28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

The scope and potential of mouldmaking and casting is fascinating, and makes it one of the most exciting processes available to today's craftsmen. Its opportunities have been developed and expanded further by a range of new methods and materials only recently made available to the domestic market.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 234

Veröffentlichungsjahr: 2013

Ähnliche

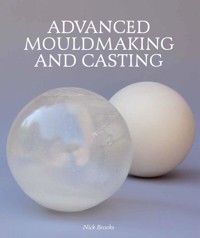

Embedded polyester resin.

ADVANCED MOULDMAKING AND CASTING

Nick Brooks

First published in 2011 by The Crowood Press Ltd Ramsbury, Marlborough Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2013

© Nick Brooks 2011

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 723 6

Disclaimer

The author and publisher do not accept any responsibility in any manner whatsoever for any error or omission, or any loss, damage, injury, adverse outcome, or liability of any kind incurred as a result of the use of any of the information contained in this book, or reliance upon it

DEDICATION

To Linki and Jake

CONTENTS

Foreword by Ken Adams

Introduction

1 Multiple-Piece ‘Cored’ Silicone Rubber

2 Plas-ti-shim™

3 Large-Scale Press Moulding on Site

4 Life Moulding Silicone

5 Jesmonite™ Multiple Piece

6 Clay Slip Moulding and Casting

7 Jesmonite™

8 Polyurethane Resins and Expanding Foam

9 Bioresin®

10 Embedding in Clear Resin

11 Silicone Rubber

12 Slush Casting

13 Multiple-Piece Casting

14 Finishing

Manufacturers and suppliers

Acknowledgements

Index

FOREWORD

What is the purpose of moulds and casts? And why does the Royal Academy of Arts mount an exhibition of Modern British Sculpture using in its poster a detail of an exact replica over 2 metres square of part of Olaf Street in London, made by the Boyle Family in 1966?

By making moulds and casting from them a unique and new form can be transformed in its material. A more durable or more beautiful or more expressively appropriate material is substituted for the original material, which was in its time appropriate for the discovery of the form. This is the use of making moulds and casting in the origination of an individual work of art.

Alternatively, a form recognized as valuable can be produced en masse, as a multiple, as we call works of art that no longer rely on their uniqueness to gain prestige. The same process is used in industries that make useful objects, indistinguishable from each other. The 100,000,000 sunflower seeds in the installation Sunflower Seeds by Ai Weiwei at Tate Modern in 2010 must set a record for quantity cast. It also set a record for the individuation of multiples. Each cast was finished and coloured by hand, and it may be said that no two are identical. The unique also remains important in utilitarian productions, as millions of ‘crowned’ teeth in the mouths of old people can testify.

The reproduction of objects mirrors biological reproduction itself. Humanity, instinct with a sense of its own value, has the urge to reproduce sexually. The same urge goes back billions of years to the earliest form of life. From its beginning, society created what we now call works of art, as religious objects for use in ritual. An artist was required to conform to a traditional mode of representation, and religion might even require details to be incorporated that could not be seen by the worshipper. In medieval Japan statues of the Buddha were cast in lacquer. These figures sometimes hid carefully cast feet within shoes that have only been broken open by accident more recently. The combination of a liquid that sets with fibrous reinforcement was the basis of Japanese casting technique. The liquid was drawn from the lacquer tree, the fibre was hemp or cotton. The expansion of Buddhist monasticism was such that in 700CE the Emperor ordered every household to plant lacquer trees. A connection between then and now can be seen in the use of contemporary resins with glass fibre reinforcement.

Putting metal aside, with its dependence on high temperatures, clay, plaster and wax form a triumvirate of traditional materials, whose strengths and weaknesses complement each other. Things made in any of them can resist entropy. The first sculpture that Degas exhibited failed to gain critical approval. Thereafter he left in wax many wonderful works, suitable for casting in bronze. They have survived, with some disputed distortions, the best to be finally cast in a more durable ma terial. Posthumous fame has conferred similar resurrections on many pieces of sculpture by twentieth-century artists for whom recognition came late.

Around 1900CE an awareness of the interplay between positive and negative versions of the same surface developed, perhaps because of the ubiquity of moulds and casting. Abstract sculptors such as Gabo came to work with thin sheet surfaces having visual access to both sides. The language of Cubism invited sculptors such as Zadkine to integrate both within a single figure. The exchange of negative and positive was demonstrated on a grand scale by Rachel Whiteread’s House which stood at 193 Grove Road in London from 1993 to 1994. There, the mass of a wall was converted into a narrow space, and the volume of a room was converted into a solid block.

In his influential essay ’The Work of Art in the Age of Mechanical Reproduction’ (1936), Walter Benjamin wrote: ‘from a photographic negative one can make any number of prints; to ask for the ‘authentic’ print makes no sense.’ He deplored the exaggerated value placed on the uniqueness of art objects, and the mystical aura with which they were endowed. He thought that from 1900 onwards the technical means existed to free art from its roots in religious practice, free it, he hoped, to engage with the practice of politics.

In the post-modern situation a variety of aesthetic convictions exist alongside the political. Consider Brian Haw’s protest against the UK government’s policies in Iraq. From 2001 till 2006 he camped in Parliament Square. He assembled some 600 banners and other items of protest. Everything in that assemblage was reproduced by the artist Mark Wallinger, in an installation State Britain at the Duveen Galleries, Tate Britain, in 2009. In such projects as this, the skills of mould-making and casting can play a crucial role. After their Olaf Street Study in 1966, the Boyle Family went on to replicate 100 randomly chosen sites in London. From that they proceeded to a global selection of samples to represent the earth. Whatever the motives and aesthetic convictions of a sculptor, the methods of making moulds and casting from them, which are taught by Nick Brooks, and which he has described with such clarity in this book, will prove of immense value.

Ken Adams Former Senior Lecturer at St Martins College of Art and Design

INTRODUCTION

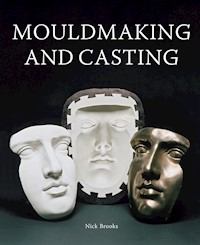

In producing Advanced Mouldmaking and Casting my aims are to provide a book that can be used both to advance levels of pre-existing skills and to introduce new techniques and materials that may not have been used previously by the reader. The content builds upon and goes beyond the fundamental techniques and principles described in the precursor to this book, Mouldmaking and Casting (The Crowood Press, 2005).

Some of the processes and materials covered are ‘traditional‘, and the reader may have had some experience of them before. Hopefully this book will address any problems encountered with these. Other processes and materials in the book are relatively new to the subject, being in use in industry but only recently available on the smaller-scale domestic market. It is hoped this book will encourage further levels of exploration and experience of the subject.

Mouldmaking and casting is, of course, not a finite process and the reader may choose to reinterpret certain processes. The options for a particular project are often multiple and varied depending on the requirements of the maker. The aesthetic, economic and timetabled requirements of the particular project in hand will all inform those options in a multitude of different ways. Having the specifications and technical practices for the processes and materials is only the foundations for a project; what the maker does with that information is what ultimately informs and inspires the work. It is hoped that this book can be a part of that process.

Multiple piece ‘cored’ silicone rubber mould.

CHAPTER ONE

MULTIPLE-PIECE ‘CORED’ SILICONE RUBBER

Creating multiple-piece ‘cored’ moulds can be quite complex to execute so the aim of this book is to cover the process in detail. Silicone rubber as a versatile and accurate mouldmaking material has been around on the domestic market for a long time and has been a key part of the generic mouldmaking process in the commercial trade for years.

From very simple blocks to highly complex multiple-piece moulds, silicone rubbers can cover almost every mould making eventuality. The ‘cored’ mould allows the mouldmaker to aspire to ever more complicated mouldmaking challenges.

The Core

The ‘core’ refers to a separate internal mould piece that cannot be reached from outside the original form being moulded. The core is supported by external mould pieces that hold it in place within the mould. To understand this fully and to proceed at this level of mouldmaking it is important to have at least an academic understanding, or preferably practical experience, of the principles of mouldmaking and casting and multiple-piece mouldmaking that are explained in the precursor to this book, Mouldmaking and Casting.

A mould core allows the mouldmaker to capture an area of difficult-to-access detail on an original that cannot be captured with other pieces. Access to this sort of area may be difficult because of undercutting into it that would not allow removal of the mould pieces, or demoulding of castings from the mould. A core may not always be strictly necessary but it can sometimes help greatly in the production of a mould and subsequent casting from it.

The necessity or usefulness of a core is best illustrated with a practical example: in this case, creating a mould from a model of a four-legged animal. If a mould were to be taken in two pieces on either side of the animal, as may seem logical, each mould piece would have the negative space of two whole legs of the animal within in them. This would work as a mould in principle, but it would make removal of the mould from the original difficult and the demoulding of a cast, in a less durable material, even more so. With the legs of an animal being much thinner than the body the mould pieces would have to be pulled down each leg and removed like a sock. On a large scale this may be practical, but on a smaller scale the removal of the mould in this way, particularly if the casting material is not very durable, may be problematic if not impossible. The answer is to create a seam down either side of each leg using one core mould piece that creates the inside leg seam of all four legs.

The core piece is created first, as one whole piece. The outside two pieces are then created over this to make the outside seam lines of the legs and the rest of the body.

This will allow the mould to be separated from either side of each leg and the core piece to be pulled away from between them. Demoulding in this way will create minimal stress on the relatively delicate leg sections of the casting.

Understanding the principles of this example will hopefully help in making decisions on the potential advantages of creating cored moulds in other mouldmaking situations. See Chapter 8 for an illustrated example of casting in this mould.

PROJECT

Specification

A three-piece silicone rubber and two-piece fibreglass case mould. From Polyurethane resin model figure of a lion on a base. Size: 320mm (L), 110mm (W) and 200mm (H).

Time Required

Approximately 7–8 hours of working time.

Materials

■ Silicone rubber (Siliastic 3495, supplied by Notcutt Ltd);

■ gel coat polyester resin (all polyester resin products supplied by Alec Tiranti Ltd);

■ general-purpose polyester resin;

■ polyester resin pigment;

■ polyester resin catalyst;

■ a heavy fibreglass mat;

■ acetone;

■ vegetable oil;

■ spray wax release agent;

■ grey clay; and

■ roofing bolts and wing nuts.

Tools

■ A modelling board;

■ dispensing and mixing containers;

■ wooden spatulas;

■ brushes (1in and ½in);

■ scissors;

■ a palette knife;

■ a craft knife;

■ wooden clay tools;

■ a rubber kidney clay tool;

■ a looped wire clay tool;

■ a clay harp;

■ disposable rubber gloves;

■ a spirit level;

■ an electric jigsaw or hacksaw blade in a holder; and

■ an electric drill.

Method

SET-UP AND PREPARATION

As with any project, careful preparation before the start of the job is crucial. Knowing the material quantities and tools needed, undertaking repairs to the original and setting-up the working area will all help to complete the job accurately and efficiently. (Tip: make sure you have enough materials to complete the job before you start. Running out of material halfway through the job is at least a waste of time and, at worst, a loss of previously executed work.)

THE MOULD CORE

The first piece of the mould to be created is the core piece, around which the other two mould pieces will be made. This is created in the space in between all four of the animal’s legs.

1. Apply a clay wall onto one side of the animal to block off the outside area of the legs on that side. Make sure the clay wall only covers the outside half of the two legs. Seal the clay wall from the outside by pinching it to the surface of the original model.

2. Ensure that the area of contact on the inside of the clay wall and the original is at right angles using a clay tool.

3. Create registration indents on the inside surface of the clay wall. This will provide ‘nipple and cup’ registration between the mould core and the outside mould piece.

4. Set the original on its side, clay wall down, on a modelling board. With a spirit level ensure that it is level between the two lowest points of the legs. (Silicone rubber will be poured into the void between the legs of the animal so it will need to rise to a ‘level’ within.)

5. Spray wax release agent within the core space.

6. Mix a batch of silicone and pour it into the core space to a midway line on the outside of the top two legs.

7. Allow to set fully.

8. With a small mix of silicone, stick pre-set and cut registration blocks on the top surface of the core. This will provide registration of the core into the other outside mould piece.

Original model.

The first wall is placed to define the ‘core’.

A clean perpendicular join is created on the inside of the wall.

Registration indents are applied.

A level is set across the legs.

The liquid silicone core is poured.

The set core, showing registration indents.

The set core, showing registration blocks.

A clay bed and top slap are created.

A registration ‘pinch line’ is cut.

The first silicone coat is applied and allowed to set.

A thixotropic coat is applied, allowed to set and registration dovetails are cut.

A polyester resin and fibreglass case is created.

The mould is flipped ready for the second half of the mould to be made.

The second silicone half is created.

The two outside mould pieces are removed to reveal the core inside.

THE CLAY BED

With the mould core created, the first side mould piece enclosing it can be made. A clay bed needs to be created to build to a midway point around the original.

1. Define where the midway point surrounding the original is and mark it or commit it to memory.

2. With small pieces of clay build up a rough clay bed to within 10mm of the division line.

3. Smooth the top surface.

4. Using a clay harp set at 10mm, cut a slab of clay.

5. Roughly cut to shape and place it on top of the rough clay bed.

6. With a clay tool make the connection of the clay bed and the division line around the original. Ensure that the point of connection between the clay bed and the original is at a right angle.

7. Smooth the surface of the clay bed with a rubber kidney clay tool. Use vegetable oil to allow the kidney to smooth the surface without dragging.

8. Using a looped wire clay tool, create a pinch line in the clay bed around the original 10–15mm out from the point of connection with the clay bed.

9. Because the model has a base the mould will need to encompass this. Secure a board against the underside of the base so the mould can be created around it.

10. Apply spray release agent to exposed surfaces of the core, original and board against the base.

THE FIRST SIDE MOULD PIECE AND CASE

The next task is to create the first side mould piece against the exposed area of the mould core and exposed half of the original using the brushable thixotropic silicone paste method and fibreglass case methods (see Mouldmaking and Casting for details).

1. Apply wax spray release agent to the exposed clay bed.

2. Paint on silicone detail coat and allow it to set fully.

3. Lay up the thixotropic coat to mould thickness and allow it to set fully.

4. Cut registration ‘dovetails’ around the silicone extending on to the clay bed. This will register the silicone into the fibreglass case.

5. Create the fibreglass case to support the silicone. Allow it to set fully.

THE SECOND SIDE MOULD PIECE AND CASE

1. Remove the board against the base of the original.

2. Keeping the previously created core, mould piece and case and the original together, carefully flip the whole mould over to reveal the second side of the original.

3. The second side of the original and mould core can now be seen sitting within the first side mould piece and case.

4. Remove the clay bed and mould core clay wall.

5. Carefully clean any clay debris off the exposed original, mould core and exposed flange of the first side mould piece with a sponge. Ensure all surfaces are dry.

6. Reset the board against base of the original.

7. Apply spray wax release agent to all surfaces.

8. Create the second side silicone piece and supporting fibreglass case as above.

TRIMMING, DRILLING AND OPENING THE MOULD

Now the mould is complete it can be trimmed, drilled and opened.

1. Remove the board against the base of the original.

2. With an electric jigsaw or hacksaw blade in a holder trim approximately 10mm off the outside edge of the fibreglass case flange. This is to remove the rough edge of the case flanges to a good edge and expose the seam line between the pieces of the case.

3. Trim the case flange around the opening of the mould in the same way.

4. Sand the surface of the fibreglass case for safe handling.

5. Drill 6.5mm holes at 40–50mm intervals, approximately 20mm out from the original around the case flange. These will accommodate M6 nuts and bolts to secure the mould pieces together.

6. Introduce a thin blade knife between the two case pieces and separate them.

7. Remove the case pieces from the silicone and peel away the two outside silicone mould pieces from the original. Sometimes the case including the silicone will come away in one operation.

8. Carefully remove the mould core from the original. There will be an ‘easy’ direction to pull the mould core away from the original, depending upon the position of the legs.

9. With the mould removed, all pieces can be washed, dried and reassembled with the nuts and bolts ready for use.

10. When reassembling first secure both side pieces of silicone into their supporting cases. Next secure the mould core into one of the side pieces. Lastly secure the second side piece.

11. When tightening nuts and bolts secure them in opposite pairs in sequence a little at a time until firm. This will ensure the seam line of the mould is secured evenly all round and not squeezed tighter at one point.

12. Do not over-tighten the nuts and bolts as it may distort the core inside and compromise the seam lines.

Silicone rubber mould created using ‘Plas-ti-shim’ system.

CHAPTER TWO

PLAS-TI-SHIM™

Developed by Andrew Sinclair in 2004 and marketed in 2008, Plas-ti-shim™ is a prefabricated plastic shim system of silicone production mouldmaking. The system has some distinct advantages over traditional silicone mouldmaking methods, namely the single application of silicone rubber in multiple-piece mould production. As Sinclair explains in his technical information leaflet on Plas-ti-shim, ‘The main motivation behind it was the obvious disadvantages and shortcomings of clay walls which to me as a commercial moulder were so frustrating especially on large or complicated moulds.’

Technical Description and Specifications

The Plas-ti-shim system comprises a set of prefabricated thin plastic shim walls with vacuum-formed registration bubbles set at regular intervals along them and a set of prefabricated plaster registration buttons (Little Buddie™).

The Plasti-shim walls, available in various sizes, are used to create mould division walls traditionally created with clay walls or beds. However, unlike traditional methods of multiple-piece mouldmaking the application of silicone rubber is performed in one operation and the separation of the pieces is carried out at the last stage of production. This system clearly has advantages, particularly with dramatic time savings on production.

The ‘Little Buddies’ are pre-made plaster buttons that are used to produce registration pockets for the case material. The Plas-ti-shim walls and Little Buddies can be used over and over again, with obvious cost-cutting advantages over clay wall systems.

The first stage of production is an application of a single coat of catalyzed silicone rubber over the entire original or pattern to be moulded. This coat is allowed to set and captures all original detail in one operation. Mould divisions are then determined and set out using a piped raised bead of very thixotropic silicone on top of the first coat. The piping process is carried out using a bag in the same way as for cake decorating. While the bead is still unset, Plas-ti-shim walls are set into it to form the mould divisions. The rest of the mould is then produced on either side of the shims as usual, using thixotropic silicone layers and backed up with a rigid case. On demoulding of the silicone the Plas-ti-shims are removed and the silicone is cut to separate the individual mould pieces.

The first stages of a Plas-ti-shim moulding a figure (H: 800mm).

PROJECT

Specification

A two-piece silicone rubber and polyester resin and fibreglass case mould. Taken from a plaster copy of the Kouros of Anaphe (510–50BC). Size: 1010mm (H) and 390mm (W).

Time Required

Allowing for setting times this project can be carried out over approximately two and a half days.

Materials

■ Plas-ti-shim (large);

■ Little Buddies;

■ magic tape;

■ Silastic™ 3495 condensation cure silicone rubber (supplied by Notcutt Ltd);

■ polyester resin gelcoat;

■ general-purpose polyester resin;

■ fibreglass mat (supplied by Alec Tiranti Ltd);

■ Fillite®;

■ spray wax release agent;

■ acetone;

■ white spirit;

■ reinforcing bars; and

■ M6 × 30mm roofing bolts with wing nuts.

Tools

■ Mixing beakers;

■ digital scales;

■ brushes;

■ a palette knife;

■ scissors;

■ a craft knife;

■ a drill; and

■ disposable gloves.

Method

SET-UP AND PREPARATION

As with any project, careful preparation before the start of the job is crucial. Knowing the material quantities and tools needed, undertaking repairs to the original and setting-up the working area will all help to complete the job accurately and efficiently. (Tip: make sure you have enough materials to complete the job before you start. Running out of material halfway through the job is at least a waste of time and, at worst, a loss of previously executed work.)

1. Ensure the original is set on a secure work surface and any surface repairs are done. In this case some minor cracks and missing pieces are filled and remodelled in clay as a temporary repair before making the mould.

2. Ensure any gap between the base of the original and the work surface is filled with clay.

3. Apply spray wax release agent all over the original and out by approximately 100mm around the base onto the work surface.

THE FIRST COAT OF SILICONE

This first coat is crucial as it is the ‘capture’ layer of all the original detail. With the Plas-ti-shim system this can be done in one operation from the outset of mouldmaking.

1. Mix batches of silicone and catalyst to their specifications.

2. Apply with a soft brush methodically and evenly over the whole surface of the original. Start at the bottom and work up to avoid drips. This coat will be very runny as it does not contain thixotropic additive. This allows the silicone to pick up all the detail of the original. It will probably only be about 1mm thick.

3. The coat should be allowed to set thoroughly. Use of an extra fast catalyst will allow you to proceed to the next step more quickly.

THE APPLICATION OF DIVISION LINES

1. Create a piping bag using a strong but flexible plastic bag. The plastic bag should be about A4 size and without a folded seam.

2. Cut off a corner of the bag with scissors, creating a hole approx 8mm in diameter. This will determine the size of the bead of silicone delivered, so on a smaller mould it may need to be smaller.

3. Determine where the seam lines of the mould are to run. (This is a matter of mouldmaking principles as explained in the precursor to this book, Mouldmaking and Casting.) The lines can either be drawn onto the set silicone first coat with a water-based marker for guidance or committed to memory.

4. Mix a batch of silicone with catalyst and a very high percentage of thixotropic additive. The silicone bead needs to support the Plas-ti-shim wall so it needs to be very thixotropic.

5. Half fill the bag and twist up the top to work the silicone down into the corner of it and out of the hole.

6. Keeping pressure on the bag by squeezing it evenly, deliver a regular bead of silicone along all the seam division lines.

The original is cleaned and surface repairs done, ready for moulding.

The first layer of silicone is applied, bottom to top.

The first coat will necessarily be thin and capture the detail of the original.

A thixotropic bead of silicone is piped along the division line of the mould.

Plas-ti-shim is set into the bead of silicone while still unset. Tape is used to join overlapping pieces.

The Plas-ti-shim wall is complete.

A layer of silicone is applied over the shim and bead.

Thixotropic silicone is applied around the set Little Buddy.

Little Buddies are removed to produce registration holes into which the mould case can locate.

The Little Buddy holes are filled with thixotropic polyester resin.

The last millimetre of silicone between the two silicone flanges is cut to separate the two mould pieces.

Reinforcing metal splints for added strength are built into the case.

The mould is trimmed, sanded and nuts and bolts are set to secure the mould pieces together.

The two-piece silicone rubber and fibreglass case mould.

APPLICATION OF THE PLAS-TI-SHIM WALLS

Once the division beads have been created the Plas-ti-shim walls need to be applied while the silicone is still wet.