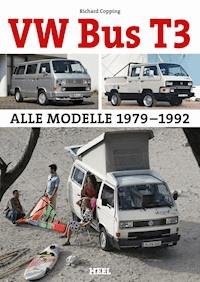

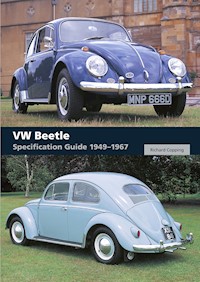

20,99 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

The VW Beetle is one of the best-loved of all classic cars, with many thousands preserved across the world, many in regular use. Over the years countless changes were introduced, together making a mid sixties Beetle, for instance, very different from one built in the mid-50s, or mid-70s, despite the obvious similarities. With the aid of hundreds of full colour photographs this new edition in paperback documents all the Beetle's specification changes and model differences during the classic period 1949-67, making it possible to determine the original specification and fittings of any Beetle from this period.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Veröffentlichungsjahr: 2018

Ähnliche

VW Beetle

Specification Guide 1949–1967

Richard Copping

The Crowood Press

First published in 2007 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

Paperback edition 2018

© Richard Copping 2007

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 490 2

About the author

Richard Copping is Britain’s most prolific author on matters Volkswagen, with well over twenty books written about Beetles, Transporters, the VW Golf and more. His deep-rooted love for the marque has encouraged him to amass a large collection of archive brochures, to travel the length and breadth of the country visiting many of the Volkswagen enthusiast events, to photograph all types of Volkswagen whenever the occasion arises and, above all, to write about the vehicles in a style that has come to be recognized as both authoritative and lively.

contents

preface

1 the KdF-Wagen

2 the Wolfsburg Motor Works

3 the Nordhoff years

4 production survey

5 specification detail changes month by month

6 engine options

7 factory-fitted optional equipment

8 paint and trim colours

9 accessories

10export –‘the Volkswagen is a favourite in 136 countries’

11Beetles assembled or built overseas

12Hebmüller Coupé and Karmann Cabriolet

13Beetle-based conversions

bibliography

index

preface

The Volkswagen philosophy,1 January 1948 – 12 April 1968:

‘ … To develop one model of car to its highest technical excellence … to dedicate ourselves to the attainment of the highest quality, to destroy the notion that such high quality can only be obtained at high prices … to give the car the highest value … to build it so that it retains that value … ’

Heinz Nordhoff, Director General,5 December 1961

Compared to the specification guides already published in this Crowood series – covering the VW Transporter and Microbus respectively, first in split-screen guise and then with the panoramic front window that led to the adoption of the ‘Bay’ nickname – this volume allocates a greater amount of space to the history of the product. The reason for this should soon become apparent. The cumulative production total of 1,833,000 for the Transporter manufactured between its debut in 1950 and the last days of July 1967 pales into insignificance when compared to that of Beetles produced during more or less the same period. One million such cars had left the Wolfsburg factory by August 1955, with a further million reached just over two years later during the last days of December 1957. By the end of 1967 and the period covered by this book, that total had risen to a figure well in excess of 10,000,000 cars.

Clearly with such volume, the Volkswagen Empire, which is what a once bombed-out ex-Nazi factory had become in the twenty-two years since the end of the war, had been created out of just one key model. Unusual in the extreme, sufficient space has to be allocated to the twenty years during which Volkswagen was ruled by Heinz Nordhoff. Why – unlike any other manufacturer – did Nordhoff fervently adhere to Ferdinand Porsche’s pre-war design throughout his reign? Was the car truly irreplaceable? What special characteristics had the Beetle, which set it on the path to becoming the most produced single model ever? And if the years 1948 to 1968 are clearly worthy of analysis, so too must be Ferdinand Porsche’s pre-war attempts to launch successfully a car for the people and the post-war military government’s desire to rescue this symbol of the Nazi Party’s bid for German supremacy in all aspects of life.

With the Beetle’s place in Volkswagen’s history duly assessed, only one problem presents itself. The specifications for the Beetles produced before the launch of the Deluxe, or Export, model in the summer of 1949 vary wildly according to the availability of raw materials and parts in the immediate post-war years. Inevitably then, the level of detail dedicated to Beetles of this vintage is less comprehensive than in later years.

No Beetle guide would be complete without the inclusion of the coveted convertible produced for Volkswagen by Karmann. Indeed, so integral was the model to the Beetle line-up from 1950 onwards, that in terms of specification it is included with the saloon in the year-by-year detail changes. With a soft-top always a part of Porsche’s original plan and even something of a plaything for the British hierarchy, aside from the Karmann Cabriolet, space is allocated to the Radclyffe Roadster, Hebmü ller coupé and other soft-top variants on the Beetle theme. For the curious, so too are some of the many coach-built models prevalent particularly in the 1950s. Sadly, space precludes more than passing reference to Volkswagen’s own Beetle with a sporty body – the Karmann Ghia.

Writing about and listing details concerning the Beetle is always a pleasure, for it is through this car that my general appreciation of all types of Volkswagen – including modern day water-cooled models – arose. That interest has extended further to include sales literature and other memorabilia – some of which are used in this volume. I trust that you will find this volume an invaluable comprehensive guide to Beetleology.

Richard Copping,2007

1

the KdF-Wagen

Two KdF-Wagens that have survived! The one bearing the number 98 is resident in Germany, the other travelled from the USA to Germany via England in 1999 to attend a classic Volkswagen event held at Bad Camberg.

FERDINAND PORSCHE AND THEVOLKSAUTO

Throughout his working life, one of Ferdinand Porsche’s passions was to design and build a Volksauto – a small car for the people. While in the employ of others, including Austro-Daimler and Daimler-Motoren AG, albeit for many years at director level – his ambition could be and was readily quashed. In what of necessity is a gross simplification of Porsche’s career, by 1931 the highly talented, yet equally volatile, designer had parted company with so many manufacturers that there remained little option for him but to set up his own bureau. With the only constraint now placed upon him being one of available funds, he was able to pursue his small car story with renewed vigour.

Labelling his small car as Project 12, what started to emerge was a vehicle that bore more than a passing resemblance to an insect when compared to conventional cars of the time. Planned to incorporate four-wheel independent suspension and to be light enough in weight for a low-horsepower engine to be sufficient, the backbone of the car was a tunnel along the front-to-rear centreline.

Fritz Neumeyer of the Zündapp Works, having already expressed more than a passing interest in developing a small car to supplement his motorcycle activities, heard of Porsche’s project and commissioned him to develop it further. The Zündapp Volksauto was duly born, the only significant difference between it and Porsche’s original concept being a water-cooled five-cylinder radial engine. Sadly, when put on test, the progress of the prototype aluminium over a wooden-frame-bodied car was disastrous. Engines boiled and Porsche’s patent torsion bars shattered. When Neumeyer realized just how costly the stamping presses required to make the final shaped steel body parts would be, he decided to call a halt and paid Porsche off accordingly.

Later in 1931, Porsche was approached by Fritz von Falkenhayn, head of the NSU Motorwerks. He too wanted a small car and by 1933 Porsche had engineered the original Project 12 design to resemble something even closer to the form the Beetle would take a few years later. Amongst this vehicle’s key attributes was a 1.5ltr air-cooled flat-four engine capable of 116km/h (72mph), while the body was shapelier than that of the Zündapp project car. Sadly, Porsche was to be thwarted once more when von Falkenhayn received a letter from the managing director of Fiat, reminding him of an agreement signed in 1930, whereby he had contracted to cease car production both then and in the future, Fiat in reality having bought the NSU operation.

FATE PLAYS HER HAND

Speaking at the Berlin Motor Show in February 1933, the newly appointed Chancellor, Adolf Hitler, spoke of the urgent need to see Germany motorized. Highlighting a programme of road building (the autobahns), the rest of Hitler’s speech lay mostly in the direction of motor sport, but nevertheless the requirement for a small car suitable for the masses was highlighted. As a result, Porsche spent the rest of 1933 preparing his now famous Exposé, in which he outlined the ideal specification for the kind of car of which Hitler had spoken. His paper was presented to the Transport Ministry on 17 January 1934, just a short time before the next Berlin Motor Show.

The historical significance of Porsche’s Exposé cannot be underrated. In his introduction, Porsche stressed that to date, manufacturers’attempts to produce a car for the people had lacked the necessary ingredient of a low selling price, while their efforts had been targeted at a limited market. The only solution was to place the development of a people’s car in the hands of the state – the benefits being the inclusion of the technical prowess of the nation’s youth, plus its pivotal role in the stimulation of the economy as a whole.

The volkswagen, Porsche insisted, should not be a scaled-down replica of a larger car – with a consequent loss in dimensions, power and weight. For its success, it had to be a complete and fully practical car, yet also capable of competing with any other model. Porsche’s definition of the volkswagen encompassed five key points:

1. The volkswagen should be a functional vehicle of normal dimensions but of relatively low weight. The use of fundamentally new processes would achieve this goal.

2. The volkswagen had to be readily capable of normal maximum speeds and climbing capabilities.

3. The volkswagen must be fully functional with a comfortable amount of space for its passengers.

4. The volkswagen should not be a vehicle limited in its possible uses. By a simple exchange of bodywork the passenger car could be transformed into either a commercial vehicle or one suitable for certain military purposes.

5. The volkswagen should not be unnecessarily complex – but rather as far as possible should be foolproof, leading to an absolute minimum in servicing costs.

Porsche’s acceptability criteria:

■ the best possible suspension and handling

■ a maximum speed of around 100km/h (62mph)

■ a climbing capability of in the region of 30 per cent

■ a four-seater enclosed body

■ the lowest possible purchase price, coupled to equally economical running costs.

With a whole series of specially posed shots advertising the merits of KdF-Wagen ownership, an endorsement from the Führer seated in the convertible version of the car and stylish artwork, the early brochures were well-thought-out sales tools.

Porsche proceeded to list the volkswagen’s key specifications, which included a track of 1,200mm (46.8in), a wheelbase of 2,500mm (97.5in), an engine producing a maximum of 26bhp at 3,500rpm, a kerb weight of 650kg (1,433lb) and a selling price of 1,550RM (roughly equal to the cheapest options from other German manufacturers). He duly recommended that the government hand the project over to him, providing the necessary funding to design, build and test one car. Should the volkswagen prove successful, the state would recommend that the ‘industry’ put it into production, with Porsche receiving royalty payments for any of his patents incorporated into the car.

Porsche’s appendices elaborated on what was to become a very familiar specification and included each wheel being independently sprung, the use of his patent torsion bars, an air-cooled four-cylinder, four-stroke engine (or an air-cooled radial three-cylinder, twostroke engine), separate bodyshell and a chassis consisting of two parallel longitudinal tubes running centrally, plus parallel lateral tubes.

RESISTANCE TO THE VOLKSWAGEN SUPPRESSED

Although the sequence of events around the time of the publication of Porsche’s Exposé is unclear, what remains certain is that Jakob Werlin visited the designer, which in turn led to a meeting between Hitler and Porsche. Porsche knew Werlin through his years at Daimler-Benz, while Hitler’s acquaintance with the salesman had been initiated when the Nazi leader bought his first car, a Mercedes, from Werlin in 1923. Porsche hastened to Berlin and the hotel Kaiserhof to discuss his volkswagen, or so he thought, with Werlin. Hitler had quite definite ideas regarding a car for the people and manhandled the course of the meeting accordingly. He wanted four-wheel drive, a 30bhp, three-cylinder, air-cooled diesel engine, which would also be suitable for military use. As for the price – it must fall below the magical 1,000RM figure.

Shortly afterwards, the RDA – the Reichsverband der Automobilindustrie, or the German car manufacturers’ trade association – was informed that Hitler wished to progress the development of Porsche’s volkswagen. The RDA’s contract with Porsche was ‘to further the motorization of the German people on the basis of cooperative action and by enlisting the best talents of German car manufacture’.

Der KdF-Wagen von Abis Zwas an elaborate manual containing all the information required by a potential owner of a KdF-Wagen. Cleverly designed, the centrefold, featuring a ghosted illustration of the KdF-Wagen, encouraged readers to find out more about each aspect of the car, by using carefully colour-coded cut-outs at the edge of the double page.

The V3 series – this is the V3/2 parked in Porsche’s garden – dated from 1936 and although recognizable as a forerunner of the KdF-Wagen and Beetle, tests and trials led to many design changes.

Following the V3 series, the W30 series – dating from 1936 to 1938 – still looked noticeably different from the final product. These were the cars that were rigorously tested over many, many miles. Rearward visibility was extremely limited, while the knuckle-scraping boot lid and ‘suicide’doors were two more features to be redesigned.

Years later, another key player in the Beetle’s story, Heinz Nordhoff – at the time Opel’s representative on the RDA – was to say that, ‘Porsche led a fight against the entire German car industry … a secret underground fight of course and one which ended to his and the volkswagen’s benefit only because Hitler stood behind the entire plan’.

At the 1935 Berlin Motor Show, Hitler sounded optimistic regarding progress with the people’s car. He spoke of preliminary design work having already been completed and plans to test the first models by the middle of the year. Reality was somewhat different and twelve months later Hitler had little option but to repeat the same story once more.

Nevertheless, from V1 and V2 to the V3, W30, V303, VW38 and VW39, the car we know today as the Beetle gradually emerged. Starting as a vehicle without a rear window and featuring a tiny knuckle-scraping boot lid, headlamps fixed to the lower and unopenable section of the bonnet, and suicide doors, it was only after considerable testing of the car’s mechanical abilities that the body progressed significantly. The VW38, which made its debut at the beginning of 1938, was the first prototype to feature the characteristic split-rear window – although this was more a matter of practicality than design, as at the time the curved glass required to produce a single window at the car’s rear could not be produced. No car was tested as rigorously as the volkswagen. The W30 series of thirty cars, for example, driven by 120 seconded SS troops, amassed a total of 2.4 million km on their combined test runs. Ferry Porsche, eventually to become head of the Porsche operation after the war, was already involved with the volkswagen project and was later to comment that ‘this was the first time in Europe that as many as thirty test cars had been used by a manufacturer’. The result was a car that was ahead of its time, uniquely efficient, serviceable, yet carrying a low initial cost – all prerequisites of the people’s car as far as Hitler was concerned.

The initial reaction to the earlier prototypes by members of the RDA was predictable, as it declared the volkswagen to be extremely ugly, while also straying almost beyond the boundaries of acceptable convention. Although the RDA was wise enough to recommend continuation of the project, it also made the suggestion that all German automobile manufacturers should be invited to take part in a competition to find the very best design for any further development. Perhaps inevitably, it was only a short time after this that all files relating to the volkswagen had to be handed over to the Transport Ministry, while an order passed in the Reichstag established control over both iron and steel. The days of any rival volksauto were strictly limited! When Opel offered to cut the price of its own people’s car – the P4 – from 1,450 to 1,250RM it was made clear – albeit unofficially – that such a move would not be tolerated, as no German manufacturer would be allowed to produce a vehicle approaching the price of the volkswagen.

In late May 1937 the Nazi-owned Gesellschaft zur Vorbereitung des Volkswagens – or the Volkswagen Development Company – was formed. Its board of management consisted of Porsche, Jakob Werlin and Dr Bodo Lafferentz, who was the chief aid to the boss of the German Labour Front (DAF – Deutsche Arbeiterfront), Robert Ley. With capital of 480,000RM at its disposal initially, Porsche could push ahead at a pace unheard of previously.

A PURPOSE-BUILT FACTORY FOR THE VOLKSWAGEN

Bodo Lafferentz was the member of the Volkswagen Development Company charged with locating a site suitable for a Volkswagen factory. His brief required finding land of around 20 sq miles (51.8 sq km) in size, with a proximity to transportation facilities and appropriately close to supplies of raw materials, without being too near to the country’s western boundaries. After thorough searching, Lafferentz chanced upon the land surrounding Schloss Wolfsburg, the home of Count Werner von der Schulenburg and conveniently close to the Mittelland Canal. Although the Count enlisted the help of numerous experts to fight his corner – including a specialist in the field of rare mosquitoes – papers transferring the land to the state were drawn up in January 1938 and duly signed. The fact that the Nazis had decided that they must have a purpose-built factory and associated township for their volkswagen’s construction proved crucial to the Beetle’s survival after the war.

Hitler laid the foundation stone of the volkswagen factory on 26 May 1938. Apart from the volkswagen saloon, both a convertible version and a sunroof model were on display. Hitler’s speech demonstrated clearly why he hadn’t countenanced opposition to the volkswagen project:

When I came to power in 1933, I saw one problem that had to be tackled at once – the problem of motorization. In this sphere, Germany was behind everyone else. The output of private cars in Germany had reached the laughable figure of 46,000 a year. The first step towards putting an end to this was to do away with the idea that a motor car is an article of luxury …

Although Hitler’s surprise name for the volkswagen – announced at the foundation-stone-laying ceremony – ‘horrified’ Porsche and anyone with an interest in selling the car anywhere other than in Nazi-controlled Germany, its use helps to distinguish the pre-war volkswagen from the post-conflict attempt to provide transport for Allied personnel and the meteoric rise of the Beetle under Heinz Nordhoff. Hitler concluded his foundation-laying speech with the following words:‘This car shall carry the name of the organization which works hardest to provide the broad masses of our people with joy and, therefore, strength. It shall be called the KdF-Wagen!’ (‘Strength-through-joy, a subsidiary movement within DAF responsible for leisure-time activities.)

The VW 38s, in both Saloon and Saloon with sunroof guise, were paraded around Germany after the factory foundation-laying ceremony and received a genuinely enthusiastic response.

SELLING THE KDF-WAGEN

The KdF-Wagen factory was designed by its architect to be 1 mile (1.6 km) in length and to include a tall administration building. A structure on this scale was essential if Hitler’s demands were to be fulfilled. Robert Ley, head of the German Labour Front, reported that it was ‘the Führer’s will that within a few years no fewer than 6,000,000 volkswagens’ would be occupying German roads. Even more extravagantly, Ley predicted that ‘in ten years’ time there will be no working person in Germany who does not own a people’s car’. Although, as events were to prove, this was totally unrealistic, the Volkswagen Development Company set targets for KdF-Wagen production even before the factory was built. From the modest 400 cars to be manufactured during the last two months of 1938, by December 1939 it was planned to be building 10,000 KdF-Wagens per month, rising to a yearly production of 450,000 by 1944.

Here was a people’s car unprecedented then – but there was one major obstacle to ownership even when availability was ignored. Hitler had demanded of Porsche that the KdF-Wagen be built and sold at a price of 900RM against the designer’s Exposé proposal of 1,500RM. The average German’s savings in 1934 had fallen below 1,000RM, while Hitler stressed that ‘it must be possible to make the German people a gift of a motor vehicle which will not cost more than they have hereto been accustomed to paying for a mediumpriced motor cycle and whose petrol consumption will be low’.

Always planned as part of the KdF-Wagen series, this Cabriolet dating from 1938 looks not that dissimilar to the early Karmann examples, which would follow some twelve years later.

Although by the time of the factory foundation-stone-laying ceremony the cost of the KdF-Wagen had risen to a basic price of 990RM at the factory, hidden extra costs such as insurance and delivery took the price well over the 1,000RM barrier. The Nazis’ answer to this predicament was the now famous, if somewhat draconian, Savings Scheme. At a rate of 5RM per week, it would take a saver a total of four years and seven months to amass the required 1,190RM, and then the person would only become eligible for a car, with a possible wait of up to a further five years to acquire a KdF-Wagen. Nevertheless, a total of 336,688 Germans eventually signed up to the scheme, although not a single one received a KdF-Wagen.

The issue of price is undoubtedly a further factor in the Beetle’s post-war survival and success story. Every costcutting step had been taken – without compromising standards. This was a people’s car without equal.

END GAME FOR THE NAZIS

Although a small number of KdF-Wagens were built as the war progressed, Porsche’s attention was diverted to military versions of his protégé. From the Kübelwagen and the amphibious Schwimmwagen, to KdF-bodied vehicles with Kübel running gear, none concern us here. Nor does the fate of Porsche after the war – for he was out of the Beetle’s story. Only one wartime issue is of importance – the survival of the KdF factory, for without it, its post-war occupants would have had no reason to be present and hence to turn their attention to the Beetle.

A number of variations on the KdF-Wagen theme were built during the war, although numbers were comparatively small. Porsche and his colleagues meanwhile concentrated their efforts on both the Kübelwagen and Schwimmwagen.

2

the Wolfsburg Motor Works

March 1946 – with Ivan Hirst at the wheel, the factory celebrated meeting its target of producing 1,000 cars in a month.

THE ROUTE TO BRITISH CONTROL

Although a defeated Hitler didn’t commit suicide until 30 April 1945 (with Admiral Dönitz’s official surrender following on 7 May), the war effectively ended at the KdF-Stadt over two days – 10 and 11 April 1945 – with the arrival of American forces.

In the death-rattle weeks of the Third Reich, some of the factory’s machinery had been despatched to the Longwy mineshafts on the Belgium–Luxembourg border. Fortunately, the chief inspector at the KdF plant managed to persuade Ferdinand Porsche to stop this practice and simply hide equipment in the township or the factory itself. Other items were stored locally and these included front ends and steering parts, which were stored in the village of Fallersleben, and engines, which were taken to a potato dehydration plant at Neinfort. Had everything been shipped off to Longwy, the factory would have been devoid of machine tools, making it impossible to restart vehicle production.

Closer still to the end of the war, the acting Mayor of KdF-Stadt was informed by factory personnel that they had been instructed to blow up the power station and the canal bridges. Fortunately, the Mayor’s protests that the generators were essential as the town’s only source of electricity were heeded. This action was another decisive factor in the factory’s post-war survival story.

Although it was the Americans who ‘rescued’ the factory and associated township, both Fallersleben and the now unnamed plant lay in the British Zone of Occupation. During May 1945, the Americans gradually handed it over to the British. A survey of the damaged factory revealed that the parts of it left unscathed after bombing raids had been looted, while the cellars were flooded thanks to a combination of bomb craters and cracked foundations. In total, nearly 55 per cent of the factory was affected to some degree by Allied action, with 20.2 per cent totally destroyed, 13.6 per cent heavily damaged and the remainder – 20.9 per cent – having suffered relatively superficial harm. However, thanks to the Mayor, the power station remained operational. A unit of the Royal Electrical and Mechanical Engineers (REME) was despatched to the former KdF factory, where it set up a repair facility for British army vehicles. In August 1945 a Yorkshireman, Major Ivan Hirst, was sent to the factory with no specific orders other than to take control. Nevertheless, the days of a nameless plant with no purpose were over – the factory and surrounding township became Wolfsburg.

Major Ivan Hirst, who was Senior Resident British Officer from August 1945 and, despite his personal modesty, the man generally credited as the driving force behind the Beetle’s reincarnation after the war.

THE FACTORY’S FATE

After the war the German armaments industry was to be completely dismantled and any building associated with such deeds demolished, while all countries that had been at war against Germany could bid for both machine tools and capital equipment as war reparations. The Volkswagen factory, despite its involvement in war work – particularly ‘V’ weapon development and production – was accepted as a building genuinely constructed for the purpose of manufacturing cars and thus spared demolition. However, a complication arose, as under the ‘Level of Industry Plan for Germany’any factory not operational in 1938 was deemed to have been built as part of Germany’s war effort and therefore surplus to requirements. Quotas had been set for each zone of occupation and vehicle production in the British zone was entirely taken care of by Ford. As a result, Wolfsburg was subject to war reparations.

Regarding ownership, Volkswagenwerk GmbH was wholly owned by the German Labour Front, itself an integral part of the Nazi Party, which had been abolished in its entirety by the Allies immediately upon Germany’s surrender. Officially ownerless, nevertheless the factory still existed as a private limited company in law and was therefore brought within the Control Branch of the Control Commission Finance Division.

From this very shaky position, Hirst and his colleagues set in place a course of action that saved both the factory and the Beetle, whilst sowing the seeds for what was to become a hallmark of post-war Germany’s economic revival.

NECESSARY TRANSPORT

Before the war, Colonel Michael McEvoy, who was based at Rhine Army headquarters, had ‘road-tested’ the KdF-Wagen at the Berlin Motor Show of 1939. Suitably impressed then, he now had the idea of resurrecting the wartime military version of the car, as much needed transport for the occupying forces, but without cost to the British taxpayer or economy.

McEvoy’s idea came to nothing due to a deal struck by Ferdinand Porsche in 1938. While on a visit to the United States, Porsche had met with the Budd Corporation and acquired the rights to manufacture the all-steel body of the KdF-Wagen using Budd techniques under licence. In return, it was agreed that should the Volkswagenwerk produce a new variation on the KdF-Wagen saloon theme – at the time assumed to be a Cabriolet – the Ambi Budd factory in Berlin would build the bodies. As a result, when the first variation proved to be the military usage Kübelwagen, it was this vehicle’s body that was manufactured in Berlin. By the end of the war, the Ambi Budd factory had suffered so much bomb damage that only a few Kübel dies remained; also, in the division of Germany by the Allies, it was situated in the non-cooperative Soviet sector of the city. Clearly, there was no realistic chance of resuming Kübel production in any shape or form.

Ivan Hirst turned his attention to the saloon, a wartime example of which was found at the factory awaiting repair. He had the car refurbished and painted khaki before despatching it to Rhine Army headquarters, where McEvoy demonstrated the Beetle with consummate skill. The positive reaction was such that in September 1945 the Military Government placed an order for 20,000 such cars, all for the armed forces or official usage. Manufacture started in late 1945 with a recorded 1,785 cars – many of which utilized the Kübelwagen’s chassis – being successfully produced by the end of the year in the most adverse conditions. Apart from factors like a missing press-shop roof and the lack of a consistent supply of parts and components, persons key to the operation were regularly dismissed, as their former affiliations to the Nazis became known.

A total of 10,020 Beetles left Wolfsburg in 1946 – a figure still short of the Government’s initial order, but there was nevertheless due celebration when the ten-thousandth Beetle to be produced under British custodianship emerged on 14 October of the same year. Ivan Hirst loved to recall those early post-war days at Wolfsburg. One of his recollections serves to show the inbuilt ingenuity he carried to overcome all obstacles to production. At one stage, only three weeks’ stock of carburettors remained. As Pierburg in Berlin made these under licence from Solex, it was apparent that no further stocks would be forthcoming for some time. Hirst stripped one of the remaining carburettors down, dividing the parts into those that might be manufactured within the Wolfsburg complex and those that couldn’t. He then proceeded to enlist the services of a camera firm in nearby Brunswick to make the precision parts in brass.

REJECTION LEADING TO GREATER THINGS

Country after country turned down both Wolfsburg and its ‘ugly and noisy’car as an option to advance their own motoring aspirations. Henry Ford II, for example, saw the proximity of the plant to the Russian Zone on a map and immediately rescinded his declared interest, while the Australian Reparations Commission was deterred from transferring the plant in its entirety to Australia when it learned of the four-year reserve placed upon it. Britain’s Society of Motor Manufacturers and Traders meanwhile commissioned a series of technical assessments, which not only were considerably less than complimentary regarding the Beetle’s assets, but also led to calls for the factory to be broken up. William Rootes – perhaps the most condemnatory of all – advised Hirst on a visit to the factory that,‘if you think you are going to get cars made here, you are a bloody fool!’

Hirst and his team persisted, introducing, for example, a service and parts manual for the car, while painstakingly endeavouring to rectify defects and improve quality. As 1947 progressed it became increasingly obvious that, despite its detractors, the Beetle had a future. Orders continued to grow, while the first tentative steps were taken to export the Beetle.

However, as the threat of war reparations began to disappear and other obstacles diminished, the reality of Hirst’s position became increasingly evident. It was not and never had been the intention that the British would manage the Volkswagen plant on a long-term basis. The German custodian, Hermann Munch, was a Berlin lawyer with little experience in any relevant field. Someone with an appropriate knowledge had to be found not only to take charge, but also to drive Volkswagen forwards. That man turned out to be an ex-Opel man, one Heinz Nordhoff.

3

the Nordhoff years

Nordhoff with the one-millionth Beetle,5 August 1955.

Heinz Nordhoff, Director General 1948–68.

INTERPRETING HISTORY

For many years now, it has been fashionable to criticize Volkswagen’s Director General of twenty years’ standing, Heinz Nordhoff (1948–68), as a blinkered individual obsessed by one car to the detriment of the company’s long-term well-being. Recent literature produced by Volkswagen’s ‘Corporate History Department’ serves to perpetuate this view of the company’s progress as the 1950s merged into the following decade. Writing of the situation at the time of Nordhoff’s death in April 1968, Volkswagen’s designated historian, Markus Lupa, felt honour-bound to declare that ‘VW’s main competitive advantage – the mass production of one model – now threatened to become an ominous disadvantage’. While acknowledging that Nordhoff had grown the business from a mere trifle to a position at ‘the pinnacle of the European automobile industry’, Lupa considered that ‘far-reaching changes were necessary … in order to maintain this position’. The clear implication is that the corporate line remains one of condemning Nordhoff for not replacing the Beetle part-way through his tenure of office.

Needless to say, not all observers share the opinions expressed by Volkswagen. To some at least, Nordhoff neither perpetuated a one-model policy, nor left the company in a position requiring radical changes on his death. No other operation had so successfully penetrated worldwide markets, while the hard-headed Nordhoff – a businessman through and through – would have been the first to abandon the Beetle if there had been serious signs of it losing its vice-like grip on worldwide small car sales. The introduction of the larger saloon – the VW 1500 – at the point when production of the Beetle finally showed signs of catching up with ever-increasing demand, demonstrated prudence in satisfying customer expectations of Beetle availability and an eagerness to develop a range when the opportunity arose. The advent of a still larger family car and variant – the 411, developed in Nordhoff’s lifetime but launched after his death – further indicated his readiness to move with the times. His willingness to replace the much-loved and highly successful firstgeneration Transporter with a new and better model in the summer of 1967, at the same point as the updated Beetle was relaunched, demonstrates a lack of sentimentality for once-potent but latterly outdated products.

Without Nordhoff, just as without Porsche, Hitler and Hirst, the Beetle wouldn’t have become the world’s most popular car. Nordhoff is no misguided villain of the Volkswagen story.

Initially, Volkswagen’s publicity material relied on black and white photography. This item, dating from 1950 and produced for the home market, gives equal priority to the Export and Standard model (depicted here).

The commissioning of the highly talented artist Bernd Reuters led to stylized images of the Beetle dominating Volkswagen’s publicity for the best part of a decade. The cover and centre pages depicted here can be dated to the period between October 1952 and March 1953. Reuters highlights all the improvements made to Beetles produced in the last months of the split rear screen with simple sketches.

NORDHOFF’S APPOINTMENT AND BACKGROUND

Nordhoff was born in 1899. His first job after completing his studies at Berlin Technical College was as an aero-engine designer at BMW. Three years later, in 1930, he joined Opel, which had recently been acquired by General Motors. His potential acknowledged, he was despatched to the USA to discover Detroit’s approach to production techniques. In 1936 he became a Director at Opel, while during the war he was put in charge of the company’s Brandenburg lorry factory, which was the largest in Europe at the time. Although never a supporter of the Nazi cause, for his services to the Reich he was awarded the minor honour of Wehwirtschaftsführer, the result of which was to make him unemployable in the US-controlled and Opel-based sector after the war. His only remaining option was to manage a small garage and repair shop, courtesy of the widow of a friend who owned an Opel dealership.

It was from this position that Nordhoff joined Volkswagen. While it has already been stated that the British needed someone capable of running Volkswagen on a long-term basis, the circumstances of Nordhoff’s appointment need clarification. The factory’s German custodian, Hermann Munch, did not have an industry background and this often caused Ivan Hirst and his colleagues additional problems. Hirst spoke to his superior officer, Colonel Radclyffe, making a good case for the appointment of an experienced number two to Munch. Through a contact in Hamburg, Hirst learnt of Nordhoff. Invited to Wolfsburg, Nordhoff so impressed Hirst that according to legend he was unable to ‘recommend’ the German for the job he had been interviewed for, resulting in Nordhoff packing his bags and making to depart. After a suitable pause, Hirst informed Nordhoff that he was proposing him for the position of Director General. Nordhoff started work on 1 January 1948, with Munch departing on 30 April of the same year. Hirst’s role changed too, as his main purpose in the remaining time he spent at Wolfsburg was simply to monitor Nordhoff’s performance and to serve as a fallback should the new Director General have to leave due to political pressures. As for Nordhoff, his only stipulation before agreeing to join Volkswagen was that he would not tolerate any interference. Again, legend has it that the question was asked whether this included the British, to which the reply was that it meant the British first of all.

From 1953–57 most brochures featured this illustration on their covers. Inside, Reuters modernized his images, as changes were made to the cars, while also varying the paintwork colour from year to year.

The cover of this brochure dating from 1959 reveals a classic Reuters ploy. The occupants of the car are smaller than reality, giving the impression that the Beetle is particularly spacious and comfortable.

NORDHOFF AND THE BEETLE

Although loosely involved with the early Beetle prototypes before the war – thanks to his position as an Opel delegate with the RDA – Nordhoff had never set foot in Wolfsburg, nor driven a Beetle before his appointment as Director General and was startled to discover that the Volkswagen had ‘more flaws than a dog has fleas’. Apart from its ugly duckling appearance, the car was both noisy and badly sprung, while the upholstery and paint finish left much to be desired. Crucially, engine life was unacceptably short.

However, the Director General, who spent the first six months of his appointment camped in a room adjacent to his office, in order that he could devote all his attentions to the matters in hand, was soon talking of ‘unlimited possibilities’ and the ‘special personality’ of the car. The Beetle, he believed, ‘had definite features which were greatly desirable and not found in cars of comparable size’.

Nordhoff openly stated that it was his ‘life’s aim to make this plant [Wolfsburg] into the greatest car factory in Europe’. His strategy to build his empire was three-fold: to make Beetle production not just financially viable but suitably profitable; to create a value-for-money product of the highest possible standard backed by first-class spares plus service facilities; and to generate the necessary income to be capable of becoming the symbol of Germany’s post-war economic success through exports.

Of immediate concern was the number of hours – some 300 to 400 in total, nobody was quite sure – it took to build each car. Speaking in November 1958, Nordhoff reminded his audience that he:

had to start from scratch in the real sense of the word. 7,000 workers were painfully producing at the rate of a mere 6,000 cars a year – provided it did not rain too much. Most of the roof and all the windows of the factory had been destroyed. At this time, nearly three years after the end of the war, 109.6 men were required to produce one car per day. Today this figure is 17.9.

Addressing the workforce just two months after he joined Volkswagen, Nordhoff insisted that,‘if we continue in this manner, we shall not continue for long. We must reach 100 hours per car’. Despite the initial reaction, which consisted of a mixture of incredulity and negativity, the workers reacted to the new spirit of urgency. By 1955, it took less than Nordhoff’s goal of 100 hours to build a Beetle, while with unstoppable drive he had set in motion the process of increasing daily production as early as mid-1949. The decree went out that 200 cars – compared to the previous 100 – would be built per day.

To Nordhoff’s dismay, there was no cost-accounting system in place under the British. Not only were the costs of building a single Beetle unknown, but also it was apparent that one car might easily have cost considerably more or less than those immediately preceding or following it. Nordhoff quickly rectified this situation.

Of equal importance to both man-hours and cost was the issue of service. Hirst and the British had instigated a policy of both issuing maintenance guidelines and providing spares. Nordhoff turned both aspects into legends of the car-manufacturing world. Otto Höhne, once production chief at Volkswagen and a member of its Vorstand, credited Nordhoff with surveying world markets and planning a global service organization.‘No one had even thought that way before’, he added. As for quality, the Director General appreciated that if the Beetle was to earn much-needed revenue from markets other than the home one, what was acceptable to a car-starved Germany would not be to the inhabitants of many other countries.

Compare Reuters’ image of the Cabriolet here with the white car reproduced on page 117 – a classic instance of reusing, or freshening, an illustration by giving both car and occupants a careful makeover. This brochure dates from 1960. Note, for example, how the sun visors have been revised in this, the later of the two publications.

Few brochures depict the rear end of a car, but Reuters was keen to remind would-be purchasers that, with effect from August 1957, the Beetle’s rear window had grown considerably in size. This brochure cover is more often seen featuring a red Beetle.

‘A FAVOURITE IN 136 COUNTRIES’

Come July 1949, an Export, or Deluxe, version of the Beetle was introduced, with production having started at the beginning of the previous month. Initially mechanically identical to the Beetle of old – a car now referred to as the Standard – the Export model featured a more upmarket trim package epitomized by ivory-coloured rather than black fittings, chrome replacing painted metal and, perhaps trivially, rear-seat bolster cushions.

The purpose of the Export model was exactly what it said on the label and Nordhoff was nothing if not persistent. His repeated attempts to penetrate the vast American market are recorded elsewhere in this volume, as are the eventual setting up of Beetle manufacturing and assembly satellites around the world. Key markets would include Brazil, South Africa, New Zealand, Australia and Mexico, plus inevitably every country in Europe, including the home of the small car – Great Britain.

Nordhoff’s additional initial motive for export sales was to counteract the worst of a German winter, which was a time of low domestic market sales due to adverse weather conditions. His workforce was to be at maximum capacity at all times.

Out of the daily output of 1,280 Beetles produced in 1955, 700 were destined for export, while 400,000 of the million Beetles in existence by this time were in use in 103 countries in addition to the home market. With further expansion, a key marketing line for the Beetle in the 1960s came in the form of a question: ‘Why is the Volkswagen a favourite in 136 countries? Because …’.

THE FIRST MILLION

The production survey contained in Chapter Four highlights the arrival of the millionth Beetle on 5 August 1955. This was an elaborate gold-painted affair, complete with diamante-encrusted bumpers. Although there had been celebrations when the five-hundred-thousandth car rolled off the assembly line and would be again for the second, third and so on millionth vehicles – none would compare with the occasion of the first. Over 140,000 people attended the lengthy celebrations, including 1,000 international motoring journalists, one of whom was Bill Boddy, a British motoring writer, well-known for his passion at the time for the Beetle. Although perhaps the single most important event was the awarding of Nordhoff with Federal Germany’s Distinguished Services Cross with Star and the Freedom of the City of Wolfsburg, for Beetle watchers, Boddy included, it was the Director General’s speech that was of most interest.

If there had been any doubt about Nordhoff’s passion for the product before, there could not be any longer. He reminded his audience that in 1948 there had been forty Beetle distributors in Germany and one abroad. By 1955 this had mushroomed to 1,000 in the home country and an astonishing 2,800 abroad. Nordhoff said that he could claim the best sales and service in Europe and no feeling of inferiority when compared to organizations of a similar nature in America.

A typical Beetle dating from the period before the introduction of the Export model.

This Maroon Red (L55) Export model dates from 1952, but was built before October of that year, as evidenced by the lack of trim inserts around the windows and by the grooved bumper.