Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The History Press

- Kategorie: Fachliteratur

- Sprache: Englisch

We think of the Stephensons and Brunel as the fathers of the railways, and their Liverpool and Manchester and Great Western Railways as the prototypes of the modern systems. But who were the railways' grandfathers and great-grandfathers? The rapid evolution of the railways after 1830 depended on the juggernauts of steam locomotion being able to draw upon centuries of experience in using and developing railways, and of harnessing the power of steam. Giants the Stephensons and others may have been, but they stood upon the foundations built by many other considerable – if lesser-known – talents. This is the story of those early pioneers of steam.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 332

Veröffentlichungsjahr: 2019

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

First published 2019

The History Press

97 St George’s Place, Cheltenham,

Gloucestershire, GL50 3QB

www.thehistorypress.co.uk

© Stuart Hylton, 2019

The right of Stuart Hylton to be identified as the Author of this work has been asserted in accordance with the Copyright, Designs and Patents Act 1988.

All rights reserved. No part of this book may be reprinted or reproduced or utilised in any form or by any electronic, mechanical or other means, now known or hereafter invented, including photocopying and recording, or in any information storage or retrieval system, without the permission in writing from the Publishers.

British Library Cataloguing in Publication Data.

A catalogue record for this book is available from the British Library.

ISBN 978 0 7509 9360 9

Typesetting and origination by The History Press

Printed and bound in Great Britain by TJ International Ltd

eBook converted by Geethik Technologies

Contents

Introduction

1 The First Steam ‘Engines’

2 Steam Locomotion

3 Some Pioneers

4 Rainhill

5 Some Early Railways

6 Some Lessons from Canal Mania

7 Tracks and Tramways

8 The Role of Parliament

9 Railways and the Industrial Revolution

10 Supplier of Railways to the World

Sources

Bibliography

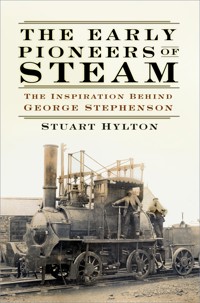

Cover image: A view back into railway history. Lyon, a Hetton Colliery locomotive, originally dating from 1822 but now thought to have been built in 1851–52 as a replica of an 1822 locomotive designed by Nicholas Wood (1795–1865). Wood was a close associate of George Stephenson (Stephenson’s son Robert was apprenticed to Wood). It was photographed for Railway Magazine in 1905 and remained in service until 1912. In 1925 the locomotive took part – under its own steam – in the centenary celebrations of the Stockton and Darlington Railway. It was one of a pair (the other was destroyed by a boiler explosion in 1858/9). (Mary Evans Picture Library)

A first-class carriage from the earliest days of the Liverpool and Manchester Railway.

Introduction

The opening of the Liverpool and Manchester Railway on 15th September 1830 was one of the epochal moments which ‘divide precisely the past from the future, the old from the new, the historic from the prehistoric and of which nothing that came after was ever quite the same as anything gone before’.

Sir Arthur Elton, quoted in Gwyn and Cossons

In 1832 an essay on the advantages of railways compared road travel and rail travel between Liverpool and Manchester before and after the opening of the railway. By road, the journey took four hours and cost ten shillings inside the coach and five shillings outside. By train the same journey took one and three quarter hours and cost five shillings inside and three shillings and sixpence outside. Compared to canal the time savings were even more significant. The same journey had taken twenty hours by canal. The cost of canal carriage was fifteen shillings a ton, whereas by rail it was ten shillings a ton.

www.parliament.uk

The great work of the Liverpool and Manchester Railway, advancing towards completion, seemed by a common unanimity of opinion, to be deemed as the experiment which was to decide the fate of Rail-ways. The eyes of the whole scientific world were upon that great undertaking; public opinion on the subject remained suspended; and hence its progress was watched with the most intense interest.

Nicholas Wood, A Practical Treatise on Rail Roads, 1832

Many of the general public think of the Stephensons and Brunel as the fathers of the railways, and their Liverpool and Manchester and Great Western Railways as the prototypes of the modern systems. But who were the railways’ grandfathers and great grandfathers? For the rapid evolution of the railways after 1830 depended to a considerable degree upon the Stephensons, Brunel and their contemporaries being able to draw upon lifetimes of experience in using and developing railways, and of harnessing the power of steam. Giants the Stephensons and Brunel may have been, but they stood upon the shoulders of many other considerable – if lesser-known – talents.

The purpose of this book is to recognise the many great contributions made over the centuries, leading to the eventual emergence of the steam railways. Among the things it looks at are:

• the use of steam power to generate movement – a story going back to the time of the ancient Egyptians;

• the use of railways to serve industry and transport, which can be dated back at least to the first millennium bc and the ancient Greek Diolkos;

• British Parliamentary processes being used to facilitate (or control) the building of railways, first recorded in 1758. This had a marked effect on the form railway building took in Britain;

• The earlier transport revolution of the canals, involving the creation of massive civil engineering works and the assembly of equally massive streams of finance to build them, which would later be needed to fund the explosive growth of the railway network;

• The emergence of the Industrial Revolution, which could not have happened in the form it did without a means for the swift mass movement of people and goods;

• The stories of some of the individuals who made a mark in the earliest days of the railway, the railways they built and ran and the locomotives they designed;

• How British steam railway technology was spread throughout the world and helped to ensure the universality of this invaluable aid to modern living.

The book will look at the many people and events that influenced the dawn of the railway age. I am grateful, not only to them but also to the many people who have written about them. I have acknowledged my main published sources at the back of the book. In addition, there is a wealth of research now available on the internet, for which I am also duly grateful. My index of internet sources is less complete, since you can see what is available by entering your topic of interest into your search engine.

I have tried to avoid infringing anybody’s copyright but if I have inadvertently failed in any particular instance, please let me know via the publisher and I will try to ensure that it is put right in any future editions.

Stuart Hylton

1

The First Steam ‘Engines’

This book looks at not one but two developments that were of vital significance to the industrial world in which we live. Taken individually, each one was of major importance to us. Brought together, their effect on the world was transformative. Each has been known about for centuries, but it was not until the start of the nineteenth century that their combined potential began to be realised.

We begin by looking at the very earliest attempts to create steam engines of one sort or another – at first, as curiosities or toys, but gradually evolving into devices that could do useful work. But what is an engine? It is a device that converts energy into mechanical power. For our present purposes we are talking about heat engines – engines that consume fuel to make heat, which is then converted into mechanical energy. They can be subdivided into internal and external combustion. A car’s petrol engine is an example of internal combustion. Petrol is injected into the engine and ignited. The hot gases this creates move the pistons that make the engine work. A steam engine, by contrast, is an external combustion engine. Fuel is burnt outside the engine, which creates heat that turns water into steam. The steam is then fed into the engine, to drive the pistons and make the engine work.

When water is turned into steam, the steam takes up about 1,600 times the space that was occupied by the water from which it was made. If it is not allowed to expand, it exerts pressure on whatever is preventing its expansion. It is this that is the driving force of all steam engines.

Hero of Alexandria’s Aeolipile – the first steam engine?

The story of the steam engine begins, improbably, in first-century Alexandria, a city in Roman-occupied Egypt. One of the tutors at its centre of learning, the Musaeum, was a man named Hero (or Heron). He lived between about ad 10 and 70, taught mathematics and physics, and in some people’s estimations was an inventive genius to rival Archimedes, Euclid or Pythagoras (or, to set it in a more modern context, Leonardo da Vinci or Thomas Edison). His versatile imagination foresaw (at least in theory) programm-able computers, robots, vending machines and surveying instruments, but among his other inventions was the aeolipile, described in Hero’s ad 60 book Spiritulia seu Pneumatica.

The aeolipile is also known as Hero’s Engine (although Vitruvius mentions it a century before in his De Architectura, it is not certain that he was talking about the same thing). Hero’s version has been described as a ‘rocket-like reaction engine’ and ‘the first recorded steam engine’. It has a central water container, in which the water is boiled. The steam from it is passed into a turbine and vented through bent or curved nozzles, generating thrust and causing the turbine to rotate. In this, it anticipates the principles of rocketry and of Newton’s second and third laws of motion. However, nobody at the time (almost 2,000 years before the Industrial Revolution) could see a practical application for the aeolipile (beyond a related device, for what seemed an unnecessarily complicated piece of machinery for opening temple doors). The aeolipile was to remain a ‘temple wonder’, or object of reverence with no serious function, for centuries to come.

The aeolipile idea was revisited in the seventeenth century by the Italian engineer Giovanni Branca (1571–1645) in his book Le Machine (1629). It was suggested that his ‘steam engine’ could drive a variety of applications, but it proved to be a blind alley, and not much of an advance over what Hero had proposed centuries before.

It was further revived in the nineteenth century, when railway pioneer Richard Trevithick tried building a giant version of the aeolipile. This was essentially a boiler feeding steam to a Catherine wheel up to 24ft (7.3m) in diameter, with steam jets coming off it. Trevithick worked on it until his death, but could not get it to build up a sufficient head of steam to work efficiently, and the idea finally had to be abandoned.

The idea of an aeolipile is sometimes said to have been quoted in 1680, in Isaac Newton’s Explanations of the Newtonian Philosophy, in which he was supposed to have included a drawing of a vehicle propelled by a jet of steam. This is apparently untrue. The idea actually appeared in a book on Newtonian philosophy by Willem ‘s Gravesande (1720), and was given only as a theoretical illustration of one of Newton’s laws, rather than being proposed as a practicable proposition with applications.

By complete contrast, there was a report from France in 1125 of a church organ that was worked by air escaping from a vessel in which it had been compressed ‘by heated water’.

In the sixteenth century a Turkish polymath named Taqi ad-Din Muhammad ibn Ma’ruf (1526–85) was working in Istanbul. He wrote more than ninety books on a variety of subjects, but among his claims to fame was the invention of a self-rotating spit that was an early stage in the history of the steam turbine. It used steam to turn the vanes, which in turn rotated the axle at the end of the spit. Again, it had no great impact, either on modes of transport or the barbecue industry.

The size and weight of atmospheric steam engines was a major impediment to their use in any means of transport. But size and weight were slightly less critical in ships, which may be why ideas for steam-powered boats appeared somewhat before the equivalent land vehicles. Possibly the earliest contender for the title of inventor of the steamboat was Blasco de Garay, though his claim was by no means uncontested. De Garay (1500–52)was a Spanish naval captain at the time of the Holy Roman Emperor Charles V, and also a prolific inventor. He submitted a series of naval-related inventions to Charles V, including diving apparatus and the use of paddle wheels as a substitute for oars, as well as a steam-powered ship.

Details of this did not emerge until 1825, when Tomas Gonzalez, Director of the Royal Archives of Simancas, came across details in a file that he had found. These were then published in 1826 by the sailor and historian Martin Fernandez Navarrete. Part of Gonzalez’ letter to Navarette reads as follows:

Blasco de Garay, a captain in the navy, proposed in 1543, to the Emperor and King, Charles V, a machine to propel large boats and ships, even in calm weather, without oars or sails. In spite of the impediments and the opposition that this project met with, the Emperor ordered a trial to be made of it in the port of Barcelona, which in fact took place on the 17th on the month of June of the said year 1543. Garay would not explain the particulars of his discovery; it was evident however during the experiment that it consisted in a large kettle of boiling water, and in moving wheels attached to each side of the ship. The experiment was tried on a ship of two hundred tons, called the Trinidad, which came from Colibre to discharge a cargo of corn at Barcelona, of which Peter de Scarza was captain. By order of Charles V, Don Henry de Toledo the governor, Don Pedro de Cordova the treasurer Ravago, and the vice-chancellor, and intendant of Catalonia witnessed the experiment. In the reports made to the Emperor and to the prince, this ingenious invention was generally approved, particularly on account of the promptness and facility with which the ship was made to go about. […] The Emperor promoted the inventor one grade, made him a present of two hundred thousand maravedis (maravedi – a medieval Spanish copper coin) and ordered the expense to be paid out of the Treasury.

Given the distinguished list of alleged witnesses to this event, it is surprising that it should have vanished into obscurity for almost three centuries. But the Spanish authorities subsequently discredited the account and the first ‘official’ steamboat to enter Spanish waters was the Real Fernando in 1817.

A Spaniard, Jeronimo de Ayanz y Beaumont, was granted a patent in 1606 for a steam-powered water pump that managed to drain some mines.

The French-born physicist Denis Papin (of whom, more shortly) also built the first piston steam engine, which he used to power a boat in 1707. His plan was to bring it from the River Weser to England, for trials on the Thames. But the boatmen on the Weser, fearing for their livelihoods, seized and destroyed it. But Dendy Marshall suggests that this boat was only a model; that the full-sized boat Papin produced was reliant on man-power and was only intended to have been driven by steam later on, if such a thing proved to be possible. It was left to Scotsman William Symington, with his Charlotte Dundas of 1802, to produce the world’s first practicable full-sized steamboat.

For the next advance in steam-powered motion we turn to a Flemish Jesuit priest, Father Ferdinand Verbiest (1623–88), who was a missionary to seventeenth-century China. His main claims to fame were as a diplomat, cartographer and translator. However, in around 1672 he also designed a steam-powered trolley as a toy for the Chinese Emperor, quite possibly the first steam-powered vehicle. Verbiest describes it in his Astronomia Europea. It consisted of a ball-shaped boiler from which the steam was directed onto a simple open ‘steam turbine’ (rather like a water wheel) that drove the rear wheels. Two doubts surround this being counted as a major development in steam transport. First, it was only just over 2ft long, and as such not able to carry a payload, let alone a human driver. Second, there was no evidence that the drawings ever got built and tested.

By the early eighteenth century a much more concerted effort was being made to harness the power of steam for industry, (albeit not necessarily for the purpose of transport) and a number of notable thinkers devoted their time to it.

Working Engines

Thomas Savery (c.1650–1715) was a Devon-born military engineer who spent his spare time conducting experiments in mechanics. Among his earlier experiments was a device for rowing becalmed ships, involving paddle wheels powered by a capstan (which the Royal Navy declined to take up). In July 1698 he patented the first commercially used steam engine, which the patent described as:

A new invention for the raising of water and occasioning motion to all sorts of mill work by the impellent force of fire, which will be of great use and advantage for draining mines, serving towns with water, and for the working of all sorts of mills where they have not the benefit of water nor constant winds.

Weightman describes it more prosaically as ‘a fairly simple contraption in which steam was run into a cylinder, where it was cooled with cold water, causing a vacuum, which sucked the water up from a mine and spewed it out’. The terms of his patent implied that Savery’s machine was a multi-purpose engine, but this was not the case. All it was really good for was pumping water, and even that not very efficiently.

Savery demonstrated the machine to the Royal Society in June 1699, but his patent itself was very vaguely drawn, having neither illustrations nor even a description of how it worked. The first such description appeared in Savery’s 1702 book The Miner’s Friend; or, an Engine to Raise Water by Fire (in which he at least explained the claim that it could be used to pump water out of mines). How true was this in practice? We will look at the Savery machine’s working in a little more detail.

Thomas Savery, inventor of the first steam mine pump.

Savery’s engine had no piston; the only moving parts were the taps. Steam was raised in the boiler and admitted into one of the first working vessels. It would blow out through a downpipe into the water that was being raised. Once the system was hot and full of steam, the tap between the boiler and the working vessel was shut and (if necessary) the vessel was cooled down. This made the steam inside it condense back into water, creating a partial vacuum. Atmospheric pressure would then push water up the downpipe until the vessel was full. The tap below the vessel would then be closed and the tap between it and the up-pipe opened, and more steam was admitted from the boiler. As the steam pressure built up, it forced water from the vessel up the up-pipe to the top of the mine.

Savery’s pumping engine.

This engine had major problems:

• It was very slow. When water was admitted to the working vessel, much of the heat was wasted in warming up the water that was being pumped;

• It involved relatively high-pressure steam and the technology of the day could not cope with it. The soldered joints needed frequent repair and there was the ever-present risk of a boiler explosion. Related to this;

• To clear water from a deep mine would have needed a series of moderate pressure engines, reaching from the bottom of the mine to the top in instalments, since the technology of the day could not have coped with the pressures required for a single machine doing longer lifts of water. This would have been impracticable. As a result;

• Because only atmospheric pressure was (theoretically) used to push water up into the engine, it could not be located more than about 25ft above the water level. (The theoretical maximum under laboratory conditions was about 33ft, but this could not be achieved in real life). A further 40ft of depth could be added using steam pressure with the technology of the day, but even this would not be enough to clear a typical mine of water. Savery claimed that his engine would raise a full bore of water up 80ft ‘with great ease’. But to do so, the boiler would have had to withstand a pressure of about 35psi, roughly that of a modern car tyre. This may help to explain the Savery machines’ reputation for exploding;

• The primitive design of the boilers made them very inefficient and heavy on fuel, even disregarding the inefficiency of the process itself, involving constantly heating and cooling the engine;

• Finally, it was not strictly an engine as we defined it; as we saw it had no moving parts other than the taps, and no means of directly transmitting its power to any other kind of machinery (such as factory or mill machines).

The ideal solution to the problem might have been a mechanical pump at the mine’s surface, which would have lifted the water out of the mine, rather than sucking it up with the aid of atmospheric pressure. Such pumps were commonplace – powered by horses – but Savery’s device was not a steam-powered replacement for them, since he had no reciprocating drive to power it.

Savery’s loosely worded patent covered all forms of engine that raised water using fire, and the 1698 patent’s fourteen years’ protection was extended by a further twenty-one years (the so-called Fire Engine Act, granted by Parliament because it had exaggerated hopes for its success). One consequence of this was that Newcomen (see later), with his more advanced steam engine, was forced to go into partnership with Savery and pay Savery royalties on each one he sold.

The Savery engine was much cheaper to buy than the Newcomen; a 2–4hp Savery engine might be had for between £150 and £200. It was also available in much smaller sizes, right down to one horsepower – much smaller than any engine Newcomen made. This was because piston steam engines were very inefficient in small sizes, right up until the twentieth century.

The experience of using Savery machines appears to have been mixed. One at York buildings in London tried to generate steam at eight to ten times the atmospheric pressure, blowing all the joints on the machine. Similar problems were encountered while trying to drain water from a pool in Staffordshire, and some nearby mines. But others, at Hampton Court and Campden House, Kensington, appear to have given reliable service, and Savery engines were produced well into the late eighteenth century.

Savery’s work apparently bears a striking resemblance to something in a book of inventions published in 1663 by Edward Somerset, Marquis of Worcester. One (unproven) account has it that Savery bought up as many copies of Somerset’s book as he could find and destroyed them, so as not to let it steal his thunder.

Savery ended his career as Surveyor of Waterworks at Hampton Court Palace.

Denis Papin (1647–1712) was a French Huguenot who originally studied to be a doctor, but discovered that his real interest lay in mathematics and mechanics. He secured a post working for Christiaan Huygens, one of the leading scientists of the day, where Papin worked in experiments with air pumps from 1671 to 1674. This work led to him being introduced to the English physicist Robert Boyle, with whom he also worked, before he became assistant to Robert Hooke at the Royal Society. In 1679 he demonstrated one of his inventions to the Society, a device that:

Exemplified the enormous elastic force that steam acquires when heated and confined. The properties of this digester for cooking and extracting gelatine from bones by high pressure steam contains all that is at present practiced in the preparation of food by this method.

His ‘digester’ was what we would call a pressure cooker, but the path from there into steam engines is not too difficult to see. Papin returned to France in 1681 but the increasing persecution of Huguenots forced him into permanent exile in 1685.

It was in 1690 that he published his first work on the steam engine, De novis quibusdam machinis. It was based on the work of Thomas Savery. The purpose of this particular machine was to raise water to a canal in Germany, though he also developed a steam engine to pump water to a rooftop tank in a palace, from where it would supply water for the fountains in the grounds. He documented his ideas in The New Art of Pumping Water by Using Steam (1707), in which a second machine incorporated a safety valve of his own design to prevent dangerous levels of steam pressure from building up. It was needed, given the lack of understanding of the day about regulating cooking temperatures and steam pressure, whoch caused many of his experiments to crack or explode. This second engine worked off steam, rather than atmospheric, pressure.

Papin’s pump of 1704.

Papin’s steam cylinder and piston experiment was his greatest contribution to the steam age. Water enters the pump through valve L. The boiler (B) and Cylinder (C) are fitted with weighted safety valves. When valve D is opened steam is admitted to the cylinder, forcing down the piston, pushing the water beneath it into the reservoir through valve K and in the process compressing the air above it. The steam in cylinder C is then condensed to form a vacuum, which forces the piston upwards, drawing more water into the system through valve L and closing valve K. Closing valve K removes the steam pressure, causing the water in the reservoir to be expelled through valve M under the action of the compressed air above it.

Like some of his other inventions, Papin’s experiment worked, but only sufficiently to demonstrate the feasibility of the principles behind them. He did not persevere with them for long enough to develop a practical working engine. His atmospheric steam engine from 1690 was very similar to the one successfully produced by Thomas Newcomen in 1712 and his development of the first cylinder-and-piston steam engine was a vital part of the Industrial Revolution.

Papin has been described as ‘a formidably obstinate character, a man incapable of conceding the least advantage to his adversary, a skilled expert in the rules and tricks of the art of disputing’.

Could this be at least part of the reason why he died in London in 1712 in obscurity and poverty, the importance of his work not recognised in his lifetime?

Thomas Newcomen (1664–1729) was born in Dartmouth, Devon, and made his living as an ironmonger, specialising in the needs of the mining industry. As such, he was keenly aware of the problem of flooding that was faced by coal and tin mines. He was also a lay preacher and a leading light of the Baptist community, with whom he had business links. This may have included the family of Thomas Savery, whose forebears were merchants in south Devon, where Newcomen originated.

The atmospheric engine, invented by him in about 1712, was the first practical machine to use steam to produce mechanical work. As we have seen, there had been various devices illustrating the principle over the years, but up until now these had either been novelties with no real practical application, or had serious design faults that prevented their being very effective for their intended purpose.

Newcomen drew upon the ideas of Thomas Savery and Denis Papin. From Savery he borrowed the idea of a ‘thermic syphon’, where steam is let into an empty container and then condensed to create a vacuum. This vacuum was intended to be used in Savery’s model to suck water from the bottom of the mine. Following Papin, Newcomen took the idea of replacing Savery’s receiving vessel (where the steam was condensed) with a cylinder and piston, where atmospheric pressure pulls down the piston.

A cutaway diagram of a Newcomen atmospheric engine.

The Newcomen engine does its pumping by mechanical means. Put very simply, it had a boiler (A) located immediately beneath a cylinder (D) containing an inverted piston (E). The boiler produced quantities of low-pressure (and hence safe) steam. The cylinder is attached to one end of a heavy beam (G), pivoted at the centre. The other end of the beam is attached by a chain to a rod (H), which drives the pumping machinery down in the mine by its up-and-down movement.

The pumping equipment attached to the beam is heavier than the steam piston, so the resting position for the beam is pump side down/engine side up – known as ‘out of the house’. But we will start with the piston at the bottom of the cylinder. As the piston rises under the weight of the pumping equipment, low-pressure steam from the boiler is let into the cylinder. The steam does little of the lifting – that is done mainly by the weight of the pumping gear. Once the piston reaches the top of its stroke, the steam valve is closed and some cold water (coming from a tank at the top of the pumphouse) (M) is sprayed into the cylinder. This cools the steam, condensing it back into water and leaving a partial vacuum in the cylinder. Atmospheric pressure then presses down on the top of the piston, driving it back down the cylinder (hence the alternative name for this apparatus – atmospheric engine). At the end of the downward stroke, the cooling water is drained from the cylinder and the engine is ready to start again. This cycle is repeated about twelve times a minute.

The earlier Newcomen engines had a copper boiler which domed top (B) was made of lead, and which could withstand no more pressure than 1 to 2psi. Later ones were made of small riveted iron plates. Another sign of the primitive technology of the day was that the cylinder was finished by hand and was not always true. So the piston had to be surrounded by a flexible seal in the form of a leather or rope ring around it. But even this was not a perfect solution, and a layer of water had to be permanently maintained on the top of the piston to complete the seal.

Newcomen’s machine was extremely inefficient and expensive but still a great advance on anything that had preceded it, being rugged and reliable. The first working version of the engine was installed in a coal mine in Dudley Castle in Staffordshire in 1712. Its cylinder was 21in in diameter by almost 8ft long and it ran at about twelve strokes a minute, raising 10 gallons of water from a depth of 156ft. It was rated at about 5.5hp and its efficiency at about 1 per cent. The second was in Griff Colliery, near Coventry. It replaced more than fifty horses and cut the cost of draining the mine from £900 to £150 a year.

The Newcomen engine was a great success. Until 1733, they had to be manufactured under Savery’s all-embracing patent, by which time about 125 engines had been installed, both in this country and in mining areas throughout Europe. By 1775 some 600 Newcomen engines had been built. Some of these were huge machines; improved casting techniques enabled machines with cylinders of up to 6ft (1.8m) in diameter to be built by the 1760s.

Although they were a step up from their predecessors and a much greater commercial success, the problem was that the Newcomen machines were still not efficient. This may have been partly due to the limits of the engineering techniques of the day, but more fundamental was the fact that a lot of heat was lost when condensing the steam. The loss of heat had to be replaced, meaning that Newcomen engines consumed fuel at a rapid rate. They must take their share of the blame for William Blake’s ‘dark satanic mills’, the perpetual pall of smoke that hung over Victorian industrial areas and their steam-driven mines and factories.

As we saw, this inefficiency was much less of a problem (at least financially) for coal mining users of the engine, for they had unsale-able ‘small coal’ on site to use as virtually free fuel. But for others, such as the Cornish tin miners, without local coal supplies, the cost of coal was a heavy burden, with it having to be imported by a combination of ship, horse and cart, and packhorse. At its worst, the cost of running a Newcomen engine could be prohibitive. According to one estimate, more than half the Newcomen engines in the West Country were lying idle by the 1770s.

James Watt

The people are steam-mill mad. The velocity, violence, magnitude and horrible noise of the engine give universal satisfaction to all beholders.

James Watt

Efforts were made over the years to improve the efficiency of the Newcomen engine. John Smeaton built many improved large engines, though he was better known as a civil engineer. But, according to some accounts, the big breakthrough came in 1763, when the University of Glasgow sent a miniature version of a Newcomen engine for repair. They entrusted it to a small workshop within the university itself, run by James Watt. Watt’s business dealt with all sorts of mechanical objects – mathematical and musical instruments, toys and other goods, but steam engines were his passion.

Even after he had repaired it, (if, indeed he did – Dendy Marshall attributes the repair to a colleague, Doctor J. Robison) Watt found that it still hardly worked (it is a feature of Newcomen engines that the smaller the engine, the more pronounced its inefficiency will be.) Watt found that three-quarters of the energy of the steam was being wasted in reheating the cylinder after each cycle, only for it to be cooled again when cold water was injected to condense the steam.

Major components of a Watt pumping engine.

Watt’s big idea (dating from 1765) was to have a separate chamber, away from the piston, where the steam could be condensed. This meant that the cylinder and piston could be kept at the same temperature as the steam (especially when it was insulated in a steam jacket) and relatively little energy was lost. This arrangement reduced the fuel bill by between a third and a quarter compared with a standard Newcomen engine of the same size.

Watt had three problems with taking his idea further. One was finding the money to build it. Another, related to the first, was securing a patent for it. The third was finding someone who could engineer the cylinder and the piston with sufficient precision. The first two were not resolved until Watt formed a partnership with Matthew Boulton (of whom, more shortly). For eight years Watt had been forced to abandon his researches in favour of more gainful employment as a surveyor and then a civil engineer. The patent was secured, after much expenditure, in 1769, and in 1775 was extended until 1800. But Watt still lacked the capital to make it a marketable concern by himself. This and the engineering problem were again resolved by the Boulton partnership and by the technical expertise Boulton’s business contacts could bring to bear on the matter.

The Boulton–Watt Partnership of 1775 came about by an unusual route. Watt’s original business partner was an iron founder, and owner of the Carrick Ironworks, named Doctor John Roebuck. He ran into financial problems in 1772, owing Boulton £1,200, and gave Boulton his two-thirds share in Watt’s patent in lieu of the debt. Boulton persuaded Watt to enter into a partnership with him, and they started developing and selling Watt’s improved engines. Watt’s work on them was already well known and Boulton’s word of mouth ensured that his reputation spread rapidly.

Boulton’s own interest in Watt’s ideas originated from problems he had with his own Soho manufactory. This was powered by water and had outgrown the power that the river could deliver. Boulton’s idea was to use steam power to lift water from below the waterwheel to above it – in effect to gain additional power by using the same water through the waterwheel twice.

Boulton & Watt developed an unusual method of payment for the engines. They compared the cost of running Watt’s machine with that of the customer’s earlier, less efficient, model and made an annual charge equivalent to one-third of the saving each year, for the next twenty-five years. This arrangement was not universally popular with the customers, though it did not stop them buying the machines – about 450 were sold between the start of the partnership in 1775 and the expiry of Watt’s patent in 1800.

Anticipating the eventual saturation of the pumping engine market, in 1782 Watt modified his engine, patenting the sun and planet gear that enabled it to convert the up and down movement of the beam into the rotational movement needed to drive factory and mill machinery. (Watt patented the idea, but it was actually invented by William Murdock.) A previous patent by James Pickard, based on the workings of a potter’s wheel (an idea some say Pickard stole from Watt in the first place) offered an alternative means of doing so, until his patent expired in 1794 and Watt could reclaim the idea. This greatly expanded the potential of the Watt machine. It meant that factories were no longer dependent upon wind, water or animal power to drive their machinery, and manufactories could locate wherever other business needs dictated.

By 1800, 308 of the 496 Boulton & Watt machines built up until that time were rotative. Some 114 of these were being used in the textile industry, along with others in ironworks, breweries and grain mills. Further improvements included the double-acting piston, whereby steam pressed on either side of the piston in turn, the improved use of expansive steam to reduce fuel consumption, and a centrifugal governor, which enabled an engine to run at a constant speed, regardless of the load being placed upon it. Savings in fuel consumption were especially important, as they made it viable to open up new mining areas away from established coalfields.

Boulton introduced one further improvement to their steam boilers, which was to have important ramifications later in the locomotive age. In about 1780 he wrote to Watt with the idea of improving the steaming efficiency of his boilers by fitting tubes to the back of the firebox, to increase the area of hot gas coming into contact with the water. He later fitted four 20in-diameter copper tubes to one of his stationary boilers. This idea had to be reinvented for locomotives, and a multi-tube boiler would become one of the reasons for Rocket’s success at the Rainhill Trials. One further improvement was introduced by John Wilkinson’s foundry at Wrexham. His improved cylinder-boring technology enabled a closer fit between cylinder and piston, and thus gave greater power.

At last human ingenuity had found a way of harnessing steam to do useful work, but the massive and slow-working Newcomen machines were never going to lend themselves to locomotion. A whole new approach would be needed.

2

Steam Locomotion

From the earliest times, people were trying to use steam power to generate movement of one kind or another. But for many centuries nobody was able to come up with practical applications for steam-driven machinery, or the technology to make steam power viable. But by the seventeenth and eighteenth centuries it seemed as if steam-powered transport might be an idea whose time had finally come.