22,49 €

Mehr erfahren.

- Herausgeber: The Crowood Press

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

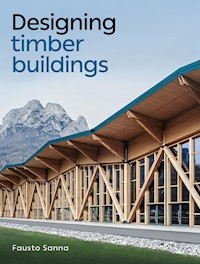

Over the last three decades, timber architecture has seen a resurgence in popularity thanks to the level of innovation, experimentation and environmental responsiveness it engenders. Designing Timber Buildings offers a comprehensive overview of timber as a construction material, in addition to practical design guidance. A series of ten exemplary case studies of award-winning timber building from around the world inform and inspire the design process. Topics covered include: the physical and mechanical properties of wood; preservative treatments; modified timber and engineered-timber products; environmental aspects of timber buildings and finally, structural systems and constructional techniques, including timber frame, structural insulated panels and cross-laminated timber. This book is richly illustrated throughout with detailed drawings and photographs documenting projects from construction to completion.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Veröffentlichungsjahr: 2022

Ähnliche

Spinelli Refugee Centre, Mannheim Germany, designed by the students of Atelier U20, Faculty of Architecture, Technische Universität Kaiserslautern. (Photo: Yannick Wenger – Mannheim)

First published in 2022 byThe Crowood Press LtdRamsbury, MarlboroughWiltshire SN8 2HR

This e-book first published in 2022

© Fausto Sanna 2022

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication DataA catalogue record for this book is available from the British Library.

ISBN 978 0 7198 4078 4

Cover design by Sergey Tsvetkov

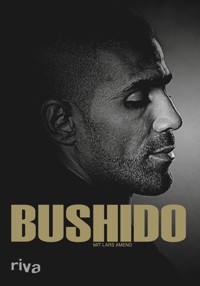

Front cover image: Congress and Exhibition Centre in Agordo (Italy), designed by Studio Botter and Studio Bressan. (Photo: Simone Bossi)

Back cover images: top left: house in Haute-Nendaz (Switzerland), designed by Jean-Michel Martignoni, Ma Maison Bois. (Photo: Franck Paubel, Ma Maison Bois, Switzerland & Kontio, Finland); top right and middle left: new FINSA Headquarters in Santiago de Compostela (Spain), designed by MRM Arquitectos. (Photo: MRM Arquitectos, Spain); bottom: Congress and Exhibition Centre in Agordo (Italy), designed by Studio Bressan and Studio Botter. (Photo: Simone Bossi)

DisclaimerThe information contained in this book is for guidance only and should only be used in conjunction with professional advice. The author and publisher disclaim all liability for any loss or damage, whether direct or indirect, arising as a result of the use of this book or the information contained in it.

DedicationTo my mother and Josema

Contents

Acknowledgements

List of abbreviations

Introduction

Chapter OneSolid wood and silvicultural practice

Chapter TwoTreated, modified and engineered wood

Chapter ThreeEnvironmental aspects

Chapter FourDesigning with timber-framed panels

Chapter FiveDesigning with structural insulated panels

Chapter SixDesigning with solid timber panels

Bibliography

Useful contacts

Index

Acknowledgements

IAM GRATEFUL TO THE PEOPLE WHO HAVE contributed to the preparation of this book: Annalaura Fornasier, Adam Primmer, Eleonora Piga, Liisa Murd and Alex Boyce.

A big thank-you to Nick Evans, Senior Lecturer at Cardiff School of Art & Design, for his very useful suggestions, and to The Crowood Press, for advice on, and insight into, the content and structure of this publication.

Finally, I would like to thank all the architectural practices, construction companies and institutions that have provided images and information on their projects:

ABCP architecture (Canada); Alma-nac (United Kingdom); Anton Varela García arquitecto (Spain); Andreas Kretzer, Hochschule für Technik Stuttgart (Germany); Atelier U20, Department of Architecture, Technische Universität Kaiserslautern (Germany); BGLA architecture + urban design (Canada); Catnic (United Kingdom), a Tata Steel Enterprise, in particular Charmaine Dean; Dietrich | Untertrifaller Architects (Austria); Dow Jones Architects (United Kingdom); Feilden Fowles (United Kingdom); Hemsec Manufacturing Ltd (United Kingdom), in particular Lizz Clarke; HK Architekten (Austria); Kontio Log Houses (Finland), in particular Pierre Vacherand; Lacol | arquitectura cooperativa (Spain), in particular Carles Baiges Camprubí and Cristina Gamboa; MAAJ Architectes (France); Ma Maison Bois – Jean-Michel Martignoni (Switzerland); Mirko Franzoso architetto (Italy); MRM Arquitectos (Spain), in particular Miguel Alonso Flamarique; Neumann Monson Architects (United States); Scotts Timber Engineering Ltd (United Kingdom); Studio Botter (Italy), in particular Andrea Botter; Studio Bressan (Italy), in particular Emanuele Bressan; Studio Weave (United Kingdom); Woodknowledge Wales (United Kingdom), in particular Gary Newman and Diana Waldron.

List of Abbreviations

AP

acidification potential

BRE

Building Research Establishment

BS

British standard

BSI

British Standards Institution

CAD

computer-aided design

CEN

European Committee for Standardization (Comité Européen de Normalisation)

CFCs

chlorofluorocarbons

CLT

cross-laminated timber

CML

Institute of Environmental Sciences (Centrum voor Milieuwetenschappen), Leiden University

CNC

computer numerical control

DLT

dowel-laminated timber

DPC

damp-proof course

EC

European Commission

EMC

equilibrium moisture content

EN

European Standards

EP

eutrophication potential

EPD

environmental product declaration

EPS

expanded polystyrene

eq.

equivalents

EU

European Union

FMB

Federation of Master Builders

FSC

Forest Stewardship Council

GHGs

greenhouse gases

glulam

glued laminated timber

GWP

global-warming potential

HFCs

hydrogenated halocarbons

IES

Institute for Environment and Sustainability

IPCC

Intergovernmental Panel on Climate Change

ISO

International Organization for Standardization

LoW

list of waste

LSL

laminated-strand lumber

LVL

laminated veneer lumber

MC

moisture content

MDF

medium-density fibreboard

MMC

modern methods of construction

NLT

nail-laminated timber

OSB

oriented-strand board

ODP

ozone-depletion potential

OPC

ordinary Portland cement

PCR

product-category rules

PD

published document (BS, ISO, CEN standards)

PE

primary energy

PEFC

Programme for the Endorsement of Forest Certification

PIR

polyisocyanurate

POCP

photochemical ozone-creation potential

POE

post-occupancy evaluation

PSL

parallel-strand lumber

PUR

polyurethane

PVC

polyvinyl chloride

RIBA

Royal Institute of British Architects

Sb

antimony

SCL

structural composite lumber

SIP(s)

structural insulated panel(s)

SO

2

sulphur dioxide

TF

timber frame

TPP

Timber Procurement Policy

UK

United Kingdom

UN

United Nations

US or USA

United States of America

VCL

vapour-control layer

VOCs

volatile organic compounds

XPS

extruded polystyrene

Introduction

Bring out the nature of the materials, let their nature intimately into your scheme. Strip the wood of varnish and let it alone – stain it. […] Reveal the nature of wood, plaster, brick or stone in your designs; they are all by nature friendly and beautiful. No treatment can be really a matter of fine art when these natural characteristics are, or their nature is, outraged orneglected.

Frank Lloyd Wright (1908, p.157)

Timber Architecture Today

Over the last three decades, timber has undoubtedly known a renaissance as a building material, especially when used structurally. However, an important distinction should be made between mainstream and one-off projects. The latter have enjoyed a very positive reception by critics and the profession at large, and favourable coverage in the media, such as magazines, journals and TV programmes, aimed at a variety of audiences. Timber architecture is also encouraged by numerous ad hoc initiatives and awards(1), organized by research institutions and professional or trade associations, which tend to reward the overall merit of timber-built projects, but also the level of innovation, experimentation and environmental responsiveness that they demonstrate.

One-off projects are often commissioned by open-minded clients, who wish to use sustainable resources and can appreciate the aesthetic qualities of timber as a construction material. Conversely, in the UK, mainstream timber architecture, especially in the residential field, tends not to exhibit its loadbearing structure but to mimic masonry construction instead. Many dwellings constructed of timber-framed or structural insulated panels adopt heavyweight cladding systems, such as brickwork or rendered blockwork (the former being particularly popular in England, the latter in Scotland). This results in timber dwellings not being easily identifiable as such, at least not at first glance and not from the outside. The reason for this preference is, on the one hand, a true appreciation for the appearance of masonry cladding and, on the other hand, a perception of masonry houses as more robust, more durable, and thus safer than their timber counterparts. This type of perception was reinforced in the 1980s, when a couple of accidental fires destroyed timber houses in Britain. This was widely covered by the media, resulting in negative publicity for the timber housebuilding sector. Unsurprisingly, developers involved in the delivery of mainstream housing – and related large schemes – need to expand their clientele, maximize their profit and therefore aspire to accommodate people’s perceptions and expectations of what a ‘good home’ (or a ‘good investment’) is and looks like.

A problem often encountered by designers leading a timber-based project arises from structural standards and building regulations. Every time a project adopts materials or techniques that are not conventional, meeting performance requirements might not be straightforward and may need special calculations or ad hoc assessments, as there is no common practice or modus operandi to rely on. This has immediate repercussions on how easily and quickly planning permissions can be obtained from relevant authorities. The same problem is also encountered in countries where, for instance, timber construction is mainstream in the residential low-rise sector, but is still much less developed for tall residential buildings or for non-domestic projects.

Another obstacle for those who embark on a timber-based project is finding the relevant expertise needed for each of its phases: requesting specialist consultancy at the design stage, ordering and stocking materials through the supply chain and using the skilled labour necessary to guarantee the desired level of workmanship.

Many of the architects that we have interviewed for the case studies presented in the book have lamented some form of difficulty or delay associated with obtaining approval for their proposed design, meeting the requirements of local building codes or finding the right expertise from amongst local tradesmen.

Structure of the Book

The first two chapters provide an introduction to wood, by explaining its natural properties and contemporary silvicultural practice (Chapter 1) and by exposing current developments in treated, modified and engineered timber (Chapter 2). Chapter 3 deals with the environmental aspects of timber architecture and illustrates some practical tools and resources to interpret the ecological credentials of wood-based products.

The remainder of the book delves into timber building techniques. Chapter 4 discusses timber-framed panels, Chapter 5 deals with structural insulated panels (SIPs), and Chapter 6 offers guidance on massive timber techniques, including cross-laminated timber (CLT).

Selection of Case Studies

The selection of cases studies presented throughout this book aims to illustrate recent developments in timber architecture, and spans different constructional techniques, building types and geographical regions.

While some of the case studies employ construction methods discussed in Chapters 4 to 6 (sometimes offering interesting variations on those themes), others employ hybrid methods or structural systems. For instance, we will see hybrid systems whereby timber-based techniques are complemented by steel or reinforced-concrete members, either to augment the overall rigidity of the building or to create an artificial platform, raised from the ground, that supports the upper storeys.

The budgetary constraints within which the buildings proposed were realized vary widely from case to case. For instance, Case Study 7 revolves around social sustainability and affordability of homes, and around novel living/housing models that can encourage these.

Although, as mentioned, the choice of projects aspires to illustrate the variety of present-day timber architecture, there are also some common denominators, one of these being the design team’s attempt to establish a strong connection between the building and its place. This connection has been achieved through different approaches: while some projects make reference to local building typology and provide an original re-interpretation of traditional building types, others create an interesting nexus with vernacular tradition by ‘citing’ just some of its elements or forms in a more abstract or metaphorical fashion.

All the selected projects, in addition, respond attentively to the characteristics of the site and often offer ingenious solutions to challenges such as very dense urban areas (with poor accessibility and consequent logistical problems for the construction phase), plots of irregular geometry, or humble surroundings (car parks, for instance, as in Case Study 9). Another aspect shared by all the projects is that the architects have resisted the temptation to conform, uncritically, to current design trends that leave little room for consideration of the genius loci and the architectural and constructional past of the place that hosts them.

For each case study, we will provide some general information first, and explain the context in which the design was commissioned and the brief generated, so that the most salient aspects of the design strategy can be appreciated. Then, we will deal with the technical aspects, to explain the materiality of the designs and how these were physically realized. We will discuss both the building techniques employed and the construction processes adopted, and how these were decided as part of a bespoke response to the unique conditions posed by the brief.

As regards the locations, some of the buildings are immersed in a rural landscape, while others attempt to make the most of the precious space within high-density urban areas. As a consequence, the residential buildings we propose are of diverse types and sizes: from detached, self-sufficient houses to flats that benefit from shared services and spaces, thus encouraging the occupants to live closely with one another and become part of a micro-community at the apartment-block level.

Finally, some of the case studies have – though to a different extent – an experimental nature and thus offer a unique and valuable contribution to the advancement of timber architecture. The details of the architectural practices that have led the projects can be found in the ‘Useful Contacts’ section towards the end of the book.

Table 0.1 Summary of the case studies, showing building type, timber techniques and geographical region.

Notes

(1) Timber competitions around the world include (but are not limited to): the Wood Awards organized by TRADA (UK), the Structural Timber Awards by the Structural Timber Association (UK), Deutscher Holzbaupreis by Holzbau Deutschland (Germany), Holzbaupreis Südtirol – Premio Archilegno Alto Adige by South Tyrol Architects’ Council (Italy), various regional awards in Austria (Holzbaupreis Steiermark, Oberösterreichischer Holzbaupreis, Niederösterreichische Holzbaupreis), Prix Nationale de Construction Bois (France), Træprisen (Danish Wood Award) by Træinformation (Denmark), Träpriset (Swedish Wood Award) by Svenskt Trä (Swedish Wood), Puupalkinto (Finnish Wood Award) by Puuinfo (Finland), the Wood Design Awards by WoodWorks (USA), the Building Excellence Awards by the Structural Insulated Panel Association (USA), the Wood Design & Building Awards by Wood Design & Building magazine (Canada), and the Australian Timber Design Awards by the Timber Development Association (Australia).

Chapter One

Solid Wood and Silvicultural Practice

Wood Species and Anatomy

Classification of woods

Trees can be divided into two broad categories: softwoods and hardwoods. However, this terminology can be misleading, in that not all hardwoods are harder than softwoods, and not all softwoods are less hard than hardwoods. From a botanical point of view, softwoods are gymnosperms (or conifers): they generally produce cones and their leaves are evergreen and shaped as needles or scales. The woody material produced by softwoods is non-porous. Hardwoods are angiosperms, as the ovaries of their flowers contain the seeds; they have broad leaves and are usually deciduous – they lose their leaves in the autumn or winter. The wood produced by hardwoods is porous.

Fig. 1.1. Redwood Grove at Leighton, in the Welsh county of Powys. (Photo: Woodknowledge Wales & Rosie Anthony)

Anatomy – macroscopic level

A tree trunk is composed of different parts, from the centre out:

• pith, which originated in the early growth of the trunk, prior to wood formation;

• heartwood, which is made of dead cells but nonetheless stores extractives (different types of biochemicals produced by the plant);

• sapwood, which conducts sap from the roots to the leaves, and also produces and stores substances that are fundamental for the living plant. In sapwood, parenchyma cells (which store nutrients) are alive;

• vascular cambium, a very thin layer that produces wood and bark via cell division, and is thus responsible for the growth of the tree;

• inner bark, through which the sugars produced by photosynthesis are transported from the leaves to the roots;

• outer bark, which protects the inner bark.

Heartwood and sapwood together constitute the largest part of the trunk; however, their mutual proportions vary greatly across wood species. Some species have a very thin sapwood band, while in others these two types of tissue are present in almost equal parts. When the cross-section of a trunk is observed with the naked eye, the distinction between heartwood and sapwood is very obvious in some species, as the two tissues have different colours: typically, sap is yellow and lighter, while heartwood is brown and remarkably darker. In other species, however, colour differentiation is much less pronounced and it is more difficult to distinguish one type of tissue from the other. The sapwood-heartwood proportion is important for applications in the construction industry, since the physical and mechanical properties of the two component parts are quite different. Sapwood tends to have lower density and lower strength than heartwood. Furthermore, in preservative treatments, sapwood tends to be more treatable than heartwood; consequently, the effectiveness and level of penetration of the preservative chemicals used depend on the proportion of these two types of tissue within the piece of wood to be preserved.

Fig. 1.2. Cross-section of a trunk (pine tree) showing the component parts of the woody material.

The anatomical axes and sections

It is very useful to consider the structure, physical properties and mechanical behaviour of wood by analysing the trunk relative to three different planes of section, which reflect its anatomy:

• transverse plane, which shows the cross-section of the trunk;

• radial plane, which is parallel to the longitudinal axis of the trunk and passes through its centre (the pith);

• tangential plane, which is parallel to the longitudinal axis of the trunk and tangent to any of its growth rings.

Fig. 1.3. The thermo-physical and mechanical properties of wood are better understood in reference to the three anatomical sections: transverse, radial and tangential.

Anatomy – microscopic level

At the microscopic level, the anatomical structure of wood changes between softwoods and hardwoods, as these are made of different cell types. Softwoods have two basic cell types: tracheids and parenchyma cells. Tracheids are very long cells (the length being around 100 times the width) and form about nine-tenths of the woody material.

Hardwoods have a more complex structure, with a larger number of basic types of cells, which show greater variation in shape and dimension. Hardwoods have vessels, which conduct water and are formed by cells (vessel elements) aligned in the longitudinal direction of the trunk. Vessels are much shorter than the tracheids present in softwoods, can have a small or large diameter and can be arranged in different patterns. The porous nature of hardwoods is due to the abundant presence of vessels. Fibres are another important cell type and offer mechanical support within the woody material; this is why the density and strength of timber depends upon the thickness of the fibres’ cell walls. Parenchyma cells are arranged in a more complex and varied manner than in softwoods.

Cell walls mostly consist of three different types of materials: lignin, cellulose and hemicellulose. In very simple terms, cellulose can be considered as a very long molecule with great tensile strength, which makes up macromolecules (microfibrils) that are part of the cell wall. Lignin is a matrix material in which the microfibrils are distributed; and hemicellulose is made of smaller molecules that improve the bond between lignin and cellulose.

Durability

Wood is vulnerable to different types of biological attack, by bacteria, insects, fungi and marine borers. Some insects attack wood because they feed on it (for example longhorn beetles and common furniture beetles); others because they form their nest inside it, but do not eat it. Fungi can cause different types of rot, depending on the components of the woody material that they can decompose and consume. For instance, brown rot is caused by fungi that break down cellulose and hemicellulose, and leave lignin intact; white rot, conversely, is caused by fungi that decompose lignin. Most types of fungi can only proliferate in moist wood: this means that the level of vulnerability of wood is directly proportional to its moisture content.

Natural defects

Wood is a highly variable material and can contain a number of natural defects, most of which originate from the history of the plant in the forest and the environmental conditions under which it grew and lived. Among other important factors that can be related to the presence of defects in the woody material sourced from a tree are: its growth on flat or sloping terrain, prolonged exposure to strong winds, and wide seasonal or diurnal variations in hygrothermal conditions (temperature and relative humidity of the air).

The size and number of natural defects have a noticeable effect on the properties of wood, especially mechanical ones: this is the reason why wood needs to be attentively inspected, graded and selected for structural applications. In each country, codes and structural standards set out the rules for the structural classification of wood and dictate what defects, and in what size or concentration, can be accepted for each structural class. The method by which the presence of defects is quantified can also vary from country to country.

In structural applications of wood, the presence of defects becomes particularly critical in the proximity of connections between members, where high stresses can form and need to be adequately resisted by the wood to avoid damage or failure.

Knots

The presence of knots is associated with the growth of branches from the trunk. A knot is the part of a branch that is incorporated in the trunk. Knots can be grouped into two types: encased and intergrown.

The extent to which knots can affect the mechanical response of a structural member depends on many parameters, such as their size, whether they are isolated or clustered, their soundness and their position within the member itself, and the type and magnitude of stresses in that location.

The detrimental effect of knots is much more evident in tension than it is in compression. For instance, in a simply supported beam that is subjected to gravitational loads and is bending as a consequence, a knot will have much greater impact if it is located at the bottom of the member (which is in tension) than at the top (which is in compression). In long columns, knots have been demonstrated to lower stiffness values. The influence of knots in roundwood is less pronounced than in sawnwood, chiefly because of the material discontinuity in the latter.

Cross grain

In the idealized tree, the direction of grain is perfectly parallel to the longitudinal direction of the trunk. However, this is often not the case in reality and cross grain is a common defect where the grain is at an angle to the longitudinal direction. Cross grain can be found in both softwoods and hardwoods and can present itself in a variety of configurations; spiral grain is one of the most common and is caused by spiral growth of the fibres around the trunk. Sometimes, cross grain is localized and limited to the area where the growth of a branch disturbed the regular orientation of the fibres around the longitudinal axis of the trunk. This is also the reason why the grain appears deviated around knots. Cross grain heavily affects the mechanical properties of wood, and experimental studies have demonstrated the relationship between the angle of slope and property loss.

Cracks and fissures

Cracks and fissures consist in discontinuity within the woody material. They can be caused by a variety of factors, some of which are associated with the felling and drying processes, others with the history of the living plant in the forest and related events. Once a trunk has been felled, the magnitude and distribution of internal stresses change and might result in cracks. Similarly, when wood loses part of its moisture content during the drying season or process, it is prone to the formation of cracks.

Reaction wood

Reaction wood is abnormal tissue that can grow within the leaning trunk of a tree. This tissue is called compression wood in softwoods, and tension wood in hardwoods. Compression wood forms on the lower side of the inclined trunk, while tension wood forms mostly, but not exclusively, on the upper side. Unsurprisingly, the tendency to develop reaction wood differs across species. Although not all the mechanical properties of reaction wood are poorer than those of clear wood, it is generally preferable (if not compulsory) to eliminate it, due to its abnormal behaviour and altered workability.

A pitch pocket (or resin pocket) is an opening within the woody material that contains resin; they can be found in some softwoods such as pine, spruce and larch. Since pitch pockets cause discontinuity within the woody material, they can result in loss of mechanical strength.

Thermo-Physical Properties

Anisotropy

Wood is a strongly anisotropic material, in that most of its physical and mechanical properties vary in the three anatomical directions that have been previously described: the longitudinal direction (parallel to the grain) and the two directions across the grain, radial and tangential. Therefore, when describing a property, especially in quantitative terms, it is in most cases necessary to specify to which direction it refers, or in which direction it has been measured. A sound understanding of the effects of anisotropy is key for designers to specify timber components correctly and to design buildings that employ timber constructional techniques.

Anisotropy noticeably affects the way in which timber changes volume due to fluctuations in its moisture content, and the way in which a structural member responds to external actions exerted in the three different directions.

Hygroscopicity and dimensional movement

Wood is a very hygroscopic material, which means that it can easily exchange moisture (both liquids and vapour) with the surrounding environment. The rate at which wood exchanges moisture with the air depends essentially on three factors: the quantity of water currently contained inside the wood, and the temperature and relative humidity of the air. The same piece of wood exhibits different thermo-physical properties and mechanical response to external actions depending on the amount of water that it contains, referred to as moisture content. More precisely, moisture content (MC) is defined as the mass of water contained in the wood divided by the mass of the ovendry wood. Although MC is expressed as a percentage, its maximum value can be much more than 100 per cent: for instance, the MC of green (unseasoned) wood can range greatly, between about 30 per cent and over 200 per cent. In green wood, MC can have different values between heartwood and sapwood, which depend on the species. It is normal for wood to undergo changes in MC as environmental conditions vary over time: a wood component in a building is exposed to fluctuations in the air around it (relative humidity and temperature) not only throughout the year (changes between one season and the next) but also throughout the day. Therefore, a wood component will undergo variations in MC as a result of these environmental variations, and the rate at which it does so will depend on whether it is has been previously treated or modified. Good design and specification should always take into account the possible variations of MC within timber building components, both structural and non-structural. The MC value at which timber is not exchanging moisture with the surrounding environment (neither absorbing nor releasing moisture) is called equilibrium moisture content (EMC).

While the exchange of moisture between wood and air is a relatively slow process, the exchange between wood and liquid water can be much faster. This means that wood can undergo rapid changes in MC if exposed to water, due to capillary action, especially if water is in contact with the end-grain. Unlike absorption of vapour, absorption of liquid water can even increase MC above fibre-saturation point.

Wood is dimensionally stable when its MC is above fibre-saturation point. Conversely, if MC is below this threshold, wood will undergo changes in volume as it exchanges moisture with the environment: it will expand (swell) during adsorption and contract (shrink) during desorption. The macroscopic variation in volume reflects the same phenomenon at the microscopic level: due to exchange of moisture, the walls of the cells undergo changes in volume.

The extent to which wood shrinks and swells as a result of changing MC varies greatly along the three anatomical axes, due to its anisotropy. Volume changes are minimal along the longitudinal axis of the trunk, but they are much greater in the radial direction and even greater in the tangential direction. Shrinking or swelling in the tangential direction is indeed about twice as great as in the radial direction. Due to this complex behaviour and marked differentiation between the three anatomical axes, a piece of wood can become distorted when it dries, especially if the drying process is rapid. It can, for instance, warp or split and this could compromise its suitability for the fabrication of a building component. Distortion and the appearance of splits and checks in a timber component can also happen during its service life, with repercussions that can vary from poorer appearance to decreased structural performance.

Thermal behaviour

Thermal conductivity of any given type of wood will vary, like most of its properties, depending on its MC. The conductivity of softwoods at 12 per cent MC is around 0.12-0.14 W/(m·K): this is an order of magnitude greater than materials typically used for thermal insulation, whose conductivity is around 0.020-0.035 W/(m·K).

Wood that has been completely dried (ovendry wood) expands when its temperature increases and contracts when it decreases, similar to most materials. The coefficient of thermal expansion reflects the anisotropic nature of wood: species and specific gravity do not affect the coefficient in the direction parallel to the grain (longitudinal direction) but do affect it in the radial and tangential directions. The dimensional change of wood that contains some moisture (as opposed to ovendry wood) follows a more complex mechanism. If the temperature of moist wood increases, the wood will initially tend to expand slightly following normal thermal expansion, but it will soon start to release part of its moisture and to contract as a consequence. These two behaviours combined will ultimately result in shrinkage as net dimensional change (because contraction due to desorption will prevail over expansion).

Mechanical Properties

Instantaneous behaviour

The structural response of timber members is rather complex. An initial simplification can be made for short-term loading conditions that cause low stress levels: wood can be considered as a material that fully adheres to the principles of elasticity. Therefore, we can assume that, in a wood member, deformation is directly proportional to the level of stress induced by the loads applied and is completely reversible. In other words, we assume the member to deform instantaneously when loaded and to revert to its original configuration immediately after unloading. This also means that we expect the wood member to respond instantaneously to both loading and unloading, without any changes in deformation if there are no changes in the loading conditions and no associated changes in stress levels.

Under this simple, elastic model, the constant of proportionality between stress and strain (or deformation) is the modulus of elasticity, which, due to wood being anisotropic, needs to be differentiated between the three anatomical axes. This means that three moduli of elasticity are to be considered: in the longitudinal direction (highest), radial direction (intermediate) and tangential direction (lowest).

When heavy loads are applied on a timber structural member that induce high stress levels, it will stop obeying the laws of elasticity and will exhibit a plastic response: this means that part of the deformation will remain after the loads have been fully removed. If the exerted loads are even greater, the wood member will eventually fail by breaking.

The modulus of rupture is the parameter used to measure the strength of wood in bending up to the elastic limit (but not beyond it). Other measures of strength must, once again, take into account the different behaviour along the anatomical axes. For instance, compressive strength is generally examined under two criteria: parallel to grain and perpendicular to grain. The former, for any given wood species, tends to be one order of magnitude greater than the latter. For example, for Sitka spruce at 12 per cent MC, compressive strength is 38.7MPa parallel to grain, but only 4.0MPa perpendicular to grain (experimental data from Forest Products Laboratory, 2010).

Structural classes

Standard BS EN 338 defines the structural classes of timber, in terms of its characteristic strength, stiffness and density. Different groups of classes are introduced: the classes for softwoods all have a C prefix (for coniferous), while the classes for hardwoods have a D prefix (for deciduous). The number following the C or D prefix designates the characteristic bending strength of the wood.

For instance, class C24 is for softwood with characteristic bending strength of 24N/mm2. Classes prefixed T (for tension) apply to softwoods used to fabricate engineered wood in which tension will be the predominant stress.

Creep: time-dependent behaviour

While the idealized assumption of elasticity for timber structures is very convenient for its simplicity and for computational purposes, it does not reflect their complex behaviour and can lead to poor, if not unsafe, design decisions. In reality, timber is a viscoelastic material and its mechanical response to external forces is the combination of two different properties, elasticity and viscosity, which yield immediate and slow responses, respectively, to the same actions.

Let us imagine that a timber member is subjected to a prolonged, constant load: it deforms as soon as the load is applied, and this instantaneous response is governed by the laws of elasticity. The deformation keeps increasing over time, governed by the laws of viscosity; this time-dependent behaviour is called creep. The rate at which the deformation increases over time however is not constant: initially the deformation increases more rapidly; then more slowly, until no more deformation occurs. If the load is removed from the timber member, a similar phenomenon will be observed. Part of the deformation will recover immediately (instantaneous, elastic response); then the deformation will continue to decrease over time, initially more rapidly and then more slowly until no changes in deformation will happen (time-dependent, creep response). However, at the end of this process, the deformation will not have completely recovered: a small portion of it is irreversible.

Creep occurs even when small loads are applied and low levels of stress are induced inside the structural members. Under typical service conditions and when constant loads have been applied for numerous years, the creep component of the total deformation can be equal to the instantaneous component. If the prolonged loads are sufficiently high, creep deformation can even lead to failure of a structural member.

Structural standards in different countries allow designers to account for creep behaviour for permanent or prolonged loads in a straightforward manner, without making calculation procedures too lengthy or onerous. It is important that designers appreciate this time-dependent behaviour of timber structures, when working on new buildings or when consolidating existing ones.

Silviculture

Global trends in the timber industry

A reliable source of information for world trends in the timber industry is the Global Forest Products, Facts and Figures report from the Food and Agriculture Organization of the United Nations(1). It divides timber production into the following categories: roundwood (used for any purposes other than energy), sawnwood, wood-based panels, fibre furnish and paper, and wood fuel.

Roundwood

Roundwood comprises pulpwood, sawlogs and veneer logs. The five largest producers of industrial roundwood are the United States of America, the Russian Federation, China, Brazil and Canada, which, combined, account for 53 per cent of global removals of roundwood.

Exports of roundwood are exiguous compared to other industries. New Zealand became the largest exporter in 2018, followed by the United States, Canada and the Czech Republic. The major producers of roundwood are also its largest consumers, with the Asia-Pacific region being the major importer, due to its relatively small production base.

Sawnwood

Sawnwood is wood that has been processed through sawing or chipping. The major producers of sawnwood are China, the United States of America, Canada, the Russian Federation and Germany, with a combined 58 per cent share of world production in 2018.

The largest exporters are Canada, the Russian Federation, Germany, Sweden and Finland. The major importers are China, the United States, the United Kingdom, Japan and Germany. China, the United States, Germany and Japan are also the major consumers, alongside Canada.

Wood-based panels

This category includes plywood, laminated veneer lumber, particleboard, oriented-strand board (OSB) and fibreboard (all described in Chapter 2). The largest producers are China, the United States, the Russian Federation, Germany and Canada, with a 69 per cent share of global production. These countries are also the major consumers alongside Poland.

The largest exporters are China, Canada, Germany, the Russian Federation, Malaysia and Thailand. The main importers are the United States, Germany, Japan, Poland and the United Kingdom.

Other forestry products

Other silvicultural activity is dedicated to the production of paper and paperboard, mainly used for packaging in the building industry. The United States and China dominate this market. Wood destined for fuel, instead, mostly originates from Africa and Latin America.

The timber industry in the United Kingdom

The United Kingdom (UK) does not play a key role in the global timber trade. Softwood accounts for the majority of British silvicultural practice: for instance, it constituted 92 per cent of total wood production in 2020(2). The UK, for this reason, does not have the natural capacity to meet its own demand for hardwood and runs a timber-trade deficit with other countries: in 2020, it imported 7.2 million m3 of sawnwood but produced 3.4 million m3 (2). It is worth noting that, out of 157 sawmills currently operating in the UK, 104 are exclusively dedicated to softwood(3).

The production of softwood and hardwood is dominated by Scotland and England, respectively. Climate affects the quality of wood: British softwood tends to exhibit lower mechanical properties than its Canadian and Scandinavian counterparts. This is because colder climates encourage a slower growth rate in trees, which has been demonstrated to favourably influence density and structural properties. As a result, UK-grown softwood tends to be used more for fencing and packaging than in construction(4).

Imports of sawn softwood mostly come from the European Union, with Sweden, Latvia and Finland providing the largest portion of trade. The UK imports particleboard from Germany, France and Latvia; fibreboard from Ireland, Germany and Spain; and hardwood from Estonia. By contrast, other products arrive from outside the European Union, with China and Brazil contributing most of the plywood, and the US and Canada most wood-pellets(5).

The management of UK forests is overseen by several entities: Forestry England, Forestry Commission (England), Natural Resources Wales, Forestry and Land Scotland, Scottish Forestry and the Forest Service (Northern Ireland). These bodies ensure the long-term sustainability of forests by issuing felling licences and Forest Management Plans, which set out the future development and strategies for individual woodlands.

Timber trade is regulated by the Timber Procurement Policy (TPP), which ensures the legality and sustainability of wood products, by asking producers to achieve official certification (such as FSC or PEFC, both explained in Chapter 3) or to present a case study with credible evidence, which will then be assessed on an individual basis(6). This framework is complemented by the European Union Timber Regulation and the Forest Law Enforcement, Governance and Trade, which prohibit trading with products from unlawful logging.

Table 1.1 Woodland area in the UK, by ownership and forest type, in thousand hectares. FE: Forestry England, FLS: Forestry and Land Scotland, NRW: Natural Resources Wales, FS: Forest Service Northern Ireland. (Source: Forestry Commission, 2020)

Table 1.2 Roundwood removals in the UK, by ownership and wood type, in thousand green tonnes. FE: Forestry England, FLS: Forestry and Land Scotland, NRW: Natural Resources Wales, FS: Forest Service Northern Ireland. (Source: Forestry Commission, 2021)

Fig. 1.4. A semi-automated sawmill in Scotland. The trees have been felled and the trunks limbed and bucked (cut to the same length). The logs thus obtained are now loaded onto a conveyor belt that takes them into the building where they will be further processed.

The timber industry in North America

The United States has become one of the largest traders in the global timber industry, which is one of the top ten employers across forty-eight American states. Oregon is the top producer of softwood(7), followed by Georgia, Arkansas, Mississippi, Alabama and North Carolina(8), while Pennsylvania, Tennessee, Kentucky, North Carolina and Virginia produce most of the hardwood(9).

The United States Forest Service is the agency of the US Department of Agriculture that administers 154 national forests and 20 national grasslands. It sells permits for wood removals. Additionally, individual states have their own forestry bodies and regulations.

Given its wealth of natural resources, it is not surprising that Canada’s timber industry plays a key role in the nation’s economy. In 2019, Canada produced 978,600m3 of hardwood and 57,653,200m3 of softwood(10). Of the total area of woodland in Canada, 90 per cent is publicly owned by the provinces or territories, 4 per cent belongs to the federal government, and 6 per cent is privately owned(11). By law, forest management plans must be put in place before any harvesting can start. These plans must be approved by the province or territory and should emphasize community participation and respect for indigenous peoples.

Responsible forestry management

Woodland occupies 31 per cent of the earth(12) and plays a key role in keeping a balanced ecosystem, especially because trees absorb carbon dioxide. Appropriate forest management can contribute towards mitigating climate change, with approaches that include reforestation (replacing harvested trees with new trees) and afforestation (planting trees where there are none). A wider palette of tree species ensures diversity and the long-term security of forests against climate change and pests. Finally, wood harvesting does not necessarily translate into complete disruption to wildlife, as careful planning can incorporate habitat maintenance and enhancement, for example by leaving soft edges (a gradual transition from open ground to forest) or by facilitating the juxtaposition of habitats (ensuring that habitat elements are located next to other critical components for the enhancement of wildlife)(13).

The UK Forestry Standard(14) includes the following elements in its requirements for responsible wood management: contribution to biodiversity, mitigation of climate change, respect for historic environments, preservation of landscape, inclusion of people and preservation of water and soil. National protection frameworks are supported by the United Nations’ six Global Forest Goals: the reversion of forest loss, the enhancement of forest economies, the increase in protected woodland, the mobilization of investment in sustainable forestry, the promotion of governance frameworks at national and international level for the sustainable management of forests, and the establishment of international collaboration(15). The United Nations places strong emphasis on the inclusion and respect for local communities and indigenous people in forest management. The World Heritage initiative, by the United Nations Educational, Scientific and Cultural Organization, also ensures that places of outstanding cultural and natural beauty are maintained, many of which include woodlands. Several protective international treaties and conventions are in force, such as the International Tropical Timber Agreement, Convention on Biological Diversity and the International Arrangement on Forests(16).

Although the rate of deforestation is decreasing, agricultural expansion continues to drive the reduction in woodland mass(15). More worryingly, illegal logging remains a huge risk to the long-term sustainability of forests with a share of 15 per cent and 30 per cent of global timber trade, with special incidence in the Amazon Basin, Central Africa and Southeast Asia, where some of the most important ecosystems are located(17). In the UK and the European Union, the requirements set by the Timber Procurement Policy and the European Union Timber Regulation fully ban trading timber products originating from illegal logging. In the United States, the Lacey Act of 1900, which forbids trading with plants and animals of illegal origin, was amended in 2008 to include timber(18). These legislative measures show that there is political will to eradicate illegal timber activity worldwide, with its devastating effects on the environment, human rights and wildlife.

Fig. 1.5. Example of stump regeneration in a coniferous forest. This process ensures the long-term sustainability of felling by replacing harvested trees with new ones. (Photo: Woodknowledge Wales & Rosie Anthony)

Notes

(1) Food and Agriculture Organization of the United Nations, 2018

(2) Forest Research, 2021

(3) Forest Research, 2019

(4) Ross, 2011; Davies, 2013; Forest Research, 2021

(5) Forest Research, 2012

(6) Department for Environment, Food and Rural Affairs, 2013

(7) Oregon Forest Resources Institute, 2016

(8) United States Forest Service, 2021

(9) Luppold et al., 2017

(10) Canadian Forest Service, 2020

(11) Natural Resources Canada, 2020

(12) Roux et al., 2020

(13) McEvoy, 2012

(14) Forestry Commission, 2017

(15) United Nations, Department of Economic and Social Affairs, 2019; Food and Agriculture Organization of the United Nations, 2020

(16) Sotirov et al., 2020

(17) Interpol, 2019

(18) U.S. Fish and Wildlife Service, ca.2008

Chapter Two

Treated, Modified and Engineered Wood

Preservative Treatments

Assessing the need for treatment

Preservative treatment is performed to increase the durability of timber and make it less susceptible to biological attack and consequent deterioration by insects, fungi, bacteria or marine borers. Thus, preserving timber lowers replacement costs and contributes to better, more efficient and sustainable utilization of forest products. The necessity for treatment should be evaluated against a variety of factors: the natural durability of the wood species, the service conditions under which the wood components will be used (expected levels of relative humidity and exposure to moisture), the presence or absence of sapwood, the expected service life of the components, and the other materials with which the timber components will be in contact (for example metal fixings or flashings, which might be prone to accelerated corrosion).

Fig. 2.1. Roof constructed of trussed rafters. (Photo: Woodknowledge Wales & Rosie Anthony)