baronet following his father’s death in 1964) and Tony Crook, kept Bristol Cars in the public eye. Sir George White’s premature retirement, forced on him by injuries sustained following a horrendous car accident in September 1969, left Tony Crook in charge of the business. Following his purchase of the White family share, in 1973, Crook became sole proprietor and Bristol Cars once more became a limited company.

Tony Crook’s tenure saw the development of the 411 series, the introduction of the 603 saloon that replaced it and Bristol’s return to the four-seater convertible market with the 412. All were cars that stood up well to their contemporaries but, as the decades moved on, Bristol struggled to keep pace. The relationship between the company and the press became increasingly fractious, with a new breed of motoring journalist tending to dismiss Bristol as an irrelevance. Respected motoring journal Car, who never got to drive a Bristol, categorized the cars in their ‘good, bad and ugly’ section as ‘individual for an individual we’ve never met’.

The introduction of turbo power for the Beaufighter and Brigand coincided with a change from numerical identification to the naming of cars after Bristol’s war-time aviation products. As the firm became increasingly introspective perhaps the adoption of the name of another piece of war-time legend, Enigma, would also have been suitable.

Just as the three-box shape of the 406 was developed into its final incarnation on the 411, so the 603 morphed from Britannia into Blenheim, the body style subtly reshaped to keep pace with the times. But by now a new car was needed – one that could launch Bristol into the twenty-first century.

New boss Toby Silverton had been on the Bristol board since 1997, when he and his father had bought a half-share in the company from Tony Crook. His vision of a 200mph+ supercar prevailed and the concept, the Fighter, was revealed to an astonished press in 1999, with production models available by 2003.

Toby Silverton took full control of Bristol Cars in 2007. Production and development of the Fighter continued alongside that of the Blenheim 3, but Tony Crook was no longer with the company. Work on a fourth incarnation of the Blenheim resulted in only one example being produced and in March 2011 the banks pulled the plug on any further financing of the company, forcing Bristol Cars into receivership.

Rescue came from Kamkorp Autokraft, part of the Frazer-Nash Group, re-establishing the link with Bristol and its postwar collaborator. Now a UK-based research and development company engaged in the development of hybrid and electric powertrains, Frazer-Nash Research Limited has great plans for the Bristol marque. Director of Operations William Chia is confident that the Bristol brand will thrive under the Frazer-Nash umbrella, with ‘plans to combine Bristol Cars’ tradition and iconic marque with Frazer-Nash’s pioneering technology’.

So begins another chapter in Bristol’s history, and it is one that aficionados and enthusiasts alike will be pleased to see. In many respects, Bristol fell victim to its exclusivity but, thanks to increased publicity from the company and more coverage of the cars in the classic car press, there is now a greater recognition of the Bristol brand. The enthusiasm expressed by journalists reporting on the early cars is once more being echoed by their modern-day contemporaries.

As awareness of the marque increases, the passion that Bristol owners share in their enjoyment of the cars can only spread. I am reminded of a comment made by the owner of both a 405 and a 412, who advised me very early on in this project, ‘Don’t look at the cars. Drive them.’ I did and I want one.

CHAPTER ONE

The 400

1946–1950

‘IF HASTE IS REQUIRED, IT WILL GIVE SPEED AND ROAD-HOLDING WHICH MIGHT BE THE ENVY OF MANY A SUPER-SPORTS MODEL.’

(The Motor, 19 May 1948)

THE FIRST PRODUCTION CAR in a distinguished line of quality high-performance vehicles to come from the Bristol Aeroplane Company Ltd (Car Division) was the 400 of 1946. A four-seat close-coupled saloon, it was based on the pre-war BMWs, notably the 327 and 326, but developed and improved by Bristol engineers at the firm’s Filton factory.

EARLY DEVELOPMENTS

Although firmly established as an aircraft manufacturer, Bristol was not without previous experience in the automotive sector. Back in 1908 the firm had started building buses and commercial vehicles as part of the Bristol Tramway and Carriage Company, headed by Sir George White 1st Baronet. In 1910, Sir George, together with his son George Stanley White and his brother Sam White, had founded the British and Colonial Aeroplane Company. The firm’s managing director was G. Stanley White, who held the post from 1911 to 1955.

Sir G. Stanley White 2nd Baronet had managed the aeroplane company since 1911 and supported his son’s ambitions for the Car Division.

SIR GEORGE WHITE

At the end of the First World War, the firm’s board of directors were concerned to secure the jobs of their skilled workforce, following the rapid decline in orders for aeroplanes. Sir G. Stanley White 2nd Bt. (who had inherited the title on the death of his father, in 1916) and fellow board members Henry White-Smith and Herbert Thomas had then approved the manufacture of bus and coach bodies, along with bodies for the Armstrong Siddeley motor company. A prototype light car, the Bristol Monocar, was also given the go-ahead, but, with spiralling development costs and only two vehicles completed, the project was shelved.

A further venture involved the Cosmos Engineering Company, formerly the aero-engine department of Brazil Straker, under the management of Roy (later Sir Roy) Feddon. Following Cosmos’ slide into receivership, Bristol was pressed by the government to take the company on. The firm may have possessed engineering designs and materials of interest to Bristol, in particular its 100hp three-cylinder ‘Lucifer’ aero engine, but their proposed air-cooled small car had ‘few commendable features,’ according to Bristol board minutes.

Come the outbreak of the Second World War, Bristol once again forged ahead with aircraft development and production. However, Sir Stanley was all too aware that, at the end of the conflict, history would repeat itself. Back in 1918 all government contracts had been cancelled within two weeks, leaving the firm’s 4,000 employees with nothing to manufacture. Now responsible for a workforce of 70,000, he did not want to replay the experience of finding the company with a surplus of skilled labour as orders for the war effort dried up. The solution came from Sir Stanley’s son George.

PLANTING THE SEEDS

George S.M. White (Later Sir George White) was responsible for the Bristol Aeroplane Company’s entry into motor car production.

SIR GEORGE WHITE

Post-war planning was taking place as early as 1941 and George White was keen to see the Bristol name on the road as well as in the air. He believed that there was a section of the motoring public that would pay for a refined, well-engineered car, built with the same philosophy as the firm’s aircraft. Supported by his cousin and fellow director, Reginald Verdon-Smith, George outlined his ideas in a memo that was presented to the board. They fully accepted George’s proposals for the firm to once again utilize the company’s engineering prowess and the skills of its employees by moving into automobile production.

Fast forward to the end of the war and some of George’s foresight is clear. In suggesting the building of a complete car, not only would the jobs of the BAC workforce be saved, but such a venture might also succeed commercially, providing a worthwhile return for shareholders. However, even though the proposal was considered for the post-war period, at this juncture such a development started from scratch would require permission from the government. It would also be difficult to undertake the design and development of such a project during wartime. George’s proposal that the new car should be based on an existing design had a two-fold advantage: the time to production would be shorter and the cost of development would be cheaper.

DEVELOPING THE IDEA

Reginald Verdon-Smith (standing) with his sister and father, Sir William.

SIR GEORGE WHITE

To facilitate the plan, in 1944 consideration was given to the purchase of Aston Martin and/or ERA (English Racing Automobiles). Although nothing came of that particular sortie, an avenue did open up in 1945. Don Aldington, an RAOC (Royal Army Ordnance Corps) captain with responsibility for BAC’s vehicle allocation, casually mentioned to George White’s assistant, Eric Storey, that he intended to return to Frazer Nash with his brother Harold. Prior to the outbreak of hostilities their company, AFN, had acquired the sole rights to market BMWs in the UK, with the stated aim of manufacturing the cars under licence. If their plan to build a car to replace the Frazer-Nash-BMW was to bear fruit, the Aldingtons would need components manufacturing. Eric Storey soon passed the message on to George White, for whom getting work into the workshops was now a priority. A meeting was arranged between the Aldington brothers (representing AFN, the sales arm of Frazer Nash-BMW) and George White and Reginald Verdon-Smith for Bristol. It soon became clear that both Harold (HJ) Aldington and George White envisaged the production of an entire car, which would be light in weight and would offer positive steering and precise handling.

At a BAC board meeting following these discussions, Sir Stanley and his fellow directors were convinced of the case for expanding on component manufacture for AFN. As far as the production of an entire car was concerned, the Bristol Aeroplane Company had the finance, the skills and the factory space. Ultimately, by purchasing a controlling interest in AFN from the Aldingtons, the company acquired those rights and personal connections for BMW in the UK that had survived the war. However, with Bristol still reorganizing itself following the conflict, it was agreed that initially the manufacture of certain major components would be subcontracted out to approved suppliers.

THE DONORS

A pre-war BMW 327 alongside the Bristol 400.

BMW had gained a strong pre-war reputation, particularly with their 326, 327 and 328 models. Introduced at the Berlin motor show in 1936, the 326 was an innovative machine. It featured torsion-bar rear suspension, which provided exceptional ride quality, together with rack and pinion steering and hydraulic brakes. BMW’s Fritz Fiedler and chief designer Alfred Böning worked with Peter Schimanowski, who penned the four-door saloon. A convertible, with two- or four-door bodywork by Autenrieth of Darmstadt, was also available. Power came from a 1971cc six-cylinder overhead-valve engine, which produced 50hp and a top speed of 71mph (115km/h).

Also introduced in 1936, the legendary 328 roadster was again powered by the 1971cc straight six. A further 30hp was wrung from the unit, thanks to the efforts of Rudolf Flemming and Rudolf Schliecher, turned it into a formidable competition machine.

In 1937 Schimanowski’s styling flair was once again displayed with the introduction of the 327. Working with coachbuilder Autenrieth, the car was designed around a short version of the 326 chassis and was available as a coupé or cabriolet. Flemming and Schliecher’s 80hp engine could also be specified by those who felt the need for a 90mph (145km/h) top speed. In common with the 328, conventional leaf-spring suspension was felt to be better suited to this elegant 2+2. Rolling chassis of all three cars were to be supplied to Frazer Nash, and they were to be sold in the UK as Frazer Nash-BMWs.

HJ Aldington, who had owned the licence to the BMW 326, wanted to see a development of that car as the starting point with Bristol, with other sporting derivatives then being introduced. George White favoured the smaller BMW 327 as the starting point. He had other models in mind too, in particular a five-seater variant, with a view to moving into the family market. Certainly, from a manufacturing point of view, with the body construction being an important consideration, the 327 offered a simpler solution.

The finer points of the design could be sorted at a later date. First it was necessary to access the plans for the cars from the remains of the BMW factory. To that end, late in 1945, citing the need to access spares for any UK-registered BMW cars, a delegation from AFN and Bristol Cars flew to Munich to collect drawings for the BMW 326, 327 and 328, in addition to engines and other components.

POST-WAR REPARATIONS

The Allied Commission on Reparations was established before the end of the war, at the Yalta Conference in February 1945. It met in June and July of that year, drawing up agreements to limit the German economy to a capacity that could meet the minimum civilian need, with industry maintained to meet that need without Allied support. In addition, the Allies would be compensated in goods on the basis of their contribution and losses incurred in bringing about Germany’s defeat.

The plans were ratified at Potsdam in July 1945: briefly, no country was to draw reparations from any zone other than the zone allocated to it. BMW’s Eisenach plant fell into the Russian sector so was lost to the West, but Bavaria (and therefore Munich) fell under US control. The Western Allies tended to have a more relaxed approach to the agreement than the East. There can be little doubt, however, that the prospect of bringing work to and securing jobs in a major British company, together with the Aldingtons’ influence and contacts, helped to secure official government support for Bristol and AFN. As a result, Bristol received official approval for its acquisition of the BMW rights assigned to it under the terms of its agreement with AFN. With this approval, information and materials required for the production of the first Bristol car could be removed from the BMW factory in Munich.

DEVELOPING THE CONCEPT

Bristol was finally released from the government restriction on private ventures in September 1945. Development work for the nascent Car Division could now begin, starting with the removal and testing of the engine from an AFN BMW 327. Assessments were also carried out on the other engines that had been brought back from the Munich trip.

By May 1946, Bristol had developed the engineering of the BMW motor to produce their own engine. An early example of the unit was installed into the 327 and the new power plant was subjected to exhaustive testing and analysis. Meanwhile, the rest of the Car Division team was assembled, mostly from existing BAC employees.

Working from a stripped-down BMW 326, former production engineer Dudley Hobbs produced engineering drawings of components, converting their metric dimensions to imperial. At the same time, BAC’s metallurgy department evaluated parts and specified their manufacture using compatible or superior materials.

The 327 may have provided the style that Bristol was looking for, but George White wanted a car that could seat four in comfort. With its short wheelbase, the 327 lacked interior space, particularly at the rear. Plus, its leaf-spring rear suspension was considered to be inadequate for British roads. As a result, it was the 326 chassis with the torsion-bar rear suspension system that was adopted, together with some suitable styling changes. Power would come from the Bristol-engineered derivative of the 328 80hp engine.

A 400 outside Filton House. Tread rubbers on the wings were purely decorative.

BRISTOL CARS

An advertisement by Frazer Nash–Bristol announced the new car in September 1946, with deliveries of early models planned for early 1947. The car’s official unveiling on the world stage, however, did not take place until the Geneva motor show of March 1947.

SIR GEORGE WHITE 3RD Bt. AND SIR REGINALD VERDON-SMITH

George and Reginald were both appointed directors of the Bristol Aeroplane Company in 1942. George had joined the firm in 1935, having previously read engineering at Cambridge. He gained practical experience working on the shop floor in the engine works before becoming General Manager in 1940. In 1964, following the death of his father Sir George Stanley White (2nd Bt), he assumed the title to become 3rd Bt.

After achieving a double first in law at Oxford, Reginald Verdon-Smith was called to the Bar. At his father’s request, he joined the Bristol Aeroplane Company in 1938; as war loomed, the firm needed to expand its legal and administrative departments. He was knighted in 1953 and was Chairman of the Bristol Aeroplane Company from 1955.

In April 1943, George White was appointed Managing Director of the Aircraft Division, with responsibility for all aircraft production. At the same time, Reginald Verdon-Smith was given responsibility for head office administration.

When car production was first mooted and then began at Filton, it was under the auspices of the Aircraft Division and so was directly under the management of George White. Reginald, as an extremely competent administrator, naturally led in negotiations with AFN and the Aldingtons. But when the two separated again, George White took on the management of the newly formed Car Division in addition to his other responsibilities. These at that time included serving as joint Assistant Managing Director of the Bristol Aeroplane Company Ltd with Reginald Verdon-Smith, and as Chairman of the newly formed Plastics Division.

George White continued to control the Car Division (or Bristol Cars) until his retirement in 1973. From 1960 onwards, he was partnered by Tony Crook, but held the controlling interest in the company. A modest man, he countered Tony Crook’s exuberance, quietly playing down his pivotal role in the firm’s founding and his personal responsibility for driving Bristol Cars through some of its most successful years.

DESIGN

The new 400 with George White (far left) and Sir G. Stanley White (far right). George Abel, general manager of the Car Division 1945–54 stands next to Sir Stanley. H.J. Aldington stands by the car’s rearside ‘A’ pillar.

SIR GEORGE WHITE

Stand a Bristol 400 next to a pre-war Frazer Nash-BMW or BMW 327 and the similarities are obvious. Some would consider the Bristol to be cleaner of line in its external appearance and less ostentatious with regard to detailing than its German relative. Inside, thanks to the use of traditional wood and leather, trademark of the great British coachbuilders, the Bristol also offered a more luxurious ambience. According to The Autocar (9 January 1948), the Frazer Nash-BMW had ‘a considerable following among those who appreciate the finer points of motoring’. By using it as the basis for development, Bristol had managed to create a discrete and well-engineered vehicle, with performance and handling to match, in a remarkably short time.

In a letter to Reginald Verdon-Smith, then on honeymoon in Lugano (14 November 1946), George White wrote, ‘I know your views on the artistic qualities of our present Car Department and as I am more responsible for the shape of the body than anyone else, I am quite prepared to take what is coming.’ He need not have worried.

The term ‘connoisseur’s car’, coined by The Autocar in that same 1948 report, came to be used regularly in relation to many Bristol models. ‘Attractive to look upon, comfortable to ride in and a constant delight to handle,’ was the magazine’s justification for such high praise. George White, together with Dudley Hobbs and his team, could certainly take credit for giving the car a design that was described in the November 1946 issue of The Motor as the ‘modern cleaned-up type’.

A modern cleaned-up streamlined look: a high waistline, narrow glasshouse, sliding front windows, contoured bumpers, spare in the boot, and a top-hinged boot lid.

BODA

There was definitely a solid and more streamlined look about it. According to The Autocar (9 January 1948), it was a car ‘far removed from the ordinary run of cars’. Later in the year, The Motor (May 1948) praised the good aerodynamic shape, which was was proven by ‘the exceptionally direct flow of mud backwards along the bonnet and mudguards’.

Straight one-piece bumper with valance, and voluptuous bonnet and wings.

NORMAN SHIRLAW

The curvaceous front end was seemingly hewn from one sculptured panel. Stylized chrome sidelights were perched on top of the voluptuous wings, whilst the headlamps were faired in at each side of the flush centrepiece BMW-style grille. A clean, light look was enhanced by a tubular-steel chromed bumper, which followed the contours of the front panel and appeared to be gently cradled by over-riders curving up from beneath. Fitting more substantial pressed-steel bumpers with valence plates and over-riders to the later cars did little to detract from the stylist’s lightness of touch.

Raked and angled back from the centre to the ‘A’ pillars, the two flat windscreen glasses sat high on the scuttle, which, coupled with a reasonably high waistline, made the glass area quite narrow. In spite of this, The Motor, in its report on the car in May 1948, commented that ‘visibility from the driving seat is adequate’. Overall, the magazine felt that ‘there [is] good vision sideways as well as through the large curved rear window’. The door windows were of the sliding variety, a design feature criticized by Reginald Verdon-Smith. Despite this, the sliders remained for the production models, although at least one car did have winding windows specified.

The thick ‘C’ pillars were most prominent from the rear three-quarter angle, but so too was the curvature of the rest of the 400’s panel work. There was not a flat surface to be found and, at the back, the contours of the roofline cascaded down to bumper level, broken only by the fuel filler on the left-hand side of the car.

Early cars featured a smooth top-hinged boot lid, with the spare wheel housed on the front wall of the boot. Reginald Verdon-Smith was critical, feeling that the wheel was in an ‘impossible position’. Furthermore, in his opinion, ‘insufficient thought [has] been given to golf clubs’. The Motor (November 1946) agreed: ‘Luggage accommodation is somewhat impaired internally.’ The magazine did, however, concede that there may have been some rationale behind locating the spare wheel in the boot at the expense of luggage space, writing: ‘this feature will be considered by many justified on the grounds of appearance.’

As development of the cars continued, boot space was increased by lowering the boot floor by about 5in (100mm) and moving the spare on to the boot lid under a body-coloured aluminium cover. Although it solved the issues of both boot capacity and spare wheel access, the extra weight on the panel meant that it was necessary to hinge the lid at the bottom. This made loading of the compartment more awkward, as luggage had to be lifted over the rear wings. However, The Motor (May 1948) praised the move, noting the ‘generous’ boot space, at the same time reporting that ‘access to the spare tyre valve for periodic inflation would appear very desirable and not difficult to arrange’.

The tail lights were situated on the rear wings. Their glass lenses were sand-blasted on the insides to diffuse the white light of the reversing lights incorporated into the units. To present a red for the tail or stop lamp, the bulbs were covered with a red glass dome. The whole assembly was decorated with a chrome trim surround. As with the front-end treatment, the bumper bar that followed the rear-end contours was later replaced with a solid pressed-steel item and valence.

The spare wheel was moved outside. The lid was then bottom-hinged, with restraining straps holding it vertical when open, and there was a neat chrome trim for the body-coloured jacket. A valve for tyre inflation would have been useful.

Rear-hinged doors and a large door pocket featured on the early car.

BODA

Rear-hinged doors were opened by chrome handles; according to The Autocar (9 January 1948), they closed with ‘an expensive specialist coachbuilder sound’. Inside, illumination was provided by a courtesy light mounted centrally in the roof lining. Early models featured an interior trimmed in brown and beige leather. The door trims incorporated elasticated pockets, which were ‘vast in capacity,’ according to The Motor (19 May 1948). Later cars kept the colour scheme, but were trimmed with leather and cloth. Less room was given to storage though, as the door pockets had shrunk in size. Extensive sound-deadening on the floor was covered in expensive leather-bound carpet.

Later trim combination, with seats that were supportive and offered plenty of adjustment, including the backrest angle.

BRISTOL CARS

The Autocar (9 January 1948) praised the seating arrangements for the occupants up front. Not only did the seats have ample fore and aft movement, but they also had adjustable backrests which the magazine felt gave ‘good back support’. A little more elbow room was also available thanks to those sculptured door panels and sliding windows.

It was a slightly different story for those travelling in the back. In that same January 1948 report, The Autocar found the rear seating ‘comfortable’, but its testers felt that the seats were really only suited to ‘occasional use’. The 50/50 split cushion, as fitted to the earlier cars, certainly hinted at it being suitable for only two occupants; it was replaced by a onepiece item as production progressed.

The one-piece rear seat of the later car. Note the winder for opening the rear screen.

BRISTOL CARS

A substantial-looking wooden dash top incorporated the ventilation slots to demist each side of the windscreen, and the theme continued elsewhere with polished wood trim framing all the window apertures. The driver was provided with a ‘comprehensive array of instruments, fully worthy of a quality sports car’ (The Motor, 19 May 1948), including internally illuminated white on black Smiths dials, which were, in the opinion of the magazine, ‘easy to read’. An assortment of knobs and warning lights were set into the three-section wooden dash, which extended over to the passenger side, and according to The Autocar (9 January 1948), contributed to ‘a practical instrument layout’. The Motor (19 May 1948) noted ‘a pleasing union of movement between the speedometer and rpm needles in top gear’, despite their separation from each other. Unusual for the time was the standard fitment of a ‘radio set’, which was inset at the bottom of the dash. Its aerial was mounted front and centre on the roof.

The white (later black)-rimmed three-spoked steering wheel had the horn push at its centre and topped an adjustable column. This, along with the adjustable seating and wellpositioned pedals (which provided plenty of space to the left of the clutch for resting the left foot), contributed to what The Autocar (9 January 1948) described as a ‘very satisfactory’ driving position.

During his time with the prototype in Italy, Reginald Verdon-Smith had considered the ventilation blower to be ‘inadequate either to warm a cold car or cool a hot one’. The Autocar’s 1948 test car was equipped with an optional Clayton heater, situated above the transmission tunnel, an item that, in their opinion, proved ‘very effective’. Fresh ambient air could also be directed into the cabin via forward-facing scuttle vents, controlled by a lever in each of the footwells. It was a system that, combined with the rest of the car’s ventilation, was felt by The Motor (19 May 1948) to be ‘sufficient for spring time weather conditions.’

The long, wand-like gear lever was ‘well sited’ on the transmission tunnel according to The Motor (19 May 1948), ‘giving light operation’. In their opinion, however, ‘both clutch and gear action was best suited to leisurely operation’.

DASH KEY FOR THE 400:

1. Glove Pocket, 2. Speedometer, 3. Radio Control Panel, 4. Hand Ignition Control, 5. Ignition Warning Light (Red), *6. Switch for Starting Carburettor, 7. Switch for Traffic Indicators, 8. Rich Mixture Control, *9. Starting Carb. Warn. Light (Orange), 10. Switch for Lights, 11. Ignition Switch, 12. Hand Throttle Control, 13. Headlamp Warning Light (Blue), 14. Starter Button, 15. Cigarette Lighter, 16. Engine Revolution Indicator, 17. Switch for Panel Lights, 18. Switch for Screen Wipers, 19. Horn Button, 20. Fuel Gauge, 21. Oil and Water Temp. Gauge, 22. Ammeter, 23. Oil Pressure Gauge, 24. Clock. (* S.U. carbs only)

400 dash layout as detailed in the handbook.

ANDREW BLOW

Roller blinds just above the windscreen. Note the Clayton heater under the central dash and the main-beam dip switch to the left of the clutch.

CONTROLS KEY FOR THE 400:

1. Headlamp Dip Switch, 2. Clutch Pedal, 3. Brake Pedal, 4. Accelerator Pedal, 5. Central Chassis Lubrication Pedal, 6. Gear Lever, 7. Handbrake Lever.

Handbook detail of 400 control layout.

ANDREW BLOW

ENGINE

From the starting point of the BMW power plant, Bristol engineers managed to create an engine that, at around 353lb (160kg), including dynamo, starter and flywheel, was light in weight. The British development won praise for the Filton team from Fritz Fiedler, the BMW engineer involved in the development of the unit in Germany.

The original German engine produced 50bhp from its 1971cc. Breathed on by Fritz Fiedler and Rudolph Schleicher, the six-cylinder overhead-valve power plant was developed into an 80bhp unit, suitable for the more sporting BMW 328 and 327 models. It featured triple carburettors and dual overhead valves, with a chain-driven camshaft.

In the summer of 1945, Bristol’s engineering team started their development work on an engine removed from a 327. Extensive research was ultimately backed up by exhaustive testing, and criticisms regarding the lack of power and poor carburation, together with poor starting and poor warm-up, were addressed during the course of development. During a series of tests conducted over the Alpine passes, H.J. Aldington also experienced valve problems. This was an issue that had affected the BMW engine too, necessitating adjustment of the exhaust valves. Eventually, the engine proved its strength and, in his test notes from the Alpine expedition, Aldington’s comments were positive: ‘a first-class sports engine, apparently unbreakable and stands flogging unmercifully’.

The advances over the standard 80bhp BMW unit were made in several ways. Higher-compression pistons were used, and there was a fully counter-balanced crankshaft. Carburation was uprated and the oilways were improved, ensuring that lubricant was always delivered to where it was needed. Through their development work, Filton’s engineers produced an engine that would become the benchmark for the two-litre class well into the1960s. It is a popular engine even today, still being used in classic racing and now capable of producing up to 200bhp.

The type 85A engine, which was most commonly fitted.

In order to draw hot air away from the engine compartment, Reginald Verdon-Smith suggested that louvres be cut into the inner wing panel.

The base engine was known as the 85. This six-cylinder 1971cc unit was fitted with a single Solex twin-choke carburettor and, according to Bristol, produced 75bhp at 4,200rpm. More powerful was the 85A evolution, which January 1948’s The Autocar found ‘silky smooth’, with a ‘sufficient suggestion of exhaust note to sound interesting’. It was equipped with three SU carburettors and had an RAC rating of 16.2hp, translating to 80bhp at 4,200rpm with 102lb/ft of torque at 3,000rpm. Compression ratio was 7.5:1, which, in The Motor’s opinion (May 1948), was ‘high enough to call for either gentle use of throttle, or some use of manual ignition control at low speeds’.

The 85B derivative produced 90bhp at 4,500rpm and 110lb/ft of torque, thanks to its ‘sports’ camshaft and triple SU carburettors, whilst the later 85C variant, with its ‘touring’ camshaft and three Solex 32BI downdraught carburettors produced 85bhp at 4,500rpm. The latter became the standard engine for the later 401model.

A single iron casting formed the cylinder block and crankcase, with all the main oilways drilled in the casting. The single camshaft was hardened and ran in four plain bronze bush bearings. It was mounted low down on the nearside of the engine and was driven via a duplex chain. Overhead valves were inclined in the aluminium cylinder head, which had bronze inserts for the spark-plug threads and hardened valve seats. Combustion chambers were hemispherical. Inlet valves worked directly through pushrods and rockers, with the exhaust valve mechanism operated by short transverse pushrods, which transferred the motion of the camshaft across the head. An AC fuel pump was driven from an extra cam positioned towards the rear of the camshaft. Forged-steel connecting rods were drilled and full-pressure lubrication was provided from the crankshaft to the gudgeon pins. The pistons had crowned domes and were made from aluminium alloy.

Lockable chrome handles released each side of the bonnet. The scuttle vent provided ambient air to the footwells.

No other car of the time had such a direct inlet porting system. Three induction tracts, which were cast integral with the head, fed each pair of cylinders. Each tract divided into two branches, feeding the induction ports and providing good flow characteristics from the carburettor mounting to the valve. A balance pipe in the cylinder-head casting between the three induction ports was left open on the 85A engine. Two flexible pipes from the air cleaner fed a cast-aluminium collection chamber, from which the air intakes to the three carburettors drew air.

A water jacket surrounded the exhaust port and their guides, the light alloy head-casting aiding heat transfer from the seats. To minimize pinking when using low-grade fuels, manual control of the ignition timing was provided. At more advanced settings, The Autocar (9 January 1948) observed ‘noticeably greater liveliness of the engine’. The report did comment on some pinking at the advanced setting, but it must be remembered that the fuel available at this post-war time was still of quite a poor and variable quality.

The four-bearing crankshaft was nitride-hardened (and so could not be reground without being re-nitrided), fully counter-weighted and torsionally damped. The damper was a rubber bonded disc pressed on to the front of the crankshaft and incorporated the fan belt pulley. The breather pipes from the engine were connected to the air-filter housing, which absorbed fumes.

Drive for the sump-mounted oil pump was from a spiral gear on the camshaft. The driven gear had an extended shank, which ran in a flanged bronze bush pressed into the crankcase from above. A spindle connected the shank of the drive gear to the oil pump. At its upper end, a dog coupling drove a vertical shaft that extended to the distributor. Drive for the tacho was provided by a pair of spiral gears in this assembly.

On earlier models, a temperature stabilizer or heat exchanger could be found low down on the exhaust side of the cylinder block. It consisted of a finned tube that ran the full length of the water jacket. When starting from cold, or during normal running, heat from the coolant was transferred to the oil to warm it up quickly. Under harsher driving conditions, the heat transfer reversed, to cool the oil. This ‘intercooler’ was quickly abandoned by Bristol and a modification kit to remove it was offered.

The cooling system consisted of a water pump attached to the cylinder head and a fan, which, along with the dynamo, was driven by a V belt. Thermostatically controlled shutters for the radiator, which were fully open at a temperature of 90°C, helped in keeping under-bonnet temperatures down and aided rapid warming. This system was also replaced pretty early on by a more conventional thermostat in the coolant pump.

In conjunction with a normal mixture-enriching control fitted to one of the three SUs, there was an auxiliary Smiths starting carburettor on the front SU, intended to aid starting in particularly cold weather. The Autocar (9 January 1948) commented that the car was ‘a joy to start in the morning’. Once running, the engine needed to be warm, with the oil up to temperature, before the true benefits of its performance could be felt. Once it was on song, it encouraged fast driving, ‘giving motoring on the highest plane’.

TRANSMISSION

Borg & Beck supplied the 8in (200mm) single dry-plate clutch, which was used in conjunction with a four-speed gearbox, with synchromesh on the top three gears. The transmission’s operation was appreciated by The Autocar (9 January 1948), whose tester liked the ‘light and quick’ gear change as well as the ‘light’ clutch operation. Moreover, they were impressed by the ‘ample space to the left of this pedal, even for a tall driver’s leg’. First gear’s freewheel was praised by The Automobile Engineer (February 1950) – ‘There is much to be said for the freewheel on bottom gear,’ they wrote. They went on to compliment ‘the certainty with which bottom gear can be engaged hurriedly,…’ and the ‘easing of the familiar jerky motion when creeping in dense traffic’. A Hardy Spicer propeller shaft transmitted drive to the 3.9:1 spiral bevel rear axle.

COMPETITION

The new Bristol quickly found favour with drivers as an effective competition vehicle. Tony Crook, Bristol dealer and the future owner of the company, was an early and enthusiastic campaigner of the cars. The first outing for the 400 with Crook at the wheel was the 1948 Eastbourne Rally. Sadly, he missed an obstacle on the driving tests and was disqualified. Competition success was not far away though and in Tony Crook’s hands the Bristol distinguished itself in many production-car races at circuits such as Silverstone and Goodwood.

Other drivers preferred to put their trust in the car’s durability as a rallying machine. At Monte Carlo in 1949, a 2-litre 400 driven by Zedenek Treybal with F. Dobry took third place behind two victorious 3.4-litre Hotchkisses. Only eight marks separated the Bristol from the bigger-engined cars.

Two months later, at the Targa Florino, H.J. Aldington and Count Johnny Lurani piloted their car to a second place in the Touring category. The pair took third in the same category at the Mille Miglia in May 1949, achieving 13th overall.

Two out of the four Bristols entered came to grief in that year’s Alpine Rally. AFN lent Zedenek Treybal and Ronnie Parkinson a 400, in which the pair negotiated the first night section through the Alpes Maritimes with no loss of marks. Later, on the timed 5km autostrada section, they beat all comers, including those in the 3-litre class, with an impressive 88.9mph (142.25km/h) run. Sadly, Treybal’s skills failed to prevent the car’s disappearance over a precipice on the Rolle Pass. Parkinson was seriously injured, but Treybal was thrown clear. Meanwhile, the second car, driven by journalist Tom Wisdom, accompanied by his wife, was involved in a head-on incident with a non-competing car, so taking them out of the competition too.

More successful were Don Aldington and David Murray, who came 4th in class after clawing back marks following losses on the first section. The fourth vehicle, a Farina-bodied cabriolet with Harold Aldington and Alan Marshal at the helm, was fastest up the Stelvio Climb and eventually took 5th.

Throughout the early and mid-1950s the 400 acquitted itself as a reliable campaigner for both road and track competition, a fact Bristol proudly used in its advertising campaigns.

A 400 at the start of the 1953 Production Saloon Car Race at Silverstone.

Tony Crook in action in 1953 at the wheel of a 400.

CHASSIS, SUSPENSION, STEERING AND BRAKES

It was underneath that the 400 most closely resembled its German cousins. BMW’s 326 (sold in the UK by the Aldington Brothers AFN group as the Frazer-Nash-BMW) had a chassis that stopped short of the rear axle, independent front suspension and torsion-beam rear suspension. Short extensions to carry the fuel tank were added to the open ‘A’ frame chassis of the Bristol, which otherwise similarly terminated just in front of the rear axle, thereby keeping its weight within the wheelbase. Deep box sections forming the chassis side members were braced by four cross-members, with the rear floor forming an integral part of the structure. A timber frame clad in steel was mounted to the ‘A’ frame, with door-skins, bonnet and boot lid being made of aluminium.

At the front the independent suspension had a transverse leaf spring acting as the lower link, with the upper wishbone links mounted on adjustable shock absorbers of Bristol’s own manufacture. Location of the rear axle utilized Fritz Fiedler’s design, with lateral location provided by a triangular linkage, which had its apex in a ball joint on the differential housing.

Each of the two ends was pivoted to the top of the rear-frame cross member on either side of the propeller-shaft tunnel. Longitudinal torsion bars were linked to either end of the axle through the shock-absorber arms, the front ends of the torsion bars being fitted into sockets bolted to the chassis frame. (Being pre-set left and right, the torsion bars were not interchangeable.) It was a design that held the axle square with the chassis and thereby eliminated roll steer.

Steering gear was rack and pinion, which, according to The Automobile Engineer (February 1950), was ‘unusually light, highgeared, yet positive’. Their praise continued as they reported that its operation not only allowed the car to be ‘placed with great accuracy’ but also gave ‘effortless operation when manoeuvring in tight spaces’. Any vibrations were isolated by a fabric universal joint positioned between the pinion and the steering column. Steering and front suspension lubrication was provided by an Enots one-shot oiling system, operated by depressing a foot-operated button mounted above the pedals.

Lockheed supplied the hydraulic braking system, described by The Autocar (9 January 1948) as ‘smooth and sure’. With braking performance proportioned 60/40 front and rear, it had 11in (280mm) drums all round with two leading shoes acting on the front and single leading shoes at the rear. Linings of the woven type were eventually replaced by moulded linings, to lessen the likelihood of brake failure. Brake fade, even after prolonged use, was reduced by the supply of cooling air through the fifteen ventilation holes of the steel disc wheels. The Motor (19 May 1948) noted that the system remained effective even ‘after usage that would have put many cars into a service station’. A fly-off handbrake was located between the seats.

The Bristol roundel adorning the nose had a yellow background.

SUMMARY

H.J. Aldington felt that the 400 would have benefited from more radical, modern styling; something more showy, perhaps even more Germanic. However, with the car’s simplicity of line, Bristol set the template for the firm’s future design philosophy. With functionality over frippery and intelligence over indulgence the company had created a vehicle that proved itself in its attention to detail. Waiting for the ferry at Dover, prior to a 2,000-mile (3,200km) pan-European test, The Motor (19 May 1948) noted the ease with which the headlamps could be changed for right- or left-hand drive. It was, they reported, ‘the work of only a moment requiring no tools whatever, but merely interchange of two under-bonnet plugs’. It was a masterclass in the simplicity of thoughtful and intelligent design.

It is interesting to note that, despite the speed with which the car was brought to market, Fritz Fiedler felt that it could have arrived even sooner. Although full of praise for the Filton team, his observation was that, had BMW engineers been involved at the early stages of the design, the project may have progressed even more quickly.

Testament to the faith given to the new 400 was Dunlop’s use of the model to test tyres. Wearing out a set of rubber per day, the manufacturer drove the Bristol flat out. On the vehicle’s return to the factory two months later, every wheel bearing had failed. Dunlop were not disappointed though. The 400 was, in their opinion, the only car that was up to the task.

Contoured bumpers cradled by support on early cars.

Wing light detail.

A comprehensive tool kit was stored under the bonnet.

The rear light incorporated a reversing light and the stop bulb was covered with a red dome. The lenses were sandblasted.

Early wheel with divot holes.

Bristols on display at Greenwich in 2011: a 400 with a 405 and a Britannia.

Besides the saloon, a drophead was displayed alongside a bare chassis at the Geneva motor show launch in March 1947. To stimulate orders prices were announced as £1,450 for the saloon, with the cabriolet carrying a £50 premium. The firm’s advance publicity was however thwarted by the government’s increase in purchase tax, from 33 per cent to an eye-watering 66 per cent for cars over £1,000. The beneficial reduction in annual road tax to a flat £10 counted for nothing in Bristol’s market. Retailing at £2,374 including taxes, the saloon became the only model on sale from July 1947 after it was decided to postpone the convertible (seeChapter 5). Interestingly, in an effort to circumvent the tax, one ‘estate’ car was constructed – more on that in Chapter 9.

The 400 was a car that made many friends, offering performance and handling qualities that were to be found on few of its contemporaries. The ability to ‘place it accurately on either straight or curving roads’ made it an easy car to use, a vehicle with an ‘outstanding factor of safety’ (The Autocar, 9 January 1948) and offering ‘effortless cruising ability’. Seats that were supportive ‘in all places’ resulted in less fatigue for the driver and made the car a comfortable mile-eater. ‘It is even possible for a passenger to write or sleep while astounding numbers of miles are being covered in the hour,’ wrote The Motor (19 May 1948). After two weeks of ‘extensive testing’ in 1948, The Autocar concluded in its 9 January issue that the 400 was ‘a real car, safe, swift and completely under control, whatever the circumstances’.

The final word though must go not to a motoring publication but to a quote from a 1927 edition of the Irish Times, which sums up perfectly the production philosophy behind the Bristol marque: ‘One does not find good or serviceable machines at Bristol. There they only tolerate those that are perfect.’ It was into this ideal that the Car Division was born and under which the 400 was produced.

BRISTOL 400 1946–1950

Engines

Type

Bristol Type 85, 85A, B, C

Configuration

Six cylinders in line

Cylinder block

Cast-iron

Cylinder head

Aluminium

Valve actuation

Inclined overhead valves operated by pushrods and rockers

Bore × stroke

66mm × 96mm

Capacity

1,971cc

Power output

Engine type 85

75bhp @ 4,200rpm (BOC)

Engine type 85A

80bhp @ 4,200rpm (BOC)

Engine type 85B

90bhp @ 4,500rpm (BOC)

Engine type 85C

85bhp @ 4,500rpm

Torque

Engine type 85

n/a

Engine type 85A

102lb/ft @ 3,000rpm

Engine type 85B

110lb/ft @ 3,000rpm

Engine type 85C

106lb/ft @ 3,500rpm

Compression ratio

Engine type 85

7.5:1 (Earlier 7.4:1) (BOC)

Engine type 85A

7.5:1

Engine type 85B

7.5:1

Engine type 85C

7.5:1

Fuel system

Engine type 85

Single Solex AAPI dual port (BOC)

Engine type 85A

Three D2 type SU carburettors

Engine type 85B

Three SU carburettors

Engine type 85C

Three 32B1 Solex carburettor (BOC)

Fuel tank

12 gallons (54 litres)

Transmission

Rear axle & final drive

Rigid, of Bristol design, E.N.V. spiral bevel

Final-drive ratio

3.9:1

Gearbox

Bristol 4-speed with synchromesh on 2, 3 and 4, freewheel on 1st

Gearbox ratios

1st, 4.3:1. 2nd, 2.17:1. 3rd, 1.3:1. 4th, 1:1. R, 3.4:1

Overall ratios

1st, 16.8:1. 2nd, 8.47:1. 3rd, 5.06:1. 4th, 3.9:1. R, 13.43:1

Clutch

Borg & Beck 8in (200mm), single dry-plate

Suspension

Front

Independent transverse leaf, with Bristol shock absorbers

Rear

Live axle with torsion bars, and Bristol shock absorbers

Steering

Type

Rack and pinion

Turning circle

37ft 6in (11.3m)

Brakes

Operation

Lockheed hydraulic

Front

11in (280mm) drum, twin leading shoes

Rear

11in (280mm) drum, single leading shoes

Dimensions

Overall length

15ft 3in (4,650mm)

Overall width

5ft 4in (1,625mm)

Overall height

4ft 11in (1,500mm)

Wheelbase

9ft 6in (2,895mm)

Track

F

4ft 4in (1,320mm)

R

4ft 6in (1,372mm)

Wheels and tyres

Wheels

Steel pierced disc wheels

Tyres

5.50 × 16

Weight

(Approx.)

2,580lb (1,170kg)

Performance

Maximum speed

90+mph (144+km/h) (BOC)

0–60mph (96km/h)

19.1 seconds (The Autocar, 9 Jan 1948)

Price

(New, inc. taxes)

£2,373 14s 6d, inc. purchase tax @ £848 14s 6d (The Autocar, January1948)

CHAPTER TWO

THE AERODYNES

The 401 and 403

THE 401, 1948–1953

‘…TWO-LITRE ECONOMY WITH FOUR-LITRE LUXURY AND PERFORMANCE.’

(John Bolster, Autosport, 1 August 1952)

In order to inject some styling flair into their design, the company turned to the Italians, with the result that the late 1930s makeover look of the 400 was superseded by the altogether more stylish and avant-garde bodyshell of the 401 two-door saloon. The car gained the generic title of ‘aerodyne’ for its aerodynamic styling and was announced to the public at the 1948 Earls Court motor show. It was joined on the stand by the earlier 400, alongside which it was sold until 1950.

Its development was built on the good relationships that Reginald Verdon-Smith and H.J. Aldington had forged with various carrozzerie