Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

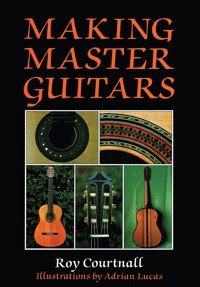

Making Master Guitars is a craftsman's handbook about the exciting and challenging pursuit of making classical guitars, a craft that the author reveals to be surprisingly accessible by following his instructions. The book is unique in that it includes nine separate detailed plans of instruments constructed by internationally famous guitar-makers. The author has had the rare opportunity of examining these instruments in detail, and has made many replicas of each one. Superbly illustrated by Adrian Lucas. Part one: The Master Makers and their Guitars is devoted to separate chapters on each famous maker, including Antonio de Torres, Hermann Hauser, Santos Hernandez y Aguado, Ignacio Fleta, Robert Bouchet, Daniel Friederich and Jose Romanillos. The reader will find historical information about the life of and influences on each makers, as well as detailed sets of working drawings for their guitars. Also included are rare photographs of the guitars. Part two: Workshop, Tools and Materials provides essential information about the tools, working environment and material needed by the guitar-maker. Part three: Guitar Construction - The Spanish Method comprises a step-by-step method of guitar construction, illustrated by numerous photographs and drawings. The method of making a guitar is presented with great clarity. So that even the newcomer to this fascinating craft will be able to produce a superb instrument. This book will be essential for the guitar-maker and the historian, providing as it does a unique record of the different methods of guitar design and strutting systems that have evolved since Antonio de Torres first defined the essential characteristics of the modern classical guitar in the 1850s.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 393

Veröffentlichungsjahr: 1993

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

TorresSantos HernándezHauserHernández y AguadoFletaBouchetFriederichRomanillos

First published in 1993 by Robert Hale, an imprint of The Crowood Press Ltd, Ramsbury, Marlborough Wiltshire SN8 2HR

www.crowood.com

www.halebooks.com

This impression 2017

This e-book first published in 2024

© Roy Courtnall 1993

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication DataA catalogue record for this book is available from the BritishLibrary.

ISBN 978 0 7198 3165 2

The right of Roy Courtnall to be identified as the author of this work has been asserted by him in accordance with the Copyright, Designs and Patents Act 1988.

Contents

List of Illustrations

Acknowledgements

Preface and Technical Terms

Part 1: The Master Makers and their Guitars

1Antonio de Torres

2Santos Hernández

3Hermann Hauser

4Hernández y Aguado

5Ignacio Fleta

6Robert Bouchet

7Daniel Friederich

8José Romanillos

Part 2: Workshop, Tools and Materials

9Workshop and Tools

10 Materials

Part 3: Guitar Construction – The Spanish Method

Introduction

11 Solera

12 Neck and Head

13 Rosette

14 Soundboard

15 Strutting

16 Back

17 Ribs

18 Linings

19 Assembly: Soundboard, Neck and End-block

20 Assembly: Ribs and Linings

21 Assembly: Back

22 Purfling and Binding

23 Fingerboard

24 Bridge

25 Final Shaping of the Neck

26 Action and Stringing Up

27 Varnishing and Polishing

Appendix 1 Conversion Tables

Appendix 2 Fret Distance Tables

Appendix 3 Suppliers of Materials, Tools and Plans

Bibliography

Index

Illustrations

fig. 1 The major components of the guitar

1-1 Guitar by Antonio de Torres (Photograph by Maurice Aeschimann, supplied by Raymond Ursell/Siegfried Hogenmüller)

1-2 Detail of rib inlays on Torres’ most decorative guitar, made in 1858 (FE 08) (Photograph by José Romanillos)

1-3 The rosette on FE 08 (Photograph by José Romanillos)

1-4 The inside of a Torres guitar made in 1888 (Photograph by A Fernandez, supplied by José Romanillos)

1-5 The inside of a Torres guitar made in 1884 (Photograph by J. Masso, supplied by José Romanillos)

1-6 The rosette on a Torres guitar made in 1859 (Photograph by José Romanillos)

1-7 The rosette on a Torres guitar made in 1884 (SE 60)(Photographed by Berard, supplied by José Romanillos)

1-8 Torres 1 – plantilla

1-9 Torres 1 – soundboard

1-10 Torres 1 – neck and body

1-11 Torres 1 – rosette

1-12 Torres 1 – head

1-13 Torres 1 – neck joint

1-14 Torres 1 – bridge

1-15 Torres 2 – plantilla

1-16 Torres 2 – soundboard

1-17 Torres 2 – neck and body

1-18 Torres 2 – rosette

1-19 Torres 2 – head

1-20 Torres 2 – neck joint

1-21 Torres 2 – bridge

2-1 A flamenco guitar by Santos Hernández, made in 1933 (From the collection of Michael Bilton, photographed by Raymond Ursell)

2-2 The cypress back of the flamenco guitar (From the collection of Michael Bilton, photographed by Raymond Ursell)

2-3 The head of the flamenco guitar (From the collection of Michael Bilton, photographed by Michael Bilton)

2-4The rosette on the flamenco guitar (From the collection of Michael Bilton, photographed by Raymond Ursell)

2-5 Santos Hernández – plantilla

2-6 Santos Hernández – soundboard

2-7 Santos Hernández – neck and body

2-8 Santos Hernández – rosette

2-9 Santos Hernández – head

2-10 Santos Hernández – neck joint

2-11Santos Hernández – bridge

3-1 Hermann Hauser I (Photograph by Hermann Hauser II, supplied by José Romanillos)

3-2 A double-necked contra-guitar by Hauser I (Photograph by Sotheby’s – London)

3-3 A later guitar by Hauser (Photograph by Raymond Ursell)

3-4 The elaborately carved head of a 1936 Hauser (Photograph by Raymond Ursell)

3-5 The rosette on a 1931 Hauser (Photograph by Siegfried Hogenmüller, supplied by José Romanillos)

3-6 Hauser – plantilla

3-7 Hauser – soundboard

3-8 Hauser – neck and body

3-9 Hauser – rosette

3-10 Hauser – head

3-11 Hauser – neck joint

3-12 Hauser – bridge

4-1 A guitar made by Hernández y Aguado in 1967 (Photograph by Sotheby’s – London)

4-2 Front view of the Hernández y Aguado head

4-3 Back biew of the Hernández y Aguado head

4-4 The rosette on the 1967 guitar

4-5 The Hernández y Aguado bridge

4-6 Hernández y Aguado – plantilla

4-7 Hernández y Aguado – soundboard 1

4-8 Hernández y Aguado – soundboard 2

4-9 Hernández y Aguado – neck and body

4-10 Hernández y Aguado – rosette

4-11 Hernández y Aguado – head

4-12 Hernández y Aguado – neck joint

4-13 Hernández y Aguado – bridge

5-1 The Fleta brothers in their Barcelona workshop (Photograph by Stanley Doubtfire)

5-2 A guitar made by Ignacio Fleta & Sons (Photograph by Raymond Ursell)

5-3 The Fleta head (From the collection of Michael Bilton, photograph by Michael Bilton)

5-4 The Fleta bridge (From the collection by Michael Bilton, photograph by Michael Bilton)

5-5 The Fleta rosette (From the collection by Michael Bilton, photograph by Michael Bilton)

5-6 Fleta – plantilla

5-7 Fleta – soundboard

5-8 Fleta – neck and body

5-9 Fleta – rosette

5-10 Fleta – head

5-11 Fleta – neck joint

5-12 Fleta – bridge

6-1 Robert Bouchet in his Paris workshop (Photograph by Stanley Doubtfire)

6-2 Robert Bouchet’s jig (Photograph by Stanley Doubtfire)

6-3 A Bouchet guitar during construction (Photograph by Robert Bouchet, supplied by José Romanillos)

6-4 Julian Bream’s Bouchet (Photograph by Sotheby’s – London)

6-5 The rosette on a Bouchet guitar (From the collection of Mr Aoyagi, supplied by Y. Serizawa/Rokkoman)

6-6 Bouchet – plantilla

6-7 Bouchet – soundboard

6-8 Bouchet – neck and body

6-9 Bouchet – rosette

6-10 Bouchet – head

6-11 Bouchet – neck joint

6-12 Bouchet – bridge

7-1Daniel Friederich in his Paris workshop (Photograph supplied by Daniel Friederich)

7-2 One of the three strutting systems used by Daniel Friederich (Photograph supplied by Daniel Friederich)

7-3 Guitar by Daniel Friederich (Photograph by Raymond Ursell)

7-4 Head by Daniel Friederich (Photograph supplied by Daniel Friederich)

7-5 Friederich – rosette (Photograph supplied by Daniel Friederich)

7-6 The initial set-up used by Daniel Friederich to measure the longitudinal flexibility of each half of the soundboard (Photograph supplied by Daniel Friederich)

7-7 Once the soundboard has been glued together, it is cramped to a guitar-shaped former so that the flexibility in the bridge area can be measured (Photograph supplied by Daniel Friederich)

7-8 Friederich – plantilla

7-9 Friederich – soundboard

7-10 Friederich – neck and body

7-11 Friederich – rosette

7-12 Friederich – head

7-13 Friederich – neck joint

7-14 Friederich-bridge

8-1 José Romanillos in his workshop

8-2 A Romanillos guitar made in 1991 (Photograph by Raymond Ursell)

8-3 A Romanillos neck ready to receive the ribs

8-4 The Romanillos rosette (Photograph by Raymond Ursell)

8-5 The back inlays on the Romanillos copy of Torres’ 1858 guitar (FE 08)

8-6 The rosette on the Romanillos copy of Torres’ 1858 guitar (FE08)

8-7 The Romanillos label that was in use until late 1991

8-8 The new Romanillos label that was introduced in late 1991 8-9 Guitars hanging up in the workshop during french polishing

8-10 Romanillos – plantilla

8-11 Romanillos – soundboard 1 8-12 Romanillos – soundboard 2 8-13 Romanillos – neck and body

8-14 Romanillos – rosette

8-15 Romanillos – head

8-16 Romanillos – neck joint

8-17 Romanillos – bridge

9-1 The Fleta workshop in Barcelona (Photograph by Stanley Doubtfire)

9-2 Changes in humidity cause the wood to either shrink or expand across the grain

9-3 Left to right: fret-slot saw, dovetail saw, small tenon saw, rib-slot saw set to produce a 2 mm wide cut, large tenon saw

9-4 Left to right: coping saw, fret saw, jeweller’s saw

9-5 Clockwise, left to right: scraper plane, block plane, smoothing plane

9-6 Left to right: half-round file, flat file, wood rasp, 3 mm chisel, 10 mm chisel, 13 mm chisel, 19 mm chisel, 19 mm carving chisel

9-7 Clockwise, left to right: 300 mm steel rule, 150 mm steel rule, marking knife, scalpel, adjustable bevel, try-square, engineer’s square, small dividers, large dividers

9-8 Left to right: various screwdrivers, hammer (flat head), hammer (round head), fretwire hammer, hand-drill

9-9 Small and large cramps

9-10 Clockwise, left to right: vapour/dust mask, goggles, disposable dust mask

9-11 Electrically operated bending iron

9-12 Thicknessing caliper

9-13 Circle cutter

9-14 Long-reach cramps with leveller supports

9-15 Long-reach cramps (screw operated)

9-16 Long-reach cramps (cam operated)

9-17 Left to right: lining cramps, spool cramps

9-18 Clockwise, left to right: Stanley knife, inspection mirror, circle cutter, 1 mm chisel, 2 mm chisel, luthier’s knife, purfling groove cutter, small violin maker’s plane

9-19 Hygrometers

9-20 Left to right: 16 mm saw-tooth drill, 11 mm brad point drill

9-21 Sanding sticks

fig. la Daniel Friederich using a device for gluing on the fan strutting (Photograph by Daniel Friederich)

9-22 Long-reach guitar maker’s cramp (screw operated)

9-23 Spool cramp

9-24 Sharpening a plane iron with a honing guide

9-25 Forming the burr on the edge of a cabinet scraper

10-1 The first stage in preparing spruce soundboards (Photograph supplied by Luthiers Mercantile)

10-2 The major components of the guitar are made from quarter-sawn timber

10-3 Spruce and Western red cedar soundboards being stored at the Fleta workshop in Barcelona (Photograph by Stanley Doubtfire)

10-4 If the tree is split, rather than sawn, the wood cells (which show as dark lines) will be parallel to the surface

10-5 Guitar necks hanging up in the Fleta workshop (Photograph by Stanley Doubtfire)

10-6 Hand-made machine head by David Rodgers (Photograph by Cliff Guttridge)

fig. 2 The mould used by Ignacio Fleta for constructing his guitars (Photograph by Stanley Doubtfire)

fig. 3 The ‘external’ mould used by Daniel Friederich (Photograph by Daniel Friederich)

fig. 4 The solera used by José Romanillos for constructing his guitars

11-1 The completed solera

11-2 Setting out the solera

11-3 Forming the slots

11-4 The neck extension is ramped down by 3 mm

11-5 By leaving a flat edge around the periphery of the guitar outline, the ribs will be simpler to fit

11-6 The cramping block

11-7 A rib-supporting block

12-1 The laminated neck is stronger, because the grain follows the direction of the head

12-2 Preparing the neck blank

12-3 Sawing the head section from the main neck blank

12-4 Smoothing the splice joint

12-5 Gluing the neck to the head

12-6 Rosewood and sycamore veneers

12-7 Gluing the veneers to the head

12-8 Levelling the side of the neck on a sanding board

12-9 A large carpenter’s square is cramped to the neck so that a line can be marked across the head veneers at 90 degrees to the neck

12-10 Left to right: three useful templates

12-11 Using a template to mark the head shape

12-12 Typical layout for the neck and head

12-13 Drilling the holes for the head slots

12-14 Checking that the drill is positioned at a right angle to the edge of the head

12-15 Drilling the holes for the barrels of the tuning machines

12-16 Removing the waste with a coping saw, to form the slots

12-17 Cleaning up the head slots with a chisel

12-18 Smoothing the head slots with a round sanding stick

12-19 Cutting the ramps with a flat chisel

12-20 Smoothing the final head shape

12-21 The heel/foot is laminated from a number of sections

12-22 Gluing the laminations for the heel/foot

12-23 Layout of the neck at the 12th fret

12-24 Sawing the rib slots – the saw has been specially set to produce a 2 mm wide cut

12-25 Cutting the waste from the foot

12-26 The completed foot is coated with sanding sealer

12-27 Cutting the heel profile on a bandsaw

12-28 The sequence for producing the heel

12-29 The neck cramped to a board, ready for the heel to be carved

12-30 The sides of the heel are first carved flush with the foot

12-31 Carving the heel where it meets the rib slots

12-32 The profile at the rib slots is completed

12-33 Smoothing the final shape with a cabinet scraper

12-34 Forming the recessed platform to which the soundboard will be glued

12-35 The method of joining the ribs to the neck used by José Romanillos

12-36 The ‘V’ joint between neck and head

13-1 Rosette design

13-2 Designing the central motif and borders

13-3 The position of each rosette component is drawn out in relation to the soundhole centre

13-4 1 mm × 1 mm inlay lines are cut to length, and taped together to represent each row of the required design

13-5 Set-up for gluing the lines into a plank

13-6 Planks scraped clean and smooth – ready for gluing into a log 189

13-7 The planks are glued together to form a log, which is then tapered so that the tiles will butt together around a circle

13-8 Set-up for gluing the planks together

13-9 Sawing the log into 2 mm thick tiles

13-10 A collection of logs and tiles, ready for inlaying into the soundboard

13-11 This ‘rope’ motif can be made from sheets of 0.6 mm thick veneer

13-12 Top: once the veneers have been glued into a stack, individual planks can be sawn off. Bottom: smoothing the surfaces of the plank with a cabinet scraper

13-13 Top: eight veneers, each 0.6 mm thick, are glued together to form a stack. Black and white stacks are made in this way. Bottom: the stacks are then glued together in a stepped formation

13-14 The stepped edge is planed flat so that long strips can be sawn off

13-15 Detail of one strip that has been sawn off the main block

13-16 Two strips have been glued together so that lengths of herringbone purfling (about 2 mm thick) can be sawn off and inlaid

13-17 Section of a rosette featuring three rows of end-grain motif with half-herringbone borders

14-1 Two battens support the soundboard so that the gluing edges can be planed flat

14-2 Using the spirit-level sander to level the edges

14-3 Gluing the two halves of the soundboard together with wedges and weights

14-4 The two halves of the soundboard are slightly off-set so that the join can later be located

14-5 A long batten cramped at one side of the soundboard allows the smoothing plane free access to most of the surface

14-6 Marking the plantilla on to the soundboard

14-7 Marking the position of the soundhole centre

14-8 The bevel of the circle-cutting blade must face the inner, waste area of the rosette

14-9 Marking the positions of each rosette component

14-10 Cutting the groove for the central motif tiles

14-11 Removing the waste with a narrow chisel

14-12 Marking the start of the groove

14-13 Inserting the tiles for the central motif

14-14 Each tile must be tapered slightly towards the inner circumference

14-15 To retain the symmetry of design, the tile that falls on the centre-line of the soundboard should be positioned centrally 205

14-16 Carving the tiles that form the outer border so that they lie flush with the soundboard surface

14-17 Inserting the veneer lines into a groove adjacent to the central motif tiles

14-18 Gluing in the tiles to form the inner border

14-19 Removing the waste to form the groove for veneer lines that will define the inner circumference of the rosette

14-20 Typical dimensions for thicknessing the soundboard

14-21 Using a circle cutter to form the soundhole

14-22 Detail of a completed rosette (1)

14-23 Detail of a completed rosette (2)

15-1 Strutting components

15-2 Marking the distance from the edge of the soundhole to the 12th fret (divided 19th fret)

15-3 Marking the distance from the edge of the soundhole to the 12th fret (undivided 19th fret)

15-4 Marking the distance from the bridge plate to the 12th fret

15-5 Marking the distance from the bridge bar to the 12th fret

15-6 The fan-struts and harmonic bars prepared for cutting to length

15-7 The reinforcing ready to be glued in place

15-8 A plywood disc with bolt is used to cramp the reinforcing to the soundboard

15-9 Detail of a fan-strut

15-10 Gluing the fan-struts to the soundboard with long-reach cramps

15-11 Gluing fan-struts with weights and cramps

15-12 Shaping the fan-struts with a small plane

15-13 Gluing the closing bars

15-14 Gluing the harmonic bars

15-15 Gluing an harmonic bar with an arch

15-16 Three typical cross-sections of harmonic bars

15-17 Shaping the harmonic bars with a small plane

15-18 Smoothing the soundboard and strutting with fine garnet paper

15-19 Typical dimensions for the bridge cramping-block

15-20 Typical dimensions for the fingerboard cramping-block

15-21 The bridge cramping-block and fingerboard cramping-block in position

15-22 A selection of cramping-blocks to suit various strutting designs

16-1 The traditional way of joining the back

16-2 The half-template is placed on the back to check that there is sufficient waste at the lower bout

16-3 Using sash cramps for gluing the two halves of the back together

16-4 If sash cramps are not available, the back can be glued together with battens, wedges and weights

16-5 Planing the back

16-6 Measuring the thickness of the back

16-7 Gluing the reinforcing over the centre back joint

16-8 Top: typical dimensions for the back bars. Bottom: the back reinforcing is positioned with the grain at a right angle to the grain of the back

16-9 Gluing the back bars to the back on a shaped solera

16-10 Top: typical half-template for the back bars. Bottom: typical arching for the back bars

16-11 Sections of reinforcing have been removed so that the back bars can be glued to the back

16-12 If a shaped solera is not used, the bars can be glued one at a time

16-13 The back ready for fitting to the ribs

16-14 Torres’ method of fitting the back

17-1 A strip of card represents the actual length of the rib

17-2 A rib is supported between two long battens

17-3 Smoothing and thicknessing the rib while it is cramped firmly at one end

17-4 Measuring the thickness of a rib

17-5 The ribs should be bent in this sequence

17-6 Bending the curve at the waist

17-7 Bending the curve at the lower bout

17-8 Trying the bent rib against the outline of the guitar

17-9 The rib is cramped against a guitar-shaped jig

17-10 The rib is placed accurately on to the guitar outline

17-11 Blocks and spool cramps can be applied if necessary

17-12 A small ramp chiselled on the waste side of the cut will ensure that the saw cut is accurate

17-13 This diagram shows the marking out required at the rib ends that will join into the neck

17-14 The distance from the centre of the neck to the beginning of the slot is measured, and then transferred to the ribs

17-15 The marking out completed

17-16 Once the ribs have been cut, they would meet as shown here

17-17 Fitting a rib into its slot

17-18 Top: the head veneers. Bottom: the centre-line of the neck

17-19 Checking that the ribs and neck can be assembled so that the ribs follow the guitar outline closely

18-1 The Fleta workshop in Barcelona (Photograph by Stanley Doubtfire)

18-2 Typical dimensions for the lining

18-3 Top: set-up for cutting the kerfed lining. Bottom: kerfed lining

18-4 Making the kerfed lining

18-5 The two common methods of lining

19-1 Robert Bouchet preparing to glue the neck to the soundboard (Photograph by Stanley Doubtfire)

19-2 Summarizing all the stages of assembly described in Chapters 19, 20 and 21

19-3 The soundboard has been trimmed at the position of the twelfth fret so that it will butt up to the edge of the recessed neck platform

19-4 Gluing the neck to the soundboard

19-5 Top: typical dimensions for the end-block. Bottom: three methods of making the end-block

19-6 Checking the verticality of the end-block with a small square

19-7 Gluing the end-block to the soundboard

19-8 The neck and end-block are both glued to the soundboard

20-1 Robert Bouchet fitting the ribs to the neck (Photograph by Stanley Doubtfire)

20-2 The harmonic bars are trimmed back by the thickness of the ribs (2 mm)

20-3 Fitting the rib to the neck and end-block

20-4 Gluing the rib to the soundboard

20-5 If necessary, additional support can be provided by the rib-supporting blocks

20-6 A Robert Bouchet guitar ready to receive individual lining blocks which will join the soundboard to the ribs (Photograph by Stanley Doubtfire)

20-7 Gluing the individual blocks

20-8 Small rib-blocks are glued in place to support the harmonic bars

20-9 Top: most makers use short rib blocks to support the transverse bars, both for the soundboard and the back. Bottom: an alternative is to extend the blocks right across the rib and house them into both linings

20-10 Trimming the harmonic bars back 2 mm from the outline of the guitar

20-11 Marking the positions of the harmonic bars on to the ribs

20-12 The kerfed lining is cut to length and fitted dry

20-13 Gluing the lining to the rib

20-14 Fitting the lined rib to the assembly

20-15 One rib has been glued and the other is ready for fitting

20-16 Rib-blocks are glued in the gaps in the lining

20-17 The second rib is glued in place

20-18 Before the back linings can be fitted, the ribs must be tapered from the waist to the neck

20-19 The angle of taper

20-20 Gluing the back lining

20-21 With all the linings in place, the back can now be fitted

21-1 Robert Bouchet fitting the back to a guitar (Photograph by Stanley Doubtfire)

21-2 Two methods of fitting the back bars to the linings

21-3 Back bars can be flat or scalloped

21-4 Marking the positions of the back bars on the ribs

21-5 Sawing the back bars to length

21-6 Sawing out a section of lining

21-7 Top: a scalloped bar fitting into a notched lining. Bottom: a flat bar fitting on to a rib-block

21-8 Fitting the back

21-9 Lowering the lining and rib in the area of the lower and upper bouts

21-10 A rib-block glued in place

21-11 Measuring the arch of the back

21-12 Gluing a block on to the foot

21-13 The foot shaped to receive the arched back

21-14 Measuring the difference in height between the top surface of the foot and the linings

21-15 The back ready to be glued to the assembly

21-16 Gluing the back

22-1 Top: typical design for the purfling and binding. Bottom: the four stages in binding the guitar

22-2 The workboard used for gluing on the binding

22-3 Typical end-block inlay

22-4 The inlay ready to be glued

22-5 Gluing the back purfling into the rebate

22-6 The back purfling completed

22-7 Cutting the rib for the binding rebate

22-8 The end-block inlay and the binding are mitred to form a neat joint

22-9 Fitting the binding

22-10 The heel capping ready to be glued

22-11 Gluing the heel capping

22-12 Marking the width of the purfling rebate with a purfling cutter

22-13 Deepening the cut with a scalpel

22-14 Forming the rebate for the purfling

22-15 The purfling glued against the edge of the rebate

22-16 At the neck end the purfling is carried 10 mm to 20 mm past the outer edge of the neck so that the fingerboard will cover it

22-17 Marking the rebate for the binding

22-18 Forming the rebate for the binding

22-19 Fitting the binding

22-20 The binding fitted

22-21 Gluing the binding

22-22 The completed binding and end-block inlay

23-1 The completed fingerboard

23-2 Workboard with stops at each end

23-3 Setting out the fingerboard

23-4 The adjustable bevel is set to mark a line that is at a right angle to the centre-line of the fingerboard

23-5 The lower (gluing) surface of the fingerboard is tapered

23-6 Measuring the distance from the edge of the soundhole to the 19th fret

23-7 Measuring the distance from the centre of the soundboard to the (extended) edge of the fingerboard

23-8 Marking the shape of the soundhole on the underside of the fingerboard

23-9 Cutting the end of the fingerboard to match the shape of the soundhole

23-10 A method of making dowels of any diameter

23-11 The fingerboard with locating dowels in place is now ready to be glued to the guitar

23-12 Gluing the fingerboard to the guitar

23-13 Smoothing the fingerboard to conform exactly to the shape of the soundhole

23-14 Removing the excess neck material so that it is flush with the fingerboard

23-15 Shaping the side of the neck at its junction with the head

23-16 Before installing the frets, a final check is carried out to ensure that the fingerboard has been correctly shaped

23-17 Marking the fret positions on the centre-line of the fingerboard

23-18 Scribing the fret positions on the fingerboard

23-19 Typical dimensions of fretwire suitable for the classical guitar

23-20 Sawing the slots for the fretwire

23-21 The top of the fret slots are bevelled with a triangular file

23-22 Hammering in the 4th fret

23-23 Applying even pressure on the fret by cramping against a rule

23-24 Cramping the short 19th fret and the 18th fret

23-25 Cutting off the excess fretwire

23-26 Top: a straight-edge placed over the frets should reveal no gaps. Bottom: some makers relieve the central area slightly

23-27 Filing the edges of the fretwire flush with the fingerboard

23-28 Shaping the inner ends of the two short 19th frets

23-29 Smoothing the fretwire with fine wet-or-dry paper

24-1 The completed bridge

24-2 Various bridge designs

24-3 The string leaves the bridge half-way between the top of the tie-block and the string hole

24-4 Recommended dimensions for the bridge

24-5 The jig for supporting the bridge while a router is used to cut the slots for the saddle and the ramp

24-6 Setting out and preparing the bridge for routing

24-7 Setting out the string holes with dividers

24-8 Drilling the string holes

24-9 The router in position on the jig

24-10 The routing complete

24-11 Removing the waste from the wings

24-12 Shaping the ramp and the front of the saddle slot

24-13 Filing the wings

24-14 Final smoothing of the wings

24-15 Cutting out the centre of the bone bridge veneer

24-16 Smoothing and levelling the cut-out area to receive the inlay

24-17 The veneer ready to be glued to the tie-block

24-18 Two methods of making the veneer

24-19 Compensation

24-20 Measuring the distance of the vibrating string

24-21 Aligning the bridge transversely

24-22 Drilling 2 mm diameter holes through the saddle slot and the soundboard

24-23 Scribing the position of the bridge on the soundboard

24-24The bridge is ready to be glued to the soundboard

24-25 Gluing the bridge

24-26Gluing the bridge (internal view)

25-1 A method of securing the guitar while the neck is shaped

25-2The neck marked for tapering

25-3 Reducing the neck thickness at the head-end

25-4 Checking that the tapered surface is flat

25-5 Shaping the junction of heel and neck with a cabinet scraper

25-6 Rounding the neck with a spokeshave

25-7 Shaping the junction of head and neck

25-8 Measuring the neck thickness at the 1st fret

25-9 Measuring the neck thickness at the 9th fret

26-1 Measuring the gap between the top of the 12th fret and the underside of the 6th string

26-2 Left: setting out the nut. Centre: the top surface of the nut slopes down towards the head. Right: the string is seated to half its diameter in the groove

26-3 Shaping the string grooves

26-4 The nut

26-5 Fitting the machine heads

26-6 The method for tying the strings to the bridge

26-7 Adjusting the action

26-8 The nut and saddle are removed before the guitar is varnished

27-1 Left to right: varnish jar; graduated measuring vessel;syringe; varnishing brush

27-2 Varnishing sequence

27-3 Varnishing the soundboard

27-4 V arnishing the b ack

27-5 The guitar is suspended so that the ribs can be varnished

27-6 Final polishing

27-7 Traditional movements of the rubber for applying french polish

27-8 The completed guitar

Acknowledgements

I am grateful to the many people who have contributed photographs, information and ideas. I would particularly like to thank Raymond Ursell, who provided access to many of the instruments; Marian, José, and Liam Romanillos; Daniel Friedrich; Siegfried Hogenmüller; Adrian Lucas; Michael Bilton; Stanley Doubtfire; Claire Edwards at Sotheby’s (London); Mr Aoyagi and Mr Y. Serizawa (Japan); Todd Taggart (Luthiers Mercantile USA); Jenny Summerfield; David Rodgers; Rob Johns; Peter Barton; Hans J. Weber; Bill Williams; Mary and Charly Lucas (translation services).

The author thanks David Collett (Guitar Salon International, Santa Monica, CA; www.guitarsalon.com) for generously supplying the jacket photographs.

Photographs are acknowledged in the list of illustrations at the beginning of the book. All photographs without acknowledgement were taken by the author.

Roy CourtnallLincoln, 1993

To Jenny, Roxy and Avalon

Preface

To make your own classical guitar is an exciting and challenging pursuit. A hand-made instrument from the workbench of a skilled luthier is an expensive investment, and to acquire a guitar made by one of the great names of lutherie is virtually impossible – not only are they scarce, but the price is likely to be extremely high. For a fraction of the cost, you can make one yourself. What you require is a reasonable degree of skill in using woodworking tools, combined with the patience and vision to see your dream become reality.

The idea for this book arose as a result of many requests, from both professional makers and aspiring craftspeople, for detailed working drawings and methods of construction of the work of those makers who have gained international recognition for the excellence of their guitars. A number of books already exist which cover construction techniques in general, but surprisingly, they tend to ignore the great makers, and proceed to provide models for instruments based on a generalized view of guitar design. One problem is of course the lack of access to these instruments, which were never produced in great numbers, and most examples are in the possession of either professional guitarists or dedicated collectors who prize their instruments greatly.

The concert guitar has only gradually begun to gain the degree of respect attributed to other orchestral instruments. Perhaps this is partly due to the lack of standardization in the plantilla (body shape), strutting system and other elements of design. (Violin design has long been established.) Yet here there is a paradox – the very life and vitality surrounding the guitar-making communities must in some way be due to this continuing fluidity, which seems to both fascinate and inspire makers in the belief that their contribution will develop guitar design further.

So there are makers, on the one hand, who believe that every aspect of guitar design has already been established by the nineteenth-century luthier, Antonio de Torres, and that no real improvements are likely. Conversely, there is a movement, particularly strong in the United States, which is working towards a radically new approach to guitar construction, utilizing scientific data in order to make decisions about the optimum design.

Somewhere between these two views lies the position taken in this book; that a close analysis of the great masters can provide the best starting-point for the aspiring maker. Thus the book aims to give an insight into the art of the master guitar makers. You will find detailed information about their work. The names of Antonio de Torres, Santos Hernández, Hermann Hauser, Hernández y Aguado, Ignacio Fleta, Robert Bouchet, Daniel Friederich and José Romanillos are synonymous with superb instruments. The guitars covered here represent a cross-section of the work of some of the finest makers. It is by no means exhaustive, but in selecting instruments, an attempt has been made to include a wide variety of ‘personalities’; each guitar presented here has its own unique identity.

Part 1 of the book comprises individual chapters, each dedicated to one maker and including detailed working drawings of one of his guitars. (In the case of Torres, two different plans are given. Torres is so important in the history of guitar design that two contrasting instruments provide a more balanced view of his work. In the cases of Hernández y Aguado, and Romanillos, alternative soundboard plans are provided. This is in order to give as comprehensive a view as possible of their ideas and work, and to demonstrate the wide variety of strutting designs that have been used.) To help place each instrument in its historical context, a brief summary of the life, the influences on the maker and the character of his work are provided. Research reveals many inconsistencies concerning dates, innovations in design and so on. Many historical references seem confused and contradictory, but as this book is primarily intended to be a ‘workshop guide’, it only skims the surface of this fascinating area. The interested reader is advised to consult reference books for a more detailed study (see Bibliography.)

Part 2 provides essential information about the working environment, tools, and materials relevant to the guitar maker.

Part 3 comprises a step-by-step guide to the traditional Spanish method of guitar making, and the newcomer to this art will find it to be a comprehensive and logical approach. It is assumed that the reader may never have made a guitar before, and therefore even basic woodworking procedures are described in detail. All the assembly methods are closely based on those used by Torres and most of the other great makers.

A Note about the Plans

All the plans were originally produced as full-size drawings, but many had to be reduced in size to fit the format of the book. For the maker who prefers working from full-size plans, these are available. (Please consult Appendix 3: Suppliers of Materials, at the end of the book.)

Interpreting the Drawings

Each set of drawings consists of:

1 Outline shape (plantilla) of half the guitar, drawn on a one-centimetre grid. In the book, these squares have been reduced in size, but several methods of enlarging back to the full size are explained in Chapter 11.

2 Plan of the soundboard, showing the positions of all strutting, bars and reinforcing. The fan struts and the harmonic bars include a hatched cross-section which represents the vertical height and shape of the strut or bar. To facilitate setting out the strutting pattern on the soundboard, each plan has a dotted line across the widest point of the lower bout. A second line is provided by the position of the lower harmonic bar (just below the soundhole). The fan struts are set out by reference to these two lines, using the centre-to-centre dimensions shown on the two lines. Where the guitar has a bridge plate, this is shown as a continuous line. Where no bridge plate is used, the position of the bridge is shown by a dotted line.

3 Plan of the rosette; this shows how the pattern of the various components is constructed.

4 Plan of the fingerboard and section through the neck; these provide all the information needed to construct the neck.

5 Section through the centre of the body.

6 Full-size plans of the head, bridge, and neck joint.

Setting the Scene

A nineteenth-century Spanish carpenter, Antonio de Torres, is generally considered to be the originator of the modern classical guitar, and his work is taken as our point of departure. He was born in 1817, and made his first guitar in Granada around 1840. Torres’ vision was of an instrument radically different from the smaller, less powerful guitars that were in use at the time.

He established a ‘plantilla’ or outline shape of the instrument, which became accepted as the standard proportions for a good guitar. He understood that the single most important component was the soundboard, and that increasing its size meant that the area of vibrating wood became much greater. Torres combined this with an elaborate system of strutting glued underneath the soundboard. This strutting provided the strength for the thin soundboard to resist the pull of the strings, yet not to inhibit the movement of the soundwaves through the wood. He also established the optimum scale length as being 650 mm. This measurement has been accepted by almost every maker since.

Virtually all luthiers of international standing have taken Torres as their starting-point. Each one has nevertheless contributed new elements of design, as well as imparting their own personal vision of what a guitar should be. They have all produced instruments of superb quality, yet in many ways, they differ from one another quite considerably – the strength of Fleta; the beauty and sustained sound of Bouchet; the calm balance of Aguado; or the firm richness of Romanillos. By following the plan of your choice, you will be well on your way to creating a guitar that captures something of the character of the original.

Technical Terms

The meaning of words in common use is given here, in order to avoid repeated explanations in the text.

Arched: a soundboard which curves only in one plane; across its width.

Binding: the strips of wood that are let in to rebates cut around the edges of the ribs.

Body: the major component of the guitar, consisting of soundboard, back and ribs.

Bridge: the block of wood glued to the soundboard, to which the strings are tied.

Closing bars: two diagonal bars attached to the soundboard, and placed near the end-block, which form part of the soundboard strutting system.

Domed: a soundboard that is arched both across its width, and along its length.

End-block: the internal block at the base of the guitar, to which the ends of the two ribs are glued.

Fan-struts: the struts glued under the soundboard to resemble a fan.

Fingerboard: the length of wood glued to the upper surface of the neck, in which the frets are inserted.

Foot: the part of the neck inside the body, which provides a gluing surface for the back and soundboard.

Frets: metal strips, fitted into slots cut in the fingerboard, which serve to define musical notes at semitone intervals.

Harmonic bar: bar glued across the inside of the soundboard, usually one above and one below the soundhole.

Head: the end of the neck in which the machine heads or pegs are housed.

Heel: the part of the neck outside the body, to which the ribs are fitted.

fig. 1 The major components of the guitar

Kerfed lining: a lining which has been almost cut through at regular intervals, so that it can be bent to conform to the curves of the ribs.

Lower bout: the section of guitar body from the waist to the end-block.

Machine heads: the geared mechanism fitted to the head, to which the strings are tied and tensioned up to the required pitch. They are also known as ‘tuning machines’.

Neck: the long shaft of wood attached to the body of the guitar.

Nut: the bone or ivory block at the head-end of the neck, over which the strings run.

Plantilla: the outline shape of the guitar body, irrespective of its actual dimensions.

Purfling: decorative strips of wood, inlaid around the periphery of the guitar on soundboard and back.

Quarter-sawn: timber cut so that the annual rings are at 90 degrees to the surface of the wood.

Rib: the two curved pieces of wood which form the sides of the guitar body.

Rib-block: the wooden block glued to the rib, to support the harmonic bars and transverse bars.

Rosette: the decorative, circular motif that surrounds the soundhole.

Saddle: the bone or ivory strip inserted into a slot in the bridge, over which the strings pass.

Scale length: the vibrating length of the open strings.

Scallop: the shape formed at the ends of the struts and bars.

Solera: the workboard on which the struts are fixed to the soundboard, often designed to force the soundboard to conform to a domed shape.

Soundboard: the front of the guitar body, which supports the bridge, and which is itself supported underneath by the struts and harmonic bars.

Spliced joint: a method of joining the head to the neck.

Strut: a long strip of wood, glued to the inside of the soundboard.

Thicknessing: the process of reducing the soundboard, back and ribs to the required thickness.

Transverse bars: the arched bars glued across the back, which are housed into the rib lining.

Upper bout: the section of the guitar body from the waist to the 12th fret.

Waist: the narrowest part of the soundboard or back.

Part 1

The Master Makersand their Guitars

1 Antonio de Torres

(1817-92)

Background

The legendary figure of Antonio de Torres has created much controversy in the guitar making world. His followers are convinced that the Torres contribution to guitar design is paramount, and that his reputation is more than justified. His critics view Torres much more as being one maker amongst many, and not all contemporary makers would acknowledge him as a major influence on their work. This is especially true of the most recent experimenters in guitar design, who are attempting to discard virtually all preconceived ideas in the hope of making radically new instruments. They are utilizing scientific data as their major source, rather than any historical or intuitive references.1

1-1 Guitar by Antonio de Torres

Any important historical figure attracts a certain amount of mythology; about their life, their work and their ideas. This is especially true in the absence of any well-documented records on which to draw. Until recently the life of Torres was shrouded in mystery. Many stories about him could not be substantiated. The English-based guitar maker, José Romanillos, has to a large extent rectified this problem by undertaking a thorough research into the life and work of Torres.2 He has pieced together a vast amount of documentation and has catalogued and examined some sixty-five Torres guitars which could be traced. The result is that there is now a much clearer picture, not only of the life and times of Torres, but also of the contribution he made to guitar design. The sixty-five guitars provide what must be a substantial summary of his work, and it is now possible to see just how his work developed – different body shapes; the method of strutting; the range of decorative inlays, and we also have an insight into his method of construction.

Torres made his first guitar around 1840. By 1854 he had a workshop in Seville, which was located in a district occupied by a number of other guitar makers. He would have seen the guitars made by José Pernas, which were typical of the design currently in use. This consisted of a smaller body shape, a bridge with fixed saddle, rather wide struts, and an elaborate, scrolled head design. Torres, however, was already producing guitars that were radically different from this earlier pattern – his instruments had larger lower bouts, and incorporated the seven radial fan struts that were to become the hallmark of modern strutting design. At that time, most strutting consisted simply of three large transverse bars. Torres must have had an intuitive grasp of the acoustic properties of wood – he selected his materials more skilfully than many of his contemporaries, who often produced instruments as decorative items of beauty rather than as functional musical instruments. Although some of Torres’ guitars exhibit elaborate marquetry and other decorative features, many are relatively simply adorned, and his main obsession was clearly with the functioning of the instruments. When he did make use of decorative techniques, they were carefully controlled so as not to become overpowering.

1-2 Detail of rib inlays on Torres’ most decorative guitar, made in 1858 (FE 08)

1-3 The rosette on FE 08

By 1860 Torres had exhibited his guitars at major exhibitions, and was well established as a maker. Nevertheless, guitar making was not a lucrative business, and he stopped making instruments in favour of opening a retail shop which sold china. It is thought that the general depression in Spain was responsible for his increasing financial difficulties. Guitar makers generally produced two types of instrument – basic student models for the amateur player, and elaborate versions for professional musicians. The large amount of time that it took to produce the finest guitars must have made it very difficult to charge a price that would reflect the true amount of labour that went into their construction. By 1875 Torres had once again started making guitars, producing about six instruments a year. This modest output doubled to twelve a year from 1883 to 1892. It is, however, the guitars produced earlier on in his career which were the most successful. The later instruments did not produce the same quality of sound. Torres died on 19 November 1892. The majority of his work was carried out between 1852-69, and then between 1875-92.

Soundboard and Strutting System

Torres thought of the soundboard as the single most critical component of his guitars – he was careful to select suitable spruce, which he thicknessed according to its characteristics of stiffness and annual ring growth. In fact, his fascination with the soundboard was so great that he was motivated to produce his now famous papier-mache guitar in which the back and ribs were constructed from cardboard, thus demonstrating the overriding importance of the soundboard in tone production. As this instrument is not in a playable condition, it is impossible to determine whether the experiment supported his idea about the relationship between the soundboard, and the back and ribs. In general, his soundboards are thickest in the central area; around the bridge and above the soundhole (2.5 mm), thinning out in the peripheral areas to as little as 1.4 mm. The papier-mache guitar has a peripheral soundboard thickness of only 0.4 mm. All measurements of plate thicknesses on old instruments must be treated cautiously, as repeated repairs and re-finishing, in which there is a temptation to sand away all dents and scratches, may result in considerable thinning of the surface. Most contemporary makers are unlikely to reduce any area of the soundboard to much below 2.0 mm.

1-4 The inside of a Torres guitar made in 1888. The struts are not original – pencil lines mark the positions of the original struts. This guitar has now been restored to its original strutting layout by José Romanillos. The second set of plans provided at the end of this chapter is based on this instrument

1-5 The inside of a Torres guitar made in 1884. The transverse back bars have remained in place after the back was removed. Note the rib strengthening bars