28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

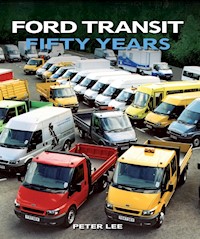

A commemorative history of fifty years of the iconic Ford Transit van, from the launch of the first-generation Transit in 1965, right up to the present day. Covering the full range of Transit models and with over three hundred photographs (including previously unpublished pictures from Ford's picture archive), Ford Transit - Fifty Years is an ideal resource for anyone with an interest in this world-beating commercial vehicle. Written by acknowledged Ford Transit expert Peter Lee, the book covers the development era - light commercial vehicles in the 1950s, the 'Project Redcap' prototypes and the first Transit. Production and development of all eight generations and variants of Transits are also covered, including custom vans, camper vans, minibuses and special vehicle options. Specification guides, awards, sales figures are all included as well as marketing worldwide. Finally, there are interviews with designers, engineers and Ford employees, along with owners' experiences. The Transit has and continues to receive numerous awards, voted 'International Van of the Year' in 2001 and 2013. With the 2014 launch of the all-new two-tonne Transit and its pioneering technology, this looks to be only the first fifty years of the Ford Transit story.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 377

Veröffentlichungsjahr: 2015

Ähnliche

FORD TRANSIT

FIFTY YEARS

PETER LEE

THE CROWOOD PRESS

First published in 2015 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2015

© Peter Lee 2015

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 874 5

CONTENTS

Dedication and Acknowledgements

Preface

Timeline

Introduction

CHAPTER 1

THE VANS THE TRANSIT WOULD REPLACE

CHAPTER 2

A NEW VAN FOR EUROPE: BRITAIN AND GERMANY MOVE FORWARD

CHAPTER 3

TESTING TIMES

CHAPTER 4

MK1 TRANSIT, 1965 TO 1978

CHAPTER 5

CAMPERVANS TO CUSTOM VANS

CHAPTER 6

MK2 TRANSIT, 1978 TO 1986

CHAPTER 7

MK3 1985/6 TRITON (VE6)

CHAPTER 8

MK5 FACELIFT ‘SMILEY FACE’ VE83

CHAPTER 9

MK6 (V184 AND V185)

CHAPTER 10

MK7, 2005

CHAPTER 11

THE NEW 2012 TRANSIT CUSTOM (V362)

CHAPTER 12

TRANSIT CONNECTS, 2002

CHAPTER 13

MK8 TRANSIT, 2014

CHAPTER 14

MARKETING TO COLLECTORS, 1965–2014

Appendix: Ford UK Transit Sales

Postlude

Index

DEDICATION

Dedicated to Henry Cooper. Henry is seen below at a Ford event near Coventry in 2010, attended by the Transit Van Club and some of its members.

ACKNOWLEDGEMENTS

There are a hundred people I would like to thank and without whose help this book would never have been achieved. They have taken the time to talk to me about the Transit in their homes, in cafés, restaurants and hotels. The designers and engineers have all been very modest about their input in the life of the Transit, while the custom van guys have brought back so many fond memories about the freedom of the roads in the 1970s. I may have put pen to paper, but it would not have been possible to complete this book without your help. My heartfelt thanks to you all.

Arthur Molyneaux, Fred Blumenthal, Brian Eckersley, Michael Hallsworth, John Packwood, Paul Bourgeois, Andy Boyle, John Reed, Gary Whittam, Barry Gale, Detlef Jenter, Dave Hill, Steve Stringer, Sandy Glen, Brian Walker, Terry Drury, Paul Harrison, Dan Jones, Alan Llewellyn, David Petts, Dugald Thompson and, last but not least, Natasha Rose and Elana Rose, and my understanding wife, Debi.

Pictures reproduced by kind permission of Ford Motor Company unless otherwise stated.

PREFACE

Writing a book on the history of the Ford Transit van has been on my mind for a number of years. Having been in contact with the Transit for all of my working life in one way or another, the Ford Transit has become an integral part of my life. Some may call my interest in the Transit an obsession or addiction. I would like to to explain just why I undertook this large and very complicated task of detailing fifty years of the Transit story.

My fondness for the Transit has grown steadily since, as early as 1965, I worked delivering papers to Underground stations, first in Bedford CA vans, then in Transits, just to get some extra pocket money, although I was underage to work in this dangerous environment. Together with a few other lads, we would be collected just outside Fleet Street and then whisked off at crazy speeds; it was all good fun for a young boy in London. Some years later my family decided to leave London and I ended up living near Ford’s Langley plant. While halfway through my bricklaying apprenticeship I decided to leave and ended up working on the Ford assembly line at Langley – yet again the Ford Transit was putting money in my pocket. When Ford moved production of the Transit to Southampton in 1971/2 I left the plant and bought my very own Transit.

I drove it to Spain (quite an adventurous thing to do at the time) but I was part of the hippy movement, and it just seemed right. I lived in the van in Spain for thirteen months. The Transit put a roof over my head and kept me safe. In the 1980s I started my own building business and ended up owning a fleet of twenty Transits, so yet again it helped me build up a business and become independent.

In the 1990s my Transits helped fulfil my dreams of building my own home (while still fulfilling all my business needs). In the new millennium and beyond it has given me a hobby in my retirement, helping to pass the time doing interesting things and meeting interesting people nearly every day.

You might think that was enough to create a fondness for any vehicle but that is only half the story. The Transit has also become a massive part of my life in so many other ways. It has given me the chance to meet people all around the world. In the 1970s I started to collect items related to the Transit and this has grown into a collection – even perhaps an archive – that numbers more than 23,000 items.

My collection of Transit-related items has become a reference point for myself and thousands of interested Transit van fans around the world. Even Ford themselves ask for help from time to time and thus I am involved with all the new Transit models. On the customizing side, having joined the National Street Van Association when I was just a lad, custom vanning has given my family many wonderful weekends and holidays visiting shows and events all round the world, building a lifetime of memories.

My knowledge of the Transit van has grown over the years and my collection has grown with it. There are now thousands of bits of paperwork and press packs at my fingertips to provide dates and information for this book, as well as hundreds of great memories and friends. This is all based on the Ford Transit van. It has helped me all my life in one way or another. So now it may just be the time to give something back.

Peter LeeApril 2014

TIMELINE

FORD TRANSIT: THE EVOLUTION OF A COMMERCIAL VEHICLE ICON, 1965–2013

Production of Ford’s legendary commercial vehicle, the Transit, has reached seven million units worldwide, almost fifty years after the first example left the line. This is the latest impressive landmark in the Transit’s extensive history, which has seen this iconic brand achieve growing popularity around the world under the One Ford strategy.

Pre-1965

Before 1965 Ford offered two independent commercial vehicle lines for European customers: the FK van built in Cologne, Germany, launched in 1953, and the Thames van built in the UK, launched in 1954. From the early 1960s there was a clear demand from van customers for more – more load area capacity, more payload, more flexibility and more speed – and Ford decided to replace the two models with an all-new generation of purpose-built vans that would address the needs of all European markets and be built in both the UK and Germany.

1965

The first Transit came down the line at the company’s Langley commercial vehicle plant in Berkshire, England, on 9 August 1965. It was already packed with such innovations as a printed circuit board in the instrument panel, an optional steering lock, a side-loading door and seatbelt attachment points. Soon after launch more innovations were introduced, including halogen headlights, tubeless tyres and weight-saving minimal leaf springs.

A 74 PS 1.7-litre engine or an 86 PS 2.0-litre petrol engine powered the original Transit, and the first diesel engine was a Perkins 4/99 with 44 PS. It was available in two wheelbases, each with three payload derivatives (short-wheelbase ranging from 610 to 1,120kg, long-wheelbase ranging from 1,272 to 1,782kg). Vans could be built with twin rear doors or a tailgate, slam or sliding cab doors, and with or without a side-loading door.

1971

Transit’s appearance was modernized with the introduction of a more car-like grille.

1972

Ford introduced its first small high-speed diesel engine, called the York. It came in two power ratings, 55 PS for use in the short-wheelbase models and 62 PS for use in the heavier, long-wheelbase models.

1973

To reduce running costs for owners, Transit was the first commercial vehicle to fit radial ply tyres across the range.

1974

New 1,000kg payload model based on the long-wheelbase body shell but running on single rear wheels.

1975

The new Transit could immediately be recognized by a new functional ‘black look’. The grille, bumpers, windscreen trim and wing mirrors were all painted black. Inside the cab the pedals were moved forward and the seat moved back to create 100mm of extra legroom, while the steering column was lengthened to improve the driving position. Even more importantly, Transit was the first to use servo-assisted front disc brakes – in short-wheelbase models from 1975, and in long-wheelbase models a year later.

1976

A new top-weight Transit, the 190, was introduced, taking Transit’s maximum gross weight to 3.5 tonnes. As part of this programme, front disc brakes were introduced across the range, with the new heavyweight 190 featuring ventilated disc brakes for the first time on a medium commercial vehicle.

A major production milestone was reached as the onemillionth Ford Transit was driven off the assembly line.

1978

Transit’s first major styling change came with the launch of the new-shape model in March 1978. The hitherto stubby bonnet was now more streamlined and lengthened so that it could adequately accommodate both petrol and the increasingly popular diesel engines. At the same time new, more fuel-efficient overhead cam (ohc) engines were introduced. Other changes included the introduction of Ford’s C3 automatic transmission and a new more powerful heater with car-like ducting.

1983

As part of the 2.5-litre direct injection (Di) diesel development programme, 100 prototype engines were used in an extensive field trial with operators.

1984

The revolutionary 2.5-litre Di diesel engine was introduced, which used a rotary fuel injection pump. It gave a power increase from 62 to 68 PS and yet at the same time led to fuel consumption improvements of up to 24 per cent on short-wheelbase models and 20 per cent on long-wheelbase models.

1985

Another production milestone – the two-millionth Ford Transit was produced on 25 July 1985.

1986

The next all-new Transit was introduced in January, just over twenty years after the launch of the original. This daringly radical ‘fast-front’ Transit had a best-in-class drag coefficient (CdA) of 0.37, which was better than a number of cars at the time. While the load space was increased by between 11 per cent and 13.5 per cent, the CdA was reduced by 11 per cent, allowing a fuel consumption saving of up to 8 per cent.

The new nose was not just an aerodynamic device; it was also designed to collapse progressively in a crash and thus improve safety. The new wide bonnet provided unrivalled access to the engine for servicing. The design team created bigger cab doors, with deeper windows, giving a greater sense of space. Load access was improved by using wider and taller rear doors and increasing the width of the sideloading door, so that it would accept a 1 metre-wide pallet. Other important changes included the introduction of modified MacPherson strut independent front suspension and rack-and-pinion steering on short-wheelbase models, direct glazing for the windscreen, plus the use of high security ‘Chubb-style’ locks on doors and the ignition to improve vehicle security.

1991

Transit broke new ground again with a major redesign of the underbody structure. It not only improved manufacturing efficiency and thus build quality, but also allowed these models to handle the full force of a 48km/h (30mph) barrier crash test. The new underbody design allowed a new one-and-a-half tonne payload short-wheelbase model, the Transit 150, to be introduced on 15-inch wheels.

Long-wheelbase models changed even more significantly. The 15-inch wheels became standard, the model adopted single rear wheels and switched to independent front suspension with rack-and-pinion steering.

The 1991 model also introduced a turbocharged diesel engine into a Transit. This new derivative of the 2.5-litre Di featured the first use of electronic management on a medium commercial vehicle, which was key to it producing 100 PS and also meeting stringent exhaust emissions standards. A new 80 PS, naturally aspirated 2.5-litre Di diesel, which used a ram effect inlet manifold and complemented the existing 70 PS unit, was also introduced.

1994

Ford produced its three-millionth Transit vehicle on 15 September, the same month in which another new Transit was introduced. Easily recognizable by its friendly oval-shaped grille, this model was the most refined, secure and safest Transit ever built. Sound levels measured at the ear were 5dB lower than before, representing a dramatic reduction in the perceived noise level of almost 70 per cent.

The security of all van and chassis cab models was significantly improved by a number of specifically designed deterrents including central locking, a perimeter alarm, doublelocking and Ford’s electronic, passive anti-theft system. Occupant safety was further improved by the introduction of a full three-point lap and diagonal seatbelt for the frontcentre passenger and the availability of driver and dual passenger airbags.

Driver comfort was improved by a restyled cab interior, featuring new trim materials in lighter, brighter colours, a completely revised dash incorporating a Mondeo-style instrument cluster and new climate control system.

1995

From the spring, the simple lap belts fitted to all rear seats of 12- and 15-seat Transit buses were replaced with threepoint, lap and diagonal seatbelts.

1996

The Transit 17-seat minibus made its debut. It had comfort, plus the highest level of safety of any vehicle of its kind including: three-part inertia reel lap and diagonal seatbelts throughout, tested to passenger car standards, high-backed rear seats with fixed head restraints, driver and outer front passenger airbags fitted as standard, and anti-lock brakes fitted as standard.

1997

Transit went into production at Ford’s assembly plant at Hai Dong, Vietnam, and the first Chinese-made Transit vehicle is built by JMC in Nanchang, a joint venture operation between Jiangling Motors Co. Ltd and Ford.

1998

Electronic Brake Force Distribution and Traction Assist were introduced along with an enhanced immobilization system and improved steering column locking. For the first time, Transits of varying specification were converted to run on liquefied petroleum gas (LPG), and an Autoclutch system was introduced with manual gear selection and automatic clutch operation.

2000

After thirty-five years, the next generation all-new Ford Transit was launched. Produced at Ford’s Genk assembly plant in Belgium, it made its public debut at the RAI 2000 European Road Transport Show in Amsterdam. It was an industry first with front-wheel drive and rear-wheel drive configurations built on a common platform.

Production milestone – the four-millionth Ford Transit was built.

2001

Formula One-style gear change technology came to the new Ford Transit range with the advanced Durashift EST automated transmission.

The new Transit was voted ‘International Van of the Year 2001’, ‘Parcel Van of the Year 2001’ in Germany. and also won the prestigious 2001 Arctic Van Test held in Lapland.

2002

The 4.25-tonne, dual rear-wheel Transit Jumbo was launched at the Amsterdam International Motor Show. Building on the success of the 3.5-tonne Jumbo, launched in 2001, the new model offered Transit’s best-ever combination of load space and payload.

Ford also unveiled the Transit Connect, a smaller member of the Transit family offering class-leading load-area flexibility and security as well as low cost of ownership.

Ford’s new common-rail turbo-diesel engine, the Duratorq TDCi, became available on the Transit, initially offered as a 2.0-litre 125 PS option on front-wheel drive Transit models.

2003

A new 2-tonne low-floor, front-wheel-drive model joined the range.

The new Transit Connect was voted ‘International Van of the Year’ for 2003 and received awards in seven individual countries.

Another industry first – anti-locking brake system (ABS) became a standard feature.

2004

Production of Ford Transit moved from Genk, Belgium, to the state-of-the-art Ford Otosan plant in Kocaeli, Turkey.

2005

The Ford Transit Connect won the 2005 Arctic Van Test, held in Lapland.

Another milestone as the five-millionth Transit was built. On 9 August 2005 the Ford Transit celebrated its fortieth birthday.

2006

A new-generation Transit was launched, with a fresh exterior design and a new cabin offering a dash-mounted gear lever and increased comfort and feature availability. Ford’s Electronic Stability Programme (ESP) feature became widely available through the product range, while a new range of engines – six diesels and one petrol, also with compressed natural gas (CNG) and LPG conversions – offered clean and efficient power.

2007

Intelligent All Wheel Drive was added, making Transit the only van to offer front-wheel drive, rear-wheel drive and all-wheel drive versions on the same platform. ESP was now standardized on all front- and rear-wheel drive models with the Duratorq TDCi engine, and the new Transit SportVan Series was introduced.

The Transit was voted ‘International Van of the Year 2007’.

2008

The powerful new 3.2-litre Duratorq TDCi engine with 200PS and 470Nm was introduced for high payload rearwheel drive models.

2009

The fuel-efficient Transit ECOnetic was launched. With the optional coated diesel particle filter (cDPF), Transit ECOnetic was the first Ford commercial vehicle to achieve Euro Stage V emission levels.

2010

Transit passed the six-million production milestone on 30 April. Transit had its forty-fifth anniversary in August.

2011

With the launch of the 2012 Transit, Ford introduced the new global 2.2-litre Duratorq TDCi diesel engine family, offering Euro Stage V emission levels and new fuel-saving technologies including Auto-Start-Stop and switchable speed limiter.

2012

Press launch of the all-new Transit Custom, a dedicated solution for the one-tonne market that offered new levels of style, safety and load-carrying ability, as well as excellent fuel economy and cost of ownership. The Transit Custom was also the first vehicle in its segment to receive a Euro NCAP five-star safety rating. Named ‘International Van of the Year 2013’.

In parallel with the introduction of the Transit Custom, Ford also revealed its full plans for renewing and extending the Ford Transit range with an all-new four-model line-up. In addition to the one-tonne Transit Custom, this line-up would comprise the all-new two-tonne Transit, for launch in spring 2014, which was also to be manufactured and sold in the USA for the first time.

2013

On 20 June Ford celebrated production of the seven-millionth full-sized Transit. At the same time, an all-new Transit Connect was launched in late 2013. The Transit Custom was again named ‘International Van of the Year’. Ford forecasted that, by 2016, a Transit would be sold every eighty seconds.

2014

The Transit Connect UK press drive days started on 17 February. The Transit Connect ECOnetic was released, with the all-new Transit Courier being launched in Frankfurt, Germany, on 27/28 May. The new full-sized Transit was launched in Barcelona, Spain. The Transit Custom showed off its new high top.

Ford’s Transit market now extends to 118 customer markets across six continents. Once its new plants are fully established, it is anticipated that Ford will produce 400,000 Transits a year.

INTRODUCTION

The life of the Ford Transit van has spanned five decades and thousands of technical advances have been introduced. Ford have justifiably been very proud of the enormous range of uses and of variations on the basic Transit van, but they have not made it easy for anyone writing a book about covering almost fifty years. The changes made to the Transit throughout its long life have not only transformed the vehicle itself, but in many cases they have also changed the whole industry. The Transit has always led the way and set the standard for other vans in the market to follow.

Nearly every motorist and journalist in Europe has encountered or written about the Transit at some time or another. During its lifetime, it has been used to transport equipment for (and indeed members of) hundreds of wellknown pop groups, been involved in thousands of high-speed police chases, taken millions of people to hospital after accidents and has become a film and television star. Not only has this amazing vehicle changed the way we look at vans, it has changed how we use them and even the way we define a van.

Every owner of this amazing van has their own stories relating to the Transit. Most of them are aware of the fifty-year history and the legendary stories that surround it. As with all iconic vehicles, astonishing facts and figures just seem to congregate around the Transit. It has broken many barriers during its long life: counting the numbers produced and the types of Transit that have been made are just the start when it comes to measuring the history of the van.

The Transit van can be adapted to incorporate any business or use. It is, and always will be, the Swiss Army Knife of light commercial vehicles, the yardstick that other manufacturers use to measure the success of their own products. It is every builder’s skip, every mechanic’s workshop, every market trader’s stall, every van driver’s office as well as being the billboard to advertise their business. Sometimes people love their Transits so much that they even give them names and the van becomes part of their family. So why do people love it so much? Well, it is really a double act: it helps put food on the table during the week and can be used for recreational purposes at the weekend. The Transit is the perfect companion.

At the heart of the Ford Transit is its capability to adjust and change into a vehicle that does any job in any environment. How many other vans have been converted to a train or been driven at 167mph? One question that comes up time and time again when talking to people about classic vans is ‘What is your favourite Transit van?’ The answer always turns out to be ‘the one I grew up with’. It’s the same scenario as when being asked to choose a favourite James Bond or Doctor Who. It all boils down to people feeling comfortable and safe with their Transit as a part of their lives.

TIME FOR A CHANGE

The light commercial vehicle market in the late 1950s was antiquated. Light goods vehicles were outdated and the ‘bricks on wheels’ vans were not really fit for the purpose, although they were the best that technology and building techniques could offer at the time. The vans of the day were noisy, dirty and very uncomfortable to drive. They could carry only light loads or they would become unstable when driven at any speed. They were hard to drive empty and even harder when loaded, with a ponderous turning circle. They were seen as light vans to carry light loads. Carrying any weight at all made the fuel consumption inefficient and not cost-effective. The driving experience overall was poor, so companies tended to make all their deliveries in larger heavy goods vehicles rather than use lighter vans.

All van manufacturers of the day knew they had to change this antiquated way of getting goods from one place to another, especially as city streets grew more congested. Most companies had brought a team together to look at the way forward. The industry looked at new light vans, but they were still using old designs and outdated technology rather than starting from scratch – making the mistake of using old models on which to base their new products.

The designers at Ford were aware that a new van was needed. They had been working on a new product for a number of years and a project called the 800E was nearing completion by 1957. Within two years this was quite an advanced project, with prototypes having been made and tested. It was not until a visit from Henry Ford II (who had been president of the Ford Motor Company but after a restructuring was now its CEO) that things changed unexpectedly. The UK was his first destination on a European tour that he undertook as he was concerned about the structure of the company worldwide. In order to achieve a better understanding of the company he had inherited, he needed to get some idea of the general day-to-day running of the operation. While in Europe he visited plants, design studios, offices and some Ford franchises. It should be noted that at this time the Ford operations in the UK and Germany were run as separate companies.

When visiting London he was invited to an impressive presentation at Ford’s Averly head office, where he was shown the complete vehicle range that Ford in the UK had planned for the near future. Centre stage was the 800E, the prototype of the new Ford Thames commercial ‘light van’, which was going to take Ford forward into the 1960s. The prototype was nearing completion and the UK team was sure it would impress the new CEO and be the star of the show.

A day or two later Henry was flown to Cologne and treated to a carbon copy of his London trip. He was then proudly shown the new commercial vehicle range that Ford designers in Germany were working on, including the new Taunus Transit van. Both countries made a point of showing off their new vehicles in lavish displays. Henry Ford II, however, remained unimpressed. He did not understand why two different Ford companies, ignorant of the other’s plans, were building two vehicles that were basically going to do the same job. It meant the two vans would then be built in two different plants, thus costing twice as much to produce. They would also be competing with each other for the same European market. He felt that the whole dual exercise was a complete waste of time. Both Ford UK and Ford Germany had put a lot of effort into their new products and made them the main focus of the visit. This only served to highlight their intentions and their expectations. Henry could not understand why, if they were part of the same ‘Ford’ team, they were competing with one another and thus escalating the ongoing battle for the van market.

Henry Ford II’s concerns were confirmed a few days later when visiting a Ford dealer in France. The Thames 400E (designed in the UK) and the Taunus Transit (designed in Germany) were on sale in the same showroom. This was also the case in the Netherlands, Italy, Spain and Belgium, where Ford Germany and Ford UK were in competition with each other. While this had been sanctioned by the earlier management, Henry Ford II knew this had to change and was concerned about the lack of communication between the companies and the resulting expense of employing two sets of manufacturing teams and their separate design costs.

Henry knew that Ford could save millions by combining the two commercial vehicle projects. His feelings were later proved correct when the new common van known as Project Redcap saved Ford around £16 million in design costs alone. It also made the upper management look at Europe in a different way: a couple of years later, as a direct result of this project, Ford Europe was born.

On his return to the USA Henry Ford II wrote to both design teams and told them that Ford was ‘one’ company selling Ford products. Since the full range of vehicles carried ‘one’ badge, the design teams from both countries should come together and design ‘one’ common van. To overcome any problems both teams were to establish a concept for this vehicle and send their designs over to the USA, where Henry himself would pick the one that would be fully designed and then manufactured for sale in Europe. The chosen design would take the project forward under one banner and one project name. It would be built by plants in both countries but, most importantly, would be embraced fully by both countries and sold across Europe and the World.

CHAPTER ONE

THE VANS THE TRANSIT WOULD REPLACE

FORD THAMES 400E

Not knowing the Ford Thames very well, I decided to ask a man who does. Sandy Glen has been driving Ford Thames vans for as long as I can remember. He runs the Ford Thames owners club and owns a vast collection of items and vehicles. Sandy kindly agreed to fill me in on the history of the Ford Thames.

Introduced in November 1957, the Ford Motor Company’s new 400E 10/12cwt and 15cwt medium range van was a massive leap forward from the, by then, archaic E83W 10cwt range that it replaced.

Gone were the transverse leaf springs, the front beam axle, the very basic E93A side-valve engine and the almost complete absence of any driver comforts. The new van did retain a live rear axle, but now it was located on a pair of longitudinal leaf springs, and drive was by a conventional open propeller shaft, rather than torque tube.

The Ford Thames 400E was sold in the UK, Canada and Europe.

At the front, things were radically different. The old beam axle had been replaced by upper and lower, unequal length wishbones, and coil springs with telescopic dampers. The new fully forward-control driving position required a much more elaborate steering linkage, but directional stability was greatly improved over the E83W, plus the turning circle was excellent.

To continue the mechanical upgrades, the 1703cc engine and three-speed gearbox from the recently introduced Mk2 Consul were used in lightly modified form for the new range. This engine had a markedly larger capacity than its direct competitors and ensured a lively performance for a commercial vehicle. Speeds of 55–60mph were easily achieved, compared to the old E83W, which was struggling at anything over 40mph.

Work on the prototype Thames van was scrapped to start the Transit project.

Unlike some of the competition, Ford did not opt to go with the unitary construction or monocoque chassis adopted by Bedford for its CA range, or later BMC for the J2 and J4, and Commer for its 1500 PA vans. Ford kept a fairly simple ladder chassis design for the whole range, although somewhat ‘beefed up’ compared to the outgoing model. This gave Ford a distinct advantage in sales for specially built bodies to be fitted. In addition to the normal van and minibus/estate car versions, Ford offered the 400E as a chassis cab, ready to have the very popular wooden drop-side, Luton or box-type bodies mounted. Ford themselves offered a steel built pick-up float from 1961 onwards.

The last Thames 400E off the line at the Langley plant.

Because the separate chassis did not need the bodywork to keep it rigid, Ford could offer the 400E as a chassis/front end, or as a chassis cowl, with just the lower front panel of the external bodywork, plus the normal floor pan/engine bay structure. This enabled specialist bodies such as laundry vans, bakers’ vans, mobile shops, ice cream vans, ambulances and many more to be built integrally on the 400E chassis. This gave Ford a considerable advantage over their rivals in this respect.

As such a large proportion of production was chassis cabs or minibus/estate cars, and a proportion of vans fitted with side-loading doors, Ford never offered a sliding door option, which was perhaps the only area where they did not try to compete.

When the 400E van range ended in August 1965 it looked pretty much the same as when it had started. It did, however, get a mechanical ‘refreshing’ in November 1962 when the uprated 1703cc engine from the new Mk3 Zephyr 4 was fitted and the Mk3’s new 4-speed gearbox became available as an extra cost option, although the old Consul 3-speed was retained as standard up to the end. Also, in 1961, the Perkins 4/99 diesel engine became a factory option for those less interested in performance than economy.

For the driver of the new 400E range things were a lot better than they had previously experienced. The new seating position made visibility much better, helped by having windscreen wipers on both sides of the screen, although still using Ford’s favoured vacuum operation. The electrics were 12 volt rather than 6 volt, and the addition of Lucas headlamps, internal sun visors, a handy glovebox in the centre of the dashboard, much more comfortable seats and an optional heater all added up to a more enjoyable experience, although still rather primitive compared to a modern Transit.

The 400E range was exported to many countries, especially the English-speaking Commonwealth. Vans, minibuses and chassis cabs were shipped as CKD kits for assembly in Australia and New Zealand. Special bodies were made locally for these markets. Assembled vehicles went to South Africa, Canada and Ireland, and were sold in North America until the US Ford Econoline models came along in 1962. Smaller numbers went to Asia and South America. Sales were made to most of Europe, where they were competing against Ford’s German-produced Taunus models, a situation that was not to last.

In the UK only a small number were sold to the largest operator of medium vans, the Post Office, but sales were made available to the military for ambulances and minibuses, and also to the Home Office for fitting Civil Defence office bodies. A few were even used by the US Navy at their Rosyth base in Scotland.

The 400E sold 187,00 in just under eight years, compared to the E83W’s total of 188,000 in nineteen years. It also compared well against the 1949–61 Morris J and JB sales of 48,600 in twelve years and the Bedford CA total of 370,000 in seventeen years. It gave Ford a leading, if not dominant, market position, but this was soon to change. Production was initially at Dagenham, but was transferred to Langley in 1961, with other commercial vehicle production, as Dagenham needed the capacity for car manufacture. Production finally stopped in August 1965, to allow for the change to the lines for Transit.

TAUNUS TRANSIT

The Taunus or, as it was known for the first few years, the FK 1000, was produced from 1953 until July 1965. It received its full name, Taunus Transit, in 1961 when it was updated to carry a heavier payload of 1,250kg (FK 1250). The most popular Taunus was the 800 panel van, which was responsible for more than 70 per cent of sales in Europe. It was only built in the ‘D’ Building at Ford Germany’s Cologne plant, where 255,824 vans, buses and pickups were made, as well as rolling chassis for SVO (Special Vehicle Options) vehicles. The models produced during the course of twelve years were FK 1000s with a Cologne-built, straight-four, 1.3-litre engine. This was later enlarged to a 1.5-litre engine.

A very early Taunus Transit prototype.

The Taunus, like the 400E, was a best-selling van for Ford.

CHAPTER TWO

A NEW VAN FOR EUROPE: BRITAIN AND GERMANY MOVE FORWARD

Over the years various dates have been claimed for when the designers working on the 800E and Taunus Transit programmes first met to discuss the way to move forward. The dates have been quite varied, ranging from 1960 to 1962: both are incorrect.

Moves towards a combined Transit programme actually started in late 1959, as Ford paperwork shows that meetings were held in January 1960. Arthur Molyneux of the product planning team revealed that the British and German cases were presented at a top-level planning meeting at Ford’s Aveley head office on 9 January 1960. Two Ford American executives also presented their case for using the Econoline as a basis for moving forward, but this was seen at the time as being too much like the Thames 400E that it was meant to replace. All three Ford companies – Britain, Germany and the USA – wanted their designs to provide the basis for this ‘all new’ vehicle.

THE TREATY OF ROME

It all began with the signing of the Treaty of Rome by Belgium, France, Italy, Luxembourg, the Netherlands and West Germany on 25 March 1957. The six states signed up to the progressive reduction of customs duties and proposed to create a common market of goods, workers, services and capital, the European Economic Community (EEC, now the EU) from 1 April 1958.

Henry Ford II (referred to by all Ford Motor Company employees as ‘Mr Ford’) was then a young man and driving Ford to achieve greater efficiency, profitability and increased competitiveness. During a visit to Paris he noted that Ford of Britain and Ford of Germany were competing in the same showroom with a similar van. Though they were externally similar, the British one was based on imperial measurements and Lucas electrics, the German one on metric measurements and Bosch electrics. Not a single component was interchangeable. From the US perspective, Ford was competing against itself. In addition, although Renault sold fewer vans in France than the combined total of Ford of Britain and Germany, the published figures showed the Renault to be the best selling van in France.

Henry Ford was concerned about efficiency and profitability. Every three months he led a team of Ford Vice Presidents to each of Ford’s manufacturing centres throughout the world (the USA, UK, Germany and Australia) to check that targets set during the previous meeting were being achieved. This was a continuous progress, so as soon as one round of meetings was completed, the next one started.

It was during one of these quarterly meetings late in 1957 that Mr Ford mentioned that he had noted the six states’ intent to establish the EEC. He was so strongly in favour of it that he decided that Ford should mark the occasion. The question for his team was, what form should this recognition take? He decided that a common vehicle should be developed to avoid Ford of Germany and Ford of Britain clashing in the same market place.

This suggestion was not without its problems. It was pointed out that Ford of Britain’s most saleable and profitable vehicles were in the Consul, Zephyr and Zodiac range. Their successor, the Cortina (codenamed Archbishop) was well on its way into production. Ford of Germany was in the same position with their Taunus M range.

PLAN FOR A VAN

After much discussion it was decided to make the new medium van project the sacrificial lamb. If this were a failure it would not be such a great loss. As to who would develop such a vehicle, it became clear in the meeting that Ford of Britain and Ford of Germany could not agree who would take the lead. The meeting decided that each would prepare studies and submit proposals at the meeting tabled for the end of 1958.

Ford of Britain was led by Sir Patrick Hennessey. He had been knighted for developing the Ford plant at Trafford Park, Manchester to volume-produce Rolls-Royce V12 Merlin engines. Ford of Germany was led by John Andrews, another very strong leader. These two appeared still to be fighting World War II!

Sir Patrick came out of the meeting and told his Product Planning Manager, Arthur Molyneaux, of the decision that Ford of Britain and Germany would compete to produce a van, adding that ‘if you use a single component produced by Ford of Germany, there will be lots of trouble’. Ford of Britain was to be ready to present its van proposal to the quarterly meeting in December 1959.

ARTHUR MOLYNEAUX

Arthur Molyneaux began his working life at the Ford Trade School, aged 14, and progressed through various departments, including sales and marketing, where his engineering background fitted him well for commercial vehicle export sales among contemporaries who lacked his ability to meet truck operators, and then to the prestigious product planning department where he became Manager of Vans and Estate Cars. In this capacity, alongside Hamish Orr-Ewing and Alec Trotman (Passenger Car Planning) and Phil Ives (Engine Plans), he felt at home. He came from a family in which his father, also called Arthur Molyneaux, ran the Ford Pattern Shop for many years. The Molyneaux family, including young Arthur’s older brother Richard, completed 100 years’ service to Ford.

I was extremely lucky to meet Arthur Molyneaux and his son Paul: it was only then I became aware of Arthur’s story about the origins of the Ford Transit van. Arthur also confirmed that a prototype van was sent over from the USA for his team to look at, which he took home one weekend; his son Paul noted how odd the van looked parked in front of the house.

On receiving his new assignment, ‘The Common Van’, Arthur immediately realized that all the marketing, research and other support activities normally required to support a proposal to the top brass were closed to him because they, together with Sir Terence Beckett, his boss, were working flat out on the Ford Cortina. He was on his own. Added to this, his three years of experience of export sales, where he was painfully aware of the shortcomings of the product he was trying to sell, made him decide to base his market research on the needs of the user, both driver and fleet operator.

MEETING THE NEED OF THE DRIVER AND FLEET OPERATOR

Arthur’s first piece of market research was a visit to a builders’ merchant where he saw builder’s van drivers desperately trying to keep plasterboard flat and dry, before the days of universal plastic sheeting and in a load space that was too small for it to lie flat. His first priority became to make the floor of the vehicle capable of accommodating a load of 8×4ft plasterboard. This required clearance between the rear wheel arches in excess of 48in (1,220mm).

Arthur immediately realized his advantage over the German team. Ford of Britain was already manufacturing the type of heavy-duty drive-train components required for the van. The V8 Ford Pilot and other V6 Essex-engined cars manufactured in the United Kingdom had suitable fabricated axles that could be extended by 8in (200mm) to meet the van requirement. That meant a modest extension of just 4in (100mm) on each side. The four-pinion differential was retained.

Ford of Germany produced none of these things. They had a maximum of a 1.5-litre engine with drive train to match: the German two-pinion differential proved unable to cope with the proposed higher-performance engines. In addition, Ford of Germany was controlled by Ford USA in ways that were not applied to Britain, due to Sir Patrick Hennessey’s acerbic rejection of interference and his friendship with Henry Ford II.

A visit to the transport manager of United Dairies, who ran a fleet of 200 Bedford vans, indicated that his vans were a constant source of problems:

Inexperienced, young drivers were constantly damaging the independent front suspension by bumping up kerbs or running into them.

Batteries failed because the engine was constantly stopped and re-started, particularly on door-to-door deliveries.

Manual gearbox failures, caused by inexperienced drivers, suggested that an automatic box should be available.

Some drivers found the steering too light, particularly on hills and icy roads. The centre of gravity should be adjusted.

Other user-driven characteristics for the new van included:

A comfortable driver’s seat. Traditionally, van seats had been hard, cheap and utilitarian. Noticing how many hours drivers spent in the driving seat each day, and despite the cost pressures, Arthur specified well-upholstered, high-backed seats to support the back.

Sliding access doors. Arthur was particularly keen that the van should have sliding access doors for easy and safe access from the pavement. The patent for suitable sliding doors, that were proven and sealed well, was held by Volkswagen and it was unthinkable that Ford would pay Volkswagen for the design rights. The issue was avoided when Arthur noticed that the Volkswagen patent was due to expire in 1963, two years before the Transit was due to be introduced.

After a few weeks, Arthur found his product development letters being handled by a very able team of truck engineers: Vernon Preston (chassis and suspension), Dick Morphew (bodies) and Chris Kope (from the USA, package engineer), who had developed a very useful wooden seating buck (a buck is a model layout of the basic van chassis) This illustrated the serious problem of accommodating the front suspension. The driver was placed as far forward as possible, allowing the wheels to turn, based on a beam axle. It also enabled a layout with independent front suspension to be illustrated. Although it could not be called a working model, it usefully enabled the steering to be demonstrated by someone sitting in the driving seat.

In Cologne, the Ford of Germany styling department was headed by Louis Bohne. He had the idea of making apertures in the side of a van body capable of taking a door, a window panel or a solid panel, and for a longer van to be produced by inserting extra panels. He had a wooden model made, measuring about 3 × 2ft, so that the advantages of this approach could be easily demonstrated. The interchangeable panels offered the opportunity to save die costs and to provide more work for the underused 2,000-tonne presses in Belgium. Louis’ plan was not accepted by the German planners.