28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

GWR; Great Western Railway; George Jackson Churchward; Boilers; Valves; GWR 4-6-0; De Glehn Compound; 4-4-2 Atlantic; Star Class; Scissors Valve Gear; L&NWR; London and North Western Railway; WWII; LNER; London and North Eastern Railway; LMSR; London Midland and Scottish Railway; Castle Class; Cheltenham Spa Express; King Class; Shrivenham Collision; 1948 Locomotive Exchanges; railway preservation; William Dean; Swindon; steam engine; Belpaire locomotive firebox; 5043 Earl of Mount Edgecumbe; R.M. Deeley; Lode Star; North Star; Dog Star; Evening Star; Morning Star; Polar Star; Red Star; Rising Star; Royal Star; Shooting Star; Western Star; Swallowfield Park; Knight of the Garter; Knight of the Thistle; Knight of the Patrick; Knight of the Bath; Knight of St. John; Knight of the Golden Fleece; Knight of the Black Eagle; Knight of Liège; Knight of the Grand Cross; Knight Templar; Knight Commander; William Stanier; Caerphilly Castle; Caldicot Castle; Cardiff Castle; Carmarthen Castle; Chepstow Castle; Pembroke Castle; Pendennis Castle; Powderham Castle; Warwick Castle; Windsor Castle; Midgham derailment; King Edward VII; King William IV; King George IV; King George III; King George II; King George I; King William III; King James II; King Charles II; King Charles I; King James I; King Edward VI; King Edward VIII; King Henry VII; King Richard III; King Edward V; King Edward IV; King Henry VI; King Henry V; King Henry IV; King Richard II; King Edward III; King Edward II; King Edward I; King Henry III; King John; King Richard I; King Henry II; King Stephen; steam locomotive; British Railways; Shakespeare Express; The Bristolian; Cornish Riviera Express; Cheltenham Flyer

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 365

Veröffentlichungsjahr: 2018

Ähnliche

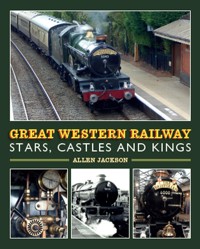

GREAT WESTERN RAILWAY

STARS, CASTLES AND KINGS

ALLEN JACKSON

THE CROWOOD PRESS

First published in 2018 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2018

© Allen Jackson 2018

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 482 7

CONTENTS

Preface and Acknowledgements

1 George Jackson Churchward

2 Star Class Locomotives: The Game Changer

3 Star Class Locomotives: Allocation and Work

4 Castle Class Locomotives

5 Castle Class Locomotives: Allocation and Work

6 King Class Locomotives

7 King Class Locomotives: Allocation and Work

Appendix I Locomotive Details and Timelines

Appendix II Engine Head Lamp Codes

Appendix III Engine Shed Codes

References

Index

PREFACEAND ACKNOWLEDGEMENTS

By the turn of the nineteenth century the Great Western Railway had put behind it the enormous expense of the change from broad to standard gauge and the building of the Severn Tunnel, and was looking forward to a new era of prosperity and stability.

The Edwardian era was to continue the foundations established under Queen Victoria whose duration of reign was eclipsed by the GWR itself who preceded it.

Oher civil engineering projects included the South Wales line through Badminton, the Berks and Hants line and that connecting with Fishguard Harbour, as well as the harbour itself. In the depression of the 1930s improvements to infrastructure, carried out to alleviate unemployment, had a positive impact on GWR facilities.

In terms of locomotives, early work by Sir Daniel Gooch, Joseph Armstrong and later William Dean had provided steady if unspectacular progress. Dean’s 4-4-0 express passenger locomotives were flyers and well capable of holding their own in a late nineteenth-century context of train loadings. His 27XX pannier tanks were the template for the enlarged 57XX panniers, which became the GWR’s most numerous class. The Dean Goods, an example of which is preserved in STEAM – Museum of the Great Western Railway, Swindon, was to serve the nation in two World Wars as well as being a model for a free-steaming and reliable 0-6-0 freight locomotive, the nineteenth-century staple.

The other pre-grouping railways had established a formula for locomotive building that had not changed radically since the days of Stephenson’s Rocket in 1830. Using that which had been tried and tested over sixty years or more was unlikely to get you sacked as a Locomotive Carriage and Wagon Superintendent.

During Dean’s final years at Swindon, his failing health caused him to rely increasingly on the engineer who was to become his successor, George Jackson Churchward. Dean retired in 1902 to spend the last three years of his life by the seaside. Dean Street, Swindon, which runs along the south side of the GWR line, is named after him.

The original intention for this volume was to use previously unpublished photographs but this has proved impossible given the age of the subject matter. Where possible, however, locomotives are shown in unusual or notable circumstances and as much information is included as space permits.

Although personnel are generally referred to by the male gender, because in history that is what they were, it is recognized that not only men provide the many crews and operating staff on the heritage scene who are carrying out valuable work in helping to keep the railway history of this country alive.

I would like to thank the Great Western Trust team at Didcot, in particular the noted author Laurence Waters for his unstinting help with photographic research. The staff at STEAM – Museum of the Great Western Railway have also provided invaluable help.

CHAPTER ONE

GEORGE JACKSON CHURCHWARD

George Jackson Churchward (1957–1933) came from Stoke Gabriel, South Devon. He was blessed with the ability to recognize and implement the best features and practice of steam engineers from around the world. Steam technology had moved almost to its limits by the end of the nineteenth century, with the possible exception of superheating.

This commonsensical approach has to be viewed in the context of how an engineer would be promoted from a practical position on the shop floor to hidebound administrative responsibilities, divorced from the practicalities of the job and possibly mostly concerned with company politics. Churchward’s common sense was derived from the acquisition of experience on the job.

Churchward was an eminently practical man who kept his engineering feet firmly on the ground, staying in touch with day-to-day practicalities. If there were any significant change to a locomotive he wanted tests and comparisons made with previous standards. The rolling test bed at Swindon and the GWR dynamometer car were testament to this measured approach. Churchward understood that the steam locomotive was principally a question of the boiler: from this all else could flow. The best valve gear and wheel arrangement were of no use if they could not be supplied with steam in abundance and at economical rates. In addition a poorly designed and constructed boiler could be ruinously expensive in maintenance costs and inconvenient in operational service.

Boilers

By the turn of the nineteenth century the GWR’s locomotive practice might best be described as Dean’s locomotives with Churchward’s boilers. Churchward had adapted best practice in terms of a Belpaire firebox and coned taper boiler barrel and this was at variance with most other designers, except perhaps Samuel W. Johnson on the Midland Railway.

The Belpaire locomotive firebox is surrounded by a water jacket to enhance steam production and the actual firebox is constructed to the same shape suggested by the outside appearance, but is smaller to allow room for the water jacket on the outside. This allows the stays that support and keep the firebox apart from the water jacket to be simple straight pieces. However, the manufacturing cost was higher than that of the standard nineteenth-century round-topped firebox, which was basically two circular structures, one within the other. The advantage of the Belpaire type is that the enlarged space above the firebox contains more water, where most of the heat is. This was described at the time as having greater evaporative or steam-making potential.

Fig. 1. Star Class 4003 Lode Star at the National Railway Museum (NRM), York, illustrating the Belpaire firebox, coned boiler and topfeed boiler arrangements, June 2004.

The Belpaire firebox, as Churchward implemented it, had an enlarged area for water circulation at the front and at the point where it was farthest away from the hottest part of the fire.

The effect of this was to enhance water circulation in that area. As well as producing more steam, this led to a reduction in local overheating nearest the fire. The disproportionate effects resulting from the rear of the firebox being intensely hot, and the rest not so, produced distortion in the boiler plating and stays and consequently increased maintenance costs. Churchward’s design avoided this pitfall. This meant that the Belpaire firebox of Churchward’s manufacture was tapered towards the cab.

The propensity of steam production at the front of the firebox meant that there was no need for a dome to collect the steam as in a parallel round-topped boiler. Churchward always regarded the dome as a source of weakness in the structure that would obviously lead to additional cost. This would have an effect on the appearance of Churchward-boilered locomotives and make the other railways’ domed engines seem stuck in the Victorian age and out of date. The appearance of Churchward’s boilers, and subsequently the locomotives, caused much criticism from frock-coated and bewhiskered traditionalists. Churchward took no notice and believed that appearance was not necessarily an attribute for efficiency.

Fig. 2. Castle Class 5043 Earl of Mount Edgcumbe displays the Belpaire taper firebox, as adopted by Churchward and continued by his successor Charles Collett. Stratford-upon-Avon, August 2017.

The coned nature of the Belpaire firebox was married to a cone-tapered boiler barrel that accentuated the property for steam collection where the two components met. The greater surface area in this region meant that fewer bubbles formed: bubbles have a water component when what is required is a gas – pure steam.

Churchward, after typically trying one boiler with a dome and one without, found there was less foaming and priming and consequently more pure steam produced in the domeless type.

Priming is the means by which water is carried through the steam production process. This has a detrimental effect on performance and damage can occur if water reaches the cylinders. Water is an uncompressible liquid and the force of a piston trying to compress the uncompressible will result in a damaged piston or cylinder.

In addition to the tapered Belpaire firebox, Churchward found that the most efficient shape to assist water flow around the fire tubes on the boiler barrel was also tapered towards the smokebox, which itself was a parallel shape.

The boiler constantly uses the boiled water as steam and so must be replenished from time to time with a fresh cold supply. Churchward found that a topfeed arrangement through clack or check valves, the water supply of which was then distributed in droplets through the use of trays, was the most efficient means of getting water into a steaming boiler.

The check or clack valve is a non-return valve that is fed from steam-driven injectors to force water into a boiler that would naturally resist such an action from any source of a lower pressure than that in the boiler. It is usually the fireman’s job to maintain a constant head of water in a boiler using the injectors. Gauge glasses are provided in the cab to enable levels to be observed.

Fig. 3. Inside the cab of 5043 Earl of Mount Edgcumbe. Stratford-upon-Avon, August 2017.

In the view of the cab of 5043 Earl of Mount Edgcumbe (fig. 3), the gauge glass is the rectangular vertical polished steel object next to the two circular gauges. Other models had thick glass panels to enclose the glass tube that indicated the water content of the boiler. These have been known to break under the high pressure within, spraying the cab with scalding steam.

The tray distribution at the top of the boiler barrel minimizes the shock of cold water entering the boiler as this is where the temperature is the highest. To introduce water at the bottom of the boiler, where the temperature is the lowest, may reduce overall temperatures significantly and so drastically reduce steam production.

Churchward also propounded higher boiler pressures than had been used hitherto on British railways. He was able to prove in a series of tests that higher boiler pressures up to 225psi (pounds per square inch; 15.65 bar) produced more power and lower coal consumption for a given boiler size. There would be a price to pay in terms of a more robust and expensive construction than required for lower-pressure boilers, but Churchward believed that the Swindon works could easily engineer it and the directors would pay when they realized the benefits.

Churchward designed a standard set of boilers that would encompass the needs of most of the GWR’s locomotives until the end of its existence, albeit with modifications en route.

Valves

With the boiler design settled, Churchward was able to concentrate on the subject of valves. Nearly all internal combustion cars in production in 2017 have four valves per cylinder whereas the twentieth-century standard was two valves per cylinder. This seeming extravagance in production costs can be explained in the efficiencies gained by getting fuel and air into the cylinder and exhaust gases out quickly in the cycle.

Churchward realized this in 1902, albeit in a steam engine context, and adopted large long-travel piston valves. However, it is first necessary to compare it with the slide valve, which had been the standard nineteenth-century design in extensive use, to see the benefits of Churchward’s approach.

Fig. 4. Principles of a slide- or flat-valve steam engine.

The principles of a slide or flat valve steam engine are shown in fig. 4. The long distance between the ports where steam is either admitted or exhausted can give rise to a lowering in temperature and efficiency. If the steam is superheated this kind of valve layout can lead to lubrication problems.

Fig. 5. Principles of a piston-valve steam engine.

Churchward, however, used large-diameter valves with a long travel, as seen in the diagram illustrating the principles of a piston valve steam engine (fig. 5). In this design the steam has a shorter journey in order to do useful work, making more efficient use of the steam and reducing the tendency for the steam to cool along the way.

The longer travel piston valve enabled a larger diameter valve to be used, making it the Edwardian equivalent of the twenty-first-century’s 4-valve per cylinder petrol car. The long travel and large valve size permitted efficient entry of steam and its consequent exhaust to get rid of the waste after the work had been done.

Churchward also adopted long lap valves. Lap is where the admission of steam is cut off by the valve’s position while steam is already in the cylinder. This allows the steam to expand more and do useful work. So it is a delay, enforced by mechanical valve positioning that enables trapped steam to do more work.

The valve gear is a means of varying the amount by which the steam admitted to a cylinder is cut off or stopped or reversed. If steam is admitted to the cylinder throughout the time that a piston is moving in one direction, this is wasteful in terms of steam used. More efficient use of the steam is made the longer that the steam is cut off during the piston’s stroke, particularly when the locomotive is at speed. Starting off with a heavy load, the cut-off is eliminated or the locomotive is said to be in full forward (or reverse) gear.

A further refinement in terms of boiler and steam production was the superheater. Churchward was fully convinced by the theory of its advantages but by 1903 no one had managed to get one to work satisfactorily. The problem was to be solved in the following years.

The superheater provides a means of raising the temperature of the steam so that, by the time it reaches the relatively cold cylinders and valves, any reduction in the steam temperature does not significantly affect the locomotive’s efficiency and eliminates priming.

The superheater is a set of pipes like a radiator placed in the way of the flue of hot gases on their way to the blast pipe and chimney. By this stage the gases have done their work of heating the water in the boiler and are now considered to be the waste products of combustion.

Now that he had addressed both the boiler and valves, Churchward set about introducing a standard set of locomotives equipped to meet the GWR’s immediate and future needs.

The First GWR 4-6-0 Locomotives

Churchward introduced the first GWR 4-6-0 locomotive in February 1902. Although William Dean was still nominally in charge, the Board of Directors had listened to Churchward’s ideas the previous year and given the go ahead to construct a batch of new 4-6-0 locomotives. Churchward’s ultimate aim was to construct locomotives that could exert a drawbar pull of 2 tons force at 70mph (19.9kN at 112km/h) and maintain this with a long-distance passenger train.

The first was numbered 100 and given the name Dean in June 1902; this was changed to William Dean after his retirement in November 1902. Number 100 was a development engine and still retained the parallel boiler without a top feed, and the boiler was set low in the frames. The piston valves were fitted and the locomotive had an angular appearance that offended Victorian and GWR sensibilities accustomed to the flowing lines of the outside frame 4-4-0s that preceded it.

The piston valve diameter was a particular feature that Churchward concentrated on, understanding that valve events held the key to efficient use of steam, and hence power and speed. He rigged up an experimental single-cylinder stationary engine at Swindon as a test bed for experimenting with various piston valve diameters and found that the 6½in (15.24cm) valve, based on slide valve practice, was too small to get the steam in and out of the cylinders efficiently. The valves were holding back the capacity of the boiler to supply the steam and the cylinders to use it effectively. Their small size meant they were a bottleneck in the engine’s running process.

Refinements to correct these deficiencies were introduced with number 98. It had 10in (25.4cm) piston valves and longer travel, which was subsequently increased to the final standard of 6¼in (15.86cm). The boiler was of the tapered short cone type and the firebox was also tapered. This form was to be considered as Churchward’s Standard No. 1 boiler. Its pressure was only 200psi (13.79 bar). The piston valves would later be modified so that they formed a ‘plug’ in the valve chamber when under steam to effect a good seal, but they relaxed when not under pressure to provide the minimum resistance to motion. The LMS and SR later copied this idea.

Fig. 6. Piston valves belonging to King Class 6023 on display at Didcot Railway Centre. The piston and rod are behind. November 2017.

Fig. 7. Cylinder and valve chest covering of Castle 4-6-0 5043 Earl of Mount Edgcumbe. Stratford-upon-Avon, August 2017.

The photograph of Castle 4-6-0 5043 Earl of Mount Edgcumbe amply demonstrates the size of the piston valve in relation to the piston (fig. 7). The housing on the upper left of the photo indicates the valve size. The three cylinder drain cocks at the bottom of the cylinder are used to evacuate condensed water from the cylinder, as mentioned above in the description of priming.

This locomotive was truly a step change in performance and efficiency compared with what had gone before. While there were to be many modifications over the years, number 98 was the template for thousands of locomotives to follow.

Engine number 171 named Albion, an ancient name for the islands of Great Britain, followed in February 1904. There was nothing ancient about its features, however, as it incorporated all Churchward’s innovations at its introduction in December 1903. It had a higher pressure boiler of 225psi (15.51 bar) and the firebox and grate area were slightly increased to give a locomotive weighing in at 70 tons (71 tonnes).

These locomotives were to become the progenitors of the celebrated Saint class 4-6-0 and were a pivotal component of British steam locomotive history. They were originally intended as express passenger locomotives with 6ft 8½in (204.5cm) driving wheels with Stephenson’s valve gear. They did all that could be asked of them at the time and more, and yet their adaption to the mixed traffic 6ft (1.85m) driving wheel Hall class 4-6-0 ensured a lasting place in railway history. The Great Western Society at Didcot has almost finished, in 2018, a Saint class locomotive, out of number and name sequence, 2999 Lady of Legend, which used parts of a Hall class. This reverse engineering seems appropriate.

Churchward had been impressed with the performance and smooth running of the de Glehn compound Atlantic 4-4-2 locomotives on the Nord Railway in France. These locomotives were 4-cylinder compounds in which the steam is used twice, first in a high-pressure cylinder and then in a lower pressure one. This design was extremely popular with marine engines but less so with railway locomotives in Britain. Marine engines would seem to have more constant working conditions and output than locomotives. The Midland Railway compound 4-4-0s were considered to be successful but only when compared with their Midland Railway predecessors, which were small and often not up to the job on their own, requiring two locomotives.

4-Cylinder de Glehn Compound Atlantic 4-4-2 Locomotives

Churchward persuaded the directors to pay for a de Glehn compound so he could compare it with his own locomotives. He wasn’t convinced that the practicalities of compounding would live up to the theoretical advantages, but he was prepared to try it out.

The 4-4-2 was arranged so that the high-pressure cylinders drove the rear driving wheels, while the inside low-pressure cylinders drove the front axle through a crank. This is described as ‘divided drive’. Although the LNWR Claughton class 4-6-0, which had all the cranks drive the front axle, was considered to be relatively successful, splitting the considerable forces over two axles instead of one would reduce the stress on the engine overall, leading to a more equitable division of wear on the bearing surfaces.

The locomotive, numbered 102 and named La France, was taken into GWR stock in October 1903. The locomotive was built by the Société Alsacienne de Constructions Mécaniques at its works in Belfort, which had remained French after most of Alsace was annexed by Germany in 1871. SACM’s descendant company Alstom, which is renowned for its TGV, Eurostar and Pendolino designs, still has a factory in Belfort, close to the Swiss border, while the manufacturing headquarters of Peugeot cars is nearby at Sochaux.

Separate sets of Walschaerts valve gear were provided for the high- and low-pressure cylinders and they could be worked either together or separately, thanks to a catch on the compound screw reverser. In addition, the engine could be worked as a simple by routing the high-pressure exhaust to the chimney, instead of to the low-pressure cylinders, and by admitting ordinary boiler steam to the low-pressure cylinders via a pressure-reducing valve. This feature would help Churchward in his comparison tests of simple versus compound.

Another novel feature was a variable blast pipe worked from the cab. It had long been a railwayman’s tradition to secure a piece of flat steel bar across the blast pipe if an engine was not steaming well. This constriction caused the fire to draw more readily and increase steam production. Items like this were advertised as the ‘Driver’s Friend’ and could be purchased for the sum of one shilling (5p).

Constriction of the blast pipe was not required, however, if the engine was at speed and working hard. This narrowing instead inhibited the exhaust flow, which was exactly what the larger piston valves had been designed to minimize. The variable blast pipe operated by the crew had the best of both worlds.

The problem with the crew-operated variable blast pipe was that the crew needed to operate it assiduously to take advantage of what it had to offer, and in the course of service the mechanism would become stuck in one position, requiring maintenance to keep it working.

Churchward designed a variable blast pipe with what was known as a jumper ring. Under the pressure of hard working from the locomotive, the ring would be raised inside the blast pipe and this would de-restrict the pipe opening. Upon reduction of the exhaust blast, the jumper ring would fall back and reduce the opening, enabling the fire to draw more readily.

Another of Churchward’s concerns involved the balancing of reciprocating masses in particular, and any moving mass in general. Unbalanced masses will tend to shake the locomotive to pieces eventually. They cause rough riding and an uncomfortable experience for the engine crew, who may ease off the speed to make their own journey more bearable and less fatiguing. Unbalanced forces also promote rapid wear in bearing surfaces. An unbalanced locomotive can even leave the rails in extremis. As a result of unbalanced forces a locomotive possesses a ‘hammer blow’ on the track and it is not unknown for badly out-of-balance locomotives to crack rails.

The GWR continued with Churchward’s balanced approach: as late as 1950 British Railways decided that, as the 2-cylinder 57XX Pannier Tanks had minimal hammer blow, they would be eased from Blue route to Yellow route availability, even though their weight indicated they should be allocated to the more restrictive Blue route.

The divided drive and four cylinders of the de Glehn compounds produced a much smoother-running machine that would be able to haul heavy trains at high speed with longer overhaul intervals. Although the initial cost of manufacture was higher, the ongoing costs over, say, a thirty-year life would be less. 102 La France remained in service until October 1926 and it ran a total of 728,031 miles (1,171,652km) before withdrawal. Not surprisingly the locomotive was non-standard in an increasingly standardized Swindon and the cost of new cylinders would be thought excessive, although 102 and its two classmates, 103 and 104, all had Churchward Standard No. 1 boilers at some point.

The only downside that Churchward could see to the de Glehn locomotive was that compounds tend to work at higher cut-off values and therefore seemingly required more steam to do the same work. He could not produce any evidence that compounding, making use of the steam twice, gave any measurable benefit.

Churchward went the distance to make the comparison between his locos and La France a fair one. He converted no. 171, later 2971 Albion, into a 4-4-2 Atlantic. Albion had been produced with a boiler pressure of 225psi (15.51 bar) and so was on a par with the de Glehn at 227psi (15.65 bar). The comparative testing lasted a year. The only thing Churchward did not do was incorporate his own advances in valve design into the French locomotive.

Another feature of the de Glehn locomotives that was admired and incorporated into the GWR engines was the design of the bogie. The French locomotive had a side-springing arrangement instead of the more usual GWR swing links. Swing links are used in coaches and HST sets where the forces caused by piston thrusts and several large-diameter driving wheels are not present. Bogies of the traditional GWR design, although they were meant to alleviate flange wear on the leading driving wheels, were not as successful as the de Glehn type. The de Glehn type of bogie favoured the outside bearing axlebox, as with coaches, but the GWR resisted this feature until the introduction of the King class more than twenty years later, and even then only in part. Some earlier 4-4-0s sported external axlebox leading bogies.

Fig. 8. The side-springing attachment on the locomotive bogie is seen here with the five nut-and-bolted angle bracket connecting the bogie to the locomotive frames. The inside cylinder piston rod is visible through the access hole cut in the frames. Stratford-upon-Avon, August 2017.

The de Glehn compounds first worked the arduous west of England expresses, but by 1907 were working Wolverhampton and Worcester expresses with some work on the Birmingham two-hour expresses. Finally they ended up on fast and semi-fast trains from Oxford to Birmingham and Paddington.

Their work done, the de Glehn compounds were to leave a lasting legacy on GWR practice, both from the point of view of what they contributed and what was missing from their design. After this valuable testing and comparison phase, Churchward moved forward with what was to be the last original design for an express passenger engine made during the GWR’s existence, the Star class in 1906. All the GWR express passenger locomotives that followed were derived from the Stars.

Churchward’s Ethos and Working Practices

The progress made was not just a matter of Churchward seeing the benefits of other technology and using it. An autocratic style of management was prevalent in the Edwardian era and rule by fear was the norm. Churchward was far-sighted enough to see that a consultative style would yield more from his staff. His unquestioned position as head of steam on the GWR meant he did not need to act as a martinet or bully, as some of his contemporaries had done.

He readily sought the opinions of foremen at the works on questions of manufacture, and of shed superintendents and locomotive inspectors on daily running of the engines. With all the information gathered, Churchward then had the depth of experience and general ability to see the way forward and decide how to proceed. His broad range of experience also enabled him to convince others that the chosen path was the right one. In this way GWR staff became involved in the process and aware that their contribution was valued and relevant. This was a great source of motivation for the company and a tie of loyalty that bound the workforce together at all levels.

Loco designers often complained that a sound design sometimes became lost in the detail left to a drawing by a junior draughtsman. For Churchward, however, the delight was in the detail and he would examine, and if necessary criticize, every detail before a drawing was signed off for manufacture.

A component for a locomotive would be assessed for the job it was to do and the following criteria had to be met before it was deemed to be successful in operation:

• Minimum cost of material.

• Efficiency of manufacture.

• Ease of maintenance in service.

Missing from the list is the need for designed items to appease Victorian aesthetic sensibilities and some of Churchward’s work was criticized for not addressing them. Harry Holcroft, a senior designer at Swindon, often tidied up the outside appearance of Churchward’s locomotives. After Churchward retired in 1922, Holcroft went to the South East and Chatham Railway, soon to become a constituent of the Southern Railway at grouping in 1923.

The downside to Churchward’s holistic approach was that it was mostly inside his head: nobody in any department had access to every detail required for the design. Most of it was transferable though: when William Stanier left Swindon to go to the London, Midland and Scottish Railway (LMS) in 1932, he took with him enough knowledge to transform LMS locomotive performance and form the foundation for the standard class of British Railways locomotives after nationalization. Churchward’s legacy lived on until the end of steam traction in Britain.

A couple of Stanier’s ideas learned at the GWR, however, were not portable. The smokebox regulator and screwed-in piston rods were both adopted as LMS practice but were abandoned when they could not be got to work properly. There was an element of practical knowledge missing that Churchward, one feels, would have known.

The performance of Churchward’s locomotives owed much to the following:

• Design that adopted and adapted the best practice of principles from around the world.

• Detail design of individual components, which, when put together, elevated the finished product beyond what could be that achieved by just adopting the first in the list.

• Economical use of the best materials.

• Superb quality of the workmanship and engineering at Swindon.

• Intelligence and enterprise of locomotive crews when driving Churchward’s locomotives.

• High standards of maintenance and a channel to feed back any problems to the designer.

Churchward had control of all of the above and so his position was unsurpassed in terms of effectiveness.

The GWR was his life and he was honoured to become the first mayor of Swindon. He continued to live in a company house after his retirement in 1922, maintaining a strong interest in the company and its fortunes: on 19 December 1933 he was inspecting a defective sleeper on the down through main line near his house when, by an irony of ironies, he was struck and killed by Castle class locomotive 4085 Berkeley Castle, which was hauling a Paddington to Fishguard express. The locomotive was a direct descendant of Churchward’s Star class locomotive, whose story is examined in Chapter 2.

It was commonplace, after the accession of a new Chief Mechanical Engineer, for the new broom to demonstrate that there was to be change, often for its own sake. There was no such activity on the GWR after Churchward retired. The succeeding CMEs sought to fine tune and adjust Churchward’s work and produce locomotives that, while larger and more powerful, were enlarged versions of what had gone before. No radical policy was introduced, given the technology of the time, that would produce any meaningful improvements until the end of steam.

For technical details of the locomotive profiles that follow, please see the Appendices.

CHAPTER TWO

STAR CLASS LOCOMOTIVES:THE GAME CHANGER

Churchward was inspired to build a 4-cylinder Atlantic 4-4-2 locomotive after his experiences with the French de Glehn locomotives. The Saint class demonstrated the additional traction afforded by the extra set of coupled wheels of a 4-6-0 and yet Churchward was to persist with the Atlantic wheel arrangement, showing how his own simple expansion design could compare favourably with that by SACM. In addition the Atlantic was seen to run more smoothly than a 4-cylinder 4-6-0 at higher speeds.

North Star was turned out in 1906. The very name, bestowed some months after it was accepted into stock, was sufficient to evoke the history of one of the first locomotives on Brunel’s broad-gauge GWR. Number 40 was to continue the legend and expand on it.

Churchward insisted that the connecting rods of the inside and outside cylinders should be the same length. This meant that, with divided drive, the inside cylinders had to be well forward of the frames, as they drove the front driving axle, and the outside cylinders had to be well to the rear of the smokebox, as they were to drive the rear coupled axle in Atlantic 4-4-2 configuration. This arrangement later caused issues with the inside and outside steam pipes that connected the boiler, cylinders and exhaust.

After he moved to the LMS, William Stanier continued with this arrangement on the Princess Elizabeth class.

Scissors Valve Gear, No. 40

The valve gear was effectively a Walschaerts design applied to the inside cylinders, with a connection to the outside cylinder on the opposite side to drive it. Churchward had devised this arrangement himself, but a similar idea had already been patented by R. M. Deeley of the Midland Railway, who objected to what he saw as an infringement of his patent. Thus no. 40 was to remain the only Star locomotive with what was referred to as ‘scissors gear’. Churchward did not perpetuate the scissors gear on subsequent locomotives, although this was less in deference to Deeley but because the valve gear arrangement of cross connection meant that a failure of one cylinder automatically disabled an opposite cylinder, which totally immobilized the locomotive. In any case Churchward could prove that he had started work on the scissors gear before Deeley’s patent had been granted.

All Star class locomotives were fitted with screw valve gear reversers.

It became apparent in service that a 4-6-0 would have greater adhesion and traction on the South Devon banks and so no. 40 was rebuilt as a 4-6-0 in 1909. In a short time forty similar 4-6-0s were built and formed the nucleus of the class that was eventually to number seventy-three locomotives.

Their power-to-weight ratio, economy of operation and smoothness of running remained unsurpassed by any British locomotive for about twenty years.

Star Class: Salient Features

After the scissors gear episode with no. 40, all subsequent class members, and indeed all succeeding 4-cylinder 4-6-0s, were fitted with Walschaerts valve gear. The Stephenson link gear used on the 2-cylinder locomotives was seen to be superior when starting off with a heavy train and under acceleration, and was thus ideal for freight and mixed traffic use, but the Walschaerts gave constant performance at all cut-off levels and was superior at higher sustained speeds. In any case the Stephenson gear was much bulkier and would not fit between the frames. The outside piston valves were actuated by rocking levers pivoted on the frames.

Design effort was required for even this seeming small detail. The outer arms of the levers were slightly longer and set back, so compensating for the angularity of the cranks at 180 degrees. The effect of this was to give more equal valve events between inside and outside cylinders, which could clearly be heard in the staccato bark of the exhaust of each side cylinder exhaust beat.

Churchward had justified the long 30in (76.2cm) stroke on the 2-cylinder Saint class by pointing out that the longer piston stroke enabled the steam to expand more readily and therefore do more useful work per cylinder event. The piston stroke on the Star class was reduced to 26in (66cm) to enable the whole valve gear to be better balanced. An even longer stroke would increase reciprocating forces and it is these types of forces that make the engine sway at speed. As the whole point of the 4-cylinder approach was the smooth running, the reduction in reciprocating out-of-balance forces was a welcome compromise.

The connection to the inside cylinders at the crank axle was known as the ‘big end’ and, in accordance with French practice, the big end was forked or split so that the bearing surface could be examined or changed more easily. Conversely, where access was not so restricted, the big ends to the outside cylinders were not forked but solid.

The 8in piston valves were larger, relatively speaking, on the 14¼in (36.2cm) cylinders than the valves of the Saint class with 18in (45.7cm) cylinders. Coupled with this, the constant lead characteristics of the Walschaerts valve gear meant that it was not necessary to restrict the Stars to the 22 per cent minimum cut-off to which the Saints were limited, owing to their Stephenson valve gear and the relatively crude lever reverse. This made the Stars more economical when running fast, while the superior balanced layout of the four cylinders also gave a smoother ride. The cost of a Star was £3,700, which was seen as a great deal before World War I, but that investment was repaid with overhaul intervals of 120,000 to 130,000 miles (193,000–209,000km), compared to the Saints 70,000 to 80,000 miles (112,600–128,700km) initially. Later, the criteria centred on the axlebox wear, which meant that some Stars were shopped when the rest of the locomotive, excluding axleboxes, was in fine fettle. Therefore, they were overhauled somewhat needlessly just because there was wear in the axleboxes.

The coupled wheels and the trailing axle were fitted with spring compensation beams, the action of which was intended to ensure more even grip of the driving wheels on the track and consequently better adhesion.

Coupling rods had long been drop forged from a steel billet using a 4 ton (4.1 tonne) steam hammer in Swindon Works in the shape of a girder or ‘I’ section. This imparts a much stronger ability to resist deflection and is exactly what’s required by civil engineers for bridges. The power output of the Stars, however, was such that it could bend the coupling rods. If the forces were extraordinarily severe, with ‘I’ section rods the bend would be permanent and the locomotive disabled or disastrously limited.

Fig. 9. The rocking lever to the outside cylinder piston valve is connected to it by a universal joint to get through 90 degrees. The near inside cylinder piston rod is below. Castle Class 4073, STEAM, September 2017.

Churchward’s solution was to use coupling rods with a rectangular section, which would flex or ‘whip’ without the deflection being permanent. Almost fifty years later someone who was not aware of Churchward’s learned wisdom repeated these events with the British Railways Britannia Pacific locomotives, although the story was complicated by the locomotive being built with incorrect quartering of the driving wheels on the axles.

The leading four-wheeled bogie was carrying a substantial part of the locomotive’s weight and it was thought that brake gear on the bogie would contribute to the overall effectiveness of the braking system. While undoubtedly correct, the differences were so small that they were not measurable and the bogie brakes were later removed. Stars would often be pulling a trailing load of 400 tons (406 tonnes), which would be vacuum braked on all passenger trains. The effect of bogie brakes acting on a carried weight of nearly 18 tons (18.3 tonnes) on a train that has an all-up weight of nearer 500 tons (508 tonnes) has to be minimal on braking efficiency as a whole. There may have been a measurable effect with Stars on unfitted goods trains, as they were to haul much later, but this was never regarded as a worthwhile issue to pursue.

Stars continued to be built in small batches until 1923, when the Castles were introduced.

Star Class: Illustrated Details

The inner workings of a steam locomotive, and particularly a 4-cylinder one built to the British loading gauge, is a complex tightly packed machine, which must have been extremely difficult to maintain in tiptop condition for regular high-speed express work.

There now follows an attempt to illustrate at least some of the workings, referring back to the reason they are there in the design process. All photographs in this section were taken by the author.

Fig. 10. 4003 Lode Star at the National Railway Museum (NRM), York, October 2017. The detail views of Lode Star that follow (figs 11–25, 27–35) were all taken at the same time.

4003 Lode Star is preserved as part of the national collection at the National Railway Museum, York (fig. 10). None of the Star class survived to run in preservation and the last of the class left service in 1957. The locomotive displays a mixture of old features and newer ones introduced after World War I. Older features include no steam pipes, top lamp iron on top of smokebox, no whistle shield, a 3,500 gallon (15,911ltr) tender, polished smokebox hinges and other steel items. Newer features include no brass beading on the splashers, D-shaped and stowed front vacuum pipe, short safety valve bonnet, ejector pipe on other boiler side, 1927 livery and no bogie brakes.

Fig. 11. Rear view.

The rear view of 4003 and the cab reveals the screw reverser in the typical GWR driving position on the right-hand side (fig. 11). The dome on the tender is to accommodate the curved water pickup scoop pipe. With only 3,500 gallons in the tender the locos depended heavily on water troughs to sustain longer non-stop runs. The Southern Railway was the only one of the big four companies that didn’t have troughs and so needed some 5,000 gallon (22,730ltr) tenders. The parts of the buffers that crews used to step on are painted black. The brass tender works plate reads:

Great Western Railway

1726

Swindon Works

JAN 1907

This dovetails well with the loco’s build date of February 1907 but it would be fanciful to suggest that the loco retained the same tender throughout its life.

Fig. 12. Front end.

On the front and left-hand side view of 4003 (fig. 12), the ejector pipe can be seen running from the cab to the smokebox. Note how the handrail is attached outside the pipe and along it. The D-shaped vacuum hose stowage no doubt assisted the positioning of the coupling on its hook below the left-hand buffer. Other railways attached the shackle to the coupling hook, but generally not the GWR. The lamp irons are at right angles to those on other railways’ engines, as GWR lamps had side brackets and so the lamp irons are not symmetrically disposed on the bufferbeam. There is no steam heating connection on the front bufferbeam.

Fig. 13. Front bufferbeam and fittings.

The close-up of some of the front end detail of Lode Star (fig. 13