28,49 €

Mehr erfahren.

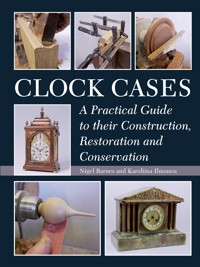

- Herausgeber: Crowood

- Kategorie: Fachliteratur

- Sprache: Englisch

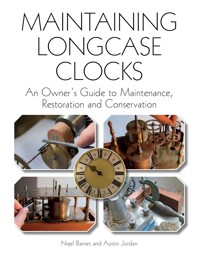

Longcase clocks were invidually hand-made during the golden age of change that took place between the late seventeenth and mid-nineteenth centuries. Longcase clocks with their seventeenth century clock-making technology were innovative and incorporated an accurate pendulum clock within an attractive piece of domestic furnishing. This invaluable book is essential reading for all those who own and collect longcase clocks as well as clock repairers, horologists and conservationists. The authors provide detailed information about how longcase clocks work and how they are made. They also cover the theory and the 'best practice' practical steps that are required in longcase clock maintenance, restoration and conservation. The book outlines the history and horological development of longcase clocks; describes how longcase clocks can be dated; considers materials, tools and equipment; examines the movement and the associated simple, and more difficult, workshop procedures; covers maintenance and effective repairs; explains the more difficult woodwork procedures. Superbly illustrated with 300 colour photographs. Nigel Barnes and Austin Jordan provide advice and guidance in the field of antique horology and regularly run weekend courses.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 328

Veröffentlichungsjahr: 2013

Ähnliche

First published in 2013 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2013

© Nigel Barnes and Austin Jordan 2013

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 84797 633 8

Disclaimer

The practical workshop procedures and the tools and equipment used by clock-repairers and conservationists are potentially dangerous. All equipment and tools employed in clock repair and conservation work should be used in strict accordance with both current health and safety regulations and the manufacturer’s instructions.

The author and the publisher do not accept any responsibility in any manner whatsoever for any error or omission, or any loss, damage, injury, adverse outcome, or liability of any kind incurred as a result of the use of any of the information contained in this book, or reliance upon it. If in doubt about any aspect of the maintenance, restoration, conservation, or repair of longcase clocks, readers are advised to seek professional advice.

Photographs by Nigel Barnes except where otherwise stated.

Contents

Preface

Chapter 1 A Short Introduction to Longcase Clocks

Chapter 2 Dating Clocks

Chapter 3 Materials, Tools and Equipment

Chapter 4 Clock Maintenance

Chapter 5 The Movement – Some Simple Workshop Procedures

Chapter 6 More Difficult Movement Procedures

Chapter 7 The Most Difficult Workshop Procedures

Chapter 8 Case-Work – Maintenance and Simple but Effective Repairs

Chapter 9 More Difficult Woodwork Procedures

Glossary

Bibliography

Index

Preface

From its early beginnings in the thirteenth century, the craft of clockmaking expanded rapidly in the mid-seventeenth century and longcase clocks first appeared at about the time of the restoration of the English monarchy in 1660; Charles II (d. 1685) was an early clock collector.

Since those early days, the emphasis of the many books written on various aspects of horology has shifted towards the appreciation and preservation of valuable horological artefacts.

Times and circumstances change and a few decades ago, clock-repair shops were plentiful and clock-repairers busy, but more recently, with the introduction of electric clocks, the old generation of time-served craftsmen has largely disappeared. That sad loss, compounded with the scarcity of formal training facilities for the next generation of clock-menders, limits the antique clock-owners’ options for maintenance, conservation and restoration work.

No book about longcase clocks can ever be complete, but in the evolving environment of more self-reliance, we have provided here a certain amount of background information and guidance for interested connoisseurs and owners of longcase clocks and, of course, aspiring menders. We describe in detail a wide range of repair work that will guide the amateur, or at least explain what is involved. However, this could never be a complete workshop manual for all longcase clocks because, in our combined experience, no two are identical; not only as originally conceived, but also through their individual history of repairs.

Traditionally, the clock-repairer was something of a pragmatist who, when faced with a problem, could engineer a sound repair without necessarily needing to consider the clock as an important historical artefact. In most cases a clock was just a day-to-day domestic appliance and he was more likely to have been primarily concerned with the proper functioning of a clock as a time-keeper, than in preserving the evidence of its place in the history of horology.

Nowadays we might regret that approach but, as with all historical artefacts, their increasing age and scarcity force changes in our perceptions about worth and importance.

Both of us have encountered and dealt with bizarre and often ineffective repairs, and we both keep to the rule of never making value judgements about such work. As Austin’s father said, ‘You never know about the full circumstances of repair work – you don’t know what tools that repairer had and what training, just accept that he was doing his best and work around it and try to do your work in a way that the original maker would approve.’

We also accept that, unlike the professional who needs to do his work to a good standard, the owner of a clock is entitled to do as he pleases with his own property. So from time to time we include gentle reminders, with phrases such as ‘historical integrity’, that hand-made, longcase clocks of the type we describe were, in general, not made after the mid-nineteenth century: they are invariably old or, in some cases, very old and as a species they are becoming endangered.

Likewise, attitudes to the restoration of clock-cases have developed to recognize the concepts of the conservation of the historically important, as against restoration with a more functional objective.

We do not set any limits to what an enthusiastic amateur can achieve, although we occasionally mention that practice and patience are required at the work-bench, especially for some of the more awkward procedures. The other aspect of longcase clock-repair that we touch on is the necessary broad understanding of the subject gradually acquired over the years by reading and research. That understanding also includes an appreciation of the social and economic development of the British Isles, because it enables an interpretation of the origins and context of any particular clock, which will be helpful in planning an appropriate repair.

Prior to the rise of consumerism and mass production in the early nineteenth century, clockmakers either undertook, or were at least able to undertake, all aspects of the work involved in making a clock movement, and we have attempted to give some, far too brief, guidance along the same principle. So in several instances where we mention that certain replacement parts are available from horological suppliers, we also describe the method of making them from scratch.

We hope that the reader will develop an interest in longcase clocks and build on this and former work to preserve these wonderful horological treasures, not as dead museum exhibits but as living, ticking contrivances that are redolent of the golden age of craftsmanship.

While Nigel describes himself as an enthusiastic collector from a long line of clockmakers, Austin is a formally trained clock-mender (also from a long line of clock-men). The approach taken here to explain about repair procedures and how the various parts work is based partly on individual experiences and partly on joint experiences, including running weekend clock-restoration and conservation courses.

With just a couple of exceptions, the clocks illustrated are from Nigel’s own longcase collection, which covers a span of about a hundred and fifty years, from the age of London clocks, around the year 1700, through the age of provincial clocks to the rise of modern society and mass production, which brought a virtual end to hand-made longcase clock production.

This book offers advice about practical workshop procedures and the reader should ensure that any tools or materials are used carefully and in accordance with the maker’s recommendations: accidents and injuries are not in keeping with the professionalism that befits a serious clock-worker.

Chapter 1A Short Introduction to Longcase Clocks

TERMINOLOGY AND THE WORDS: REPAIR, RESTORATION AND CONSERVATION

‘Clock-repairer’ is a term that is used to describe people who correct wear and defects in clocks and although we use the word ‘repair’ rather loosely to cover all corrective procedures, ‘restoration’ is a more appropriate concept for longcase clocks because they are invariably old and could be considered as horological artefacts. In more extreme cases of age, rarity or quality of workmanship, the ‘conservation’ approach implies stabilization and preservation of important heritage objects, even at the expense of functionality.

A responsible clock-mender takes care to preserve a horological artefact as far as possible, while keeping it in a good state of repair.

For clarity, the difference between the concepts of repair and restoration is explained by defining the terms:

Repair means a purely functional mending process intended to return a clock to working order without any particular consideration of the clock as it was when first made.Restoration means returning a clock to its supposed original state sympathetically, using the same style of craftsmanship and materials. An element of heritage value is implied.Conservation – unlike museums, private owners of historical clocks generally prefer to have them working rather than in a state of suspended silence, preserved for all time, so the concept of conservation often presents conflicts and difficulties for both owners and conservators. Essentially, conservation means preserving original parts in their original context or relationship, and if some are missing or beyond use, any replacement parts should only be introduced to make sense of the original, with no attempt to mimic what was once there. Likewise, with case-work, new work should only be introduced into a clock-case in order to stabilize and preserve the structure. New work should be clearly identifiable, with no attempt to make new parts that might be mistaken for original. Conservation work should be carefully recorded with illustrated descriptions of the clock and all the work including evidence of previous work or alterationsTHE BASIC CONCEPT OF A PENDULUM CLOCK

It is a basic law of physics that over small arcs of swing, and gravitational forces being constant, the time taken for a pendulum to swing from one extremity to the opposite is only dependent on its length. A pendulum clock is designed and built around this isochronous behaviour of simple pendulums.

The movement in a longcase (or any mechanical) clock performs two separate but related tasks: it maintains the swing of the pendulum by giving it a little nudge at each swing to make up for natural damping; and, second, it counts the number of swings, which it shows as seconds, minutes and hours of the day. The word ‘dial’ is derived from the same root as our word ‘day’, because the clock dial is a representation of the day.

The length of a pendulum is taken to be the distance from the point of suspension to the centre of gravity (quite close to the centre of the bob). A regulating screw is used to make small adjustments – a 1mm adjustment is equivalent to roughly 43sec per day.

HOW THE TWO MAIN TYPES OF LONGCASE CLOCK EVOLVED

The terms, ‘longcase’, ‘tall case’ (in North America) or otherwise ‘grandfather’ are used to describe floor-standing, weight-driven clocks that have their dials approximately at adult eyelevel. A wooden case supports the movement and dial at that convenient height, while providing a vertical space through which the driving weights descend and the approximately one metre-long pendulum swings.

The fact that the pendulum is roughly one metre long is no coincidence: in 1790 the French National Assembly proposed to define the metre as the length of a pendulum with a half-period of one second. (In other words, by that definition, a 1m-long pendulum takes exactly 1sec to swing from one extremity to the other.) In the event, an alternative, geodetic, definition was adopted, so the one-second pendulum is actually 994.16mm or 39.14in.

Since a longcase clock is both functional and decorative, the case is necessarily both structurally sound and aesthetically pleasing. Like all good furniture, a well-designed and made clock-case is the meeting of the craftsman’s hand with the artist’s eye.

From the end of the seventeenth century and into the early eighteenth century, when longcase clocks became fashionable in London, they were fabulously expensive symbols of status and wealth. However, after about 1730, production of longcase clocks in London began to decline as fashions changed once more, this time in favour of bracket clocks. About the same time, there was a rapid expansion in clockmaking activity in the provinces and from then, the continual interpretation of national fashions, coupled with the development of regional styles, usually make deductions possible about when and where a longcase clock might have been made and the status of the first buyers, because longcase-clock ownership ceased to be the sole prerogative of the very wealthy.

By the 1740s, approximately fifteen or twenty years after the general introduction of the break-arch style of longcase dial, longcase clocks had ceased to be at the forefront of London fashion. Thereafter, with the London makers concentrating on bracket clocks, London longcase clocks made after the mid-1700s are surprisingly uncommon.

However, the period also saw the beginnings of a huge proliferation of country longcase clocks throughout the towns and villages of the British Isles. In many instances, young men who had migrated to London to be apprenticed to good makers, returned with their new skills to their native towns and villages. Of the 70,000 clockmakers listed in Brian Loomes’s Directory of Watchmakers and Clockmakers of the World, a very high proportion were working in country towns and villages in the hundred years from the mid-eighteenth century to the end of longcase production in the mid-nineteenth century.

In the first-half of the eighteenth century, as longcase clocks increasingly transcended the social strata, large variations emerged, both in their style and complexity, from plain country versions to the most elaborate examples from the golden age of cabinet-making.

Although movements do not vary much, they usually contain subtle clues about approximate age, but dials and cases continued to develop until the effective end of longcase clock production in the mid- to late nineteenth century, when cheaper mass-produced clocks became widely available.

Within all that variation, there are naturally a number of rules about dating longcase clocks based on their movements, dials and cases, even their hands, but there are exceptions and, with longcase clocks, there are a great many exceptions. The one rule for which there seems to be no exception is that there are no two identical longcase clocks, nor even two identical dials.

Craftsman’s hand and artist’s eye. The proportions of this quite small provincial clock, made in Oxfordshire in the 1770s, suggest that, in addition to good clock work, fashionable design was a consideration.

Classic London styles are recognizable in earlier country clocks. This oak-cased clock was made in Yaxley, Suffolk in the mid-1700s by Thomas Henson. It is tempting to conjecture that he is actually the Thomas Hanson who is recorded as apprenticed in London in 1745.

THE MECHANICAL DIFFERENCES BETWEEN THE TWO TYPES OF LONGCASE MOVEMENT

In broad terms there are two main types of longcase clock movement: first, those having two weights, suspended by cords of cat-gut, each wound onto a drum by a key inserted through holes in the dial; and, second, those having a single weight wound by pulling an endless rope or chain. Two-weight clocks usually have a duration between re-winding of eight days, hence the generic name, ‘eight-day’ clocks (effectively, weekly winding), while the pull-up type usually, but not always, has a duration between re-winding of not much more than a day, hence the name ‘30-hour’.

Within these two quite similar and yet quite different basic clock layouts, there are many variations: clocks designed to run as long as a full year between windings; clocks made for extreme accuracy, even to forecast the time of high tide at a local seaport; and clocks designed to amuse with a collection of tunes sounded on bells or automata depicting rocking ships or people in various activities.

The vast majority of longcase clock movements contain two trains of gears: one driving the hands and the pendulum, the watch or going train; and the other driving the clock or strike train. With the older names, watch and clock, for the two trains (clock from the Latin, ‘clocca’ – a bell), it is not unusual to find the letters ‘C’ and ‘W’ scribed onto the two drums of eight-day clock movements by an early repairer, those two parts being the only ones that are more or less interchangeable.

An eight-day dial: because eight-day movements are invariably wound by a key, two winding holes are made in the dial.

A 30-hour clock is almost always wound by pulling on the chain to raise the driving weight. Consequently there are no winding holes in the dial and 30-hour clocks only rarely have seconds hands.

EARLY BIRDCAGE MOVEMENTS THAT RETAIN MANY OF THE FEATURES OF SEVENTEENTH-CENTURY TABLE CLOCKS

The longcase clock that is recognizable today developed in the second-half of the seventeenth century. While it relied on the development of two of its parts – the one-second pendulum and the anchor-recoil escapement – it is also a direct development from a previous form of clock. Verge escapement, short pendulum, lantern clocks, made from the mid- to late 1600s principally in London, share some features with early London-made and much later English provincial longcase clocks. They are both constructed with the two wheel-trains mounted one behind the other (strike to the back) in an open framework, usually described as a posted or birdcage construction. They each have a bell for the hourly strike directly over the movement and, in common with lantern clocks, the bell of a birdcage longcase movement is struck by a hammer located on the inside of the bell; but, most significantly, the actual layout of the two sets of moving parts is effectively the same.

The two examples below only have a single (hour) hand moving over the usual silvered chapter ring in which the deeply engraved Roman numeral hours are filled with black wax. The ornamental brass-work and overall design are so similar that they might have been made by the same hand. Indeed, the maker of the 30-hour longcase, Benjamin Shuckforth, is known to have made lantern clocks after he returned to his native Norfolk from London, where he served his apprenticeship.

Front and side views of a lantern clock made in London in the 1660s. (Dennis Benson, London Clocks, Worcester)

The dial and hand of an early eighteenth-century birdcage longcase clock. Behind the dial, upper and lower plates support four corner posts and the narrow, central, vertical strip-plates in the same layout as earlier lantern clocks.

PLATED CONSTRUCTION

Although provincial 30-hour clocks occasionally retained the posted or birdcage layout well into the eighteenth century, by far the more usual configuration of the two wheel-trains is side-by-side between two solid brass plates held apart by (usually) four brass pillars. The side by-side arrangement is referred to as ‘plated’ construction.

Plated movements are practically universal from the late seventeenth century for eight-day and longer duration movements but, on the other hand, it is not impossible to find a birdcage movement dating from the painted iron dial period at end of the eighteenth century.

Unlike the sudden and universal adoption of plated construction for eight-day clocks from the late seventeenth century, the gradual change from birdcage to plated frames for 30-hour movements seems to have been slower in certain areas and certain makers or groups of makers. The plated movement is intrinsically more rigid, but for reliability and ease of repair work there is little difference between the two types.

One of the idiosyncrasies of normal eight-day clocks is their behaviour during winding, when the driving power is temporarily relieved from the movement. An odd effect can often be seen during winding an eight-day clock that has a seconds hand, when the seconds hand tends to move in an anticlockwise direction. The explanation is that once the driving force is relieved from the movement, rather than the escapement wheel driving the pendulum, the pendulum causes the escapement wheel to rotate, but in reverse. That does not happen with the 30-hour type of clock, where the single weight is suspended by an endless chain or rope and the driving force is never relieved from the going side of the movement during winding, so it always drives the movement clockwise. That quirky behaviour of the eight-day clock, which obviously affects the time-keeping, is got around in more accurate or ‘better’ movements by introducing a subsidiary means of maintaining the power on the clock wheels while it is being wound.

Early plated movements used a system known as ‘bolt and shutter’, where in raising two spring-loaded plates behind the winding holes, the spring keeps some pressure on the going side train for a few moments while the clock is being wound. Bolt and shutter clocks are recognizable by the plate that blanks off the winding holes and, if that has been removed, by the way the winding squares are recessed. Later, John Harrison, famous for his work on maritime chronometers, developed a simpler maintaining-power device using a spring and ratchet wheel on the great wheel.

Typical early plated movement. The maker has made no attempt to smooth the front face of the front-plate, which retains marks from hammering and sand-casting.

An early provincial clock made in Rochdale about 1700. While the dial is similar in style to contemporary London clocks, the layout of the movement is strikingly different. Although the pillars and wheel-work are typical of 1700, the plates are very tall when compared to London movements.

THE LESS COMMON TYPES OF CLOCK

In general, longcase movements made before the mid-eighteenth century tend to be horologically interesting, often individualistic in layout and, occasionally, even experimental. Although the early London makers are credited with much of the technical innovation in the development of longcase movements, with the introduction of rack-striking, the dead-beat escapement and alternative tooth-counts in the wheel-work, developments were also made in the provinces. In 1713, John Harrison made his first longcase clock movement in the North Lincolnshire village of Barrow-upon- Humber, using wood wheels; and advances were made in clockmaking, especially in the north-west.

VARIATIONS IN MOVEMENT DESIGN IN THE FIRST-HALF OF THE EIGHTEENTH CENTURY

Longer Duration Versions

For some reason, single-weight clocks appear not to have been made for longer durations, but long-duration versions of the eight-day clock – one-month, three-month and even one-year durations between winding – were achieved by the introduction of more gearing and heavier weights. The fashion for long-duration clocks in the early part of the eighteenth century is difficult to reconcile at a time when clocks were owned exclusively by the wealthy who had plenty of household staff to wind clocks, and it is reasonable to conclude that there was an element of ‘one-upmanship’ involved in this otherwise ostensibly futile development of horological excellence. It seems that the names of ‘good makers’ are most frequently associated with longer duration clocks, and it is quite likely that for the clockmaker, a long-duration clock bearing his name would have been a useful marketing feature. As a rule, while the usual eight-day clock has four wheels in the going train, a month-going clock has five wheels and (extremely rare) year-duration clocks have six. In both cases, the plates and pillars are more massive to ensure that the frame remains rigid, despite the heavier weights.

Ways of arranging the tooth counts for a one-second pendulum – the table shows a few examples for 30-hour, three-wheel clocks

Movements with ‘Odd’ Pendulum Lengths

There are several ways of arranging the tooth counts for a one-second pendulum and the table above shows a few examples for 30-hour, three-wheel clocks.

However, a surprising number of longcase movements, especially country-made, three-wheel, 30-hour clocks, are made with a pendulum beat that is not exactly one second. That type of clock has no seconds hand, so there would have been no particular reason for the maker to stick rigidly to an exactly one-second pendulum layout. There are a great many possible wheel counts for beats that only approximate to one second, many of which are documented in English 30 Hour Clocks by Jeff Darken and John Hooper.

Movements with 1¼sec Pendulums

A special case of the ‘odd’ pendulum clocks – the 1¼sec pendulum clock – seems to have disappeared by the end of the seventeenth century. Extant examples are very rare, but they turn up from time to time and can often be identified by the lenticle in the base, and often by wheel counts that cannot be reconciled with 1sec pendulums. Despite the great length of the pendulum at 61½in (1,563mm), the clock cases are of similar height to their one-second counterparts. Only two examples are described by Cesinsky and Webster in English Domestic Clocks: one by William Clement, 74in (1,865mm) high and the other by Thomas Tompion, less than 78in (1,981mm) high. Even the Wetherfield collection of 150 or so ‘old master’ longcases included only four examples and each of those was made by a prestigious London maker.

At first sight the movement of this early 30-hour clock is not unusual, but the tooth count reveals an impossible gearing onto the (missing) hour wheel. The clue is in the thirty-four tooth escapement wheel. Recalculating on the basis of a 1¼sec pendulum results in an elegant ratio of 15:14 to drive the motion-work.

The movement of a Victorian domestic regulator. The characteristically tall deadbeat escapement (with forward-pointing escape wheel teeth) is accompanied by the pawl and ratchet wheel to the front of the main wheel.

Precision Movements

Clocks designed for accurate astronomical observations appeared in the late eighteenth century, and precision movements with temperature- compensated pendulums, dead-beat escapements and built-in maintaining-power arrangements, were more widely produced in the early eighteenth century. Usually known as regulators, early examples used the bolt and shutter type of maintaining power, but later, the Harrison spring and ratchet type was the norm.

An accuracy of plus or minus a few seconds a day is quite acceptable for domestic use, but in the days when there was no radio to set the clock by, a very accurate clock was useful as a standard for other clocks in the locality. The temperature expansion of pendulum rods was compensated in more complex pendulums or minimized by using wooden rods, which are far less susceptible to thermal expansion and contraction than metal.

Musical Clocks

More complex chime-work, often with a third train of wheels to drive a set of hammers that struck bells in sequence, first appeared in the late seventeenth century, but a third chime train was an additional feature often adapted into older clocks, especially during the nineteenth century.

Astronomical and Celestial Clocks

Astronomical features, such as moon phase and times of high tides, were often built into clock movements and displayed in the dial arch. Because of the approximately 29½ days of the lunar cycle, the tooth ratios of the wheel-work are usually simplified by using a 118-tooth wheel with two moons, moving one tooth every 12h. A more accurate wheel train is not recorded until that devised in the nineteenth century by Lord Grimthorpe, designer of the Big Ben movement.

At certain times of the year, solar and average time may vary by nearly a quarter of an hour. The elusive connection between solar time and average time is frequently incorporated into ‘equation of time’ clocks: the usual arrangement of showing the difference is a pointer attached to a cam on a wheel that rotates once in a year.

Four-Wheel or Centre- Wheel 30-Hour Clocks

Although the going train of a 30-hour clock usually comprises three wheels – the great wheel, the inaccurately named third wheel and the escapement wheel – there is a relatively unknown variation comprising four wheels on the going side, with the extra wheel (equivalent to the centre wheel in an eight-day clock) driving the minute hand through the front-plate in the same arrangement as the centre wheel of an eight-day clock.

Such clocks tend to crop up at auction sales with no reference made to the fact they are only 1 per cent of all 30-hour clocks. The odd feature that often alerts a collector to the presence of the fourth wheel is a seconds hand in a subsidiary dial. It is extremely rare to see a seconds hand in an ordinary, three-wheel, 30-hour clock because the escape wheel rotates anticlockwise; so a seconds hand, if fitted, would likewise run backwards. There are collectors who specialize in four-wheel, 30-hour clocks, including birdcage examples from the late eighteenth century. Apart from their inclusion in English 30 Hour Clocks by Jeff Darken and John Hooper, they are not well-written up, which may stem from their still being 30-hour movements and the perception that they were (and still are) seen as a cheaply made, poor relation to the eight-day clock.

Actually, there is very little difference in the complexity, and hence cost, of a four-wheel, 30-hour clock against an eight-day type, so any argument about cheapness is difficult to justify.

A four-wheel, 30-hour clock. The hour wheel has been removed to show how the centre arbor is driven off the main wheel, in the same way as an eight-day movement.

EVOLUTIONARY PARALLELS IN EUROPE AND AMERICA

Dutch Longcases

Longcase clocks are not unique to the British Isles, there were well-established links between what is now the Netherlands and East Anglia and hence, London. It is natural that communications in the seventeenth century related to trade, and Dutch involvement in the land drainage of East Anglia led to wider cultural exchange. That connection was further reinforced when William of Orange, of the Dutch House of Nassau, invaded England in 1688 and subsequently eclipsed his father-in-law James II as king. Consequently, early Dutch clocks can be strikingly similar to their English counterparts and arguably are part of the early development of the English longcase.

Danish Bornholm Clocks –a Special Case

A British ship carrying longcase clocks ran aground on the island of Bornholm in the 1740s and initiated a longcase clockmaking tradition there, which persisted for many decades.

Other Scandinavian Clocks

The port of Tallinn is suggested as the centre of Baltic and Scandinavian clock and watch activity from the fourteenth or fifteenth centuries; but in Sweden, longcase clocks were produced at several locations, of which the town of Mora is often used as the name for such clocks.

Although the cases of Swedish clocks that were produced from the mid-eighteenth century are reminiscent in overall appearance to French Comptoise clocks, their movements are fundamentally different in layout. The typical plated, two-train movements are more reminiscent of an English 30-hour plated movement and it is likely that, through the Bornholm incident or some earlier evolutionary ancestor, they are related.

A Swedish longcase clock of the early nineteenth century. The movement is about half the size of an English 30-hour movement, with significant differences, especially in the method of count-wheel locking.

French Clocks

The rapid expansion of provincial clockmaking took place in the British Isles in the early eighteenth century, and a few decades later a similar parallel provincial clockmaking activity commenced in the Franche Compté region of France, near the Swiss border. That activity seems to have had parallels in the Black Forest area of Germany and, in each case, clockmaking developed into a cottage industry followed by farmers during the winter months. It is not surprising that the birdcage-type of movements characteristic of Franche Compté are quite dissimilar to English birdcage movements in wheel layout, but whether they are an evolutionary development, or just share a common ancestor, is not clear.

A typical French Morbier clock movement. Although the frame is reminiscent of an English birdcage clock, the wheel trains are arranged side-by-side.

Although they were made as hanging wallclocks, they were also housed in what is now, the instantly recognizable pot-bellied Comptoise or Morbier clock-case.

American Tallcase Clocks

The first longcases to appear in America were imports from the British Isles and, naturally, it is likely that American-made clocks were produced by immigrants. One way or another, an indigenous clock industry started and later developed into the mass-production of weight and, later, spring-driven clocks.

UNDERSTANDING CLOCK MOVEMENTS

To the novice, any clock movement seems to be an incomprehensible jigsaw of strange parts that can be assembled into just one solution, like a mechanical Rubik’s Cube. Clock movements are ingeniously thought out and the layout of parts is the product of many years of gradual evolution from early clocks.

A good understanding of the way a longcase, or any, clock movement operates is one of the basic requirements for the repairer – more important than tools. In essence, the movement of the clock does two things: first, through the escapement, it maintains the uniform rate of oscillation of the pendulum by giving it a little nudge every swing; and, second, it mechanically displays the number of swings.

UNDERSTANDING ESCAPEMENTS

The swinging pendulum counts off the seconds consistently because it can only swing at the speed that is governed by its length. In order to maintain the motion, the escapement gives it a slight nudge at each swing, compensating for the natural mechanical losses.

Anchor Recoil

Almost all longcase clocks use an anchor-recoil escapement, which can continue to function despite quite heavy wear and misalignment. Eventually, if that wear continues unchecked, the efficiency of the escapement will inevitably fall to a point where it can no longer maintain the swing of the pendulum.

A healthy escapement will give the pendulum a noticeable supplementary swing, which can be seen by watching the motion and listening to the tick. The pendulum will be seen to continue swinging farther towards its extremity after the tick and, conversely, if the tick occurs just at the point of greatest amplitude, the clock is on the point of stalling and is probably in need of corrective work.

There are many variations in the detail but the general design persisted unchanged from its introduction in the late 1650s. It is particularly suitable for longcase clocks for several reasons:

The small angle of displacement makes for simple regulation and good time-keeping because as a ‘simple’ (small angle) pendulum, it closely follows a basic law of nature: that in constant gravity, the time for one swing is only proportional to the square root of the length.The small amplitude of pendulum swing (typically between 4 and 6 degrees total swing, which equates to total pendulum displacements of between 75 and 100mm) has a direct bearing on the design and aesthetics of clock-cases.It is quite straightforward to make, set up and repair.It requires a fixed or stationary clock-case.The term ‘recoil’ is often overlooked but the recoil effect is a necessary part of the functioning of this type of escapement.

Recoil is directly related to the supplementary swing that is necessary for the escapement pallet to lift clear of the escape wheel tooth. The effect of recoil can readily be seen in the behaviour of a seconds hand, which, having moved forward, regresses slightly after each tick. During the recoil phase, the escape wheel exerts a braking effect on the pendulum that counters the supplementary swing.

In most cases, the wheel teeth are cut far deeper than necessary, which makes the system immune to extreme swings of the pendulum. In other words, at the most extreme swing, when the pendulum bob contacts the inside of the case trunk, the back face of the pallet should be close to touching the back face of the wheel tooth.

Most early escape wheels have a hollow formed in the leading face of the teeth. That curve is not vital and in fact there is no one radius of curvature that must be used in designing the wheel.

The entry pallet is to the left and the exit pallet to the right. As the pendulum swings to the left, the nib of the entry pallet rises to the point of the wheel tooth. The wheel is now at the point of escaping.

As the pendulum swings farther to the left, the pallet lifts clear, allowing the wheel to turn clockwise until a tooth hits the exit pallet with an audible tick. The wheel has now escaped.

The supplementary swing forces the exit pallet downwards, which pushes the escape wheel backwards – that is the recoil. The pressure of the tooth on the pallet tends to check the supplementary swing and the pendulum reverses direction.

As the pendulum swings towards the right, the entry pallet falls and the exit pallet lifts to where the nib of the pallet is level with the tooth point. Again, the wheel is on the point of escaping.

As the exit pallet lifts clear, the wheel escapes until it is stopped by an entry tooth striking the entry pallet with an audible tick.

Deadbeat Escapement

The year 1715 is usually given for the invention in London of the deadbeat escapement by Thomas Tompion’s son-in-law, George Graham. The statement by Cesinski and Webster in their book, English Domestic Clocks, that ‘It is incomparably superior to the recoil type, as far as precision is concerned’, is left without explanation, although one of the features of deadbeat escapements is the necessity to keep power on the going train during winding. (With a recoil-type escapement, there is a tendency for the swinging pendulum to drive the train in reverse direction during winding.) Consequently, deadbeat escapements are used in conjunction with some form of maintaining-power device in key-wound clocks. (In an endless rope, single-weight system, a deadbeat escapement will work satisfactorily without the necessity of a maintaining-power device because winding only relieves the pressure on the strike train.)

The entry pallet is to the left and the exit pallet to the right. The point of the wheel tooth is in contact with the entry pallet impulse face. As the escape wheel rotates clockwise, the pallet is forced upwards, nudging the pendulum to the left.

After the wheel tooth has escaped from the entry pallet, an exit tooth strikes the check-face of the exit pallet.

As the pendulum reaches its extremity of swing and starts to return, the check-face of the exit pallet slides against the radial leading face of the wheel tooth, temporarily preventing any movement of the wheel.