20,99 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

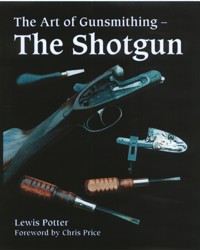

This volume is written about working on one of the finest sporting firearms ever invented - the shotgun. Included are types of shotgun from everyman's dream gun, the sidelock ejector, to the everyman gun, the humble economy single barrel. It covers the work a gunsmith actually encounters, much of this information has never previously been published and may help the reader appreciate the complexity and great range of skills and knowledge a gunsmith needs, something unique in the 21st century. Topics covered include: guns and gunsmithing; tooling & equipment; stripping & servicing and examination for faults; minor and advanced barrel work; rejointing barrels to actions and lockwork; minor and major stock repairs; blacking, bluing, browning and engraving, and finally gun proof and the Law.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 511

Veröffentlichungsjahr: 2013

Ähnliche

The Art of Gunsmithing –

The Shotgun

Lewis Potter

Copyright

First published in 2006 by The Crowood Press Ltd, Ramsbury, Marlborough, Wiltshire, SN8 2HR

www.crowood.com

This e-book edition first published in 2013

© Lewis Potter 2006

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

ISBN 978 1 84797 541 6

Dedication This book is dedicated to my friend and mentor, G.L. (Geoff) Hart, Gunmaker.

Disclaimer The author and the publisher do not accept responsibility in any manner whatsoever for any error or omission, nor any loss, damage, injury, or adverse outcome, or liability of any kind incurred as a result of the use of the information contained in this book, or reliance upon it.

Frontispiece: Checking by sight that wired-on ribs are true

Except where stated otherwise, all illustrations in this book are by the author.

Contents

Acknowledgements

I thank The Crowood Press for their help. I can happily blame my friend, George Wallace, retired firearms officer of the BASC, for volunteering me for this project – I know he was, as ever, only doing his best to help another member of the shooting community.

I thank Chris Price, proprietor of Helston Gunsmiths and Master of the Worshipful Company of Gunmakers, for his enthusiasm in volunteering to proof-read most of the book and his helpful advice and comments; Ken Halbert, foreman at Westley Richards, for his help with historical detail; and Peter Spode for his contribution and guidance about engraving. I wish also to thank the following who have helped or assisted in any way, often at short notice: the Proof Master and staff of the Birmingham Proof House; Graham N Greener (W W Greener Sporting Guns Ltd); Mark Crudgington (Crudgington Gunmakers) and Peter Thomson; Pete Green for his computer advice; Pierre Shone for assistance with photography; Nigel Teague (Teague Precision Chokes); Tony White (T R White & Co, Gunmakers); Graham Walker and Lawrence and Yvonne Langridge who always enthusiastically support my various projects. In fact, my appreciation goes to all who have shown their kindness by supporting this project, particularly those who let me photograph their guns for inclusion in this book.

It is not even all my own work. My wife, Sue, using considerable ability and determination, managed as always to turn my handwritten scribble into legible print. My daughter, Lucie Ellen, a student of the English language, exercised her skills by correcting the grammar. When required,my sons, Matt and Dan, proved good male models and Jamie helped whenever he could. Truly a family effort.

Foreword

The gun trade in the United Kingdom is quite rightly regarded as one that boasts some of the best gunmakers in the world, not just from the gunmaking centres of London and Birmingham, but also from the provinces. Less famous are the ‘best gunsmiths’, who look after the shooting sportsman and woman with gun repairs, alterations and refurbishment.

Many gunsmiths, whether self-taught or drawing on experience gained during time served under a skilled gunsmith or gunmaker, like to preserve the mystery of the art of the gunsmith by protecting their secrets. Fortunately, Lewis Potter, a true craftsman and accomplished gunsmith, is not so selfish. His book, The Art of Gunsmithing, is long overdue. Each chapter specializes in an area covered by most competent gunsmiths, describing the problems encountered and some of the tricks of the trade used to effect a satisfactory repair. Two things strike me more than anything else with the content of this book: first, the way it is written makes for compulsive reading; second, and more importantly, it clearly reflects the author’s commitment to quality. Lewis is not prepared to send out a poor-quality job, and does not mince his words when he encounters the work of the ‘bodger’.

Those of us who have spent a lifetime in the gun trade enjoy the company of fellow craftsmen -- there is so much to talk about, including our little ways of doing things, and so much helpful advice to be shared. The family spirit and camaraderie can be time-consuming and I have often spent up to a couple of hours talking gun repairs; I know Lewis has too!

Lewis is a modest man who loves his work, but he is also a master in his profession, and his book is a must for all readers interested in the true art of gunsmithing. For the old gunsmith it will inspire a thousand memories; for the new gunsmith it will provide a good push in the right direction. I am sure that everyone who reads this book will be looking out for the next volume; I do hope we get one, as Lewis has so much more to tell us.

Chris Price, Master, The Worshipful Company of Gunmakers, 2005

Preface

It gives great pleasure to be asked to write a book as, apart from a fortunate few, many talented would-be authors spend what must seem like a lifetime trying to convince agents or publishers of their literary worth. Yet at first I hesitated, for the gunsmith’s trade is one of the last in which, to a certain extent, the principles of the craft societies of old hold sway. It is a world in which, at one time (like so many crafts), a man was sworn not to divulge his master’s secrets; knowledge was power and could place you above other men.

This, of course, has its down side. Men of amazing skills whom I have known, and have even been fortunate enough to count as friends, have gone to their grave with more accumulated knowledge than many of us could hope to acquire in two lifetimes. They took their secrets with them and I know I would have been richer for a share of their wisdom. Even when a man does try and pass on his knowledge it is not possible either to give or absorb everything so, inevitably, with each passing generation we lose a little more.

I put my thoughts to some other members of the gun trade whose knowledge and skills I admired, and was pleasantly surprised to receive their unhesitating support for this project. The general view was that, in these times when gunsmiths often find themselves in a declining trade with, seemingly, the hand of Government against them, shared knowledge is a valuable support. Such a book might also help foster a broader interest, and this is important because the present insularity held so dear by some in the trade will surely only hasten our decline.

Added to these considerations was the thought that, given the rate of change away from practical skills, some information should be recorded before it is lost. Consequently, some historically significant techniques that are now little used have been dealt with so that not only the principles but the actual working methods have been detailed.

If this all sounds rather grand that is not the intention. What is recorded within these pages is my own working experiences – the work of a country gunsmith whose customer base varies from the Range Rover-driving Purdey owner to old Fred with his bucolic wit, bicycle and worn Stevens single.

L.A.S.P.

CHAPTER 1

Guns and Gunsmithing

Introduction

Gunsmithing as an occupation is probably unique. Its existence, whether described as ‘Hainaulter’, ‘armourer’, ‘smith’ or ‘gunsmith’, depending upon what part of history you examine, stretches right back in time to the earliest hand cannon of the fourteenth century. It has continued through periods of great technical change, from the matchlock to the wheel lock, the flint and percussion eras, and the overlapping use of all these types of firearms. The quantum leap in the nineteenth century was to the breech loader, which as a sporting shotgun was already perfected by the start of the twentieth century and has changed very little since. It is interesting to consider, when examining the latest creation from a maker of note, that when the first firearms were in use the longbow was at its peak and armoured knights rode to battle on horseback.

Today there are spy satellites and fearsome nuclear weapons, and some six centuries of progress have slipped by into history. Yet the sporting guns we use today still embody the same basic principles as those primitive hand cannon that first coughed their smoky challenge on some medieval battlefield. Fortunately, shooting as a sport attracts enthusiasts who strive to keep this history alive. Reenactment groups firing matchlock and cannon provide a wonderful spectacle of family entertainment. Sportsmen and women still use flintlock and percussion muzzle loaders for competition. On a small English game shoot it is still possible to meet the black-powder breech-loading aficionado and other shooters of quite delightful, almost Edwardian eccentricity. Clay pigeon shoots vary from fun farmers’ knockabout shoots, where socializing is more important than the score, to fiercely competitive prize events.

The gunsmith may be called upon to work on firearms from anywhere across this broad spectrum of our heritage. However, for the local gunsmith the bulk of work is on breech-loading side-by-sides and imported over-and-unders, the latter of which can receive some seriously hard work on the clay pigeon circuits.

The Gun Trade

Nowadays we tend to use the word ‘gunsmith’ to describe a repairer of guns as distinct from a gunmaker (a manufacturer), although in reality it is not that clearly defined. A gunsmith who has the requisite skills, or access to carefully selected subcontractors, may well build the occasional gun and as such, if he wishes, he may be entitled to advertise as a gunmaker. Many small gunmakers actually only do the part of the job at which they are particularly accomplished, and subcontract the other work or manufacture of parts. This makes good sense; it would be foolish for, say, a good stocker who also had other general gunsmithing skills suddenly to decide to make his own barrels without any experience. This, after all, was always the basis of the gun trade: the specialist skills available were used. Only the few larger companies might employ a variety of craftsmen to enable them to manufacture completely in-house, but at times of peak production even they would have to subcontract work to keep up with demand.

From the outside it would seem logical to assume that a gunmaker would carry out repair work or gunsmithing as well as new builds, and this is usually true. Most gunmakers have a workshop and carry out a variety of work, even if they choose to subcontract some of the new gun work to other specialists. As long as the work is to their standard of quality, specification and design, there is nothing wrong with this as it is the way of the manufacturing world at large; the integrity of the final product is their responsibility.

There are, and always have been, the individuals who promote themselves as gunmakers but have no facilities, hands-on skills or real technical knowledge or involvement. In short, they subcontract the complete manufacturing process to others, sometimes abroad, and often their only contribution is the name. Similarly, a retail shop that has the word ‘gunsmith’ following its trading name may carry out some or all of the repair work or, again, subcontract it in its entirety. However torturous the route, the job usually finishes up in the hands of a gunsmith at the workshop bench. So, for the purposes of this book, we will accept the generally held view that the gunsmith is a repairer of guns capable of carrying out a broad range of repairs to lock, stock and barrel.

What does it take for someone to be a gunsmith? It is almost an article of faith in the traditional gun trade that an engineer, for instance, will never make a good gunsmith, and that a cabinetmaker will never be a stocker of any consequence (although I know of two who produce particularly fine work). There is some truth in such statements, but it is never possible to generalize and all too often such comments are simply a form of protectionism. So much depends upon the skills, knowledge and adaptability of the individual. While it is true that nothing illustrates the different approach better than the engineer reaching for his micrometer while the gunsmith uses the smoker for blacking down, really the two functions are complementary, and now quite formal engineering practices have come to the aid of the gun trade.

Much fuss is made about ‘hand-built’ guns; in fact, they are really hand-finished guns, the bulk of material being removed by machine. Cutting a large piece of metal away with a hammer and cold chisel is just hard work and has no bearing on the finished product. Many years ago the firm George Gibbs of Bristol used semi-skilled workers for this function, providing hardened filing jigs to work to. Advancing a stage further to the manually operated milling machine, it is then not much of a step, apart from the cost, to the computer numerically controlled milling machine – in other words a computer-operated machine. Parts can be produced that only require hand fitting and finishing, and this is where the skill lies. The finest example of this is the stock work, most of which is still done by hand to produce that look suggesting that the metal grew out of the wood. There is a lot of satisfaction lining out a stock blank and forming it into a delicate thing of beauty, but, realistically, cutting away large amounts of surplus wood by hand is a waste of time. No one suggests a stocker should really do without a bandsaw, neither was there criticism when Webley & Scott used a stock copying machine for the basic shaping of their shotgun stocks.

From the gunsmith’s point of view it means, with some makers, that accurate, standardized spare parts are available thanks to good engineering practices. However, what is admirable about the gunsmiths and gunmakers of old is that they produced exquisite pieces of work, often with the crudest of tools and almost entirely ‘hand’ technology. In spite of technological progress, many of these traditional skills are still required today. For most aspiring gunsmiths here lies the heart of the problem – how would the experienced gunsmith do the job? For me it was a long road. I repaired my first gun at the age of thirteen, a rather awful Chassepot bolt action twelve-bore. My next was a double twelve by Fletcher of Gloucester that required stock repairs to make it usable. In between time I amused myself by making miniature cannon which, with the carelessness of youth, I fired from my bedroom window sill into the chicken run down the garden. I never hit one of the fowl, who eventually got so used to this ‘gunnery practice’ that they took little notice. I remember, in my search for more performance, trying smokeless powder; I never did find all the parts of that particular cannon.

I hung around gun shops and gunsmiths to glean information and borrowed books from the library that have now become collector’s items. I hoarded knowledge like a miser and eventually learnt, mainly by trial and error, to carry out simple repairs such as spring making, barrel dent raising, making strikers and recutting chequering. Years later I went to work with a gunmaker whose first advice was to tell me to forget what I thought I knew already because he would show me how to do the job properly.

I learnt that a gunsmith needs a variety of well-practised skills, an eye for the smallest detail as well as an appreciation of line and form and the ability to think in three dimensions. Then there was that indefinable feel for the job that is more artist than artisan. Most important was the knowledge, the know-how – the gunsmith’s way. Although now very much a blend of ancient and modern, gunsmithing is still steeped in the practices and techniques of the past; real living history.

Variations on a Theme

In the simplest terms a shotgun is a smooth-bored firearm used for discharging multiple shot, which may also be used for firing a single projectile such as ball or rifled slug. The archetypal shotgun that most members of the general public will recognize is the double-barrelled gun with the barrels laid side by side – the most simple form of repeater. As a boy I rarely heard anyone refer to a ‘side-by-side’; it was simply a double- as distinct from a single-barrel gun. It was only the rise in popularity of the gun with superimposed barrels, the over-and-under (or, as an old customer of mine insists, the ‘up-and-under’), that led to the need for differentiation. Interestingly the over-and-under pre-dated the side-by-side, usually in the form of the turnover gun, on which one lock served each barrel as it was rotated to the top position. The side-by-side was king in the nineteenth century and for most of the twentieth century, but now the over-and-under has overtaken it in popularity.

The single-barrel guns vary, from the simplest single-shot to more technically advanced designs such as the pump-action and semi-automatic magazine guns. The latter are sometimes erroneously described as automatic or auto, which they are not, as this would imply multiple shots from one squeeze of the trigger. If the semi-auto had been developed in the UK it would undoubtedly be described as a self-loading shotgun.

Combination guns that have both shot and rifled barrels are typified by the Austrian or German drillings. Most common are two shotgun barrels with a rifle barrel laid underneath. There are variations, including one shot, one rifle barrel in over-and-under format and, far more rare, over-and-under shot barrels with a rifle barrel laid alongside. Cape rifles, a type of firearm very much associated with the days of the British Empire, are side-by-sides with one shot barrel and the other (usually the left but not always) rifled. Another gun from this period is the paradox gun, a smooth bored gun with heavy, ratchet-like rifling in the last few inches of barrel. Of great rarity are multi-barrelled shotguns with three or even four barrels, which qualify as the ultimate collector’s item.

There is a distinct limit to the number of ways barrels can be assembled, but not so with actions, which are many and varied. In that great era of invention, the nineteenth century, gunmakers strove to come up with something new, better or perhaps just different to get around someone else’s patent.

Of the single-barrel guns, the most common are the break-open type with the barrels hinged to the action, typically the Harrington and Richards, Cooey and Astra Cyclops; despite their different countries of origin, these are nearly identical guns. A poor second are bolt-action guns; undoubtedly the most popular of these in the UK is the Webley and Scott .410, which is so often a youngster’s first gun. The Marlin goose gun in twelve-bore three-inch magnum with box magazine is one of the longest-produced larger guns of this type. Both of these later designs are well advanced from the early Chassepot bolt-action black-powder guns, whose least endearing features were an awkward cock-on-opening bolt, misfires and poor extraction.

One of the rarest: believed to be one of only seven sixteen-bore four-barrelled Lancaster shotguns produced, and a particularly early example, dating from 1883.

Top: the unmistakable profile of a Martini action, in this case a twenty-bore converted rifle.

Bottom: one of the larger bolt actions, an American Mossberg.

A more elegant solution is the Snider action, which involves a hinged breech block swinging out and being drawn backwards for extraction. Once reasonably popular for large-bore wildfowling guns, this design originated as a simple breech-loading conversion for military muzzle loaders and has those desirable features of strength and simplicity.

Another single-barrel shotgun with military links is the Martini, originally Martini-Henry’s – ‘Henry’ referring to the original form of rifling used. When converted to a shotgun, the Henry part of the original designation is not applicable so it becomes a Martini action. At one period it was quite common to convert ex-military Martini rifles to both .410 and twenty-bore; the latter, due to the constraints of the military action, was the largest cartridge to be chambered and that was at only two-and-a-half-inch (65mm) length. When Greener enthusiastically took up the design and made a commercial twelve-bore version, the well-regarded GP (general-purpose), later manufactured by Webley and Scott, was capable of taking a variety of cartridge lengths.

A fascinating array of single-barrel breech designs may be found on small Belgian ‘Flobert’ guns. Many of these, although smooth bore, were actually made to fire a single ball in a very short rimmed case. Although of very low power – the .22 version is particularly anaemic, and less useful than many air rifles – the 9mm shotgun version is quite handy for ratting around the chicken run. These guns, in part due to the materials used but mainly because of the designs, are not suitable for conversion to centre fire. Also, due to the changes in British law in 1968, many fall below the minimum length of barrel to qualify as a shotgun in the UK, even though they are smooth bore.

The great majority of double-barrel guns, whether side-by-side or over-and-under, are of the hinged, break-open type. They are held shut with some form of locking device (of which more later), which, when released, allows the barrels to hinge open for loading or unloading. It is a type of action that has found universal appeal, used not only for shotguns but also the best double rifles. In the UK, breech-loading development as we know it, using a type of self-contained centre fire cartridge, dates from the 1850s. Prior to that there was the Lefaucheux pin fire and the Pauly of 1812. Rather typically, it seems, British gunmakers were tardy at first to develop these European advances. Once they got into their stride, however, they had, within forty years, perfected a style and design that became the world standard. There were blind alleys and strange variants, but a century that started with muzzle loaders finished with the perfected boxlock and sidelock breech-loading ejector gun that is still produced today.

It is, however, an immutable fact of life that someone will always try to find an improvement, so there are other double guns with different methods of breech closure. One of the best known, not so much for its availability but more for its curiosity, is the French Darne with fixed barrels and sliding breech. Even the idea of a kind of side-by-side Martini, which originally surfaced as a Money-Walker, has in more recent years been proposed again, although it has not been produced. Possibly the most prolific seeker of something different was P.V. Kavanagh, who seemed to revel in what might be described as the unusual alternative. As late as the 1970s this small company produced double-barrelled guns in which the barrels turned through ninety degrees and pushed forward to open, and a few on which the side of the breech hinged open, which became known as the ‘book opener’. Its main production model had superimposed barrels that moved forwards on a tapered slide to open. At one stage Webley and Scott was in negotiation with Patrick Kavanagh with a view to adding it to its range – they did not, at the time, have an over-and-under – but negotiations failed and the gun continued to be marketed by Kavanagh as ‘The Fenian’.

At one time a great many rifles were converted to smooth bore, either to qualify as the less legally restricted shotgun or because suitable rifle ammunition was no longer in production. The former relates mainly to twentieth-century military firearms such as the Lee Enfield and the latter to a lot of pretty little rook and rabbit rifles, spoilt by conversion to .410. Fortunately, as the interest in vintage firearms has grown so has the availability, if not of loaded ammunition, then at least of cartridge cases, so it is now a popular move to reconvert them by sleeving with full-length rifled tubes. It was not just small rifles in break-open falling block, tipping block and any other types that were subject to this form of vandalism. Bigger rifles could be opened out for larger shot cartridges and elegant falling blocks such as the Field action adopted by Holland and Holland were targeted for conversion.

Locking the Gun Shut

The hinged break-open action is now, along with the top lever means of opening, the industry standard. The top lever is connected to a spindle (with some guns integral with the lever), which, when pivoted to one side, draws back a locking bolt in the manner of Scott’s patent of 1865; the double-locking underbolt being a Purdey patent of 1863. It was not always thus and there are some interesting variants. The firm of William Powell & Son used, at one time, a well-regarded and now much sought-after lift-up lever with only a single locking engagement known as a single bite. The Westley Richards patent top lever, which is still produced, pivots on one side and draws back a top locking bolt that engages with a barrel extension. With early guns this was the sole and remarkably effective method of locking. Later guns are triple bite, incorporating also the Purdey-type double underbolt.

The 1970s rather different Kavanagh ‘Fenian’ action, the gun that nearly became a Webley & Scott. A striking example, fitted with Tungam barrels, a form of hydraulic tubing that is bronze in colour.

Powell lift-up top lever on a pretty little twenty-bore, a design dating from 1864.

These side-lever action Belgian-made .410 folding shotguns were once very common and a favourite with poachers.

Push-down sidelevers are mainly found on economy .410s of Belgian origin with a simple locking method, but much more sophisticated versions may be found on double guns. Even in the cheaper forms it still produces unfailingly elegant lines, as well as a practical and handy method of opening. The underlever also had its day; one of the important historical milestones being the Murcott hammerless gun of 1871, which had an underlever wrapped around the trigger guard that also cocked the locks. Others include the Purdey underlever snap action at the front of the trigger guard, but the great long-lived design was the notably sturdy Jones underlever.

Henry Jones patented his important underlever design in 1859, and, although it was harder to make than some rival designs, it became deservedly popular due to its robust simplicity in operation and great strength. It survived on large-bore shotguns and big-game rifles for years after the top lever became popular on game guns. The Jones lever pivots out to one side and operates a double screw bite, which not only locks in place, but pulls the barrels down on to the action. It was used on a wide range of guns, from some of the cheapest to many of the most expensive models, the only criticism being that it was slow to operate, especially if mated to a gun with double-cocking hammers. Occasionally the Jones underlever may be found in a later modified form with a sprung underlever that snaps shut just as the action is closing.

The main component parts of Henry Jones’ double-screw grip underlever, originally dating from 1859. This particular example is built into a Wilkinson patent Joseph Lang action.

Technically interesting Pountney double-bite latch-bolt action of 1878: easy to use but developed too late.

There were other means of holding a break-open gun closed that were practical and handy, if short-lived. The latch bolt fits crossways through the bar of the action and is pushed laterally, moving the bolt against a spring and releasing the barrels. Joseph Lang was one company that made use of this system but one of the best, although rather late on the scene, was the double-bite Pountney of 1878. Although it was doomed to obscurity, I know from practical experience with possibly the only example made that it was delightfully quick and easy to use. The great weakness is due to the large slot through the action. It would be ill suited to a hammerless gun and possibly somewhat weak for nitro proof.

Most over-and-unders stick to the well-tried principle of the top lever/spindle underbolt system, which, due to the constraints of the action, operate only a single locking bite, albeit across a very wide area. A notable exception is the Beretta, on which the top lever engages directly with the bolt, which locates halfway up the superimposed barrels. Less well known is the top lock system, where a kind of hood engages on lugs on either side of the top barrel; this was a system much favoured by Valmet and also used by others such as Miroku and Remington.

Valmet top-lock over-and-under, a type once imported to the UK by BSA guns.

One thing is certain: if you dream up an idea for ‘the perfect gun’, it has probably been done before. The great thing is that from time to time those oddballs that occasionally surface keep the mind lively and in good working order. After a week or two of broken firing pins in cheap over-and-unders, worn-out unreliable ejectors and a run of barrel dent raising, I find myself ready for an interesting challenge, something the like of which I may never have seen before.

Relative Values

Ultimately the value of anything is what someone will pay for it, and sometimes logic does not enter the equation. The general consensus is that a sidelock is worth more than a boxlock, a trigger plate action lies somewhere in between and, in the very conservative world of shooting, oddball designs are for collectors. On the same theme, a famous-name gun should be worth more than a less well-known name, and expensive top-grade guns may be ‘previously owned’ while factory-produced items are simply ‘second-hand’; it means exactly the same thing, but there is a social distinction. There are also some enthusiasts whose interest is confined to one maker and who may value its products above all others. Everything is relative to what someone will pay, and any attempt to link values can only be a guide, even for items all in similar sound and tidy condition.

What is rarely considered – because it does not necessarily have a direct monetary link – is the worth of a gun to an individual. A shotgun is, after all, in its most basic definition, a mechanical device for projecting lead shot at a (usually) moving target. If a gun, whatever its origins, fits an individual so well that it has become an unconscious extension of the body, effortless in use and gives a satisfactory high standard of success, it should be worth a lot whatever its market value. Alas, how many shooters have traded in their ‘old faithful’ for a better make or type of gun only to find that their standard of shooting, and therefore their enjoyment, plummets. It may feel good to be on a shoot with a fine gun bearing a well-known or perhaps even famous name, but if that gun was originally made for someone with quite different physical characteristics it will be more of a burden than a help. It will also bring a certain piquancy to the embarrassment of having the best gun and perhaps being the worst shot on the day. The lesson here is that there is nothing wrong with having a better-quality gun, indeed, there may be a lot of advantages, but it is more important to find a gun that fits, or to have it altered to fit properly, to gain any real benefit.

In monetary terms, it is best to forget that old imported single worn to a silver sheen as it is quite worthless (although it may be still capable in the right hands of dropping a pigeon or tumbling a rabbit dodging through the brambles). Even an immaculate Cooey single is almost unsaleable, and the aluminium-alloy-actioned BSA Snipe is something most shooters avoid. As for the single marketed as the Argyle, it was a brave try but surely a triumph of doubtful theory over good practice.

At one time most shooters in the UK had a single-barrelled gun tucked away either as a knockabout or hedgerow gun, perhaps a first gun kept for sentimental value. With the 1988 Act bringing in mandatory shotgun registration and the imposition of security devices, room in the gun cabinet was at a premium and many singles were scrapped or handed in during the Government ‘amnesty’ of the period. (Incidentally, most of the guns handed in were legally owned under the previous system of shotgun certification. Unsurprisingly, criminals proved themselves disinclined to hand in their illegally held weapons.)

The consequences of approved security requirements, even at a time when theft of shotguns was at an all-time low, very much depressed the bottom end of the market, and single-barrelled guns became virtually worthless. There are exceptions, including the Greener GP and the slim and stylish hammer guns of the late 1800s, but the only real value in a single is a big bore; this is an area where size really does matter – the bigger the better. There is something romantic about these big wildfowling guns, which recall mist-shrouded mornings and the call of wild geese. Sadly, the reality is that, with the ban on using lead shot over wetlands, most of these magnificent old fowling pieces no longer boom out across the salt marsh. In any case, in recent years it was never the real market – that belonged to collectors.

Regarding side-by-side doubles, the most affordable end of the market (ignoring hammer guns for the moment) was always the boxlock non-ejector but nowadays most game shooters prefer an ejector gun even if they do not need one for their particular sport. Best boxlocks were invariably ejector guns, although non-ejectors can be found built on ‘best’ actions, probably as special orders. Ejectors will often increase the value of a boxlock by as much as fifty per cent, and that is why it is still occasionally profitable to convert a good quality non-ejector gun to an ejector.

Side plates are fitted to add the style and elegance of a sidelock without the complication. They are no more than dummy lock plates and to some possible purchasers an affectation; there is also no doubt that, as some of the work is so neat, a number of guns have been purchased in the mistaken belief that they are real sidelocks. Done properly, side plates can transform the appearance of a deep, boxy action, especially an over-and-under, and give further scope for decoration. However, that is their only purpose and they are very much a matter of individual taste.

The same applies to chequering within a carved side panel behind the action of a boxlock. A plain panel with a carved drop point is probably the most desirable of this form of decoration. Next is the plain panel with oval form, and following on from that the panel that goes to a point, while the chequered panel (which serves no practical purpose) is, to many potential owners, possibly one of the less desirable forms of decoration.

Side plates on an over-and-under.

Fairly typical German-made drilling. A double-barrel sixteen-bore with 8 × 57 JRS (8mm rifle barrel) underneath, an example of a trigger-plate action.

Sideclips – projections on either side of the breech that engage against the barrels – have been fashionable in the past and seemed more favoured on the continent, but tend to slightly depress the value of a gun. This partly because they are not necessary and spoil the lines, but mainly because they are a little unusual, and the market for good guns was always rather conservative.

Trigger-plate actioned guns are not common but are usually of good quality; one of the best known of this type is the Dickson Round Action gun, noted for its especially fine handling characteristics. In real terms this kind of gun runs second to the proper sidelock in the valuation stakes. As for those trigger-plate actioned drillings, because they have a rifle barrel they are, of course, a firearm and this always reduces the value in the UK because of the extra restrictions on ownership of rifled firearms.

A sidelock non-ejector is normally an economy, bottom-of-the-market gun with simple locks, but this is not always the case. In the past, not everyone wanted ejectors on a bespoke gun and early sidelocks often did not have ejectors. As a result, famous-name guns can very occasionally be found in sidelock non-ejector form. They do lag in value behind ejector guns because ‘best’ guns are expected by most shooters to have ejectors. Over the years a number of the later versions of these guns have been retro-fitted with ejector mechanisms, usually of the Southgate type. As for the basic, simple Baker-type sidelock, a plain non-ejector version fetches about the same as, or a little more than, a comparable boxlock. Ejector versions fare much better and, with some reasonable engraving, fetch more than the average English boxlock ejector gun, but considerably less than a famous-name boxlock.

The sidelock ejector gun is the one to which most shooters aspire, so naturally it carries the most value, although there is a broad spectrum of prices within the type. Exquisite workmanship goes into these fine guns. As already mentioned, conservatism is everything and a bar-lock sidelock ejector gun is king of the shooting field. Single triggers and easy-opening devices attract extra value but the increased complication is not to everyone’s liking. Back-action sidelocks, which many shooters regard as being visually less elegant, do not normally fetch the same money as a bar-lock gun. Unusual designs, such as the Lancaster Easy Opener, more often known as the ‘wrist breaker’, can sometimes be obtained for little more than the cost of a good boxlock ejector; this makes them something of a bargain, albeit they are an acquired taste.

As a young boy, the only over-and-under gun I had seen was a fine Edwinson Green sidelock made in 1912 (reputedly this design was the basis of Purdey’s first over-and-under). Not only was this gun regarded as unusual and particularly beautiful, it would also now be towards the top end of price range, although still fetching much less than those produced by better-known names. It is also true to say that, even in this rarefied atmosphere, at the best end of the market over-and-unders fetch less than a side-by-side of the same quality.

The mass market for over-and-unders is dominated by the Browning B25, or what the Americans call the Browning Liege shotgun. The original John Moses Browning design, made in Belgium, combining the aspects of a practical, if slightly heavy gun with the flavour of old-world tradition, this has achieved something of a cult following. Indeed, it is not uncommon to find a lower-grade gun (this really means a plainer gun, as they are all essentially the same workings) upgraded with better wood and engraving.

The simple internals of what is commonly known as a Baker lock. Compare this with the ‘true’ sidelock (see Chapter 8).

Miroku and Beretta vie very much for the same share of the market and the shooter’s choice can come down simply to styling preferences. Dedicated competition guns, although initially some of the more expensive, are a little less saleable than all-round sporter-cum-game guns, and with a single trigger most users prefer a pistol grip to either a swan neck or a straight hand stock (which is rare with an over-and-under).

The interest in good-quality hammer guns has seen a revival in recent years, although many seem to be destined for export to the USA. Their chances of survival there are probably better than in the UK, considering recent events. As with single-barrelled guns, many hammer guns in the UK were handed in during ‘amnesties’ for scrapping off, some without even being valued. Some very fine guns, including antiques that did not need to be given up, were lost in this way. As a result, the survivors have seen a rise in interest, and, therefore, in value, but it is still very much a collector/shooter market.

Again, as with single-barrelled guns, the bore or gauge of a hammer gun has a considerable impact upon its value. The benchmark is the ubiquitous twelve-bore; the fairly rare short two-inch chambering is not the most popular because, although ammunition is available, it can be difficult to find a stockist. The twenty-bore has been very much in favour for the last twenty-five years or so and fetches a better price than a twelve-bore of similar quality. (However, for someone who cannot shoot with a twelve-bore, changing to a twenty-bore will be no help at all.) The sixteen-bore is the neglected Cinderella and yet it is a fine cartridge for game shooting, especially as many twelve-bore users now favour one ounce (28g) loads; the fifteen sixteenths of an ounce (26.5g) of the sixteen-bore is no real disadvantage. The advantages are a gun that is like a lightweight twelve-bore but with a bit more substance than a twenty-bore, an aid to most shooters, and at a cost that is lower than either of the others. Given time, interest in the sixteen-bore will increase and values should rise. For anyone wanting a good-quality gun at a reasonable price, now is probably a good time to buy a sixteen-bore.

The Americans have done much in rediscovering the twenty-eight-bore and promoting interest in this super little cartridge, possibly saving it from extinction. Traditionally, youngsters were introduced to shooting via the use of a .410, but a twenty-eight-bore would always have been a better choice had they been more readily available. Now, having risen from obscurity, a quality twenty-eight-bore can fetch serious money, even more on occasions than a twenty-bore.

The .410 is available in two-inch (50mm) fourten, two-and-a-half-inch (65mm) fourlong and three-inch (76mm) extra long or ‘three-inch magnum’ chambering. The bulk of .410s were cheap, starter guns; a great many for the two-inch cartridge, which is not as popular as the two-and-a-half-inch. Really good-quality guns are rare and expensive but it is something of an unpredictable market. Many .410s, perhaps because they were youngsters’ guns, were neglected, so even at the more modest end of the market you have to be lucky to find a good one. Although a .410 is still one of the least expensive shotguns, unfortunately the cost of ammunition is high compared with twelve-and even twenty-bore. Consequently, many shooters regard this as being poor value for money.

Upwards from the twelve-bore is the ten-bore, again, like the sixteen-bore, an overlooked size without the cachet of its larger-bore brethren. The problem with the ten-bore is that, in most shooters’ minds, it is not sufficiently bigger than the twelve-bore to make a worthwhile difference. It is true that the standard two-and-five-eighths-inch (67mm) chambered ten-bore was outclassed years ago by plenty of ‘hot’ two-and-three-quarter inch (70mm) twelve-bore cartridges, and compared with the three-inch (75mm) magnum, it is positively anaemic. Even the two-and-seven-eighths-inch (73mm) gun struggled. More recently, however, loads have been developed that bring it nearer the bottom loadings of the eight-bore. It is a pity it is not more popular, as a ‘double-ten’ is a gun of satisfying substance, an amiable light heavyweight that is easier to carry on a long walk down to the marsh than anything bigger. While not the most desirable in collector terms, when appearing in over-and-under form mated to a well-known name, that is entirely a different matter.

This leaves the eight- and four-bore guns. Of the two, the four-bore is the most desirable size but the eight is possibly the most used. The four-bore’s attraction is that it represents the ultimate, although there were two bores that served as both shoulder and punt guns; fairly modern breech-loading punt guns have also been manufactured in two-bore. Of the shoulder guns, allowing for quality, they fetch more than any other size and new double-fours are once again occasionally being made.

Muzzle loaders represent a specialist field and a great explosion of interest in the UK started about thirty-five years ago. Prior to that, muzzle-loading shotguns were a bargain, being much less desirable to collectors than pistols or rifles. For example, in the 1960s one of our local gunsmiths, who had a fondness for old guns, would restore muzzle loaders to shooting order. Singles started at £18/£20, doubles from £25. Now it is becoming increasingly difficult to find a decent gun and quite what has happened to them all is something of a mystery.

Fine flintlocks in good order are very hard to find and command some of the best prices, while drum and nipple conversions to percussion are looked down on as less interesting than a gun originally made with a percussion lock. Needless to say, drum and nipple conversions have been converted back to flint. Double guns, as always, fetch more than singles of comparable quality and, as with breech loaders, big singles are worth more than smaller bores and, as ever, well-known or recognized names count for a lot.

Customers often believe that the gunsmith has a personal collection of fine guns stashed away, but I am served well by a very good-quality breech-loading black-powder hammer double and a four-bore muzzle-loading single. If I were to add to those it would be a double ‘flinter’, preferably with inset locks. After all, some of us know in our heart of hearts that smokeless powder, hammerless ejector guns are really only a passing fancy!

The Gunsmith’s Language

The first step on the road to understanding something of the world of the gunsmith is an appreciation of the names of gun parts used within the gun trade. At first, to the outsider it is a strange world where screws become pins, and occasionally nails; barrels have lumps; actions are made with fences; and hammers may have ears. The catch under the barrel that locates the forend is a loop, even if it never looks anything like one; on early guns at least the loop is a rectangular slot and the forend held by a crossbolt, which, of course, is nothing like a bolt that you might fit with a nut!

It is pleasing to think that, while they have probably changed subtly, these historic descriptive terms are still in use after many years. Nothing, though, seems to be carved in stone; there are certainly regional differences and, as this is something of an informal language, there may have been differences from one large gunmaker to another, or even between individuals. To confuse things still further, modern factory-made guns use different descriptions, so, for example, while a boxlock over-and-under exploded drawing will show it to be equipped with ‘firing pins’, the same components on a traditional side-by-side are ‘strikers’. Similarly, where a side-by-side ejector mechanism uses ‘kickers’, in an over-and-under these are more often ‘hammers’. Still, at least this ancient language lives on in regular, if limited, use.

The Traditional Hinged, Break-Open Gun

Whether single, double, boxlock, sidelock or trigger-plate action, most of the same parts have the same or similar names. However, I have taken one small liberty in this book as an aid to clarity. Screws are usually referred to as pins but they vary in type, so I have described those having a full length of thread as screw pins, the type that have a parallel section and a threaded end as pins, and plain pins without head or thread as dowel pins. The location of these pins is also reflected in the description, as in hand pin or bridle pin. Those wood thread types (actually a tapered Whitworth thread) holding the tang to the stock are usually described as tang screws, a term that I have chosen to retain, although some in the trade would refer to these as pins.

Types of gun pin, below from left: pin, screw pin, tang screw; below: plain or dowel pin and roll pin as found on some modern guns.

The main parts of an English Anson & Deeley boxlock action.

The Basic Action

The basic action is an L-shaped forging or casting consisting of the bar, which is the forward projection where the barrels fit, and the standing breech, against which the barrels close. At the rear of this is an extension in the form of the top strap. At the front of the bar is the knuckle, which fits into the mating part on the forend. In the middle of the knuckle is the cam (sometimes fitted in the forend), which pushes open the extractor, and behind that a cross pin fitted through the bar of the action as a hinge for the barrels. The two flat sections either side of the top of the action bar are, appropriately, the flats, against which the barrels sit. Between the flats, the front slot, bridge and rear slot are cut to accept the barrel lumps.

The area of the standing breech against which the barrels sit is the face, action face – at one time called the false breech – or breech face, drilled with striker holes and sometimes cut with vents (slots to allow gas escape in the event of a punctured or failed primer). The strikers are sometimes fitted behind discs screwed into the face of the breech, hence the description ‘disc set strikers’. At the base of the breech face where it rises up from the bar is the root or radius; early actions were square-cornered and this part was always the root.

At the top of the standing breech there may be a piece cut to match the end of the top rib, which may be referred to as the shield. Either side of this lie the fences, which nowadays are usually ball fences (like half a sphere) or cutaway fences (in a ‘D’ shape). Guns followed a slow process of evolution and breech-loading fences developed from the raised fence around the nipples on muzzle loaders to help protect the user from the detonation of the percussion cap. Many early breech-loading hammer guns display beautiful raised fences that rival those on any muzzle loader. On some more expensive guns, gas vents are in the form of hollow pins – vent pins – which may serve the additional purpose of locking in place the striker discs.

The top strap at the rear of the standing breech is sometimes referred to as the tang, but it is the top strap when there is not a safety incorporated, and only the reduced part of the top strap when fitted with a safety is a tang. The safety may be described as a safety button, a safety catch or simply a safety. There are also side-mounted safeties, usually of the Greener design.

In terms of the internal mechanism, a boxlock contains hammers that may have fixed noses or separate strikers. The cut-out where the sear engages is the bent, and that part of the sear that contacts the bent is the sear nose. The sear, like the hammer, has a pivot through which is fitted dowel pins, also variously described as action dowels, sear and hammer dowels, or plain action pins. The sear extends back into a leg with a peg set at right-angles, which is the point of contact for the trigger blade to lift when the finger piece or trigger is pulled.

Hammer gun with deep carved fences and nipple retaining strikers.

To cock the mechanism and compress the mainspring there are cocking dogs, sometimes called limbs, which project through the knuckle to engage into the mating knuckle of the forend iron. If it is an ejector gun, the cocking dog may be cut to incorporate a trip to operate the ejector sear. Alternatively, ejector trips in the form of rods or plates lying alongside the hammer may be fitted.

Boxlocks invariably have a bottom plate held on by a screw pin to cover the lockwork lying in the action slots. Back from that is the trigger plate, held in place with a front screw pin and, most often at the rear, a hand pin. Part of the trigger plate is the box, which connects with the action or breech pin and is the pivot point for the trigger blades.

The two common forms of safety mechanism are the push-up safe, used for economy purposes, and the rocker or dickie-bird safe, used on more expensive guns. With the latter the rod that connects the top lever with the safety button is the safety slide or range. This connects to the crank with a simple form of articulated joint that links it to the rocker, which in the ‘on’ position locks against the trigger blades.

With the simpler, push-up safe the range is a vertical bar that fits into the base of the safety button, formed at right-angles with a rod that operates the safety from the rear of the locking bolt.

The locking bolt, or simply bolt, slides in the bar of the action below the flats and between the action slots where the hammers, and so on, sit. It is connected to the spindle by an offset lug, the spindle running through to the top of the action behind and between the fences and connected by a square to the top lever. The top lever in turn is secured to the spindle with a top lever screw pin.

The vee mainspring is nothing complicated – the sears are spring-loaded by means of flat sear springs, the top lever by a top lever spring and the safety with a safety spring.

The Forend Iron

The forend iron is comprised of the knuckle and the end of the top face is the toe or nib. The long bar to which the forend is fixed is the stale or steel and, if an Anson & Deeley pushrod mechanism is fitted, the front of the stale is the tube or pipe. With the Anson & Deeley system, the forend knob that is depressed to remove a forend is part of the rod that locates on the bolt that locks the forend in place.

The Barrels

The barrels have two lumps (occasionally called steels) underneath, between the barrel flats. The front lump has the half-round cut-out of the hook and at the back there is a bite where the bolt engages, and a semi-circular profile known as the run up. The similar but concave face of the rear lump is the draw, or circle, and at the back of the lump is another bite. The ends of the barrels that sit against the face of the standing breech are known as the barrel faces or breech ends and between is the extractor, which may be one piece, as on a non-ejector gun, or split in two, as on an ejector gun. The cut-out that accommodates the extractor is the extractor bed and the leg of the extractor fits into the extractor hole. There are several ways of keeping the extractor in line: it may be connceted into a cut-out in a barrel extension or it may use a peg that fits into a second extractor hole. This may be a single peg (non-ejector) or separate pegs (ejector gun) or, in the case of the latter, a split peg formed as part of the extractor.

One of the two most common safety mechanisms on side-by-side shotguns: the economy push-up safety.

The more expensive ‘dickie bird’ system.

Barrel extensions that engage into the top of the standing breech are most commonly doll’s head (which appear shaped as a head and neck), Greener cross bolt, or as a third bite engaging under the top lever and sometimes hidden until the gun is opened.

The top rib may be concave, flat or Churchill type (raised and tapered). At the front of the rib is the foresight bead and at the rear where the barrels are held together it may be a laid-over rib, which is the full length of the barrels and a feature of best guns. Better ribs also have vee-shaped ends that fit between the barrels at the muzzle, sometimes referred to as nose ends. Cheaper ribs are finished by plugging the gap with solder. At the business end there are, of course, the muzzles, then underneath, the bottom rib, forend loop and keel rib, sometimes called the quarter rib. In the better designs, the keel rib is joined to the forend loop and is then almost always referred to as the keel plate.

The relevant parts of a hinged break-open barrel

W.H. Monks patent of 1881, which states how the breech and lumps are made in one piece and the barrels sleeved in from the rear of the breech piece. Monks recommended brazing or soldering in place or, as an alternative, shrinking the breech piece on to the barrels.

Barrels are made from either steel or Damascus steel (a mixture of iron and steel forge welded in the form of a helical strip). Steel barrels are finished blacked while Damascus steel is browned to bring out the contrasting patterns produced by the alternating bands of darker iron against the lighter-coloured steel. Sometimes the broad use of the word Damascus is improved upon to describe the individual type of pattern produced by this manufacturing process. Therefore we have single iron, two iron and three iron stub Damascus, as well as a variety of other names. The simpler and cheaper way of manufacture is scelp, which appears as a simple twisted pattern sometimes called Damascus twist. Single iron Damascus can appear as a rather broken pattern, which gives rise to the description ‘puddled’, which I do not believe to be correct.

With a double gun, barrels may be described as chopper lump. This indicates that the lumps are made in two halves as extensions of the barrel tubes and look rather like choppers, or small axes. Another method of double barrel assembly is to dovetail the lumps in between the barrel tubes; in both cases the breech assembly is brazed together. The most economic method of assembly is to spigot the tubes into a machined block that forms the breech part of the barrels and includes the lumps. This is, in essence, the same as barrel sleeving as a method of repair. Just to prove that little is new, a similar method, albeit inserting barrel tubes from the breech end, was patented by W.J. Monks in 1881, the same system, I believe, as used on the French-made ‘Robust’ gun.

Stock and Forend Wood

The forend may be either a splinter (narrow) forend or, less commonly, a wide beavertail type, which wraps partly around the lower side of the barrels. The bottom of the forend that rests in the hand is the belly. The front is the tip, which may be plain wood or fitted with a forend tip formed from horn or steel.

The stock has a head where it fits against the action. To the sides at the head of the stock there may be carved panels, some with a small carved end known as a drop point, tear-drop point or, to some older hands, a bottle point. Further back is the hand, where the stock is held, and the grip, that is, the chequering. Occasionally, the hand is described as the wrist! Back from the hand is the raised comb, along the side of the comb is the face, and at the end of the comb is the bump or heel. The shoulder end of the stock is the butt, the position at the middle of the butt is the middle, and the bottom end is the toe. The butt may be made of plain wood or fitted with a heel plate, butt plate or butt pad. The term heel plate has been used to describe both a butt plate made of steel or horn (or other material) or a butt pad. Additionally, there are delightful small fancy plates fitted to the top and bottom of the butt, variously described as tip and toe plates, quarter plates or toe and heel plates.

The underside of the stock may be straight hand – as in a straight line – or in a shallow curve to form a swan neck. Alternatively, it may have a short, curved grip that is rounded on the end (bag grip) or a grip with a flat grip cap. That final component, the trigger guard, is formed from the bow that wraps around the triggers, which may have a rounded edge, known as a rolled edge, the bow extending into the tang or tail, which lies along the stock. Sometimes there is a delightful piece of silver or gold let into the stock for the owner’s initials; this is an escutcheon if shield-shaped or an oval if oval-shaped (actually nearer to round until it is fitted with the curve of the stock).