153,99 €

Mehr erfahren.

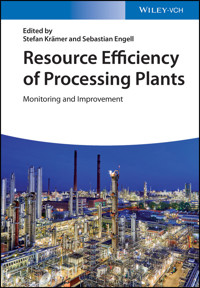

- Herausgeber: Wiley-VCH Verlag GmbH & Co. KGaA

- Kategorie: Fachliteratur

- Sprache: Englisch

This monograph provides foundations, methods, guidelines and examples for monitoring and improving resource efficiency during the operation of processing plants and for improving their design.

The measures taken to improve their energy and resource efficiency are strongly influenced by regulations and standards which are covered in Part I of this book. Without changing the actual processing equipment, the way how the processes are operated can have a strong influence on the resource efficiency of the plants and this potential can be exploited with much smaller investments than needed for the introduction of new process technologies. This aspect is the focus of Part II. In Part III we discuss physical changes of the process technology such as heat integration, synthesis and realization of optimal processes, and industrial symbiosis.

The last part deals with the people that are needed to make these changes possible and discusses the path towards a resource efficiency culture.

Written with industrial solutions in mind, this text will benefit practitioners as well as the academic community.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 906

Veröffentlichungsjahr: 2017

Ähnliche

Table of Contents

Cover

Title Page

Copyright

Preface

Part I: Resource Efficiency Metrics and Standardised Management Systems

Chapter 1: Energy and Resource Efficiency in the Process Industries

1.1 Introduction

1.2 Energy and Resources

1.3 Energy and Resource Efficiency

1.4 Evaluation of Energy and Resource Efficiency

1.5 Evaluation of Energy and Resource Efficiency in Real Time

1.6 The Chemical and Process Industry

1.7 Recent and Potential Improvements in Energy and Resource Consumption of the Chemical and Process Industries

1.8 What Can Be Done to Further Improve the Resource Efficiency of the Process Industry?

1.9 Conclusions

References

Chapter 2: Standards, Regulations and Requirements Concerning Energy and Resource Efficiency

2.1 Introducing a Long-Term Development

2.2 Normative Approaches on Energy and Resource Efficiency

2.3 Achievements of Energy and Resource Management

2.4 Conclusion

References

Chapter 3: Energy and Resource Efficiency Reporting

3.1 Executive Summary

3.2 Introduction

3.3 Obligatory Reporting Mechanisms

3.4 Voluntary Reporting Mechanisms

3.5 Other Reporting Mechanisms

3.6 Summary of the Energy and Resource Efficiency Reporting Requirements

References

Chapter 4: Energy Efficiency Audits

4.1 Introduction

4.2 Stage 1: Current Energy Status

4.3 Stage 2: Basic Analysis

4.4 Stage 3: Detailed Analysis and Collection of Ideas

4.5 Stage 4: Evaluation and Selection of Measures

4.6 Stage 5: Realization and Monitoring

4.7 Extension to Resource Efficiency

4.8 Closing Remark

References

Part II: Monitoring and Improvement of the Resource Efficiency through Improved Process Operations

Chapter 5: Real-Time Performance Indicators for Energy and Resource Efficiency in Continuous and Batch Processing

5.1 Introduction

5.2 Real-Time Resource Efficiency Indicators

5.3 Evaluation of the Suitability of Resource Efficiency Indicators

5.4 Hierarchical Modelling of Continuous Production Complexes

5.5 Batch Production

5.6 Integrated Batch and Continuous Production

5.7 Conclusions

Appendix: Decomposition of

References

Chapter 6: Sensing Technology

6.1 Introduction

6.2 Sensing: General Considerations and Challenges

6.3 Energy Saving by Means of Accurate Metering

6.4 Latest Advancements in Spectroscopy Technology for Process-Monitoring-Based Efficiency

6.5 Process Analytical Technologies (PAT)

6.6 Soft Sensors. Access to the “Truth” Distributed Among a Plurality of Simple Sensors

6.7 MEMS-Based Sensors. Smart Sensors

6.8 Future Trends in Sensing with Promising Impact on Reliable Process Monitoring

6.9 European R&D: Driving Forward Sensing Advancements

6.10 Conclusion

References

Chapter 7: Information Technology and Structuring of Information for Resource Efficiency Analysis and Real-Time Reporting

7.1 Introduction

7.2 Information Technology in the Process Industries

7.3 Resource Flow Modelling and Structuring of Information

7.4 From Formulae to Runtime Software

7.5 Industrial Installations

7.6 Summary and Conclusions

References

Chapter 8: Data Pre-treatment

8.1 Measurement Errors and Variable Estimation

8.2 Data Reconciliation

8.3 Gross Errors Detection and Removal

8.4 Data Pre-treatment and Steady-State Detection

8.5 Dynamic Data Reconciliation

8.6 Conclusions

References

Chapter 9: REI-Based Decision Support

9.1 Introduction

9.2 Visualization

9.3 What-If Analysis

9.4 Optimization

9.5 Conclusions

References

Chapter 10: Advanced Process Control for Maximum Resource Efficiency

10.1 Introduction

10.2 The Importance of Constraint Control

10.3 What is Advanced Process Control?

10.4 Benefits and Requirements for Success

10.5 Requirements for success

10.6 Conclusion

References

Chapter 11: Real-Time Optimization (RTO) Systems

11.1 Introduction

11.2 RTO Systems

11.3 Optimization Methods and Tools

11.4 Application Example: RTO in a Multiple-Effect Evaporation Process

11.5 Conclusions

References

Chapter 12: Demand Side Response (DSR) for Improving Resource Efficiency beyond Single Plants

12.1 Executive Summary

12.2 Introduction

12.3 Structure of this Chapter

12.4 Motivation

12.5 Demand Side Response at Large Consumers

12.6 Valorization

12.7 Summary and Outlook

References

Chapter 13: Energy Efficiency Improvement using STRUCTese™

13.1 Introduction

References

Part III: Improving Resource Efficiency by Process Improvement

Chapter 14: Synthesis of Resource Optimal Chemical Processes

14.1 Introduction

14.2 Heuristic Methods

14.3 Superstructure Optimization Based Method

14.4 Other Impact Factors on Resource Optimal Chemical Processes

14.5 Conclusion

References

Chapter 15: Optimization-Based Synthesis of Resource-Efficient Utility Systems

15.1 Introduction

15.2 Definition of Utility Systems

15.3 Problem Statement

15.4 Modelling

15.5 Solution Methods for Optimal Synthesis of Utility Systems

15.6 Analysis of Multiple Solutions for Decision Support

15.7 Industrial Case Study

15.8 Conclusions for the Utility System Synthesis in Industrial Practice

Acknowledgments

References

Chapter 16: A Perspective on Process Integration

16.1 Overview

16.2 Introduction

16.3 Heat Integration

16.4 Energy and Resource Integration

16.5 Summary

References

Chapter 17: Industrial Symbiosis

17.1 Syn-Bios and Syn-Ergon

17.2 Industrial Symbiosis

17.3 Business Clustering

17.4 Conclusions

References

Part IV: Company Culture for Resource Efficiency

Chapter 18: Organizational Culture for Resource Efficiency

18.1 Introduction

18.2 The Basics

18.3 Implementation

18.4 Giving It a Meaning

18.5 Closing Remarks

Acknowledgments

References

Index

End User License Agreement

Pages

xvii

xviii

xix

xx

xxi

xxii

xxiii

xxiv

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296

297

298

299

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

333

334

335

336

337

338

339

340

341

342

343

345

347

348

349

350

351

352

353

354

355

356

357

358

359

360

361

362

363

364

365

366

367

368

369

370

371

373

374

375

376

377

378

379

380

381

382

383

384

385

386

387

388

389

390

391

392

393

394

395

396

397

398

399

400

401

403

404

405

406

407

408

409

410

411

412

413

414

415

416

417

418

419

420

421

422

423

424

425

426

427

428

429

430

431

432

433

434

435

436

437

438

439

440

441

442

443

444

445

446

447

448

449

450

451

452

453

454

455

456

457

458

459

460

461

462

463

464

465

466

467

468

469

471

473

474

475

476

477

478

479

480

481

482

483

484

485

486

487

488

489

490

491

492

493

495

496

497

498

499

500

501

502

503

504

Guide

Cover

Table of Contents

Preface

Part I: Resource Efficiency Metrics and Standardised Management Systems

Begin Reading

List of Illustrations

Chapter 1: Energy and Resource Efficiency in the Process Industries

Figure 1.1 Improvement of production in general terms.

Figure 1.2 Qualitative visualization of the required effort and of the benefit of solutions for the improvement of process operations.

Chapter 2: Standards, Regulations and Requirements Concerning Energy and Resource Efficiency

Figure 2.1 Energy intensity of an economy as level of primary energy per GDP between 1990 and 2012 normalized on the year 2011 [23].

Figure 2.2 Timeline of EnMS standardization projects.

Figure 2.3 Timeline of the development of EN 16001 and ISO 50001.

Figure 2.4 Overview of current standardization activities around the ISO 5001 series.

Figure 2.5 The ISO 17743 and ISO 20366 families.

Chapter 4: Energy Efficiency Audits

Figure 4.1 Five-stage process.

Figure 4.2 Cooling water pump case study: piping and instrumentation diagram.

Figure 4.3 Pump cooling water load frequency distribution and pump characteristic curves.

Figure 4.4 Waterfall chart of pump losses.

Chapter 5: Real-Time Performance Indicators for Energy and Resource Efficiency in Continuous and Batch Processing

Figure 5.1 Definition of hierarchical resource managed units with REI attached.

Figure 5.2 Simple definition of a resource managed unit.

Figure 5.3 Evaluation of proposed REI using the RACER framework.

Figure 5.4 Aggregation hierarchy for production complexes.

Figure 5.5 Extension of a resource managed unit for aggregation purposes.

Figure 5.6 Graphical explanation of the different performance measurements.

Figure 5.7 Simple production complex consisting of two plants.

Figure 5.8 Extension of the aggregation concepts with a utility provider.

Figure 5.9 Sketch of the production complex for the illustrative example.

Figure 5.10 Change of energy and product flows and plant performance over time.

Figure 5.11 Performance of the complex and the corresponding baseline (a) and plant-performance-induced deviation from the baseline (b).

Figure 5.12 Visualization of load and performance contribution to the deviation from the baseline of a production complex.

Figure 5.13 Power plant performance and electricity production over time.

Figure 5.14 Performance and load contribution integrating the power plant within the balance domain.

Figure 5.15 Product-oriented REI for each product, PP outside the balancing domain.

Figure 5.16 Product-oriented REI for P2 and P4, with and without PP inside the balancing domain.

Figure 5.17 Simplified batch balance for REI calculation.

Figure 5.18 Batch distillation with removal of raw material residue and excess water .

Figure 5.19 Process structure with parallel production of two intermediates that are merged to the final batch.

Figure 5.20 Process for two products based on homogeneous splitting.

Figure 5.21 Membrane separation process, where both phases yield a product.

Figure 5.22 Buffer tank between batch and continuously operated section (a), timing of transfer operations to and from buffer tank (b).

Figure 5.23 Resource load per product in the buffer tank for different transfer times (solid line: 2 min/10 min, dotted line: 10 min/2 min) for the same two batches with different efficiencies.

Chapter 6: Sensing Technology

Figure 6.1 PAT as the source of information, artificial intelligence (or advanced computing) as the tool for taking optimal decisions towards data-driven actions to optimize productive actions in relation to the Industry 4.0 paradigm.

Figure 6.2 Typical structure of a hyperspectral imager.

Figure 6.3 A representation of a typical hypercube. Each plane is related to a specific wavelength, while the false colour gradation informs about the signal (reflectance or transmittance) intensity.

Figure 6.4 Raman effect takes place almost synchronously with the excitation pulse. However, for this example, the fluorescence signal reaches the maximum around 300 ps later and remains for a long.

Figure 6.5 Spectra of a calcite mineral sample with luminescent impurities. These impurities are often rare earths or transition metals embedded within the crystal. The associated photoluminescence is strong but relatively long-lived (µs–ms range) and therefore effectively rejected by time gating. Comparison between time-gated and CW 532 nm systems, and a CW 1064 nm system [21].

Figure 6.6 An affordable off-the-shelf miniaturized near infrared spectrophotometer that operates on the basis of a MEMS Fabry–Perot tuneable filter .

Chapter 7: Information Technology and Structuring of Information for Resource Efficiency Analysis and Real-Time Reporting

Figure 7.1 Functional hierarchy of production-oriented IT systems according to IEC 62264.

Figure 7.2 Resource managed unit.

Figure 7.3 From functional view to an abstract information model.

Figure 7.4 Three-tier architecture.

Figure 7.5 From data point-oriented systems to context-centred information management.

Figure 7.6 Typical workflow to develop comprehensive REI applications using a resource flow information model.

Figure 7.7 Step 1 – specifying a Type Model.

Figure 7.8 Step 2 – modelling a site- or plant-specific resource flow structure.

Figure 7.9 Step 3 – linking properties to RMUs and resource flows.

Figure 7.10 Production scheme of first example of an industrial installation.

Figure 7.11 Schematic overview of the monitored process part.

Figure 7.15 Dashboard of the REI case study example 1.

Figure 7.12 Block hierarchy of first example.

Figure 7.13 Steam flow with attached measurement property.

Figure 7.14 Steam flow type with attached property calculating the energy value.

Figure 7.16 Modern HMI elements.

Figure 7.17 Extract of the modelled site-wide resource flow model.

Figure 7.18 Extract of the Type Model of example 2.

Figure 7.19 Extract of the site-wide resource flow model of example 2.

Figure 7.20 Screenshot of the REI dashboard of example 2 (yield overview).

Figure 7.21 Screenshot of the REI dashboard example 2.

Chapter 8: Data Pre-treatment

Figure 8.1 The “control” pyramid.

Figure 8.2 Distribution of measurements around a certain value following a Gaussian distribution.

Figure 8.3 Flow measurements in a liquid junction.

Figure 8.4 A heat exchanger with temperature measurements.

Figure 8.5 Mixing of two liquid streams.

Figure 8.6 Mixing of two liquid streams with a different set of measurements.

Figure 8.7 EcosimPro window for selection of boundary variables (partition).

Figure 8.8 Non-Gaussian distribution of the measurements around the process variable.

Figure 8.9 Steps to be followed in statistical methods.

Figure 8.10 F-distribution and the corresponding critical value of 2.8588 for a level of significance of 5% and degrees of freedom 4 and 37.

Figure 8.11 Shapes of different cost functions: LS Least Squares, Fair function (

c

= 15) and Welch (

c

= 2.9846).

Figure 8.12 Process signal in a transient and moving average.

Chapter 9: REI-Based Decision Support

Figure 9.1 Visualization of different levels of decision support.

Figure 9.2 Structure of well-organized dashboard configurations for Western users.

Figure 9.3 Efficiency bars included into the plant structure diagram.

Figure 9.4 Sankey diagram for materials (a) and energy (b).

Figure 9.5 Sankey diagram with highlighted raw material feed A with a measured flow rate of 100 kg/min and a theoretical minimum of 80 kg/min to produce the same amount of product.

Figure 9.6 Bullet chart representation with current value, direction of movement, historical variability and relation to target value.

Figure 9.7 Stacked area plot.

Figure 9.8 Stacked bar chart for batch applications.

Figure 9.9 Sparklines for three REI in different setups.

Figure 9.10 Difference chart to reference: light areas are losses compared to reference, and dark areas are gains compared to reference.

Figure 9.11 Aggregated tile plot with colour according to the efficiency.

Figure 9.12 Flow sheet of the sugar plant for the production of food-grade sugar from sugar beets.

Figure 9.13 Dashboard concept for the sugar plant application case.

Figure 9.14 Sequence of a what-if analysis.

Figure 9.15 Cooling tower array as an example for the what-if analysis approach.

Figure 9.16 Exemplary results of the cooling tower example.

Figure 9.17 Distillation column as an example of multicriteria optimization.

Figure 9.18 Representations of a three-dimensional Pareto front.

Figure 9.19 Example process for the multicriteria optimization of resource efficiency.

Figure 9.20 Multicriterial optimization results of the combined cooling towers and the extractive distillation process.

Chapter 10: Advanced Process Control for Maximum Resource Efficiency

Figure 10.1 Simple distillation column.

Figure 10.2 Graphical representation of multiple process constraints.

Figure 10.4 Dynamic model matrix for the depropanizer column.

Figure 10.3 Levels of process control and optimization.

Figure 10.5 Block diagram for model predictive control.

Figure 10.6 Simplified process flow diagram of the NMP butadiene extraction process.

Figure 10.7 Improved control of impurities in a 1,3-butadiene product.

Figure 10.8 Benefit estimation from reduced distillation column fractionation.

Chapter 11: Real-Time Optimization (RTO) Systems

Figure 11.1 Diagram of a typical DCS and information system.

Figure 11.2 Basic concepts in MPC. Evolution of one controlled variable (PV) computed with the model as function of the values of a manipulated variable (MV).

Figure 11.3 Improving control allows moving the set point to a better operating point.

Figure 11.4 (a) The economic optimizer fixes the SP of the MPC controller and the final resting values of the MVs. (b) Hierarchical structure of the control and optimization layers in a MPC controller.

Figure 11.5 A CSTR where the reaction A → B takes place, showing a RTO module that generates optimal set points for the MPC. The MPC commands the process acting on the set points of two flow control loops of the basic control layer.

Figure 11.6 Scheme of a typical RTO application showing the main elements involved.

Figure 11.7 Two iterations of the Newton–Raphson method for solving

f

(

x

) = 0.

Figure 11.8 Scheme of an evaporation plant with standard instrumentation.

Figure 11.9 Schema of a cooling tower.

Figure 11.10 Identified patterns with experimental data. (a) Flow coefficient. (b) Tower performance.

Figure 11.11 Evolution of the main input and output variables during a year of operation. (a) Evaporated water and (b) steam consumption.

Figure 11.12 Evolution of the resource efficiency indicators. (a) REI

1

. (b) REI

2

.

Chapter 12: Demand Side Response (DSR) for Improving Resource Efficiency beyond Single Plants

Figure 12.1 Transformation of the Grid, source ABB.

Figure 12.2 History of demand side response [7–13].

Figure 12.3 Impact of energy efficiency (constant improvement) related to a fixed plan (Gantt chart).

Figure 12.4 Energy systems and production planning must be better coordinated.

Figure 12.5 Energy portfolio example from the steel industry.

Figure 12.6 Various load management strategies: No load management, peak shaving, load shedding and load shifting.

Figure 12.7 Illustrative consumer surplus approach according to [10].

Figure 12.8 Production schedules not considering (a) and considering (b) electricity prices.

Chapter 13: Energy Efficiency Improvement using STRUCTese™

Figure 13.1 Closing the awareness gap is a challenge.

Figure 13.2 Simple monitoring with lack of transparency.

Figure 13.3 Energy Management Cycle:

STRUCTese

TM

follows a PDCA-cycle in accordance with the standards for EnMS.

Figure 13.4

STRUCTese

TM

workflow: Energy Efficiency Check and Energy Efficiency Management.

Figure 13.5

STRUCTese

TM

energy scope.

Figure 13.6 Typical results of the analysis phase – energy distribution of the plant (a) and main steam consumers (b).

Figure 13.7 Optimization levels considered in the Energy Efficiency Check .

Figure 13.8 Typical energy savings portfolio.

Figure 13.9 Energy loss cascade (ISBL: inside battery limits, OSBL: outside battery limits).

Figure 13.10 Concept of best demonstrated practice, consideration of suboptimal operation and partial load.

Figure 13.11 Development energy efficiency over time.

Figure 13.12 Integrated energy efficiency management tool addressing all levels of the organization.

Figure 13.13 Reduction of specific energy consumption for a polymer plant over several years.

Figure 13.14 Steam loss cascades from 2006 to 2011 for a polymer plant.

Figure 13.15 Exemplary energy efficiency online monitor – several energy levels, best demonstrated practice and loss codes are shown for the main utilities.

Figure 13.16 Exemplary daily energy protocol.

Figure 13.17 Online monitor.

Figure 13.18 Development of GHG emissions and energy consumption.

Chapter 14: Synthesis of Resource Optimal Chemical Processes

Figure 14.1 Converting natural resources to various products.

Figure 14.2 Growth rates of global consumptions of fossil fuels from 2004 to 2014 [3].

Figure 14.3 Illustration of pinch technology targeting utility consumption: (a) hot and cold composite curves; (b) grand composite curve.

Figure 14.4 Illustrative mass flows of a mixer, a separator and a reactor.

Figure 14.5 Illustrative heat exchange between a cold stream and a hot stream.

Figure 14.6 Summary of cost components of a chemical plant. TBM, total bare module cost; DPI, total direct permanent investment; TDC, total depreciable capital; TPI, total permanent investment; TCI, total investment; DMC, direct manufacturing costs; COM, cost of manufacture; FC, fixed costs; TPC, total production cost.

Chapter 15: Optimization-Based Synthesis of Resource-Efficient Utility Systems

Figure 15.1 Workflow of a project for the optimization of utility systems. The steps of this work flow are described in the sections of this chapter (section numbers in brackets).

Figure 15.2 A chemical site is composed of a process system and a utility system. The utility system is connected to the public energy market and to the process system, and provides the final energy for the process system.

Figure 15.3 Levels of decision in optimization of utility systems: Structure, sizing and operation.

Figure 15.4 Graphical illustration of the trade-off between modelling complexity and decision levels with increasing computational effort. The trade-off is abstractly visualized (dotted line); however, no strict mathematical relationship exists.

Figure 15.5 Pattern of non-zero coefficients in the aggregated matrix of the matrices for MILP problems: “simple problem” (a), “complicating variables” (b) or “complicating constraints” (c).

Figure 15.6 Accuracy measure (▵TAC) for time-series aggregation in the domain of the objective function, as difference in total annual cost (TAC) between an aggregated synthesis problem (b) and an operation problem (c). The large original synthesis problem (a) is unsolvable or requires high computational effort.

Figure 15.7 Flow diagram of the algorithm for automated superstructure and model generation. Voll

et al

. 2013 [15].

Figure 15.8 Flow diagram of the successive algorithm for automated superstructure generation and optimization of utility systems' synthesis problems. Voll

et al

. 2013 [15].

Figure 15.9 Flow diagram of an evolutionary algorithm.

Figure 15.10 Energy conversion hierarchy.

Figure 15.11 Flowchart representing the algorithm for generation of rational decision options.

Figure 15.12 Schematic plant layout of the industrial case study. The plant is divided by a public road in two sites. Site B is not connected to the existing cooling network on Site A.

Figure 15.13 Monthly averaged demand profiles for electricity, heating and cooling (stacked bar chart). Additionally, peak loads for winter (PW) and summer (PS) are considered.

Figure 15.14 Optimal solution of the industrial case study, . Selected equipment (white) and spare equipment (dashed) of the superstructure built by the successive superstructure expansion. The electricity demand is not shown. B, Boiler; CHP, CHP engine; CC, Compression chiller; AC, Absorption chiller; H, Heating demand; C, Cooling demand.

Figure 15.15 Pareto front regarding total investments and cumulated energy demand (CED). The Pareto-optimal solutions are clustered in five groups of similar structure (I – V). Additionally, the net-present-value-(NPV)-optimal solution is shown.

Figure 15.16 10th best solution of the industrial case study, . Selected equipment (white) and spare equipment (dashed) of the superstructure built by the successive superstructure expansion. The electricity demand is not shown. B, Boiler; CHP, CHP engine; CC, compression chiller; AC, absorption chiller; H, heating demand; C, cooling demand.

Figure 15.17 Selected near-optimal solutions of the industrial case study: (a) 2nd best solution, (b) 3rd best solution, (c) 7th best solution, (d) 10th best solution. The x-axis shows the sizing of the equipment. On the y-axis, the equipment is listed sorted by technology. B: Boiler, CHP: CHP engine, CC: compression chiller, AC: absorption chiller, E: existing equipment, N: new equipment.

Chapter 16: A Perspective on Process Integration

Figure 16.1 The process energy system.

Figure 16.2 The process unit operation.

Figure 16.3 One hot and one cold stream in counter-current heat exchange.

Figure 16.4 Hot and cold composite curves with utility requirements and heat recovery potential.

Figure 16.5 Grand composite curve (GCC) for the example composite curves.

Figure 16.6 Composite and Grand Composite Curves of the process after heat integration.

Figure 16.7 Composite Curves after improvement potentials.

Figure 16.8 Principles of MVR and heat pumping.

Figure 16.9 Energy integration representation of rotary steam cooker, exhibiting the interaction of resources, heat, electricity and support materials.

Figure 16.10 Pareto frontier showing potential solutions having an economic and environmental trade-off.

Figure 16.11 Summary of SPI and TSI for the three process subsystems of the site.

Figure 16.12 Composite curves of process system A from black-box to simple-model analysis with SPI (100% corresponds to the present total site consumption).

Figure 16.13 Composite curves of process system B from black-box to detailed-model analysis with SPI (100% corresponds to the present total site consumption).

Figure 16.14 Composite curves of process system C with black-box analysis (100% corresponds to the present total site consumption).

Figure 16.15 Systematic improvement of CC and GCC of the total site by combining different energy requirement levels (100% corresponds to the present total site consumption).

Figure 16.16 TSI for the process systems with and without pressure modification.

Figure 16.17 TSI for the process systems with and without MVR or heat pumps [6].

Figure 16.18 Site utility integration and optimization for three different scenarios.

Chapter 17: Industrial Symbiosis

Figure 17.1 Individual companies join forces to manage and grow cluster activities.

Figure 17.2 A wide range of cluster activities benefitting from umbrella management.

Figure 17.3 Book series on eco-industrial parks, from a legal, economic, spatial and technical perspective.

Figure 17.4 District networks using process waste heat, case Kuurne Flanders (Belgium).

Figure 17.5 Cluster activities driving sustainability management.

Figure 17.6 Integration of the sharing and the caring economy.

Figure 17.7 Industrial competitiveness and corporate responsibility as pillars of the Europe 2020 strategy.

Figure 17.8 Corporate sustainability at the heart of the People–Planet–Profit triangle.

Figure 17.9 Cluster activities driving responsibility management.

Figure 17.10 Indicative energy system superstructure and technology measures for low-carbon business parks.

Figure 17.11 Symbiosis in industry goes by many names.

Figure 17.12 Textbook example of eco-industrial parks: Kalundborg (Denmark).

Figure 17.13 Petrochemistry symbiosis with horticulture, OCAP case Port of Rotterdam (Netherlands).

Figure 17.14 Second life platform for waste and resources, case International Synergies & NISP (UK).

Figure 17.15 Flemish decree on carbon neutrality for business parks.

Figure 17.16 From corporate over concerted towards circular responsibilities in decade strides.

Figure 17.17 LESTS pentagon to visualise inter-firm collaboration.

Figure 17.18 Steel and petrochemical symbiosis: case Marseille (France).

Figure 17.19 Triple helix, university–industry–government collaboration for a sustainable society.

Figure 17.20 SET Plan to advance development and deployment of low-carbon technologies.

Figure 17.21 Business improvement district, case Technology Park Ghent (Belgium) and Wase Wind cooperative, Flanders (Belgium).

Figure 17.22 Energy integration at petrochemical site level, case Lavera (France).

Figure 17.23 Energy integration at the chemical cluster level, case Stenungsund (Sweden).

Figure 17.24 Outline of the circular economy .

List of Tables

Chapter 2: Standards, Regulations and Requirements Concerning Energy and Resource Efficiency

Table 2.1 Success stories of energy checks and EnMS

Chapter 3: Energy and Resource Efficiency Reporting

Table 3.1 Aspects of the environmental category in GRI guidelines [6]

Table 3.2 GRI indicators related to resource efficiency [6]

Table 3.3 Sector-specific GRI indicators related to resource efficiency [17, 18]

Table 3.4 The reporting requirements set in ISO 14000 standards relevant to resource efficiency

Chapter 4: Energy Efficiency Audits

Table 4.1 Case study calculated power consumption

Table 4.2 Example of life-cycle cost saving potentials

Table 4.3 Comparison of evaluated power saving potentials

Chapter 5: Real-Time Performance Indicators for Energy and Resource Efficiency in Continuous and Batch Processing

Table 5.1 List of generic indicators for continuous processes

Table 5.2 Influenceable and non-influenceable factors in chemical plants

Table 5.3 Values for the analysis of the plant complex in Figure 5.7

Chapter 6: Sensing Technology

Table 6.1 Summary of the novel sensing technologies covered in this chapter

Chapter 8: Data Pre-treatment

Table 8.1 Measured values of the mixing streams example

Table 8.2 Measured and reconciled values of the mixing streams example

Table 8.3 Measured and reconciled values of the mixing streams example with leakage

Table 8.4 Measured and reconciled values of the mixing streams example with a gross error

Table 8.5 Sets of process measurements free from gross errors/reconciled values

Table 8.6 Residuals and their corresponding normalized value.

Table 8.7 Covariance matrix of the normalized residuals of the data sets free from gross errors

Table 8.8 Results of the data reconciliation after removal of the term with gross error in the cost function

Table 8.9 Results of the data reconciliation with a gross error using M-estimators

Chapter 9: REI-Based Decision Support

Table 9.1 Comprehensive overview of the visualization methods introduced

Chapter 10: Advanced Process Control for Maximum Resource Efficiency

Table 10.1 Steady-state model gains for a depropanizer

Chapter 12: Demand Side Response (DSR) for Improving Resource Efficiency beyond Single Plants

Table 12.1 Barriers and drivers

Chapter 14: Synthesis of Resource Optimal Chemical Processes

Table 14.1 Example of process steps for property difference

Chapter 16: A Perspective on Process Integration

Table 16.1 Multi-Level energy requirement definition [6].

Table 16.2 Summary of comparisons between SPI and TSI

Table 16.3 Summary of site utility integration for three scenarios

Resource Efficiency of Processing Plants

Monitoring and Improvement

Edited by Stefan Krämer and Sebastian Engell

The Editors

Dr.-Ing. Stefan Krämer

INEOS Köln GmbH

Alte Str. 201

50769 Köln

Germany

Prof. Dr.-Ing. Sebastian Engell

Technische Universität Dortmund

Department of Biochemical and Chemical Engineering

Process Dynamics and Operations Group

Emil-Figge-Str. 70

44221 Dortmund

Germany

Cover

INEOS in Köln, Oliver Brenneisen

All books published by Wiley-VCH are carefully produced. Nevertheless, authors, editors, and publisher do not warrant the information contained in these books, including this book, to be free of errors. Readers are advised to keep in mind that statements, data, illustrations, procedural details or other items may inadvertently be inaccurate.

Library of Congress Card No.: applied for

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

Bibliographic information published by the Deutsche Nationalbibliothek

The Deutsche Nationalbibliothek lists this publication in the Deutsche Nationalbibliografie; detailed bibliographic data are available on the Internet at http://dnb.d-nb.de.

© 2018 Wiley-VCH Verlag GmbH & Co. KGaA, Boschstr. 12, 69469 Weinheim, Germany

All rights reserved (including those of translation into other languages). No part of this book may be reproduced in any form – by photoprinting, microfilm, or any other means – nor transmitted or translated into a machine language without written permission from the publishers. Registered names, trademarks, etc. used in this book, even when not specifically marked as such, are not to be considered unprotected by law.

Print ISBN: 978-3-527-34074-3

ePDF ISBN: 978-3-527-80414-6

ePub ISBN: 978-3-527-80416-0

Mobi ISBN: 978-3-527-80417-7

oBook ISBN: 978-3-527-80415-3

Cover Design Adam-Design, Weinheim, Germany

Preface

“Natural resources are materials and energy in nature that are essential or useful to humans.” G. Tyler Miller and Scott E. Spoolman are pointing this out in their book Living in the Environment: Principles, Connections and Solutions. This statement already implies that the human race would face serious problems if the essential resources were not available any longer.

Three of these resources that today's society relies heavily on are non-renewable organic fossil resources, oil, gas and coal.

These three fossile resources are used in two ways:

1.

They are burned directly to produce more usable secondary energy such as heat, electricity or perpetuation, for example, within public and individual transport.

2.

They are used as raw materials in combination with the secondary energy to produce a very large range of products used in our daily lives such as polymers, pharmaceuticals, fertilizers and agricultural support products.

Apart from non-renewable organic fossil resources, non-renewable (precious) metals and rare earth elements processed from ores play a major role and are important ingredients in our daily products. Finally, our production processes often release previously earth-bound materials or results of chemical reactions that are not typically found in nature to the environment where they are potentially harmful to us and to nature.

While we are progressing towards replacing power generation and fuels for mobility and transport by renewable sources such as the energy from the sun (solar and wind), this change is not as obvious for the materials that go into products that we use in our daily lives. For 150 years, fossil resources have been available in abundance, used to produce both secondary energy and usable products. In the future, this will most likely change, whereas the energy provided by the sun and the earth's core will stay available for a very long time compared to human lifetime.

The latter point is the reason this book concentrates on resources, encompassing both energy and raw materials. Standardization and legislation today is mainly concerned with sustainability from an energy point of view. Even the terms used are sometimes misleading; some reporting, for example, CEFIC,1 counts the raw materials used by the chemical industry as energy inputs, an “energy” that is then turned into products, while other reporting counts them as raw materials.

Producing and thereby using our resources efficiently, especially the ones that we deplete and that cannot be replaced easily, is one of the important cornerstones of maintaining our safe and comfortable lifestyle, most certainly during the bridging period of the next few decades between now and the emergence of new “quantum-leap” technology that can replace the way we produce our day-to-day necessities, during which we have to use old technology with fewer and fewer resources.

The aim of this book is to provide ideas to the process industry on how to improve its resource efficiency over the next decades until different, not yet envisioned technologies are available that will change the game completely.

Parts I to III discuss a broad range of ideas on how to improve resource efficiency by better plant management, process operations and changes of the plant setups. We provide concepts that can be applied directly. We review existing technologies and suggest new approaches and explain how to apply them and thus improve resource efficiency.

Most plants in the process industries operate for long periods of time, often for several decades. The measures taken to improve their energy and resource efficiency are strongly influenced by regulations and standards, which are covered in Part I, Resource Efficiency Metrics and Standardised Management Systems, of this book. Without physically changing the process equipment, the way the processes are operated can have a strong influence on the resource efficiency of the plants and this potential can be exploited with much smaller investments compared to the introduction of new process technologies. This aspect is the focus of Part II, Monitoring and Improvement of the Resource Efficiency through Improved Process Operations. In Part III, Improving Resource Efficiency by Process Improvement, we then discuss tools and ideas for changes of the process technology such as heat integration, synthesis and realization of optimal processes as well as industrial symbiosis as a means to improving resource efficiency.

The last part, Part IV, Company Culture for Resource Efficiency, deals with the people that are needed to make these changes possible and discusses the path towards a company and sector-wide resource efficiency culture.

In Chapter 1, Energy and Resource Efficiency in the Process Industries, the editors of the volume provide an overview of the situation of the process industries in Europe with respect to resources and discuss the meaning of resource efficiency today, pointing out that there is a specific interpretation of resource efficiency for the process industries. The options for improving resource efficiency by improving plant operations are also discussed.

Based on this introduction, the standard approach towards improving resource efficiency is discussed, mainly from the viewpoint of saving energy, as energy efficiency has been the focus of standardization and regulation in the first half of the current decade (2011–2015). Jan Uwe Lieback, David Kroll, Jochen Buser, Nico Behrendt and Seán Oppermann from GUTcert in Germany share their knowledge and experience in energy and resource management systems in Chapter 2. This chapter, Standards, Regulations and Requirements Concerning Energy and Resource Efficiency, provides an introduction to energy and resource management systems, describing the historical background and the evolution of the international standard on energy management systems ISO 50001 and its application. The chapter highlights how energy efficiency measures impact resource efficiency and where standardization for resource efficiency currently stands.

Marjukka Kujanpää, Tiina Pajulaa and Helena Wessman-Jääskeläinen from VTT in Finland discuss Energy and Resource Efficiency Reporting in Chapter 3. The chapter provides an overview of different mechanisms that can be used for resource efficiency reporting today and points out that none of the mechanisms include specific indicators for resource efficiency. However, the general ideas of these mechanisms are relevant when developing resource efficiency reporting schemes.

Gunther Windecker from BASF in Germany contributes industrial experience with Energy Efficiency Audits in Chapter 4. Energy efficiency audits are a consultation process that can be conducted independently from an energy management system. The audits are standardized and pursue the target to systematically identify energy flows, potentials for energy efficiency improvements and subsequent action plans. Gunther Windecker shows the practical steps of an energy audit for the process industries using a typical example – a cooling water pump system. While being an important measure to improve energy efficiency, energy audits do not cover resource efficiency in the process industries on a broader scope.

Part II, Monitoring and Improvement of the Resource Efficiency through ImprovedProcess Operations, describes new approaches to monitoring and reporting resource efficiency in real time for integrated processing plants. It focuses on operational improvements by means of defining suitable resource efficiency indicators, real-time reporting, improving online analytics, using IT systems to collect and process the data and pre-treating the data and using it for advanced control, optimization and decision support systems. In order to optimize the resource efficiency of the complete production system including the generation of electric power outside the plants, a chapter on demand side response shows how to use the flexibility of processing plants to respond to requests for increasing or decreasing their electric power consumption or the consumption of other resources in a controlled manner to deal with supply fluctuations. Part II finishes with a real industrial example in which many of the methods described in the previous chapters were applied such that a large chemical company saved significant amounts of energy.

In Chapter 5, Real-Time Performance Indicators for Energy and Resource Efficiency, Benedikt Beisheim and Stefan Krämer from INEOS in Köln, Germany, and Marc Kalliski, Daniel Ackerschott and Sebastian Engell from the Technical University of Dortmund in Germany describe results from the EU co-funded research project MORE2 (Real-Time Monitoring and Optimization of Resource Efficiency in Integrated Processing Plants). In this chapter, real-time resource efficiency indicators are discussed as the basis of solutions for real-time decision support and optimization to improve the resource efficiency of chemical plants. The indicators are related to the best demonstrated practice of the plants or units under consideration, which are computed taking into account the main influencing factors for the resource efficiency (e.g., the plant load) that cannot be influenced by the operators. The aggregation of indicators from plant sections to the enterprise level is described as well as methods for the analysis of the contribution of different plants or units and the root causes. The developed methods are explained for continuous, batch and batch-continuous processes and applied to a generic example of an integrated production site with continuous processes and a power and utilities provider.

In Chapter 6, Sensing Technology, Alejandro Rosales and Oonagh McNerney from IRIS, Spain, provide an insight into what is possible with today's and tomorrow's sensing technology. The chapter provides the reader with the authors' knowledge and experience in relation to a number of key metrological concepts, which are fundamental in the context of resource efficiency by rationalizing production processes. The chapter thus describes a number of relevant sensor technologies from as basic as energy metering to the latest advancements in spectroscopy, process analytical technologies (PAT) and soft sensors. It discusses the challenges in relation to sensor integration and sample interfacing for reliable in-line use. The focus of the measurement techniques described lies on PAT and their contribution to the Fourth Technological Revolution or Industry 4.0. For resource-optimal operations of chemical plants, PAT is very important as it is often required to know the composition of the process streams, both of the final product and also during processing, either at the key apparatus in the process or during intermediate batches. Knowing these compositions exactly means that the right amount of energy is used for separation and purification and this knowledge certifies that only product of the right quality is produced and delivered to the customer. Especially if their results are used in process control, feedstock and intermediate material, quality measurements lead to optimal process operations for varying stream compositions and result in a reduced amount of off-spec material.

For measurements to be useful in resource efficiency indicator visualization, process control and manufacturing execution, process-related information technology as well as a sensible structuring of information is required. In Chapter 7, Information Technology and Structuring of Information for Resource Efficiency Analysis and Real-Time Reporting, Udo Enste from Leikon in Germany describes current and new methods and ideas in IT and information structuring. The chapter gives an overview of how to provide real-time resource efficiency indicators using state-of-the-art production-oriented IT systems as well as of new innovative concepts to deal with context-sensitive information management in real-time applications. It explains aggregation and contribution through a plant hierarchy by introducing the concept of a “resource managed unit” and its use in the structuring and displaying of information.

Once the necessary measurements of streams and stream properties are available so that resource efficiency indicators can be computed, it is often necessary to perform data pre-treatment to reduce the influence of measurement errors. Cesar de Prada from the University of Valladolid in Spain and Daniel Sarabia from the University of Burgos in Spain focus on data reconciliation for measurement error treatment in Chapter 8, Data Pre-treatment. They explain the concept of data reconciliation and the current research in this area. The chapter discusses the problem of errors in data and methods that can be applied to mitigate it. Special emphasis is laid on the detection and correction of gross errors or outliers in measurements.

Resource efficiency is a multidimensional attribute, and it can only be improved by the plant operators and managers if easily comprehensible information on the current resource efficiency relative to a baseline is provided. Marc Kalliski, Daniel Ackerschott, and Sebastian Engell from the Technical University of Dortmund in Germany and Benedikt Beisheim and Stefan Krämer from INEOS in Köln, Germany, describe current research on decision support resulting from the research project MORE in Chapter 9, REI-Based Decision Support. From general principles of the visualization of complex data, a generic dashboard for the visualization of resource efficiency indicators is derived and illustrated by an example. Furthermore, the chapter outlines how resource efficiency indicators can be used for interactive decision support solutions that can help managers and operators to steer the production processes towards a more resource-efficient operation. Specifically, simulation-based support for what-if analysis and the use of multicriterial optimization are discussed.

In Chapter 10, Advanced Process Control for Maximum Resource Efficiency, André Kilian from Applied Manufacturing Technologies (AMT), USA, describes how to implement APC solutions in order to optimize chemical production processes and why they are successful. Chapter 10 introduces Model Predictive Control (MPC) as the method of choice for advanced control of complex plants. Modern MPC solutions include a computation of the setpoints of the process inputs and outputs that approximately optimize the plant economics and steer the process towards these setpoints using multivariable dynamic process models. In contrast to classical control solutions, constraints on process variables can be formulated and are respected by the control scheme, which is extremely important as the optimal operation both with respect to economics and with respect to resource efficiency typically is at an intersection of the constraints.

Real-Time Optimization (RTO) is a further step that can be applied to improve resource efficiency. It is usually installed on top of the control layer and optimizes the setpoints of the plant using a rigorous nonlinear process model that is adapted to the observed data. Cesar de Prada and José Pitarch from the University of Valladolid in Spain explain the concept of RTO in Chapter 11, Real-Time Optimization (RTO) Systems. The chapter firstly explains the mathematical background needed to understand real-time optimization applications and then moves on to present an explanatory example. An explanation of typical mathematical solvers for optimization problems and solver implementations are given that are needed when developing optimization solutions from scratch. The provided industrial example where RTO is applied to a multiple-effect evaporation process shows how the presented methods can be applied and that this results in resource optimal operation.

Demand Side Response (DSR) is an approach that helps to valorize market fluctuations and varying availability and carbon footprints of raw materials and energy, especially of electric power. If a correlation between the price of a resource and its scarcity is assumed or, as is the case for electricity in Germany, more power from renewable sources causes lower prices, DSR under economic considerations simultaneously optimizes the resource efficiency when the plant and the energy system are considered together. Iiro Harjunkoski, Lennart Merkert and Jan Schlake from ABB Corporate Research in Germany explain how demand side response works and how it can be applied in Chapter 12, Demand Side Response (DSR) for Improving Resource Efficiency beyond Single Plants.

Many of the methods discussed in Part II of the book have already been applied in industrial practice. Guido Dünnebier, Bayer, Germany, and Matthias Böhm, Christian Drumm, Felix Hanisch and Gerhard Then from Covestro, Germany, share a successful industrial implementation of energy management and energy optimization at Covestro, formerly Bayer MaterialScience, using the in-house software STRUCTese™ in Chapter 13, Energy Efficiency Improvement Using STRUCTese™. Bayer initiated a global climate program in 2007 with ambitious targets for cutting specific GHG emissions. One of the lighthouse projects is the Bayer Climate Check that was applied to over 150 of the most energy-intensive plants of the Bayer group. It incorporates two essential elements, quantification of the climate footprint and identification of savings potential through an energy efficiency check. The energy efficiency check follows a structured and universal approach that involves optimization of the consumption of utilities as well as the energy efficiency analysis of plant-related facilities, energy generation units and buildings. The resulting plant-specific implementation plan of evaluated and prioritized energy efficiency projects is the basis for a continuous and sustainable improvement process within the plants.

The focus of the book shifts from plant operations that can improve resource efficiency without changing the equipment of the plant to the optimization of the physical plant and its equipment in Part III, Improving Resource Efficiency by Process Improvement. The described methods require plant modifications for resource optimal production such as heat and mass integration and optimal process synthesis. The application of the structured approaches opens the door for the optimization of industrial symbiosis as a means to improve resource efficiency of overlapping industrial sectors.

Minbo Yang from Northwestern University and Jian Gong and Fengqi You from Cornell University, USA, describe the synthesis of resource-optimal chemical processes in Chapter 14, Synthesis of Resource Optimal Chemical Processes. The chapter also provides an introduction to Part III of the book and explains the path towards designing or retrofitting chemical processes using structural optimization.

While Chapter 14 explains this synthesis for the process itself, Chapter 15, Optimization-Based Synthesis of Resource-Efficient Utility Systems, describes similar methods that are extended by a time series analysis to find the optimal utilities system to support a set of chemical plants. Björn Bahl, Maike Hennen, Matthias Lampe, Philip Voll and André Bardow from RWTH Aachen University, Germany, present a general method that can be used to optimize chemical sites and manufacturing sites, a university campus or a medical centre. They provide a practical work-flow consisting of five steps to formulate, identify and analyse synthesis problems of utility systems.

In Chapter 16, A Perspective on Process Integration, Ivan Kantor and Francois Maréchal from EPFL and Nasibeh Pouransari from Syngenta in Switzerland discuss the importance of process integration and its application using optimization techniques to realize the efficient use and conversion of energy and material resources in a process. The chapter focuses specifically on the perspectives of mass and energy integration within processes and plants by optimizing both the mass and heat exchange within a process and the supply of utilities such as steam and cooling water. Integration options within plants, for example, heat integration, and also within production sites, then labelled total site analysis, are explained.

The extension to multiple sites with exchanges between various sub-processes of the individual plants is possible following the same path and leads to the idea of Industrial Symbiosis covered in Chapter 17 by Greet Van Eetvelde from Ghent University, Belgium. The chapter works out in general terms how co-operation exceeds competition with respect to resource efficiency and shows the symbiosis strategies that have to be developed and implemented to create economic and environmental win-win situations for both companies and society as a whole. The approach is described in detail for the manufacturing industry as a whole. The chapter furthermore shows that successful win-win situations require a strong partnership and transparent management structures.

People are the key drivers for improving resource efficiency using all of the above tools and methods. We therefore included a chapter that is dedicated to this aspect. In Chapter 18, Organizational Culture for Resource Efficiency, Klaus Goldbeck, coach and management consultant from Leverkusen, Germany, supported by Stefan Krämer, presents insights into the human part of improving resource efficiency. All operational changes and physical plant improvements require human support, management and operators. Human beings, in contrast to technical systems, act and react in more complex and subjective ways and are less predictable. They need a culture of trust and a common goal to actually implement improvements and recommendations. This is true within a company just as much as between companies. The methods of Chapter 18 target structures inside companies but can easily be applied to a task force that is set up to improve industrial symbiosis.

The first idea for this book was developed by Claudia Ley from Wiley and Gunther Windecker from BASF in 2014, mainly focusing on the improvement of energy efficiency. After Gunther Windecker had to concentrate on other duties, we took over and – motivated by the work done in the EU FP7 funded project MORE on real-time resource efficiency indicators – extended the scope to resource efficiency. We tried to cover a broad range of aspects to provide the reader with an overview of the available technology as well as current research and innovations. In the process of editing the book, it became obvious that the extension of the scope is fully in line with the trend towards considering resource efficiency on a broader basis rather than just focusing on energy efficiency. We therefore believe that this comprehensive collection of articles will remain interesting to the readers for the next few years and will help the process industry to become more and more resource efficient and to be able to show improvements using the right indicators. The path towards a truly circular economy will require many steps and measures and the methods presented in this book are essential elements.

The main work for this book was done by the authors of the chapters. We are very grateful for their diligent work and the extra hours that they have invested, and we are sure that the readers will appreciate this, too.

Apart from the authors there are a few more people whom we would like to thank:

Claudia Ley and Samanaa Srinivas from Wiley who put their faith in us finishing this work and patiently worked with us, when we modified our initial ideas or extended deadlines.

Our colleagues and coworkers, especially in the case of INEOS in Köln, who supported this project besides the day-to-day work that still needs to be done. Gunther Windecker from BASF who thought that we would be a good choice to replace him as the editor.

Sebastian von Heldreich, who as a student spent some of his private time to fix formal issues such a bibliographies and images.

Svetlana Klessova, the coordinator of the project MORE who always reminded us how important it is to disseminate the project results, and our colleagues from the MORE project, many of whom contributed directly, and all of whom contributed indirectly to this volume.

And finally to our families, in the case of Stefan Krämer especially to my daughters Amelie and Lena who had to spend several weekends without their dad.

August 2017

Leverkusen and Wetter (Ruhr)Stefan Krämer, Sebastian Engell

1

The European Chemical Industry Council.

2

The MORE project has received funding from the European Union's Seventh Framework Programme for research, technological development and demonstration under grant agreement No 604068.

Part IResource Efficiency Metrics and Standardised Management Systems

Chapter 1Energy and Resource Efficiency in the Process Industries

Stefan Krämer1 and Sebastian Engell2

1INEOS Köln GmbH, Alte Str. 201, 50769 Köln, Germany

2Technische Universität Dortmund, Department of Biochemical and Chemical Engineering, Emil Figge-Str. 70, 44221 Dortmund

1.1 Introduction

Climate change, reduced access to fresh water, loss of biodiversity and pollution are possible downsides of industrial production. Among the different sectors of industrial production, the sector of the chemical and process industry has a relatively large impact on resources and on the environment as most production units in this sector use natural, often non-renewable resources directly or via their supply chains. One main goal of current environmental policies is to slow down global warming by decreasing CO emissions. The most significant measure in this direction is to switch to renewable resources in the generation of electric power, heating of buildings and industrial production. When the source of raw materials cannot be changed in the short or medium term, an important intermediate step is to increase the overall resource efficiency, in power generation as well as in industrial production.

Energy efficiency has been a prominent topic of public discussion, scientific research and engineering; it is covered in many books and publications as well as by legislation. Resource efficiency