23,99 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

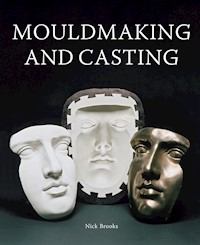

Mouldmaking and Casting is a technical manual of the many techniques of this ancient craft and art form. With step-by-step illustrations, it explains the materials required and the processes involved to create reproductions of a range of pieces. The book covers traditional techniques as well as today's more advanced technical methods.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 345

Veröffentlichungsjahr: 2013

Ähnliche

MOULDMAKING AND CASTING

Nick Brooks

First published in 2005 by The Crowood Press Ltd Ramsbury, Marlborough Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2014

This impression 2010

© Nick Brooks 2005

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 730 4

Dedication

To Clementine and Talia, my best work ever.

Acknowledgements

Clementine, Talia and Dan for technical assistance.

Clive and Diana.

Jack Ludlum (www.londonpaparazzi.com) for photographic contributions.

Simon and Anna Cooley for sculpting and modelling clay portrait head in Chapter 4.

Tony Lall-Chopra and Sabine Heitz for mouldmaking and modelling in Chapter 9.

Central Saint Martins' staff for encouragement and support.

Norman Balon for C&H services.

Brendan and Vicki.

Buzzcocks for broken ankle.

Praveera for being there at the beginning.

Alec Tiranti Limited - Sculptors' tools, materials and equipment, established 1895, for supply of all mouldmaking and casting materials used in producing this book.

Disclaimer

Safety is of the utmost importance in every aspect of mouldmaking and casting work. When using tools and/or chemicals, always closely follow the manufacturer's recommended procedures. The author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

CONTENTS

Preface

1 HISTORY

2 MOULDMAKING AND CASTING PRINCIPLES

3 RELEASE AGENTS

4 PLASTER MOULDS

5 PRESS MOULDS

6 SILICONE MOULDS

7 VINYL MOULDS

8 FIBREGLASS MOULDS

9 LIFE MOULDS

10 PLASTER CASTING

11 POLYESTER RESINS AND FIBREGLASS CASTING

12 CIMENT FONDU CASTING

13 WAX CASTING

14 ALTERNATIVE AND ADDITIONAL MOULDMAKING AND CASTING IDEAS

Manufacturers and suppliers

Index

'Leaf'. By Antigoni Pasidi. Silicone rubber, life-size.

PREFACE

I have taught and practised mouldmaking and casting techniques and processes for many years, and have been encouraged to write something on the subject many times. It is not an easy subject to put into the written word - the multiple possibilities and unique requirements of any individual project potentially present as many multiple alternative possibilities. However, there are a number of fundamental techniques that can be taught; these represent a starting point for anyone interested in the subject, and can then be adapted, combined and even potentially 'reinvented' to an individual project (there are few 'rules'!).

When considering this project, I came to the conclusion that the main requirement was for a book that would explain and illustrate the principal techniques and processes. These techniques and processes may be covered elsewhere individually, but are seldom to be found combined in the one book. I have learnt many of the techniques and principles contained here formally but then adapted them over the years. In my opinion, this is the purpose of any acquisition of knowledge, to make it one's own.

Whether you use this book as an introduction to a new subject or to further existing knowledge, I hope you will find the creative scope that mouldmaking and casting offers as exciting and fulfilling as I have and do.

Nick Brooks

'Augustus'. Ancient Roman emperor. By Nick Brooks. Cold-cast resin bronze. H 27cm, W 17cm, D 10cm.

CHAPTER 1

HISTORY

The Beginning of Mouldmaking

Long before humans walked the Earth, countless species of animals stamped their footprints in the mud. Fossilization has turned some of these footprints into moulds from which present-day anthropologists, using modern plastics, are able to make casts for scientific records and museum exhibits. The Earth itself was therefore the first mould.

To recreate the visual world in three dimensions was an astonishing cognitive leap for humanity. Many creation myths name clay as the material from which gods or goddesses made the first humans and animals. We know that Upper Palaeolithic hunter-gatherers made small, portable human and animal figurines, usually of ivory, stone, bone or clay. One of the earliest known baked clay sculptures, the 26,000-year-old Venus figurine found at Dolni Vestonice in Moravia, shows that clay was fired at an early date.

The ritual burial of objects of cult significance, often in the form of small animal and human figurines, has occurred in almost every culture throughout the world. The Ancient Egyptian Ushabti figures, the remarkable figures from the island necropolis of Jaiana of the classical Mayan period (AD700-800) and the more recent painted terracotta Mexican sculpture are some examples. The urge to make the 'one' into the 'many' has long inspired humanity to replicate those objects found to be beautiful or useful. A proficiency in sculptural mouldmaking generally appeared in societies where organized religion or burial customs required votive images, symbolic objects as offerings to the gods and tomb figures to be buried with the dead. Initially these were handmade by the women or shaman of the tribe, but with the coming of more formalized religious practices the demand for repeated designs increased and as a result various techniques of moulding were used to speed up the output. In many cases, moulding was used in conjunction with hand modelling of faces, hands and other details so as to individualize each figure. The craft became specialized, often resulting in a high degree of artistic production.

An example of such a sequence of events, spanning many centuries, can be seen in China, where an impressive Neolithic ceramic tradition paved the way for the unparalleled skill in moulding of the Shang Dynasty (1523-1 027BC). Human sacrifice originally played a prominent part in burial traditions, but when the practice was outlawed tomb figures were required in large numbers as symbolic substitutes. The most famous example in China is the terracotta army of Shih Huang Ti at Xian, C.200BC, in which the trunks are moulded but no two faces are the same. The beautifully expressive terracotta Tang figures of around the eighth century AD were perhaps the ultimate artistic achievement in the production of tomb figures. For these, both press moulds and multiple moulds were used, with the figures and animals being finished by hand modelling and the use of richly coloured glazes. The same techniques were used for other sculpture intended to provide inspiration for the living. The larger-than-lifesize Lohan Buddhas of the tenth to thirteenth centuries AD were possibly moulded from an admired original, then individualized by modelling before being fired, often in one piece - an impressive feat for such a large statue.

The discovery of new materials ensured the continued development of ceramic techniques. Around the fourth century AD the Chinese invented stoneware, and by the eighth century porcelain had been perfected. A wide variety of techniques again combined moulding with modelling to produce porcelain statuettes for domestic shrines. These figures in white porcelain, which came to be known in Europe as blanc de chine, were among the most prized works of Eastern art in Europe in the early eighteenth century. Copies of small figures of the Buddhist Bodhisattva Gwanyin were amongst the earliest works sold by the Royal Saxon Porcelain Manufactory at Meissen.

The ceramic traditions of China, though rarely surpassed, had impressive parallels in ancient Mediterranean civilizations. In seventh century BC Greece the growing importance of sanctuaries such as Delphi and Olympia created an increasing demand for votive offerings. When the small figurines originally made for votive offerings became a popular secular genre it was necessary to speed up production. At first, just details or parts were stamped or press moulded; next, use of a two-part mould enabled the front and back to be moulded separately and joined with slip to form a rounded image. Finally, the use of multi-part press moulds meant that the parts could be assembled when the clay was leather hard in any variety of poses and gestures. The koroplasts who made the patterns were not only fine craftsmen but truly creative artists as well who could demand high prices for their work. Both finished figures and moulds were exported widely around the Mediterranean area.

Press Moulding

The more practical uses of casting and moulding also date back many thousands of years. Stamp seals carved in intaglio and impressed on clay have been dated from C.7000BC. These were the origin of the use of a positive and a negative. By the late fourth millennium BC Sumerians were using cylinder seals, and the seal cutter, or purkullu, was a high-ranking professional craftsman who had to complete a four-year apprenticeship. The subjects depicted on seals have proved a mine of information for historians. Seals were put to many uses. Ownership could be established, property could be marked. Clay-stamped ropes were used to seal the doors of storage areas. Seals were also amulets and had a magical as well as a practical purpose. They were used in rituals for symbolic sealing. Figures of pregnant women were 'sealed' to ensure the safety of the unborn child, and clay tongues or lips were 'sealed' to indicate the need for secrecy. The legal and administrative use of the seal extends to this day.

The use of clay to make pottery vessels appears at widely varying times in different parts of the world, but generally coincides with the abandonment of the Palaeolithic hunter-gatherer culture for a more settled agricultural lifestyle. Neolithic people caulked their baskets with clay to store grain, and so the burning of discarded baskets may have led to the development of the moulding and firing of pottery vessels. Large shells and skulls served as moulds for smaller clay vessels. Pottery fragments with pressed cord decorations at later settlements in Jarma and Jericho (7000BC) suggest an early link between clay with the lighter portable basket. Handmade coil and slab pots can be found in every early ceramic culture, but the concept of using a mould to achieve standardization and high productivity, though obvious to us, was for early humanity a great technological step forward.

Although the potter's wheel was known by 4000BC in Mesopotamia, its use spread slowly and a variety of other ceramic techniques continued to be used in other places. The Ancient Egyptians pressed clay over a core of wood to produce plates and bowls in the Early Dynastic period (3000-2600BC). In the New World, where the wheel was a later development, Pre-Columbian potters developed a high degree of skill in the use of moulds. The Romans, who brought the wheel to Britain, also brought their knowledge of forming bricks in moulds. Although more complex multipart moulds and other techniques were developed, the simple technique of press moulding continued to have its uses throughout the world for many centuries. It continued to be used for architectural details until the nineteenth century AD, for example on the decorated terracotta facades of European buildings.

Metal Casting

The way in which expertise in working one material can further the development of a technique in another can be observed in the influence that metal casting had on mouldmaking. Although the natural progression within the development of metal working, from hammering, annealing, smelting to casting, took the same course in the early metal technology of various cultures, it followed different time scales. Sometimes a considerable time elapsed before a connection was made between concept and practical application. Carved stone seals, which harness the idea of positive and negative, were in use at Cayonu in Turkey (C.7000BC), at about the same date as objects hammered from native copper, and yet there is no evidence of metal casting in the Middle East until more than 4,000 years later. The oldest known metal casting is a copper frog made in Mesopotamia around 3200BC. By this time copper was more plentiful, as the ore was being mined, smelted and exported both in the Near East and in the Balkans.

The appearance of bronze around 3000BC led to further development of casting techniques. As the alloy was initially scarce, costly and much in demand for weapons and tools, solid-cast sculpture started mostly on a small scale. By the time of the New Kingdom in Egypt, larger statues were being cast in bronze around a clay core. During the XXII-XXIV Dynasties greater skill succeeded in achieving thinner casts. By the eighth century BC heavily leaded bronze with a low melting point was being used to mass-produce votive statuettes that were often inlaid with gold or silver. According to tradition, the first hollow-cast statues in bronze were made by Rhoecus and Theodorus of Samos in the seventh century BC, who were said to have learned their craft in Egypt. Two life-sized bronze statues of warriors found in the Ionian Sea in 1970 were made around the fourth century BC, and are amongst the finest examples ever of bronze casting.

An earlier tradition of metallurgy existed in the East. It is thought that bronze was introduced into China from the West around 2000BC. The Shang Dynasty craftsmen soon discovered that the core casting method was more economical than solid casting, and were assisted in this by their ability to make elaborate moulds in clay. Piece moulds were taken from prototypes of carved wood or pottery and large numbers of moulds were produced for the foundries. This was an early example of the Chinese use of the production line. But though mass-produced, the Shang bronze ritual vessels are undoubted masterpieces. They demonstrate a skill in casting, which, although possibly equalled by the Greeks, has never been surpassed. The expertise of Shang craftsmen in the making of reusable piece moulds may account for the fact that no evidence has been found of the use at that date of waste mould methods of casting such as the cire perdue (lost wax) method. This method was certainly known by the Sumerians, by the Indus Valley Civilization in the third millennium BC, and by the Egyptians from the XVIII Dynasty. The bronze statuette of King Tuthmosis IV (c.1 385BC) in the British Museum is hollow cast around a clay core. Cire perdue was used extensively by jewellers and goldsmiths for all intricate, finely detailed work.

In the New World where the goldsmith's art reached a high degree of perfection, there are accounts by Spanish colonists of the casting of gold by the lost wax process. The Renaissance Italians also excelled in this technique, often casting very large statuary in separate sections on the ground before assembling them. The best description of this process is to be found in Benvenuto Cellini's sixteenth-century Autobiography, in which he described the casting of his masterpiece statue of Perseus.

Although the lost wax process remained the favoured method for the casting of bronze sculpture, many other methods have also been used. Sand casting, a simpler and cheaper process, was used in China as early as 645BC; cast-iron plough shears dating from 233BC have been found. Although only relatively simple forms could be cast in sand, the method continued to be used for weapons, domestic vessels and cooking pots, and in more recent centuries for decorative cast ironwork. The process was refined and developed by the skilled use of tooling and burnishing during the eighteenth and nineteenth centuries AD, particularly in France where bronze and brass were used for decorative mounts on vases, and on handles and feet on furniture. In Germany it was developed for editions of bronze and iron sculpture. Today it is used mainly industrially for the casting of machine parts.

The casting of sculpture in metal was revolutionized by the invention in c.1860 of electroforming. This process uses an electric current to transfer particles of metal from a bar suspended in an electrolytic solution, so as to build up a deposit on the face of a mould until sufficient thickness has been established. This technique has made possible the creation of very fine and accurate casts.

Plaster Casting

Plaster was an ideal material for making moulds and casts. In its liquid state it could be poured into moulds of wood, clay or plaster. From the nineteenth century flexible moulds of gelatin were used, and from the twentieth rubber and plastics. Plaster has been used for casting from life or for death masks, for architectural decorations, and as a mould material for casting bronze or porcelain. There is evidence of plaster being used as a building material over 9,000 years ago. Neolithic houses at Abu Hureyna in Syria have plastered floors. At shrines in Neolithic houses at Catal Huyak in Anatolia walls are decorated with plaster reliefs, and at Jericho, buried skulls have been found with faces modelled in plaster. Gypsum painted on the banks of the henges at the Neolithic site of Thornborough in Yorkshire is thought to have been used to reflect the sunlight or moonlight during rituals. The Ancient Egyptians used plaster on pyramids, and were probably the first to use it for mouldmaking. The earliest death mask is believed to be that of King Teti (C.2400BC), and plaster casts found in the studio of Tuthmose, the chief sculptor to Akenhaten, at Amama (c.1340,), are presumed to have served as sculptor's models. The use of plaster casts as an aid to sculptors was further developed in the fourth century BC by Creek sculptors, who, stimulated by the popularity of the new art of portraiture, perfected the technique of piece moulding.

The Greeks were probably the first to use the process of 'pointing' for mechanically transferring the proportions from a plaster cast of a model made in wax or clay onto a block of stone or marble before carving. Pliny describes this change of technique from a direct to an indirect method of stone carving in Natural History (xxxv.153). He writes that the brother of the celebrated sculptor Lysippus, Lysistratus of Sicyon, was the first to make plaster casts from the living subject and he instituted the practice of making final corrections on a wax model taken from the plaster. The same man also invented taking casts from statues, and this practice increased to such proportions that no figure or statues were made without 'the da/ (a clay model). The Romans, who held Greek sculpture in high regard, cast many thousands of Greek sculptures. Archaeological excavation during the 1950s in the area around Naples, at Baiae, revealed the remains of a first-century AD workshop belonging to a manufacturer of plaster casts of Greek statues for wealthy Roman patrons. A well-known example of this, the Apollo Belvedere, is a Roman marble copy of a fourth century BC Greek bronze. In fifteenth-century Florence the coexistence of a renewed interest in portraiture with a demand for replicas of ancient Roman statues led to the development of the technology of bronze casting and a revival of the use of plaster casts and piece moulding. According to Giorgio Vasari (1511-74), Andrea Verrocchio (1435-88), who was much involved in bronze casting, also pioneered the making of plaster casts from life and promoted the fashion for death masks.

For many hundreds of years plaster and stucco were used as a building material and for decorative architectural mouldings, but the production of ceramics remained a workshop-based craft. Wheel-thrown pots developed their own national character through styles of decoration and glazes rather than techniques of manufacture. By the end of the seventeenth century increasing trade and travel intensified the demand, particularly amongst the aristocracy, for novelty or foreign goods and influenced local styles in sculpture, ceramics and architectural decoration. The need to cater for this demand led to two discoveries that were to be of the utmost importance in the field of ceramics in the eighteenth century. The secret of making porcelain, so long the exclusive knowledge of the Chinese, was discovered by Johann Friedrich Bottger at Meissen in 1708. In 1740 the introduction of plaster moulds by Ralph Daniel into Staffordshire meant that the mould no longer had to be made laboriously from clay, then fired. The porosity of plaster meant that even liquid clay would lose enough water to form firm walls inside the mould. With plaster moulds, slip casting therefore became possible.

As a result of these developments, ceramic production began on an industrial scale and in Britain it was to play a major role in the Industrial Revolution. Factories making soft-paste porcelain were set up in many areas and the innovations by people like Josiah Wedgwood, who opened his first factory in 1760, were to revolutionize the production and marketing of china in Staffordshire. (Ironically, the thriving international market created at that time is now threatened with extinction by competition from the East.) The finely modelled and decorated porcelain figures first produced in Meissen were soon imitated by almost every European factory of note. The moulds were made from an original master model made of wax, clay or wood. When undercutting was necessary, the figures were usually cast in separately moulded sections. The work of master pattern-makers such as Johann Joachim Kandler (1706-75), the most notable of the artisans engaged in this work at Meissen, imparted a new artistic dimension to ceramic art, just as the Greek koroplast had done centuries earlier.

Replication Through Casting

One of the great virtues of casting works of sculpture is the ability to create an identical replica of an admired but unobtainable original. The perfection that could be achieved by the use of plaster began to make it an acceptable material amongst collectors. Louis XIV had set a fashion for casts of antique sculpture in the late seventeenth century that had spread to England by the eighteenth century. The aristocracy found it to be a satisfactory alternative to expensive copies in marble by sculptors such as Canova and Thorwaldson. Casts in plaster were now valued in their own right and by the early nineteenth century casts were being taken in situ of Classical sculpture and architectural decorations and brought back in great numbers by connoisseurs and collectors. In 1816 the purchase of the Elgin Marbles generated a series of requests for casts from European museums and although these were not always granted, casts of the Marbles and other such antiquities were sometimes used to engender good public relations or to resolve the occasional restitution issue. In 1848 the British Museum paid £400 for casts of the Elgin Marbles to be sent as a gift to the King of Greece. In 1870 the 'International Convention for Promoting Universally Reproductions of Works of Art for the Benefit of All Countries' gave the final stamp of approval to the making of facsimiles in plaster.

The British Museum 1856 catalogue lists a huge variety of casts for sale. A Caryatid from the Erectheum cost £6, whereas a panel of the Parthenon Frieze could be bought for only £1 and busts generally cost from between 10/- to £1. The Natural History section included an Asiatic Elephant's tooth for 14/- and the foot of a Dodo, a bargain at 2/-! The Museum's casting department seemed to have been admirably non-commercial and more concerned with such issues as their moral duty to keep prices affordable to educational institutions and to maintain a very high quality of casting in spite of a huge demand from all over the world. They were also very aware of the irreversible damage that could be caused to originals by the taking of casts. It was noted that any remaining traces of colour may have been lost from the Elgin Marbles when 'the whole surface of the Marbles had been twice washed over with soap lyes as that, or some other strong acid, is necessary for the purpose of removing the soap which is originally put on the surface in order to detach the plaster of the mould.' The department insisted on a faithful copy of the original and any attempt at reconstruction, however scholarly, was out of the question.

Second-generation cast section of the Parthenon Frieze. Greece, fifth century BC. By Nick Brooks. H 103cm, W 125cm, D 10cm.

By 1840 the British Museum had direct control over the casting of its antiquities, but it was not until 1881 that it employed a permanent member of staff to make casts. Previously, the work had been done by firms of mouldmakers on a freelance basis and in order to fulfil the increasing demand this still continued. One such firm, Brucianni's, which set up in 1837 in Covent Garden, became the Museum's chief supplier of casts and by 1867 its catalogue boasted 'copies of all the finest statuary in existence' and offered a huge selection of 1,200 items. It was probably Brucianni's that made the famous 48cm fig leaf for the cast of Michelangelo's David to protect the modesty of visiting female dignitaries to the Victoria 8c Albert Museum. This huge 18ft cast, an unwanted gift from the Grand Duke of Tuscany, was presented by Queen Victoria to the Museum in 1857, and was displayed in the Architectural Courts that were opened to the public in 1873. Casts of antiquities were also in great demand in the new art schools where drawing from the 'plaister' occupied a large part of the students' time. The Royal Academy Schools were established in 1769 and during their early years gifts and acquisitions came from the collections of many leading artists and English aristocratic patrons of the arts. A survey of the cast collection of the RA Schools undertaken by John Flaxman in 1810 lists 250 'principal pieces'. These were joined in 1816 by a generous gift from the Prince Regent of 100 casts from his collection. Until the 1960s drawing from plaster casts of antique sculpture was an important part of the curriculum in European art schools, some of which still have collections of fine casts often forgotten and collecting dust in their basements.

'House'. Sculpture of inverted house by Rachel Whiteread by permission of the artist and Gargosian gallery.

The great virtue of casting is the creation of an identical replica. Equally the danger of this facility has often been the multiplication of florid and tasteless forms and an inevitable loss of direct artistic expression. The feeling, often justified, that a reproduction was an intrinsically inferior production lacking in artistic expression began to have its effect on ceramics in the latter part of the nineteenth century. Influential reformers such as John Ruskin and William Morris and the Arts and Crafts Movement protested against the increased mechanization of the production of decorative objects and mourned the demise of the artist/craftsman. However, it soon became apparent that Morris's romantic insistence on the ideals of fine craftsmanship and well-designed objects for the masses was an impractical dream, and the artist/craftsman could only cater for a few wealthy patrons. In Europe the design of decorative objects tended to culminate in stylistic cul-de-sacs such as Art Nouveau. Finally, it was left to the industrial designer to come to terms with the machine in order to produce well-designed articles for the masses.

A similar change was taking place in museums. In response to the growing enthusiasm for casts, the V&A opened its new cast courts to the public in 1873. But the increasing perfection of casting techniques brought with it a need for a clear distinction to be made between reproduction and original. People wanted to be sure they knew what they were looking at. The practice of using casts to fill the gaps in a display sequence of, for instance Creek sculpture, was no longer found acceptable.

By the end of the nineteenth century sculptors and potters had begun to learn and profit from industry. By adopting the new techniques and materials used in industrial processes for moulds and casts they were able to produce increasingly perfect results. Flexible moulds first made of gelatin and later rubber compound or synthetic materials could be pulled away easily from undercut and complex surfaces without damage to the original model or cast. It was not until the 1950s that gelatin moulds were superseded by Vynagel/Vinamould (a vinyl moulding compound). By 1961 even the admirably cautious British Museum cast service was using it. The minutes of that year record that 'It has outstanding advantages over gelatin of enabling an unlimited no. of casts to be obtained from the same moulds, in contrast with gel moulds which can only provide three or four casts', and in 1962 it was noted that 'The new material described in last year's report has proved to be very durable and new moulds are being made of this wherever suitable.' Silicone rubber was, it seems, introduced shortly afterwards. Minutes in 1965 record that silicone rubber moulds 'are being made in the laboratory with Dr Werner's kind permission ... Dr W thought it possible that under his supervision Mr Prescott could teach the making of silicone rubber moulds to Mr Langhorn of the casting shop within a week.' This was obviously a success as in 1966 a memo refers to 'combining the cast service working in plaster with that working in resins'. Many artists of the latter part of the twentieth century and the early twenty-first have used aspects of mouldmaking and casting in their work, continuing many of the ancient techniques developed over the centuries and adding some new ones.

Synthetic resins and fibreglass which had been used in industry for car and boat bodies have, since the 1950s, developed into an important material for sculpture. Light, durable and relatively easy to cast they can be painted or used in conjunction with powdered metal fillers in order to produce cheap 'cold-cast' substitutes for bronze and aluminium. Fibreglass can also be used for making moulds and to provide support for flexible moulds of rubber or vinyl. In the mid 1960s Duane Hanson used polyester resin and fibreglass for his life-sized super-real sculptures which were cast from human models.

Rachel Whiteread's conceptual use of casting and moulding brings us full circle. When in 1993 she made her Turner Prize-winning work House, the piece drew crowds and made newspaper headlines throughout its two-and-a-half-month life. She used a Victorian terrace house as a waste mould for a concrete cast of the inside empty space.

Laser copying of computer-generated patterns is the latest addition to the mould medium and may one day threaten to replace the more traditional methods of reproducing the art object, but I somehow feel it will become yet another addition to the ancient desire to reproduce and conserve the three-dimensional creative expression.

'Section'. By Nick Brooks. Plaster.

CHAPTER 2

MOULDMAKING AND CASTING PRINCIPLES

The reasons for making a mould to produce a casting may be many, as can be seen in the ancient history of the techniques and their evolution. The artist may want to reproduce a pattern in a more durable material, for instance a clay pattern made into a plaster one. It may be desirable or necessary to produce multiples of the pattern, either for commercial possibilities or to preserve a record of the pattern. It may be easier, cheaper and more accurate to produce a mould and cast of a pattern than to try to copy it by hand modelling, for instance architectural or mechanical reproductions. All of these requirements can be satisfied with the production of a mould and cast, of which there are many types. The choice of which to use will largely depend on what the requirements are.

The following form the essence of mouldmaking:

■ the mould – a shaped cavity used to give a definitive form to fluid or plastic material;

■ the cast - an object shaped/formed in a mould;

■ the pattern - a model used to make a mould (the word 'pattern' will be used throughout this book to describe the original form to be reproduced through a mould and cast. The pattern may be a pre-made form, for instance an industrially made object, or handmade by the artist, for instance a form made in clay).

Initial Considerations

Before embarking on any mouldmaking and casting project it is important first to consider the requirements, principles and materials of the pattern, mould and cast you will be working with. An understanding of the basic principles will help you to decide which mould and cast are best for the job.

■ Pattern material This is the material from which the original pattern is made. It will determine what the moulding options are, and the requirements of its production.

■ Pattern complexity The complexity and detail of the pattern will determine which type of mould will be easiest and most accurate to produce and use to cast from.

■ Casting material This is the material in which the pattern is to be reproduced. It will have a bearing on which type of mould will be most suitable.

■ Cast detail The level of reproductive detail reproduced from the pattern will be determined by the choice of mould being used. What degree of detail is required? For instance, is the cast to be reworked once it has been taken out of the mould? If so, a fairly crude moulding process may suffice.

■ Cast run This is the number of castings required from the mould. Some moulds are reusable, and can be used to produce multiple casts, whereas others are 'one-offs'. Different moulds will produce different numbers of castings before detail starts to be lost, although this is also dependent upon what casting material is being used for the mould.

■ Release agent This is a medium that is applied to a pattern to prevent the moulding material sticking to it. A release agent is also applied to a mould surface to prevent a casting sticking to it.

Basic Principles of Mouldmaking

An understanding of the essential principles of moulding is vital if the outcome is to be successful. These are outlined below.

Positive to Negative to Positive

This sequence is the fundamental working principle of mouldmaking and casting. The original pattern (positive form) is moulded (negative form of the original pattern) and then cast (reproducing the original positive form) (see diagram 1).

Diagram 1 Positive to negative to positive

Undercutting

These are the points on a pattern where it would become 'locked' into a mould. This can best be described using a sphere as an example. If a mould were to be taken from a spherical pattern the point at which it would 'undercut' would be at any point past the halfway line. Unless a mould were made in more than one piece, the pattern could not be removed, and therefore would be unusable to produce a cast. Furthermore, unless the line between the pieces of a two-piece mould were made exactly to the halfway line of the pattern, one or other of the mould pieces would be undercut. The way around this is either to produce a mould in more pieces, working around the undercutting, or to use a flexible mould that will 'bend' around the undercutting. A pattern with no undercutting could theoretically be moulded in a one-piece mould; however, in reality it would sometimes still be necessary to make the mould in more than one piece, to ensure removal of the pattern and subsequent casts (see diagram 2).

Diagram 2 Undercutting

Division Lines

These are the lines on the pattern to which the mould pieces will need to be made, in order to be able to remove them past any undercutting. Once the points of undercutting have been determined, these lines should be carefully worked out and either committed to memory or marked temporarily on the pattern. The division lines do not need to be straight, but can undulate following the undercutting of the pattern (see diagram 3 a, b, c).

Diagram 3 Division lines

Clay Bed

A temporary bed of clay is used to divide and mask a pattern into the separate sections it will be moulded in. Once the division lines on a pattern have been established the pieces of the mould can be made one at a time. While making each mould piece, the others will need to be masked off, and this can be done by building a clay bed up to the division lines of the piece being made. As each piece of the mould is completed the clay bed is removed and built up to the lines of the next piece to be made (see diagram 4).

Diagram 4 Clay bed

Access into the Mould

Once the mould has been made there will need to be some sort of access into it, in order to fill it with the casting material. If the pattern has a 'footprint' (a base or area from which it stands), this will be the obvious place to become the opening into the mould. The mould is built up around this area, leaving it uncovered by the moulding material. When the mould is inverted this area will then become the 'mouth' of the mould. The size of the footprint will determine how the mould can be filled (see diagram 5).

Diagram 5 Access into the mould

If the mould is in pieces and the footprint is large enough it can be filled with the mould pieces assembled, via the mouth of the mould; otherwise, the mould will have to filled with the pieces separated and joined afterwards. In either case, the mouth of the mould needs to be at least large enough to pour some of the casting material into the mould either to fill it or to join separately filled pieces of the cast. If a pattern has no footprint and the mould is to be made completely 'in the round', a pour point will need to be built into the mould. This can be done by building a stalk of clay onto the pattern, around which the mould can be built. When the mould is completed, the stalk of clay can be removed, leaving a hole through which the casting material can be poured (see diagram 6). Clay stalks should be positioned on an area of the pattern where the loss of detail at that point will be least visible or easily remodelled. Stalks of other materials can be used as long as they can be temporarily securely attached and are treated with an appropriate release agent in order to be able to remove them from the moulding material when set.

Diagram 6

Registration

Registration between mould pieces is important in order to be able to relocate accurately the pieces when casting. Initially, the shape of the mould pieces should be considered when creating masking beds or walls. Beds and walls should be created perpendicular to the pattern surface to avoid 'feathered' edges that will create weak inner edges between mould pieces (see diagram 7), but also the points of division around the pattern should create slightly wedge-shaped pieces (see diagram 3 a, b) that naturally lock together, but will release from the pattern and subsequent castings with ease. Other registration methods are 'nipples and cups' and 'pinch lines' (see diagram 8).

Diagram 7 Registration

Securing Mould Pieces Together

This can be done with rubber bands, cut-up pieces of bicycle inner tube, wire or string ties, clamps or nuts and bolts. Holes for nuts and bolts should be drilled before the mould is released from the original pattern in order to maintain accurate registration when reassembling the mould. Whichever method is employed mould pieces need to be accurately and securely held together during casting to reduce seam lines.

Flanges

Flanges are probably one of the most important aspects to creating a successful mould. They are an extended width to the edges of the mould pieces, which create a positive area of registration to locate and secure the mould pieces together (see diagram 8).

Diagram 8a Nipple and cup registration

Diagram 8b Two-piece mould

Walls

Patterns that are too big to lay down or cannot be moved will be a problem when building clay beds up to division lines. In these cases walls can be built onto the division lines on a pattern to mask off mould pieces as they are being made. In the same way as with a clay bed, the walls are removed and repositioned as the mould pieces are made. Walls can be made of clay, brass shim (see plaster waste moulds), or any other material that can be cut to shape and temporarily attached to the pattern (see diagram 9).

Diagram 9 walls

Mould Categories and Types

Moulds can be split into four principal categories, of which there can be up to four types.

Categories

■ Rigid This type of mould is constructed from a rigid material, and will usually need to be constructed as a multi-piece mould to facilitate the removal of the rigid material around any undercutting on the pattern.

■ Flexible These moulds can be stretched over a certain amount of undercutting on a pattern and can therefore sometimes be constructed as one-piece moulds. Patterns with deep undercutting may require a flexible mould to be made in pieces. However, due to its flexibility, the mould can be made in less pieces than a rigid mould.

■ One-off cast These moulds will produce a one-off casting before the mould is destroyed.

■ Multiple cast These moulds can be used to produce multiple castings until the mould becomes depleted.

Types

■ Type 1: one piece This type of mould is constructed around a pattern in one piece (see diagram 10a).

Diagram 10a

■ Type 2: multi-piece