28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

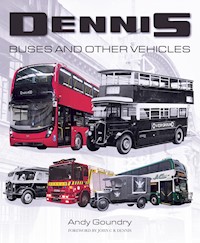

The Dennis company has been building vehicles since 1895, making it the oldest continuously producing British manufacturer. From its origins in a small Guildford shop, the company has grown to become a major bus manufacturer with its products selling around the world. This book discusses the company's highs and lows, through two world wars, challenging markets and ownership changes. It documents the vehicles produced and their innovative design features, from early cars and street-cleaning machines to vans, buses, trucks, fire engines and ambulances. First-hand descriptions of how, and why, some of the company's most successful products such as the Dart, Trident and Enviro buses evolved. It explains why their once market-leading fire engines are no longer made. It also analyses the reasons why some products were less successful and explores what happened to parts of the company that were sold over the years. Finally, the company's future opportunities and challenges are considered. The author, Andy Goundry, has not only drawn on his own personal experience of almost twenty years of employment with the company but he has drawn on what is left of the company archives, private collections and first-hand accounts, to produce this book as a salutation of over 125 years of continuous manufacturing.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 393

Veröffentlichungsjahr: 2020

Ähnliche

DENNIS

BUSES AND OTHER VEHICLES

One of the first Enviro 400s was this one, ‘Spirit of London’, built to replace the Trident destroyed by a terrorist bomb in London on 7 July 2005. It is shown here at the 2005 NEC Show launch of the Enviro 400.ADL

DENNIS

BUSES AND OTHER VEHICLES

Andy Goundry

FOREWORD BY JOHN C R DENNIS

First published in 2020 byThe Crowood Press LtdRamsbury, Marlborough Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2020

© Andy Goundry 2020

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 708 8

CONTENTS

Foreword

Dedication and Acknowledgements

Timeline

CHAPTER 1

THE EARLY YEARS: 1895–1918

CHAPTER 2

BETWEEN THE WARS: 1918–1939

CHAPTER 3

WORLD WAR II AND AFTERWARDS: 1939–1972

CHAPTER 4

THE EARLY HESTAIR ERA: 1972–1985

CHAPTER 5

HESTAIR – THE RENAISSANCE PERIOD: 1985–1988

CHAPTER 6

UNDER NEW OWNERSHIP – TRINITY HOLDINGS: 1989–1998

CHAPTER 7

MAYFLOWER MISMANAGEMENT: 1998–2004

CHAPTER 8

TRANSBUS PRODUCT DEVELOPMENTS: 1998–2004

CHAPTER 9

LAST-MINUTE SAVIOUR: 2004 ONWARDS

CHAPTER 10

WHERE ARE THEY NOW?

CHAPTER 11

ADL TODAY

Index

FOREWORD

It is interesting to reflect that of the major UK vehicle manufacturers, Henry Ford of the USA decided that Dagenham would be his UK base following a major corporate decision. Similarly, Herbert Austin chose Longbridge in Birmingham, William Morris selected Cowley in Oxfordshire, and many others also decided that the ideal place would be where manufacturing and a potential workforce were readily available.

However, the chassis manufacturer Alexander Dennis, originally Dennis Brothers, was destined to be located in the market town of Guildford after a Devon farmer’s son answered a ‘situation vacant’ advertisement in the early 1890s. Guildford is probably the only town in the UK that has a vehicle manufacturer that has been building vehicles continuously under its own name in the nineteenth, twentieth and twenty-first centuries.

Alexander Dennis and its forebears have been fortunate in being exempt from the industrial problems that have beset many of its larger competitors and, despite a few corporate issues in the past, has been able to weather the commercial storm. Now, under the safe ownership of its Scottish parent, it is looking forward to many more years of manufacturing in Guildford.

Andy Goundry is the ideal author to celebrate the 125-year history of Dennis in Guildford, being both an acknowledged automotive historian and also having worked as a senior engineer within the company.

John C.R. DennisGuildford, EnglandJune 2019

DEDICATION

This book is dedicated to the late Bob Loveland, for many years the Dennis technical publications manager. Without his foresight in collecting a vast amount of historic material, this book would not have been possible. Thanks go also to his son, Mike, for allowing me access to Bob’s collection.

ACKNOWLEDGEMENTS

Particular thanks also go to Richard Norman, Dennis chief engineer for many years, both for contributing his accounts of how some of the company’s most successful products came about, and for the loan of his extensive archive materials.

Many other people have contributed both technical and historical information as well as photographs, including the following:

John Dennis, without whose family the company would never have existed!

Colin Robertson and Carrie Szeremeta, respectively chief executive and marketing manager of Alexander Dennis, for their assistance in providing photos of current and recent products, and permission to reproduce Dennis Archive material;

My ex-ADL colleagues Gary Avery, Andy Boulton, Paul Bromley, Peter Cooper, Graham Harrington, John Hood, Roger Paice and Richard Winkworth for photos, technical information and recollections;

Di Stiff and Lawrence Spring of the Surrey History Centre, for their assistance during my many visits to unearth items from the Dennis Archives;

Raymond le Mesurier-Foster of the Aldershot & District Omnibuses Rescue & Restoration Society for providing the E-Type restoration information;

Danny Chan, Joe Devanny, Neil Jennings and John Turnbull for providing images to enhance the book;

The Crowood Press for their help and guidance throughout;

Last but not least, I must thank my wife, Cecilia, for the endless cups of coffee, the hours of proofreading and forebearance of the many domestic tasks left uncompleted while this book was being put together.

Every effort was made during the preparation of this book to identify and contact copyright holders of the illustrations included in it, although this was not always possible, particularly with older archive material. Please contact the publisher with any omissions so that corrections can be made at reprint.

TIMELINE

1895First bicycleUniversal Athletic Stores opened1898First motorized tricycle1899First motor quadricycle1900Factory moved to the Old Barracks1901First carDennis Brothers formed as private limited companyRodboro’ Buildings factory opened1903First bus1904Worm drive axle patented First commercial vehicle1905Woodbridge Works site purchased1908First fire engine1910Annual production exceeds 1,000 vehicles19122,000th vehicle produced1913Dennis Brothers (1913) Ltd becomes public limited companyLast car manufacturedAll production now at Woodbridge Works1915Woodbridge Works Power House opened Company under Ministry of Munitions control1918Renamed Dennis Brothers Ltd1919Rodboro’ Buildings vacated White & Poppe acquiredRaymond Dennis 60,000-mile (100,000km) world sales tour1921First municipal vehicle (a cesspit emptier) First lawnmower1923Annual production reaches 2,000 vehicles1925First dedicated bus chassis introduced (the E-Type)1933White & Poppe production moved to Guildford1934Dennisville estate build commences1937250th Dennis fire engine for London delivered O4 diesel engine introduced1939John and Raymond Dennis both pass away1962Alfred Miles fire business acquired1964Mercury Truck & Tractor business acquired1966Bus production ceases1970Dennis Motor Holdings set up1972Acquired by HestairCompany renamed Dennis Motors Ltd, a division of Hestair Special VehiclesTruck production ceasesTow truck and tractor business sold to Marshalls1973Woodbridge Works site sold, 10 acres (4ha) leased back1976Mower business sold1977Re-entry into bus marketDennis Motors Ltd renamed Hestair Dennis Ltd1978Re-entry into UK truck market1983Duple acquired1985Company renamed Dennis Specialist Vehicles LtdFire bodybuilding transferred to Carmichael Cab production moved from Guildford to Blackpool1987John Dennis Coachbuilders set up1988Dart launched1989Dennis Specialist Vehicles sold to Trinity Holdings1990Dennis Specialist Vehicles vacate Woodbridge Works and move to Slyfield site1992Carmichael Fire & Bulk acquired Trinity Holdings flotation1995Douglas Equipment & Schopf acquired1998Dennis Specialist Vehicles bought by Mayflower Bus & Coach1999Dennis Eagle sold to their management Douglas Schopf and Carmichael International sold2000TransBus International formed by merger with Henlys (as a Mayflower subsidiary)2004Mayflower enters administrationTransBus assets acquired by Alexander Dennis LtdPlaxton’s assets acquired by their management2005Alexander Dennis turnover £150.3 million2007Last fire engine builtPlaxton acquired by Alexander Dennis Ltd2008First hybrid buses in service2018Alexander Dennis turnover £577 million, with 2,533 buses delivered worldwide2019Prototype self-driving busPrototype hydrogen fuel cell busAlexander Dennis bought by NFI Group IncCHAPTER ONE

THE EARLY YEARS: 1895–1918

Britain’s Industrial Revolution saw the rapid development of the railway system, offering for the first time a comparatively fast way to transport both goods and people over relatively long distances. However, even as the nineteenth century was drawing to a close, railway supremacy was about to be challenged and beaten by a new form of transport – the internal combustion engine.

In that time of rapid technical development, inventive Victorian minds created endless new products; many flourished briefly then disappeared, themselves overtaken by newer inventions. Such was the pace of change that few of the pioneers of this second industrial revolution, such as John Cawsey Dennis, could have imagined in their wildest dreams how their new inventions would develop.

John was born in 1871, the son of a long-established farming family from Huntshaw in Devon. Despite his deep roots in farming, John’s interests lay in machinery, so at the age of sixteen he began an apprenticeship with Tardrews, a Bideford ironmonger. While still an apprentice, John applied for and was successful in obtaining a position as assistant to an ironmonger in Guildford, almost 200 miles (320km) away. Moving there at the age of twenty-three, and having no friends or family locally to occupy his time, he decided to build a bicycle, using parts bought from his new employer, Filmer and Mason.

Proud of his creation, he borrowed the window of a friendly tailor at the top of Guildford High Street to display it, an act which within a couple of hours resulted in its profitable sale. That first bicycle led to others until before long his hobby was more lucrative than his day job.

Pondering his next move, John realized that his employer bought components from Brown Brothers in London, so if he also bought directly from them, he too could increase his profits. He went a step further and joined Brown Brothers as an employee for several months to learn as much as possible about making and sourcing engineering components.

With that knowledge under his belt, together with a ready supply of parts assured from Brown Brothers, he returned to Guildford in January 1895 to set up a bicycle shop, Universal Athletic Stores on Guildford High Street. Cycle assembly was carried out with the frame suspended from a pear tree in the garden of his shop, giving the pear tree the distinction of being the first piece of Dennis assembly tooling!

Showing the marketing initiative that characterized the company, on opening day his shop window hosted a ‘Spinning Wheel Competition’. When the wheel was set spinning, the assembled onlookers were asked to estimate how long it would take to stop. It took 12 minutes and 10 seconds, during which time he had subtly indicated to his audience the engineering quality of his product, and drawn many customers into the shop.

The founding brothers.AUTHOR

Sales of his Speed King and Speed Queen cycles became plentiful, and soon John’s younger brother, Herbert (better known by his middle name, Raymond), then still only seventeen, joined him as an equal partner in the business. Raymond provided cycling lessons to new riders, and also became an accomplished competitive cyclist, his many successes helping promote the brothers’ products.

As the business developed, the brothers began to design and make many of their components, notably patenting a popular pneumatic saddle. Their component manufacturing took place in the garden of the shop, by then equipped with a small workshop containing plating vats, enamelling stoves and other equipment.

Dennis’s first motorized tricycles appeared in 1898, quickly followed by quadricycles.AUTHOR

DENNIS SPEED KING QUADRICYCLE, 1899–

Configuration: Two in-line seats, convertible to singleseat tricycle by loosening four bolts

Engine: De Dion Bouton Max. power RAC: 2.25HP

Steering: Bicycle-type handlebar

Tyres: 26in (660mm) × 2.5in (63.5mm) Wheels: Bicycle-type, steel, spoked

Price (1899): 95 guineas (£99 15s/£99.75) (Source: Dennis Bros. advertisement, 1900)

SPEEDING FINE

Although inevitably primitive, the tricycle must have been reasonably effective, for as John was testing his machine around the hilly streets of Guildford one summer day in 1899, a policeman saw him hurtling up Guildford High Street at a speed that he subsequently affirmed to the magistrate as at least 16mph (26km/h). Despite John’s defence that the tricycle was incapable of such a speed, particularly on the High Street’s 1 in 11 (9 per cent) uphill gradient, prosecution duly followed, the outcome being a not inconsiderable fine of twenty shillings. So John became one of the first, if not the first, person to fall foul of motoring law. However, that fine was repaid many times over as the Dennis brothers used this incident in their advertisements as proof of the machine’s speed, measured ‘on the sworn testimony of a constable’. Then – as now – speed sells!

FROM TWO WHEELS TO FOUR

In a far-sighted move, in 1898 John and Raymond built a motorized tricycle fitted with a single-cylinder 3HP De Dion Bouton engine. Motorized tricycles soon became motorized quadricycles, and both tricycles and quadricycles competed with great success in several races and events, usually piloted by Raymond Dennis.

Building these new-fangled machines needed more space than the small Universal Athletic Stores garden workshop could provide and so, in 1900, the company made its first move, just around the corner into disused army barracks in Friary Street. The decision was also soon made to formalize the company, which became Dennis Brothers Limited, a private company. The first board meeting was held on 29 July 1901, with four directors, seven subscribers and capital of £7,500, subsequently increased in 1906 to a notinconsiderable £100,000 – over £12 million at 2019 levels. Part of a document from that time discovered in the Dennis Archive notes that: ‘With the extra capital, a great many new automatic labour-saving machines were installed, and by their aid the accuracy has been increased to the point of absolute interchangeability, allowing a large output of the best possible at a minimum cost.’

The same document also notes that: ‘We commenced manufacturing before the passing of the Light Locomotive Act, which gives us the position of the oldest Makers in England.’

Quadricycle manufacture led to the development in 1901 of a ‘proper’ car, still using De Dion Bouton engines, this time an 8HP unit specially tuned for Dennis Brothers. The use of De Dion engines was typical of the brothers’ understanding of their business, for this French manufacturer produced engines that were already well regarded and in relatively large-volume production. Doubtless the brothers could have developed their own engine, but this would have been both time-consuming and expensive. Initially, it was intended to market the Dennis cars under the same ‘Speed King’ brand as the company’s previous products; however, this policy was abandoned at the 27 January 1902 board meeting in favour of adopting the simple brand ‘Dennis’.

The Dennis archives include this 1,000-mile Certificate of Performance from the 1903 Reliability Trial.DENNIS ARCHIVES

WIN TODAY, SELL TOMORROW

Quickly realizing the benefits of the publicity that could result from success in competitive motoring events, the brothers were soon entering their machines in speed and reliability trials.

One hill climb event took place in 1901 at Tilburstow, near Caterham in Surrey. Not only was the Dennis car successful in climbing the hill, with its maximum gradient of 1 in 10 (10 per cent), faster than any other competitor, many of whom failed to climb the hill at all, but it also won the prestigious Championship of the Meeting.

Two cars were entered into the Automobile Club’s 1902 reliability trial, the challenge being to complete a journey from London to Oxford without stopping, a distance of around 60 miles (100km). Both cars completed the task successfully and were awarded diplomas.

A further reliability trial in 1903, this time of 1,000 miles (1,600km) and again organized by the Automobile Club, saw the winning 16HP Dennis awarded 2,991 marks out of a possible 3,000. A 20HP car was then entered into the Club’s 4,000-mile (6,400km) reliability trial in March 1906, achieving an unbroken run. That performance helped the company win the first-ever prestigious Dewar Challenge Trophy for the most outstanding motoring achievements of the previous twelve months.

Events such as these helped to develop Dennis products’ reputation for excellent reliability and raised their image in the minds of the motoring public. Even at that time, though, there must have been board members unhappy at some of the innovative sales tactics employed by the brothers, for the 20 April 1906 board meeting minutes note somewhat sourly that ‘profits might have been larger but for the expenses incurred in the entering of two cars in the Isle of Man Tourist Trophy Race’.

RODBORO’ BUILDINGS – DENNIS’S FIRST PURPOSE BUILT FACTORY

In 1901, motor cars were still a rarity, with probably no more than 500 in Britain. Dennis products were selling well, and the brothers continued to invest in their fledgling business, expanding further with a 27,000sq ft (2,500sq m) purpose-built office and factory on the corner of Guildford’s Onslow Street and Bridge Street.

Rodboro’ Buildings was Dennis’s first purpose-built factory, opened in 1901. Demand for Dennis products was such that they moved into the new factory even before it was finished.DENNIS ARCHIVES

Although the plans submitted for the building described it as a facility for the manufacture of bicycles and motors, the industry’s pace of change was such that bicycle production had almost ceased by the time the building came into use. Indeed, the board meeting minutes of 6 April 1905 record the decision to ‘discontinue the manufacture of bicycles entirely’.

The layout of the building was novel. The ground floor housed two showrooms with space for up to twenty cars, as well as offices and the power plant for the factory. In the basement was the stores area, while the first floor contained machine shops, electroplating equipment and a polishing shop, as well as the body shop. Car assembly took place above that, along with shops for final finishing activities such as painting. Above that again were the upholstering and enamelling shops with their large drying stoves. All levels were connected by a large lift, which was used to lower the finished cars to the ground.

The building still exists today and is known locally as the Rodboro’ Buildings after the Rodboro’ Boot and Shoe Company who bought the premises in 1919 after the Dennis business moved again. Visually, it is largely unchanged externally, although not everyone enjoying a quiet drink in the Wetherspoons pub that now occupies part of it is aware that they are in the former factory of Britain’s oldest continually functioning automotive manufacturer, and indeed one of the oldest in the world.

In 1902, an account of a visit made to these works appeared in the Gentleman’s Magazine. The article described Dennis Brothers as ‘probably the principal pioneers of the motor industry in this country’ noting that ‘the firm was one of the very first in England to devote its attention to automobilism’.

This superb 1902 Dennis car is owned by John Dennis, grandson of one of the founding brothers. John has participated in over sixty London– Brighton Veteran Car Runs with the car, probably an unmatched achievement by anyone.AUTHOR

All this positive publicity meant that 1903 was a year in which the company did exceptionally well. By then, the range had expanded to include a wide range of models. At the 1903 Motor Show held at Crystal Palace, they received orders for eighty-three cars at a total value of £27,900. These ranged from thirty-two 16HP tourers at 550 guineas each (£60,000 in today’s money) to five motor tricycles at 95 guineas apiece. One buyer paid a £1,000 deposit to secure twenty vehicles, which was reported by Motoring Illustrated as ‘the highest aggregate amount of business done at one stand’.

Not for nothing did Dennis describe themselves in a 1907 brochure for their cars as producing ‘the pioneer car of England’!

DENNIS 3-TON CHASSIS, 1906–c.1925

Layout and Chassis

Two-axle rigid bolted ladder frame suitable for normal-control double-deck bus, lorry or van bodywork

Engine

Type: Aster

Block material: Cast iron

Head material: Cast iron

Cylinders: 4 in-line

Cooling: Water, pumped

Bore and stroke: 120 × 130mm

Valves: Side valve

Max. power: RAC 35HP; 35hp (26kW) at 900rpm

Fuel capacity: 15gal (68ltr)

Transmission

Gearbox: Dennis 4-speed, aluminium-cased

Clutch: Cone, leather-faced

Ratios:

1st: 3.29

2nd: 2.01

3rd: 1.36

4th: 1

Reverse: 4.33

Final drive: Dennis worm drive

Suspension and Steering

Front and rear: Steel multi-leaf springs

Steering: Worm and segment

Tyres: Front: 34in (864mm) single solid rubber

Rear: 34in (864mm) twin solid rubber

Wheels: Artillery wood pattern

Brakes

Type: Footbrake: steel drum on propellor shaft with two cast-iron contracting shoes

Handbrake: drum brakes on rear axle with cast-iron shoes, rod-operated

Dimensions

Track, rear: 66in (1,676mm)

Wheelbase: Bus 160in (4,064mm)

Lorry 150in (3,810mm)

Body length: Lorry 120in (3,048mm)

Payload: 6,720lb (3,048kg)

Capacity: 34 passengers (double-deck)

Performance

Top speed: 14.5mph (23km/h)

Price (1908)

Chassis with tyres: £650

Double-deck body: £150

Lorry body: £75

(Source: Dennis Bros. Ltd catalogue, 1908)

INNOVATION AND DIVERSIFICATION

The brothers were at the forefront of technical advancement, with experiments going on continually. One of the most significant innovations was the development of a worm-driven rear axle, at a time when many competitors still relied on noisy and unreliable chain drives. The worm drive was patented in 1904, giving Dennis products a longlasting and smooth transmission. This axle was so good that other manufacturers used it; the first London bus, in around 1906, had a Milnes-Daimler chassis fitted with a Dennis worm-drive axle.

In May 1907, this tower wagon was produced for Dick, Kerr and Co. Ltd for use in maintaining overhead cables, and was probably the first of its kind in the UK. This line drawing is from a 1908 Dennis catalogue.BOB LOVELAND COLLECTION

As the sales of cars increased, more manufacturers jumped on the bandwagon, so the Dennis brothers looked for diversification opportunities. They quickly realized that the systems developed for moving people via motor cars could be adapted for moving goods, thereby providing significant benefits to businesses large and small who had hitherto been reliant on horse-drawn transport.

So, in 1904, Dennis built their first commercial vehicle, a 15-cwt van for Harrods department store in London, which appeared at that year’s Crystal Palace Show. This appearance was so successful that the company took 160 orders, the most significant number of any manufacturer. In 1905, Dennis produced their first bus, using a 4-cylinder 28HP Aster petrol engine, with the engine and gearbox mounted on a subframe to reduce stresses. It was sold to Benjamin Richardson and plied between Kingston-upon-Thames and Richmond, carrying its passengers in a body that had previously seen service as a horse-drawn bus.

At first, the 28HP chassis was used for 3-ton (3,050kg) payload commercial vehicles as well as buses, but by 1906 a range of lower-capacity chassis was also available, with 4-cylinder engines rated from 14 to 40HP and payload capacities from 8cwt (400kg) to 5 tons (5,080kg). The 4-tonner was often used to carry a double-deck body, dedicated chassis to suit passenger applications not being introduced until 1925.

The export market was not neglected. In just two years, between 1904 and 1906, single- and doubledeck buses had been shipped to Italy, Holland, South Africa, New Zealand and Australia. Raymond Dennis undertook an extended sales tour in 1908, one outcome of this visit being an order for the first buses ever seen in Russia.

Dennis built probably the UK’s first tower wagon in 1907, and also one of the first breakdown trucks, for the General Cab Company of London.

By 1909, total production numbers exceeded 300 vehicles.

THE PERILS OF NOT BUYING DENNIS

The threat from other manufacturers at this time must have been significant, causing the company to publish this stern warning to anyone tempted to buy anything other than a Dennis:

There are a large number of mushroom firms, with no backbone whatsoever, and who have been trading upon the deposits received from their clients; such firms cannot last, and if you find yourself the possessor of a Car made by such a firm, or the possessor of a Car imported by the so-called Sole Concessionaire who has to suspend business, then you have made a very inadvisable purchase. Both because of the difficulty to obtain spare parts, and the name not being kept constantly before the public, any reputation the Car may have soon goes and with it your chance of resale except at a considerable sacrifice.

THE FIRST FIRE ENGINES

Typical of Dennis Brothers’ continual quest for innovation and preparedness to back a hunch was the production in 1908 of their first fire engine, for the City of Bradford brigade. Traditionally, fire engines had been horse-drawn, with steam-powered piston pumps, so were not only slow to attend an incident but had limited pumping capacity when they got there. Back in 1903, Merryweather had recognized the benefits of petrol power, which would enable a motor fire engine to be on the scene of a fire quickly, rather than having to wait for steam to be raised. However, the piston pumps then in use were neither particularly quick to bring into use, nor effective. The Dennis Brothers fire engine, in contrast, used a Gwynne-Sargeant turbine pump that could begin pumping immediately. This new pump produced a much more stable water pressure than had hitherto been possible and was also much more tolerant of the dirty and sandy water supplies, which were often all that was available. This revolutionary vehicle participated in several impressive demonstrations to senior fire brigade personnel from around the country.

This print is taken from an early Dennis catalogue and shows the very first fire engine, the 1908 Bradford N-Type.BOB LOVELAND COLLECTION

At the heart of every fire engine is a high-pressure water pump. This sectioned view shows the type of turbine pump that helped the early Dennis appliances quickly gain an outstanding reputation for performance and reliability.BOB LOVELAND COLLECTION

One of these demonstrations was held in London, where two Dennis engines, coupled together, threw a jet of water over the dome of St Paul’s Cathedral, a height of 366ft (110m). Another took place nearer to home on a Guildford river bridge. The pièce de résistance of the day to demonstrate the capabilities of the machine was to shoot a jet of water 100ft (30m) into the air. Unfortunately, a sudden change in wind direction at the critical moment resulted in the assembled VIPs getting thoroughly soaked and the company having urgently to take over most of the available hotel accommodation to enable their guests to dry out.

In launching this machine, the N-Type, Dennis were pushing at an open door, for the government of the day had already realized the deficiencies of traditional steampowered fire engines and were urging towns and cities to equip themselves with something better, so the launch of the Dennis appliance was incredibly timely.

The success of, and well-deserved publicity given to, the new appliance soon led to London and other fire brigades throughout Britain, and indeed throughout the world, buying Dennis fire appliances in increasing numbers. A copy of the 1908 Dennis commercial vehicle catalogue contains images of machines for various home and export customers as well as Bradford. However, it seems that the company was slightly ahead of itself in claiming these, as their sales records for 1908 indicate that payment was only received for one fire engine that year. However, 1909 saw income from sales of eight engines, to Rowley Regis, Glasgow, Kingston, Birkenhead, Christchurch, Fremantle and Birmingham. In 1910, vehicle sales numbered twenty-seven, including the first seven N-Types for London. With such widespread sales, it was not long before the name Dennis soon became synonymous with fire engines in the public’s eye, where it stayed for the next century.

The chassis configuration of those first Dennis fire appliances generally followed the company’s by then standard convention, although the usual Aster engine was replaced by either a 40/45 or 60HP 6.24-litre White & Poppe sidevalve petrol engine coupled to a four-speed gearbox, with the gearing allowing an impressive 30mph (50km/h) top speed. The higher-power engine was usually fitted to vehicles with wheeled escapes. The rear axle was, of course, the patented Dennis worm-drive unit, while the wooden artillery-type wheels were either shod with ‘KT’ air cushion tyres or solid rubber tyres. Braking followed the typically basic standards of the day, with cast iron drum brakes on the rear axle only, augmented by a drum-type transmission brake on the rear of the gearbox, again with cast iron friction blocks.

In 1909, the New Zealand town of Christchurch took one of the first N-Type fire appliances, as shown here, becoming probably Dennis’s first export fire customer.DENNIS ARCHIVES

This Black Maria prisoner transport was built in 1914 for Salford. The name ‘Black Maria’ apparently has its origins in a lady by the name of Maria, who in the 1840s owned Maria Lee’s Lodging House in Boston, Massachusetts, USA. Maria, it seems, let the police know whenever she thought one of her lodgers was up to no good. As a result, the police attended Maria’s premises so often that their horse and cart became known as the ‘Black Maria’. Soon, all vehicles for moving prisoners became known as Black Marias in the UK as well as in the USA.DENNIS ARCHIVES

The bodies were of the Braidwood type, named after the well-respected James Braidwood (1800–1861), who was instrumental in developing the equipment and techniques of the British fire service. A Braidwood body could carry up to ten firemen, the four on each side having to hang on for dear life in their exposed positions. The idea was that they could get on and off quickly – challenging enough on a horse-drawn appliance but far less easy on a much faster motor vehicle. Sadly, although perhaps inevitably, it was not long (1910) before the first firefighter lost his life being flung from a Dennis fire engine when it skidded on a wet road in Birmingham.

Fuel consumption was claimed to be 8–12mpg, (23–35ltr/100km), and the cost, for a typical appliance, was quoted as £850 in 1909 (around £100,000 today).

Most N-Types left the factory with a distinctive darkblue bonnet, a finish that resulted from dipping the bonnet panels in a hot cyanide solution; this proved a better alternative to paint, which was often severely affected by engine heat.

Early post vans on the 30-cwt 12HP chassis of 1906 had stylish bodies to the specification of McNamara & Co., the company who for many years carried the mail on contract for the GPO. By July 1912, they had a fleet of over seventy Dennis vans.DENNIS ARCHIVES

This 1912 photo shows some of the Metropolitan Asylums Board ambulances. Despite the austere name, these asylums were in fact Britain’s first state hospitals, covering both physical and mental infirmity. These vehicles replaced the previous horse-drawn ambulances.DENNIS ARCHIVES

Two of the Dennis cars owned by John Dennis. The 1909 car, nearest the camera, was repatriated from Australia by John in 1969 in a derelict condition and fastidiously rebuilt. The other car dates from 1906.AUTHOR

The same chassis type was used for the ambulance bodies that were also offered by the company. One of the first customers for these was the Metropolitan Asylums Board of London, who by 1912 had a fifty-strong fleet.

Sales success in fire engines was matched by thriving orders for buses and other heavier vehicles at the expense of the original cars. Indeed, in 1909 the company issued a statement confirming that it was still building ‘passenger cars’. In truth, however, the manufacture of Dennis cars was a relatively short-lived venture. Fittingly, three of the few remaining vehicles are in the care of John Dennis, grandson of one of the original Dennis brothers.

DENNIS 60HP N-TYPE, 1908–

Layout and Chassis

Two-axle rigid bolted ladder-frame fire appliance chassis

Engine

Type: White & Poppe

Block material: Cast iron

Head material: Cast iron

Cylinders: 4 in-line

Cooling: Water, pumped

Bore and stroke: 127 × 180mm

Capacity: 9120cc

Valves: Side valve

Carburettor: White & Poppe with gravity feed

Max. power: RAC rating 60HP; 65bhp at 1,180rpm

Fuel capacity: 20gal (91ltr)

Transmission

Gearbox: Dennis 4-speed, aluminium case

Clutch: Cone clutch, leather-faced

Ratios:

1st: 3.77

2nd: 2.32

3rd: 1.48

4th: 1

Reverse: 3.07

Final drive: Dennis worm drive, 4.85

Suspension and Steering

Front and rear: Semi-elliptic multi-leaf steel springs

Steering: Worm and segment

Tyres: 34in (864mm) solid rubber or KT air cushion, twin on rear axle

Wheels: Artillery-type wood, later cast steel hollow-spoke

Brakes

Type: Footbrake: steel drum on propellor shaft with 2 castiron contracting shoes

Handbrake: drum brakes on rear axle with cast-iron shoes, rod-operated

Dimensions

Overall length: 222in (5,639mm)

Overall width: 84.3in (2,140mm)

Overall height: 90in (2,286mm)

Unladen weight: 9,000lb (4,000kg) approx.

Water capacity: First aid tank: 40gal (182ltr)

Hose capacity: 1,200ft (365m) of delivery hose;

30ft (9.1m) of 5in-diameter (127mm) suction hose

Turbine pump: Three-stage Gwynne, 400gal/min (1,818 ltr/min) at 120lb/sq in (8.3 bar)

Performance

Top speed: 30mph (48km/h)

Cost

60HP: £975

(Sources: ‘Instructions for Management and Control of Dennis Turbine Motor Fire Engines’, c.1913/1914, and ‘Dennis Motor Fire Engines’ catalogue, c.1910)

THE AIRFIX N-TYPE

Several of these old appliances still exist in running order, including one that is owned by the company. This vehicle, registration number DU 179, was immortalized by Airfix in the 1960s with a delightful 1⁄32 scale plastic kit. It was originally used by the City of Coventry and subsequently by the industrial concern GEC before being purchased by Dennis in 1958. It can sometimes be seen in events such as the London–Brighton Commercial Vehicle Rally. The author can testify to the surprisingly impressive turn of speed of this handsome beast, which is not accompanied by an equal braking ability, making an open-air ride on it exhilarating!

Still pumping at 103 years old: this 1916 N-Type is cared for by the students at London’s Royal College of Science.AUTHOR

DENNIS 18HP MOTOR VAN CHASSIS TO CARRY 15-CWT, 1904–

Engine: Aster 4-cylinder

Max. power: RAC rating 18HP; 18hp at 900rpm

Gearbox: Dennis 3- or 4-speed plus reverse, aluminium casing

Clutch: Dennis cone clutch, leather-faced

Final drive: Dennis worm drive

Suspension: Multi-leaf springs

Brakes: Footbrake: drum at rear of gearbox

Handbrake: side expanding brakes on rear wheels, rodoperated

Wheelbase: 108in (2,743mm)

Overall length: 165in (4,190mm) approx.

Overall width: 63in (1,600mm) approx.

Overall height: 88in (2,235mm)

Top speed: 14.5mph (23km/h)

Price: Chassis £375;

Body £45

(Source: Dennis Bros. Ltd catalogue, 1908)

DENNIS 25- 30-CWT CHASSIS, 1906–

4×2 rigid ladder-frame chassis for van and ambulance bodywork (as supplied to the Metropolitan Asylums Board)

Engine: Aster 4-cylinder side valve

Max. power: RAC rating 18HP or 28HP; 18hp or 28hp at 900rpm

Gearbox: Dennis 3- or 4-speed, aluminium-cased

Clutch: Cone, leather-faced

Final drive: Dennis worm drive

Suspension: Steel multi-leaf springs

Tyres: 34in (864mm) solid rubber on artillery wood pattern wheels

Brakes: Footbrake: steel drum on propellor shaft with 2 cast-iron contracting shoes

Handbrake: drum brakes on rear axle with cast-iron shoes, rod-operated

Wheelbase: Ambulance 150in (3,810mm); van: 126in (3,200mm)

Overall length: Ambulance 200in (5,055mm) approx. including rear steps; van 181in (4,597mm) approx.

Body length: Ambulance 82in (2,083mm); van 96in (2,438mm)

Overall width: 60in (1,524mm)

Overall height: Ambulance 97.5in (2,477mm); van 101in (2,565mm) approx.

Payload: 2,800lb/3,360lb (1,270kg/1,524kg)

Capacity: Ambulance: stretcher plus four passengers

Van: approx. 220cu ft (6cu m)

Top speed: 16mph (26km/h)

Price: 18HP chassis with tyres £435; 28HP chassis with tyre £520

Ambulance body: £100

Van body: £75

(Source: Dennis Bros. Ltd catalogue, 1908)

DENNIS 18/24HP CAR, c.1906–1913

Layout and Chassis

Chassis suitable for 2- or 4-seat bodywork

Engine

Type: Aster

Block material: Cast iron

Head material: Cast iron

Cylinders: 4 in-line

Cooling: Water, thermo-syphon

Bore and stroke: 18HP: 90 × 110mm; 24HP: 100 × 150mm

Carburettor: Variable single-jet

Max. power: RAC rating 18HP/24HP

Fuel capacity: 9gal (41ltr)

Transmission

Gearbox: Dennis 4-speed and reverse, aluminium casing

Clutch: Hele-Shaw patent disc clutch

Final drive: Dennis worm drive

Suspension and Steering

Front and rear: Semi-elliptic multi-leaf springs

Steering: Worm and segment

Tyres: 810 × 90 pneumatic

Wheels: Artillery wood pattern

Brakes

Type: Rear only: internally expanding drums with cast iron shoes. Independent shoe pairs for footbrake and handbrake

Price (1911)

18HP chassis with tyres: £325

24HP chassis with tyres: £440

4-seat touring body, less hood and windscreen: £55

2-seat body: £50

(Source: Dennis Bros. catalogue, c.1911)

ANOTHER NEW FACTORY – WOODBRIDGE WORKS

Even though the Rodboro’ Buildings factory was extended twice, in 1903 and 1905, rapid growth in sales of the broadening product range meant that the factory’s capacity was again soon exceeded, and a new facility was needed.

In August 1905, the company purchased a 10-acre (4ha) site at Woodbridge Hill, then a greenfield location on the edge of Guildford. To save money, one of the first buildings on the site was the disused 29,000sq ft (2,700sq m), 5,500- seat Torrey-Alexander Mission Hall from Brixton, south London, which after being dismantled was transported 30 miles (50km) to Guildford and re-erected to become No. 1 shop, going on to perform a useful function for a further eighty years. No. 2 shop was soon built, followed by Nos 3 and 4 shops. Nos 5, 6 and 7 shops, providing an additional 124,000sq ft (11,500sq m) of space were laid down in 1916 to support the war effort.

All production had been moved from Rodboro’ Buildings to the new Woodbridge Works by 1913, with the office functions following in 1919.

Dennis seized every opportunity to promote their patented worm drive axle, including this impressive mosaic on the floor of the Woodbridge Works reception area, reportedly crafted by Italian experts.RICHARD NORMAN

The factory had its own railway system, complete with a couple of loading docks and several locomotives. In later years, although the rail link to the national network was lifted, the tracks remained in situ inside the factory, albeit with the gaps between the rails filled in. One of the first locomotives, which ran until 1942, was designed in house and based on a Dennis tractor from 1909.

Employee welfare was considered important from the outset, with the board meeting minutes of 5 March 1907 noting the plans to create football and cricket grounds for the newly formed Dennis Athletic Club. Even before that, the idea of offering efficiency bonuses to staff was under discussion by the board.

The new Woodbridge Works was intended to impress potential customers from around the world as well as being a state-of-the-art vehicle manufacturing facility. The reception area floor, for example, was of marble, with an inlaid worm and wheel motif promoting the company’s innovative axle design, an icon that also featured in the firm’s letterhead.

The factory was surprisingly advanced environmentally, with considerable attention having been paid to ease of operation and decent working conditions. For example, the offices were equipped with effective ventilation, which gave an air change every twenty minutes. They were located on the first floor, to allow the entire ground floor to be devoted to manufacturing and avoid the need to lift heavy components between levels.

Charabancs with a folding canvas roof were a popular configuration for the earliest buses. This particular vehicle, however, which was supplied to T. Copp of Ilfracombe in May 1910, was built with a fixed roof and side curtains. Unlike this example, most charabancs at least offered doors to keep the passengers from falling out!DENNIS ARCHIVES

Woodbridge Works. No. 1 shop can be seen in the bottom right-hand of this aerial photo. Alongside it is the power house, with the offices facing the main London Waterloo–Portsmouth railway line at the bottom of the picture. This image was taken in the early Hestair days, shortly before they began to sell off the site as part of the retrenchment and rationalization of the business. North Gate, the main entrance to the site, can be seen in the centre right of the picture, adjacent to what is now known locally as the Dennis roundabout under the A3 Guildford bypass. By the end of the Hestair era, all of the site had been sold off other than No. 11 shop, which was located at the top right of this picture and was where all remaining functions of the company had been crammed. Ironically, even after the move to the new Slyfield factory, No. 11 shop remained standing, although derelict, for many years.RICHARD NORMAN

By 1911, water was being obtained from artesian wells on-site, while gas for the case-hardening furnaces was generated by burning wood shavings and sawdust from the woodworking shop. Electricity came initially from the fledgling public supply, although in 1915 the company invested in their own power house, a highly impressive building with tiled walls and floors that contained an extensive range of generating equipment.

Perhaps one of the company’s greatest strengths in those pre-Great War years of rapid growth was their ability to understand the needs of their customers, however unusual, together with their willingness to produce specialized vehicles to meet those needs alongside their more standard ranges. Their 1909 ‘Fire Engine and Ambulance Catalogue’ made this clear, proclaiming confidently that ‘the makers are prepared to submit designs and estimates for any variation from their standard designs.’ This flexibility was made possible by the Woodbridge Hill factory making complete vehicles rather than just bodies or chassis.

By 1910, Dennis’s claimed proudly, and justifiably, that their fire engines operated all over the world, from Auckland to Zanzibar, while over 1,000 Dennis lorries and vans were at work moving goods around Britain.

By then, Woodbridge Works employed more than 400 staff and was producing 1,000 vehicles annually. The factory covered over 260,000sq ft (24,150sq m) by 1916, making it one of the largest commercial vehicle factories in Europe at that time. The product range was both broad and diverse, with chassis capacities from 15 cwt (760kg) to 5 tons (5,080kg), usually fitted with either lorry or van bodywork for haulage work or bodied as single- or doubledeck buses.

POWER HOUSE

The power house equipment included two massive 270bhp 4-cylinder 4-stroke single-acting Sulzer air-blast injection diesel engines running at 187rpm, each coupled to a 180kW dynamo to supply 440-volt power to the factory. A third Sulzer set was added in 1917, and a fourth should have followed shortly afterwards. The ship bringing it to the UK, however, was sunk in the North Sea by a U-boat, and the fourth engine eventually only arrived in 1924.

Further expansion of the power-generating capability became necessary in the early 1930s, when engine production was moved to Guildford from Coventry. After consideration of the relative costs of taking this power from the public supply versus generating it in-house, two additional high-speed Mirrlees-Ricardo 300bhp 900rpm 6-cylinder diesel engines were installed, each coupled to a 205kW dynamo. They were shortly followed by a third set, collectively producing 615kW and nearly doubling the capacity of the powerhouse.

The Mirrlees-Ricardo engines, together with their dynamos and a huge rotary converter, were at the time the biggest high-speed diesel-engined generating plant in the UK, while the original Sulzer installations remained operational right up to 1986. It is an impressive measure of their reliability that during the World War I the Sulzer engines regularly ran non-stop for five weeks at a time.

Sadly, very little physical or documented evidence remains of the Woodbridge Power House. However, memories linger, and Richard Norman, a one-time Dennis apprentice who was to become their chief designer, recalls that ‘when the wind blew from the north, exhaust fumes were drawn from the power house into the office ventilation system. Complaints to the maintenance manager, one Tom Ralph, were brushed off with the riposte that pollution levels were no worse than standing next to the adjacent A3 road!’

Inside the Woodbridge Works power house, showing the Sulzer engines.RICHARD NORMAN

FIRE FIGHTING ON THE WATER

The early days of fire-fighting on the water were, like those on land, characterized by slow responses as steampowered craft and pumps needed lengthy preparation times before they arrived on scene of the blaze. In 1905, Bristol Fire Brigade took delivery of a steam fire float, Salamander, equipped with Merryweather piston pumps. Salamander served at Avonmouth Docks for many years, and on one occasion in 1917 demonstrated the major drawback of steam power. A fire was discovered at 7.30am in a transit shed at Avonmouth Dock, and Salamander was called out. By 8:30am, shore appliances had almost extinguished the fire. Meanwhile, Salamander had finally raised sufficient steam to lend a hand and arrived at 8:36am!

Even before that incident, Bristol’s far-sighted port authority, having recognized the potential of the Dennis N-Type internal combustion fire engine, and more particularly its highly effective turbine pump, had commissioned a fire float that incorporated that same Dennis equipment into what they hoped would be a radical and efficient marine fire-fighting vessel for use in Portishead Harbour. The resulting boat entered service in 1916 and was named Denny (apparently after the small island in the Severn Estuary rather than being a play on the Dennis name).

The Bristol authority’s faith was not misplaced, and this first experimental effort on their part soon led to such vessels being commissioned worldwide, although sadly none with the same Dennis equipment on board.

The Denny featured a steel hull containing a White & Poppe engine together with a turbine pump as used in the N-Type fire engine. The power unit, mounted towards the rear of the hull, provided power both to the boat’s propeller and to the fire pump itself. It seems that the unfortunate engineman responsible for managing the engine was incarcerated in splendid isolation in the bowels of the hull alongside the engine in what must have been a very unpleasant, fume-laden, environment. How he received his instructions to adjust speed remains a matter for conjecture, for the photographs and drawings that remain show no evidence of a speaking tube or any other form of communication device with the helmsman!

Sadly the full-size fire float no longer exists, but this magnificent 1/24 scale model built by Richard Norman, Guildford’s longserving chief designer, faithfully portrays the layout of the craft.AUTHOR

This 34-seater was built on a 30HP chassis, and was one of five supplied to West Bridgford Urban District Council in January 1914.DENNIS ARCHIVES

Nevertheless, the Denny must have been a success, for it remained in service in Portishead until 1953.

In 1916, Dennis joined forces with Mr W. A. Stevens to produce the Dennis-Stevens bus, which had a 4-cylinder Dennis petrol engine driving a generator, which in turn powered electric motors driving the rear axle, so creating one of the first of the hybrid vehicles now so much in favour a century later. However, at the time they found few customers, the most notable being Cardiff and Walsall corporations, with production ceasing by 1922.

FIRE FLOAT HULL

Between 1873 and 1886, a massive construction task took place to create the first railway tunnel under the River Severn, linking South Gloucestershire to Monmouthshire in South Wales. Its completion has been regarded as the crowning achievement of the civil engineer Sir John Hawkshaw, the chief engineer of the GWR.

Such was the scale and duration of this development that the contractor, Thomas A. Walker, developed a whole small town, Sudbrook, at the site. Sudbrook contained both housing for the workers, and a steel fabrication factory, run by his nephew C. W. Walker, to produce the tunnel lining plates.

With the completion of the tunnel in 1886, the fabrication factory looked around for other work and decided to become a constructor of steel boat hulls, a brave move at a time when the vast majority of boats were still of conventional timber construction. Walkers were approached by the Portishead authorities and duly constructed the 40ft-long (12m), 10ft-beam (3m) steel hull for the fire float.

THE DENNIS LOCO TRACTOR