73,99 €

Mehr erfahren.

- Herausgeber: John Wiley & Sons

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

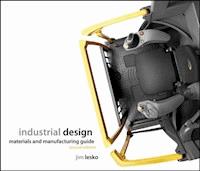

Industrial Design: Materials and Manufacturing Guide, Second Edition provides the detailed coverage of materials and manufacturing processes that industrial designers need without the in-depth and overly technical discussions commonly directed toward engineers. Author Jim Lesko gives you the practical knowledge you need to develop a real-world understanding of materials and processes and make informed choices for industrial design projects. In this book, you will find everything from basic terminology to valuable insights on why certain shapes work best for particular applications. You'll learn how to extract the best performance from all of the most commonly used methods and materials.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 285

Veröffentlichungsjahr: 2011

Ähnliche

Table of Contents

Title Page

Copyright

Acknowledgments

Chapter 1: Introduction

Chapter 2: Overview

Chapter 3: Metals

3.1 Properties of Metals

3.2 Ferrous Metals

3.3 Powdered Metallurgy

3.4 Nonferrous Metals

Chapter 4: Metal Forming

4.1 Liquid State Forming

4.2 Plastic State Forming

4.3 Solid State Forming

Chapter 5: Metal Cutting

5.1 Sheet Punching and Shearing

5.2 Chip Forming Cutting

5.3 Nonchip Forming Cutting

5.4 Flame/Thermal Cutting

Chapter 6: Metal Joining

6.1 Soldering

6.2 Brazing/Welding

6.3 Adhesives

6.4 Mechanical Fasteners

Chapter 7: Appearance Finishing and Coatings

7.1 Formed Textures/Molded In

7.2 Cut Patterns and Abrasive Finishing

7.3 Coatings

Chapter 8: Plastics

8.1 Properties of Molded Plastics

8.2 Thermosets

8.3 Thermoplastics

Chapter 9: Plastic Forming Processes

9.1 Liquid State Forming

9.2 Plastic State Forming

9.3 Solid State Forming

Chapter 10: Machining Plastics

Chapter 11: Joining Plastics

11.1 Chemical Bonds

11.2 Welding Plastics

11.3 Mechanical Fastening

Chapter 12: Finishing Plastics

12.1 Formed

12.2 Paintings/Coatings

Chapter 13: Rubbers and Elastomers

13.1 Thermoset Rubbers

13.2 Thermoplastic Elastomers

Chapter 14: Natural Engineering Materials

14.1 Engineering Ceramics

14.2 Glass

14.3 Manufactured Carbon

14.4 Refractory Hard Metals

Chapter 15: Composites

15.1 Metal-Matrix Composites

15.2 Plastic Matrix Composites

15.3 Advanced Composite Materials

Chapter 16: Rapid Prototyping

Index

This book is printed on acid-free paper.

Copyright © 2008 by John Wiley & Sons, Inc. All rights reserved

Published by John Wiley & Sons, Inc., Hoboken, New Jersey

Published simultaneously in Canada

Wiley Anniversary Logo: Richard J. Pacifico

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per-copy fee to the Copyright Clearance Center, 222 Rosewood Drive, Danvers, MA 01923, (978) 750-8400, fax (978) 646-8600, or on the web at www.copyright.com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748-6011, fax (201) 748-6008, or online at www.wiley.com/go/permissions.

Limit of Liability/Disclaimer of Warranty: While the publisher and the author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Neither the publisher nor the author shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information about our other products and services, please contact our Customer Care Department within the United States at (800) 762-2974, outside the United States at (317) 572-3993 or fax (317) 572-4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic books. For more information about Wiley products, visit our web site at www.wiley.com.

Library of Congress Cataloging-in-Publication Data:

Lesko, Jim.

Industrial design : materials and manufacturing guide / Jim Lesko. -- 2nd ed.

p. cm.

ISBN 978-0-470-05538-0 (cloth)

1. Design, Industrial. 2. Manufacturing processes. 3. Materials. I. Title.

TS171.4.L47 2007

745.2--dc22

2007017878

Acknowledgments

The idea for Industrial Design: Materials and Manufacturing began about 1975 when Professor Born asked me to teach the subject at the University of Cincinnati. I had the good fortune of having an exceptional group of students, including John Bucholtz, Mike Gallagher, and Sam Lucente, whose enthusiastic response to my organizational structure of the subject convinced me that a simple visual text was necessary to get the interest of students trained in art. Many of the existing texts and journals on the subject do a great job for those students whose interest is in the amount of detail presented, with an emphasis on quantifiable arguments and explanations. I learned from these texts and journals, and they remain a necessary part of the learning process for design students. But impatient industrial design students who want to understand concepts, need an overview: read a summary, see examples, and go on to the next topic in some logical manner. Design students seem to sense that they will not have the prime responsibility in selecting materials or in specifying the manufacturing process in the design of products, but intuitively they understand that they must be conversant on the subject and that materials and manufacturing methods will be a determinant in the design process.

There is a growing excitement and exploration in materials and manufacturing in the design community because of the recent explosion of ideas engendered by the advances in aerospace research. Mutant Materials in Contemporary Design, organized by Paola Antonelli, Associate Curator at the Museum of Modern Art, and the Material Connextion conceived by George Beylerian, are outstanding examples of this renewed energy focused on this essential aspect of design. Within the Industrial Designers Society of America (ISDA), Dave Kusuma was instrumental in organizing the Materials and Processes Group and in bringing the Society of Plastics Engineers and IDSA together for meetings and conferences.

For years I hoped that someone else would produce such a text. After teaching the subject for more than 15 years, I realized that no designers were presumptuous enough to try to develop a text for industrial design students, so I began to collect my notes. While at Pratt Institute, I received a Mellon grant to produce a structure for the information. During this first phase, several students assisted me, including Deborah Zweiker and Eileen Lee. Without the advantage of a computer, we labored most of the summer laying out the organizational charts and making the many lists of information by hand. While I was at Carnegie Mellon University, Professor Alex Bally, head of the Industrial Design Department, and Professors Greenberg and Paxton of the Materials Science Department, reviewed my preliminary concepts and provided many suggestions and encouragement.

While I am responsible for the use I made of the information that I received, it was impossible to complete this undertaking on my own. In fact, this book is the work of many people: the many students who sat through the lectures and provided feedback, and the manufacturers and suppliers who graciously spent valuable time and had endless patience with me trying to ensure that I received the information I needed. There are many who stand out, who went way beyond that call of duty.

This book would not have been completed without Ed Eslami, who on a number of occasions, rescued me from panic, and whose calm assurance, clever drawings, and graphic layout brought the book out of the morass that it was in at times. I am grateful for his help and his exceptional talent. Many students helped with research and drawings, including Kyang Haub Kang, Tong Jin Kim, and Minghsiu Yang.

Don Blair of Talbot Associates was with me almost from the beginning, and later Jeff Talbot joined him to provide hours of discussion, stacks of brochures, and many sources of information on casting. Christine Lagosz and her associates at Trumpf, Inc., Bill Guftner of US Amada Ltd., Steven Friedman of Peterson, Walter Ackerman of Risdon, John Matthews of ESAB Welding & Cutting Products, and Bob Cook of Bridgeport Machines were just some of the great individuals who provided all the information I requested on metal forming and cutting.

Dave Kusuma and Michael A. D'Onofrio, Jr. and their associates of at the Bayer Corporation; Jack Avery, George Whitney, and their associates at GE Plastics; Steve Ham; Dave Beck of Pappago; Victor Gerdes and his associates at the Stevens Institute; Bill Fallon of Sikorsky; and George Cekis of Solvay provided important parts in building the plastics section. I am thankful that the publishers of Injecting Molding Handbook by Rosato & Rosato and Plastics Engineering Handbook by the Society of the Plastics Industry allowed me to reproduce many drawings.

For this second edition, I am extremely fortunate that Edward Eslami again was my guiding light and helped make new ideas happen. Mike Gallagher, a former student and now a colleague, provided inspiration and enthusiasm once again by inviting me to Crown Equipment Corp. for a tour of its design and manufacturing facilities. Jim Kraimer, Jeff ery Mauch, and Doug Rinderle and their many associates led this tour and ably answered my many questions. Manuel Saez and Lachezar Tsvslotinv, also former students, described their work at HumanScale and provided images of their current projects. Peter Bressler and his associates and Dave Kaiser and his associates kindly responded to my call for images. David Stricker of Production Resources and Robert Hagemeister of Parametric Design Associates provided important current information.

Many of the casting descriptions were taken from the 2006 Casting Source Directory, published by Engineered Casting Solutions, with the kind permission of Publisher and Editor Alfred T. Spada. John Chion of Talbot Associates reviewed my draft of the casting section and provided guidance and suggestions. Obviously, many others plowed through my drafts and patiently corrected my errors and contributed their expertise; their thoughts are somewhere inside these pages.

I am grateful that an endless number of students are always ready to help. Zackary Smith helped with the graphic layout, and Soo Hwan Cho and Wooyeon Cho provided many illustrations. When I arrived at Dongseo University in Korea Sang-Hwan An, Sang-Wook Eom, Ji Young Kang, Hyo-Jin Kim, and Joon-Goo Lee helped with illustrations and drawings. I would also like to thank the many companies at the INTERMOLD KOREA 2007 Exhibition for the stacks of brochures and endless pictures. The enthusiasm and willingness to help on the part of nearly everyone whom I contacted kept me going. I am grateful to all.

I would also like to thank the many engineers and designers who helped and encouraged me. This book is dedicated to them; to the memory of Donald R. Dohner, the father of American industrial design education; and to Peter Megert, who has provided inspiration and endless wisdom for so many young designers.

Overview Chart

figure 1-1. materials and manufacturing

Chapter 1

Introduction

Need for Materials and Manufacturing

The industrial designer, whether on a design team or acting alone, is responsible for the appearance and form of a product. If the form of a product is to some degree the result of how it was manufactured, it follows that the designer must have a good understanding of all manufacturing processes available, in order to have confidence that the proposed manufacturing process is the most economical and appropriate. If a designer is unaware of certain available processes creative potential is limited. It would be like a composer writing a symphony totally unaware of the color and full range and capability of some instruments.

Design Education

Industrial design students should have an understanding of materials and manufacturing—ideally in the sophomore year. This is important because as projects are assigned, students need to visualize and develop forms that ultimately will be manufactured (even if theoretically). Without a comprehensive knowledge base of materials and manufacturing possibilities, students can only fantasize and flounder along, limited by ignorance of the subject and oblivious to the variety of possibilities available. Conversely, with a good knowledge base students can propose an array of possible design solutions and have some confidence that they can be manufactured.

This guide is specifically designed as a two-semester classroom guide for industrial design students. It should also be useful for other professionals who require an introductory understanding of this information. It is not, and is not intended to be, an alternative to the standard engineering texts on the subject. It would be wise for designers to acquire such a text at some point. Industrial Design: Materials and Manufacturing Guide is intended to give an overview in simple words and visual images and to serve as a guide and introduction to this rather complex field, a necessary part of industrial design education.

An excellent example of the need for a full understanding of materials and manufacturing is the Crown TSP 6000, especially the cab shown on the cover. While consumer products are challenging from many perspectives, including marketing, industrial products like the TSP require exceptional demands for excellence in design and engineering, such as extreme attention to ergonomics and to cost benefit analysis, as well as the traditional design concerns. The TSP is a perfect example of where the designers clearly demonstrate an understanding of the full range of materials and processes available. This is particularly exemplified in the cab for the TSP. The designers explained that for every single part they considered all the possible materials and related processes available. The best option for each part was selected through a rigorous analysis of the cost–benefit analysis charts that were developed as a normal operating procedure of the Crown design program. The result is a spectacular and aesthetically successful use of materials fulfilling every demand, economically manufactured to meet the production requirements, but more important to anticipate and fulfill the rather extreme operational demands of users.

figure 1-2. Crown TSP 6000 Turret Stockpicker (courtesy Crown Equipment Corporation)

Product Design Sequence

figure 2-1. product design sequence

© Jim Lesko and Edward Eslami

Chapter 2

Overview

Form Is the Resolution of Function

Design is in essence a search for form. “Form follows function” has been on the banner of designers since the Bauhaus. However, this statement suggests that function leads and form follows, relegating form to a subordinate position. Restated, it might read “Form is the resolution of function,” where function has two major components: (1) performance specification demands, including all user-friendly aspects, and (2) cost and manufacturability. The former refers to ergonomics—aspects concerned with the abilities and limitations of the product’s users. The latter refers to the physical aspects of the product, including material selection and manufacturability. “Form is the resolution of function” suggests that form is dynamic and interactive, whereas “Form follows function” implies that form is passive, following behind function as the primary determining factor in a design. If the revised “Form is the resolution of function,” is used, then manufacturability is understood in its rightful place as an equal determinant in the design process.

Form is realized or made visible in a material or a combination of materials, which are shaped by tools. In creating a form, the designer is by default selecting a manufacturing process. Normally the designer creates models to demonstrate a concept in substitute materials—not the actual material—and by so doing is removed from a real understanding of the way the manufacturing process will impact the material and form. If product concepts are created on paper using pencil or on a computer, there is a danger that the designer is not only removed from an understanding of actual manufacturing ramifications, but is also another step removed from dimensional reality and material behavior altogether. It takes a real-world understanding of materials and manufacturing methods to create successful products. This cannot be accomplished alone in a studio: It requires teamwork with materials and manufacturing engineering development and support. The Clinto, by Manuel Saez and his Humanscale team, is an excellent example of a successful product whose form is not only a celebration of materials and manufacturing, but is the essence of function for human need. Each element of this design was chosen to meet all factors involved. The forms seem simple but perform complex functions under the severe demands of cost restraints. The materials and production process selected and the form that evolved were developed inter-dependently, in an optimization process in which the best possible solution was determined after deliberation and exhaustive search and testing.

The violin is the absolute epitome and essence of a product in terms of materials and manufacturing. No other human invention is so perfect in its resolution. If made by Stradivarius, nothing can match it in its ability to reach the sublime. Of course, it takes a master to play it properly. There is no use playing a Stradivarius unless the music is written by a master such as Bach or Beethoven.

Industrial Design Materials and Manufacturingis an overview of the key processes and salient related supporting information intended for (student) industrial designers. It is limited to engineering materials (excluding natural materials). The goal is to distill the key information on the subject, organize it, and present it as simply as possible. One visual representation of full design process is shown on the facing page. This guide is limited to a discussion of some of the objective considerations printed in green text.

figure 2-2. Clinto (courtesy Humanscale Design Studio)

figure 2-3. manufacturing methods chart

Materials and Manufacturing Methods

This guide is an overview of the key materials, processes, and salient related supporting information intended for (student) industrial designers. It is limited to engineering materials (excluding natural materials like wood, stone, etc.). The goal is to distill the key information on the subject, organize it, and present it as simply as possible. Existing engineering-oriented texts on this subject attempt to be inclusive, with extensive technical information geared to engineering.

This guide summarizes the materials and processes important to industrial design. This information is presented simply and graphically. It does not attempt to present all available materials and manufacturing processes; it is intended to be a designer’s guide to materials and manufacturing. The methodology used may help readers organize additional information on these subjects.

figure 2-4. materials chart

figure 3-1. Unisphere, Flushing Meadows Park, New York

Chapter 3

Metals

figure 3-2. metals chart

Pure metals are composed of atoms of the same type. Metal alloys are composed of two or more chemical elements, of which at least one is a metal. This blending of elements gives alloys their greater mechanical properties. The majority of metals used in engineering applications are alloys. Metals are generally divided into ferrous and nonferrous. Each metal alloy has specific mechanical and physical properties that will make it a good fit for a specific application. Fairly recently, metals have become available in a powdered form. This has expanded the opportunities, making it possible to provide totally new alloys that were not previously available. Powdered metals are now being alloyed with nonmetals, including ceramics, rubber, and plastics, thereby creating new categories of product design.

figure 3-3. elastic behavior

figure 3-4. plastic behavior

3.1 Properties of Metals

Brief Definitions of Mechanical Properties

Metals exhibit elastic as well as plastic behavior, both of which are necessary for the forming process. These unique behaviors allow most metals to bend and draw during the shaping process.

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!