Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Lebensstil

- Sprache: Englisch

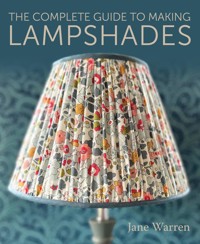

This practical handbook teaches you all the methods needed to make your own lampshades in a wide range of styles — from the simple drum hard lampshade to the more complex hand-sewn traditional gathered and pleated designs. As well as clear demonstrations, it gives information on frames and fittings, how to work with different fabrics and papers, and showcases how using your own designs offers a truly bespoke approach. Here you will learn everything you need to make wonderful lampshades to feature in your home, or to offer professionally.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 301

Veröffentlichungsjahr: 2024

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

CONTENTS

Introduction

PART 1: HARD LAMPSHADES

1 Materials and Getting Started

2 Making Hard Lampshades

3 Further Ideas and Techniques for Hard Lampshades

PART 2: SOFT FABRIC LAMPSHADES

4 Materials and Techniques

5 Traditional Tailored Lampshades

6 Gathered and Pleated Lampshades

7 Further Ideas for Soft Lampshades

8 Trims for Lampshades

Appendix

Glossary

Suppliers

Contributors

Index

INTRODUCTION

Lampshades were first created to have a practical role in our homes – to hide the glare of the light emitted from the light fittings – but they soon became a key decorative interiors item as they literally light up the design on the fabric or paper used to make them. The designs of lampshades also have to meet the need of the lighting that is required:

• ambient – the key overall lighting in the room

• task – directional lighting, for example over a kitchen work surface, or a standard lamp to aid reading

• accent – personalising your space with a particular design – statement lampshades that highlight a room’s interior decor.

Learning the skills of lampshade making will allow you to make unique and bespoke lighting, including recycling traditional frames and partnering them with beautiful fabrics. (Photo: Caitlin Warren)

All these layers of lighting add to the atmosphere created in our homes. Consequently, there are many different types and styles of lampshades that are required and we often change our lampshades when we redecorate or move house.

Large commercial outlets often cannot supply us with the exact lampshade we want – in the right frame size or shape, with certain fittings, using a matching or designer fabric or adding trims to create interest, and they are often imported in mass quantities. As a result, there is a return to making our own – as with many interior and craft items, there is a surge of interest in revisiting traditional skills, combined with an increasing love of interiors fashion and style. With the advent of more people designing their own fabric, and more students graduating with degrees in surface pattern and textile design, there are more interesting and impactful designs available and therefore to choose from – they deserve to be lit up!

This book teaches you the key methods for making lampshades in many different styles – starting with the simple contemporary hard backed drum, progressing to the more complex hand sewn, including traditional tailored and gathered and pleated lampshades. You can also add your own design detail by making hand sewn trims, in your own choice of fabrics and materials, making your lampshades truly bespoke – the options are endless! Making lampshades is not a difficult process. Indeed, the simple drum takes little time and a small amount of fabric. It is not expensive and they are fun and interesting to make. To make hand sewn lampshades, you do need – or require the desire to have – a love of hand sewing; they are a slow make, taking time to stitch for a great finish.

It is always beneficial too to remake our lampshades using the original materials; with the goal of preserving both the environment and the craft, top tips are included here. Start the book by learning the basic ‘how-tos’, and as you progress through the tutorials, you will develop your skills to make some wonderful works of art, fashioned to your own designs.

PART 1HARD LAMPSHADES

Hard lampshades, also known as ‘card’ or ‘firm’ lampshades, refer to the fact that the materials used to make them are rigid – usually a vinyl laminate backing onto which fabric or paper are attached. The laminate material is fire retardant, and remains so once the chosen material is adhered to it. Unlike ‘soft’ traditional lampshades, there is no hand sewing to make these, they are relatively inexpensive, take little time to make and a wide variety of fabrics and papers can be used to make them. They can also be made in many different shapes and sizes, including square, rectangular, oval, hexagonal as well as the classic empire and drum shapes. In addition, doublesided lampshades add extra interest with perhaps a plain linen on the outside with a vibrant patterned fabric inside. As well as the size and shape, the fabric or paper chosen is the main star of the show, with endless options giving different ‘looks’, from traditional to contemporary to luxury designer fabrics that really bring personality. You can also add interest with metallic liners and eye-catching and opulent trims.

As well as using available fabrics, and for something entirely unique and bespoke, lampshades can be made using your own designed fabrics or paper, using block-printing techniques or painting a plain lampshade in a chosen design (seeChapter 3), and by adding various trims and bindings.

Drum lampshade made using luxury velvet with gold liner made by Rab Moghal of Light Owl, bringing opulence to lighting design.

AKINDE African wax print drum lampshade by Detola and Geek. Made by Tola Laseinde, whose handcrafted, African-inspired lampshades are bold, colourful and unique.

CHAPTER 1

MATERIALS AND GETTING STARTED

The materials needed to make hard lampshades can be found in a lampshade-making kit or you can buy the individual components.

Kits versus the Individual Components

There are two ways of making hard lampshades – either using a kit or using the individual components needed. The kits come with all the materials (apart from the chosen fabric or paper cover required) and are good to purchase if you wish to make one or two lampshades at a regular size, or if you are making your first hard lampshade, as the laminate panel is pre-cut for you. However, if you wish to make lampshades with different heights, or to make more of them, then it is worth buying the individual components. The instructions for both methods are included in the step-by-step instructions in Chapter 2.

The laminate used to create hard lampshades can be cut to the size and shape needed.

Laminate Backing Panels

The laminate materials come in a wide choice of colours and finishes that show on the inside of the lampshade. Most often used is white laminate; however, clear, gold, silver and copper are very popular, as are cream and white card. Also available is eco-board, which is more environmentally friendly, and is sourced from carefully managed and renewed forests. The reverse side of the laminate is covered in a backing paper, underneath which the surface is adhesive. It is this side that the selected fabric or paper is adhered to, and will be on the outside of the lampshade.

There is a large choice of lining backing materials to make lampshades – from white to neon PVC to cream card. Stick-It ® materials manufactured by Dannells.

TOOLS AND MATERIALS NEEDED TO MAKE HARD LAMPSHADES

The key tools and materials are:

• a laminate panel

• ring sets

• double-sided sticky tape

• card or roll-edged tool

• scissors

• pencil

• ruler or grid rule

• tape measure

• your choice of fabric or paper.

Gather together the tools and materials needed to make hard lampshades.

Hard Lampshades and Fire Retardancy

All laminate materials made for hard lampshades have been tested in the Lighting Association Laboratories and have passed the glow wire test. Fabrics and papers that are adhered to the laminate materials are therefore fire resistant – even those adhered to the inside of the lampshades, as in the double-sided laminate. However, always use LED bulbs, which are cool to the touch, and will help prevent any scorching to the inside of the lampshade.

Ring Sets and Fittings

Hard lampshades have two wire rings that are needed for the structure of the lampshade. One ring is plain, and the other is a ‘utility’ ring. This ring holds the light fitting used to connect the lampshade to the lamp holder – either on a lampbase or on a ceiling/pendant – using ‘gimbals’ (the metal arms that connect the light fitting to the ring). The laminate backing with your chosen fabric is then adhered to the rings to make the lampshade, with the following choices of utility rings.

Plain Rings

Plain rings are paired with a choice of utility rings to make hard lampshades in all shapes and sizes.

A plain ring is paired with a utility ring that holds the light fitting to create the lampshade.

Standard Utility Rings

Standard utility rings are manufactured to fit European lamp holders, and an adaptor plug is fitted to reduce the diameter so that it can fit standard UK lamp holders (bayonet cap B22). This can easily be removed to fit European lamp holders (Edison screw E27).

A utility ring holds the light fitting, as well as a removeable adaptor to suit both EU and UK lamp holders.

Washer Fittings

Some lampshades have a washer fitting for use with a harp and finial, most commonly used in the USA, the opening of which is just 10mm diameter. You can also purchase converters so that your EU/UK standard fitting can be converted to use as a harp and finial lamp holder.

A US washer ring is for use with a harp and finial fitting, most commonly used in the USA, and is just 10mm (⅓in) wide.

Duplex Fittings

A duplex fitting is a large ring positioned within the top ring. It offers flexibility for your lampshade, by either being used for a lamp base or standard lamp (you will need a shade carrier for this) or as a ceiling/pendant shade (you will need a spider fitting for this). Shade carriers come in a variety of heights, from 10cm to 30cm. Spider fittings come in an EU size with a UK converter. Therefore you can make a lampshade with a duplex fitting to give you full flexibility should you wish to. They are also chosen because the standard utility ring’s light fitting is positioned 4cm above the base ring, and this may mean the lampshade is too low for the lamp base.

A duplex ring/fitting is positioned in a top ring and allows the lampshade to be used both for lamp bases and as ceiling fittings.

Candle Clip Fittings

Candle clip fittings are attached to the top ring of small lampshades, usually made for wall lights or chandeliers, and neatly fit onto a candle or small golf-ball bulb.

Candle clips are fixed to the top ring and fit neatly onto a candle or small golf-ball bulb.

Drop-Down Fittings

A drop-down fitting is where the light fitting is attached to the top ring but is ‘dropped down’ to the middle of the lampshade by long gimbals. These are particularly useful if making lampshades that require a top ring only, such as scallop or paper pleated lampshades. Some drop-down fittings have hinges so that the lampshade can be tilted (for reading) or for allowing the lampshade to work for a ceiling pendant fitting.

A drop-down fitting is attached to the top ring but ‘dropped down’ to the middle of the lampshade by long gimbals (the metal arms that attach a light fitting to a ring).

FIXTURES FOR YOUR DUPLEX RING FITTING

Shade carriers fit onto table or standard lamps by being placed onto the lamp holder fitted to the base. The lampshade is then simply placed onto the top of the shade carrier. As mentioned, they come in a variety of heights, from 10cm to 30cm. This is useful as you can then choose one that suits the lamp base perfectly. If it is too low it may hide some of the lamp base design; if it is too high it will reveal the metal or plastic lamp holder and bulb. In addition, having a shade carrier makes it easy to clean your lampshade as it can be simply lifted off the base. Having a duplex fitting in your lampshade offers flexibility as it can also be used as a pendant lampshade – simply add a spider fitting to a ceiling fitting and place the shade onto that.

The duplex fitting is placed in the top ring of the lampshade, ready for either a shade carrier or a spider fitting.

A shade carrier is fixed onto a lamp base, and the lampshade is placed on top of this.

By using a spider fitting, the lampshade can be connected to a ceiling light fitting to become a pendant lampshade.

Diffusers

A diffuser is used to soften the light that comes into the room, to hide the inside of the lampshade, and for decoration. They are therefore mainly used with ceiling lampshades and focus the eye on the design of the outside. The diffuser is a disc the size of the circumference of the base lampshade ring. They come in a variety of styles, from translucent to featuring cut-out designs. In addition you can adhere your choice of fabric onto these (see Suppliers), offering a totally bespoke lighting option. They are installed by simply placing them at an angle, and then straightened to sit in the base ring.

Tube Lights by The Bespoke Boutique in collaboration with Eva Sonaike for C.P. Hart.

SIZES AND SHAPES OF HARD LAMPSHADES

There are many different shapes of hard lampshade to choose to make:

• drum lampshade – the top and base rings are the same size

• empire – the top ring is half the size of the base ring

• French drum – the top ring is smaller than the base ring, as in the empire, but less so

• cone or coolie shape – the top ring is far smaller than the base ring

• oval – the top and base rings are oval – much wider than the depth

• rectangular and square

• hexagonal

• tiered shades

• half frames, wall lights.

The rings and ring sets you can buy now mostly come in increments of 5cm, ranging from 10cm to 100cm. However, you can get different sizes made to order by commissioning a frame maker or by remaking older hard lampshades (seeChapter 3 for remaking hard lampshades).

Laminate Panel Lengths for Drums

If a lampshade-making kit is being used, the laminate panel will be pre-cut with a determined height. If you are using all the individual materials, however, the panel will need to be cut from a roll of laminate.

First work out the amount of laminate needed to fit around the ring sets, plus allow an extra 15mm minimum for the seam allowance. For example:

• You can calculate that a 30cm diameter drum will have a circumference of 94.2cm (diameter × pi (or 3.14)) + 15mm seam = 95.7, rounded up to 96cm.

• You then need to decide on the height of the lampshade.

• Using a rule, draw these measurements onto the paper-covered side of the laminate and use scissors or a knife to carefully cut it out, taking time to be accurate.

The fabric requirement will be the same as the panel, plus some extra to gain neat edges and for tucking under the rings (see tuition in Chapter 2) – allow some extra all the way around. The table shows the sizes of materials needed, when not using a kit, for drum shades:

DESIGNS AND SUGGESTED SIZES OF HARD LAMPSHADES

In a lampshade making kit, the sizes have already been decided. However, you may wish to make some with different dimensions. The laminate panel can be cut to have different heights for drum lampshades, but for other shapes they should be in proportion. The table offers suggested sizes; however, you can create your own templates and choices.

SUGGESTED SIZES FOR HARD LAMPSHADES

HOW MUCH LAMINATE AND FABRIC TO CUT FOR NON-KIT DRUM SHADES

Drum lampshade size (diameter)

Panel length to cut (including 15mm seam)

Fabric length (minimum)

15cm

49cm

53cm

20cm

64.5cm

69cm

25cm

80cm

84cm

30cm

96cm

100cm

35cm

111.5cm

115cm

40cm

127.5cm

132cm

45cm

143cm

147cm

50cm

159cm

163cm

55cm

174.5cm

179cm

60cm

190.5cm

194cm

70cm

222cm

226cm

Notes: Figures have been rounded up for ease.

Choose the height of the shade for non-kit lampshades, just cut the panel to the required height, plus allow around 4cm extra fabric for the height.

Lampshades over 40cm will usually need to have fabric either turned sideways (railroaded) or joined with an extra seam positioned opposite the main seam (seeChapter 3 for tuition).

How Much Fabric Is Needed for Empire Lampshades?

Empire, French drum, and cone lampshades have curved panels, and therefore the fabric requirements are different from the drum lampshades. The empire and cone lampshade-making kits advise how much fabric is needed to cover the area of the laminate panel. When using a template and using the individual components required, however, the following guide advises how much fabric will be needed for a few examples of empire-shaped lampshades.

AREA OF FABRIC NEEDED FOR EMPIRE SHADES

Templates for Hard Lampshades

Creating and cutting a laminate panel to the correct size for drum lampshades is a straightforward process. However, to make empire, French drum, or cone-shaped lampshades, a templated laminate panel is required for this as they are curved. There are various ways of achieving this:

• Purchase a kit with a ready-cut laminate panel to use.

• Arrange for a bespoke templated panel to be made by visiting the website of the lampshade materials manufacturer who offers this service and ordering a bespoke size (see Suppliers on page 172).

• Similarly, the supplier offers the option to use a tool on their website to download a template that you can then print at home.

• Work out a template or pattern at home.

In all cases, once the lampshade has been made, the backing paper of the laminate panel can be kept as a pattern to use should you wish to make more of that lampshade size in the future.

MAKING A TEMPLATE OR PATTERN YOURSELF

You can work out the drawing for a template by following these steps and using these tools and materials:

• large piece of paper or card

• pencil

• string or waxed jewellery cord

• pin

• set square and rule

• tape measure

Decide on the dimensions of the lampshade you wish to make, and make a note of them, for example:

• base 25cm diameter

• top 15cm diameter

• height 17cm (note this is the vertical height; the slope height will be slightly longer)

Work out the circumferences (diameter × pi (3.14)). For the above example, the base would be 25 × 3.14 = 78.5cm and the top would be 15 × 3.14 = 47.1cm.

Use the template pattern maker at home to create various sizes for your lampshades.

Follow these steps to make the template:

1. Lay the card or paper on a table, and in the right-hand base of it draw a horizontal line the measurement of the base ring diameter (line A).

2. Find the centre point of this line and draw a vertical line upwards from that point, the height of the lampshade (line C). Use a set square for precision.

3. Now draw a horizontal line the measurement of the top diameter of the lampshade (line B). This should be centred above line A.

4. Draw lines upwards from the ends of lines A, B, and C, to where they connect, which will make a triangle. Make a mark at this key point.

5. Put a pin in this key point, attach a piece of string or cord (waxed, thin jewellery cord is best as it doesn’t stretch) to it, and attach the other end of this to a pencil.

6. Position the pencil exactly at the right-hand point of line A, and draw the arc around, as long as the measurement of the circumference plus 15mm for a seam allowance. You can mark the circumference by making small measurements around the curve, placing small pencil marks for accuracy – use a measure and place a mark every 1cm, so that it is exact.

7. Then attach the pencil to the cord so that it is positioned to the right edge of line B and draw another curve, again taking care to get the circumference measurement exactly right, adding on the 15mm seam allowance.

8. Draw a line connecting the two ends of the curves (which should include the 15mm seam allowance).

9. Cut out the template carefully all around. Place it on top of some laminate and draw around this. It helps to weigh it down for accuracy; use a pencil or knife to cut out and make your lampshade.

FABRICS AND PAPERS TO USE

There is a huge amount of fabrics and papers available to choose from, both from shops, fabric suppliers, and online.

Fabrics

As a rule, the easiest fabrics to work with are medium-weight cottons or cotton mixes, as they are happy to be adhered to the laminate panel, don’t fray particularly, and don’t pucker or shift when you make the lampshade; in other words, they behave well. The weave is important to consider, as loose weaves may mean the laminate might be visible, and the fabric could shift when using it. Other materials to use are hessian (made from jute), raffia (a thicker weave than hessian), and parchment (traditionally made from animal skin, now available using a thin translucent paper). Obtain samples first and adhere them to a piece of the laminate to check they will work and stay stuck down in advance of making the lampshade.

Tips on Using Different Fabrics

Wool: Ensure a little more fabric is cut along the horizontal edges, as they are thicker to fold under the rings.

Velvet: As with wool; with both wool and velvet, it may help to hand sew down the seam once you have made the lampshade, to keep the seam closed (seeChapter 3 for tips and Chapter 4 for sewing tuition).

Silk: This has a tendency to pop away from the laminate panel, as it notoriously doesn’t like being stuck down. However, try small samples of different types on samples of laminate to check if it will stay in place before making the lampshade, as some may be successful. Faux silks are perfect for hard lampshades as the synthetic material happily adheres to the laminates.

Thin fabrics: Take extra care to ensure the fabric stays straight when you adhere it to the panel; it can move or ‘shift’ around and can easily pucker. Taking your time and re-doing it if necessary will help.

Calico: This can pop away from the laminate after the shade has been made. Wash in advance to help with this.

Embroidered fabrics: Although it is possible to use these, bear in mind that the area around the embroidered part may lift away from the laminate, as it is thicker than the base cloth used.

Working with Papers

As well as using fabrics, papers can also be used to produce wonderful hard lampshades. There are a variety of types to use, including Japanese washi paper, hand-marbled papers, wallpapers, and even gift wrap. They easily adhere to the laminate but are often not wide enough to cover the whole length of your laminate panel, and therefore widths of the paper are used to fit. In this case, it is important to pattern match the design, so consider this when you choose your paper and how much you will need (see how to join fabric and papers for larger shades in Chapter 3). Consider also using a cream card laminate as the backing; because it is thicker, the design on the paper is more pronounced when the lampshade is lit.

This hand-marbled paper by Rachel Maiden for Maiden Marbling was used to make this stand-out drum lampshade. Made by Jane Warren.

Designs and Patterns to Consider for Hard Lampshades

When choosing patterned fabrics or papers to make hard lampshades, it is worth being mindful of the following design tips:

• For empire lampshades, the panel will be curved but the pattern will not be. It is therefore better to use a fabric or paper with a small pattern repeat.

• Large patterns may not fit in the confines of the laminate panel, so use them only for larger shades.

• If a lampshade-making kit is being used, it will have a defined height. Therefore it is worth considering where the elements of your design may lie – it is best to avoid large blank spaces or a feature cut in half, for example.

• As the length of the laminate panel cannot be changed, it is not possible to pattern match your fabric or paper at the seam; check the placement before making to get the best result.

When working with papers, it is best to use the thicker card laminate backing so that the design stands out. Paper by Cambridge Imprint, in various colourways of their ‘Milky Way’ design.

See more information and practical tips on pattern placement in Chapter 2.

Trims and Bindings for Hard Lampshades

Trims can easily be attached to the outside of hard lampshades by simply placing double-sided sticky tape or glue around the edge of the base and top of the lampshade, and adhering the chosen trim. Bias binding can be made or purchased to add a complementary or pop of colour too; it is also widely used to make lampshades using paper, because often the paper puckers as it is folded over the rings. There are instructions for making bias binding in Chapter 8 and how to adhere it in Chapter 2.

Bias binding is often attached to hard lampshades as a trim, to complete a design and particularly for those made using paper.

CHAPTER 2

MAKING HARD LAMPSHADES

THE CLASSIC DRUM AND EMPIRE

Drum lampshades have the same size top and base rings, and empires have a larger base ring than top ring, but both are made using the same methods.

A selection of St Jude’s Fabrics drum and empire lampshades, expertly made by Karen Revill of Revill, Revill Lampshades.

Getting Started

Before starting to make a lampshade, it is good working practice to put together the equipment and materials needed in advance so they are all to hand:

• table – a long table that is 500cm minimum deep, and which should be clean and free of clutter

• self-healing cutting mat – this is useful to have on the table because they offer perfect protection for tables as well as making it easier to cut the fabric and laminates, especially if using a knife or rotary cutter; plus they have marked measurements and angles

• ironing board and iron – it is imperative that the fabric is ironed really smooth, as any wrinkles or creases will show up on the lampshade, especially when lit

• a lampshade-making kit, and extra materials (or if not using a lampshade-making kit, the correct length of laminate, ring sets, and extra tools and materials, as outlined in Chapter 1)

• an item to help weigh down the panel as you make the lampshade – anything from a tin of beans to an old iron weight

• your choice of fabric or paper to make the lampshade.

Gather together the tools needed to make a classic drum lampshade on a large clean table.

Preparing the Laminate Panel Included in the Kit

The lampshade panel will be rolled up very tight in the kit box, and if used straight after unrolling it, may result in having a wavy lampshade. Take it out of the box, unroll it, and lay it flat, placing heavy books or other weights on it for a few days until it is totally flat and ready to use.

Making Drum Lampshades

Drum hard lampshades are perhaps the most straightforward to make, and therefore are a good choice for a first lampshade, especially if using a lampshade-making kit. Because the rings are the same size, it is easier to both adhere your fabric for pattern placement and to roll the ring sets onto the laminate panel.

Drum hard shades are perhaps the most straightforward lampshade to make, and you can add trims and use different colour linings for interest and variety.

Pattern Placement

It is worth spending time considering the pattern on your chosen fabric. Using a kit means that the finished lampshade will not be as tall as the laminate panel supplied. This is because there are scored edges (sometimes known as ‘kiss cuts’) along the lengths both top and base; these edges are 15mm in height and will be removed to leave some fabric to be tucked under the rings, meaning the finished lampshade will be 3cm less tall. As an example, the 25cm diameter drum lampshade that will be used in the tutorial has a laminate panel height of 24cm, but will in fact end up being 21cm. Therefore there is little point in using a design with a large dog that stands 25cm high, for example, as either its feet or head will be partly cut off.

Seam Pattern Placement

In addition, be mindful of what will appear at the seam. It is very unlikely that you can pattern match here, as the panel has a fixed length to fit around the circumference of the ring set. Although with checks and stripes there will not be a problem, there can be with patterns. For this reason, move the panel along the width of the fabric to see which position works best at the seam (ensuring you allow for the 15mm seam allowance). However, it does work out by chance from time to time, if very lucky!

Fabrics with a defined pattern rarely match at the seam due to lampshades having a fixed circumference and panel length – this example was a lucky result! Lampshade by Jane Warren.

Perfectly Straight Patterns

In order to guarantee that the pattern on the fabric runs straight along the top of the finished lampshade, it helps to place pins along the horizontal pattern repeat face up. This is because, when making the lampshade, the fabric is placed face down onto the table, and therefore the pattern may not be visible. Adding these pins will ensure a straight line.

Find a pattern repeat across the fabric and place pins in the repeats. This will ensure the pattern runs straight across the lampshade.

Plan your pattern layout: measure the height of the laminate panel and find the centre point; then match it with the centre of the fabric design for symmetry.

Planning Your Pattern Layout

Because of the fixed height of the lampshade panel in the kit, plan for a balanced pattern placement – perhaps choose a feature to put in the middle. Use a ruler to pinpoint the centre of the panel and then the centre of the pattern on the fabric. Place a pencil mark on the laminate edge and a pin in the fabric. These points can then be married to ensure the perfect central positioning of your design.

TUTORIAL: MAKING THE LAMPSHADE – USING A KIT

Having flattened the laminate panel and planned the fabric layout, follow these step-by-step instructions to make a drum lampshade. A 25cm drum kit has been used in this tutorial.

The completed drum lampshade, with the pattern placement planned in advance.

Cut the fabric 5cm larger than the panel, iron it well, and lay it face down on the table. Place the laminate panel on top (with the paper side underneath) in position, taking note of pins if used for pattern placement. Draw short lines (key lines) with pencil or chalk on the fabric, right up against the panel edge, all around.

Starting at one end of the laminate (it does not matter whether it is the left or right end), peel away around 10cm of the laminate’s backing paper, and fold it underneath the panel. Ensure there are no loose threads of fabric between the sticky panel and the underside of the fabric. Now stick it down accurately in the key lines drawn. Check the front to ensure there are no wrinkles.

Now work along the panel length using the following four key steps. 1. Take hold of the backing paper, and pull away the next 10cm of the paper to reveal more of the sticky side. 2. Check that the panel is in the right position in the pencil key lines. 3. Smooth it onto the fabric underneath. 4. Check the front to see if it is adhering with no loose threads or wrinkles in the fabric.

To achieve a neat seam (and to avoid a cut raw edge), draw a 1cm vertical line down one end of the fabric using a grid rule or ruler. Also add extra fabric tabs at the top of the 1cm cut fabric – 1.5cm high and 1.5cm across the panel. Add a strip of double-sided tape onto this extra fabric – from the base of the scored points, not the current height of the laminate panel.

Cut away the excess fabric around the panel, except the extra 1cm edge and tabs – start there first. Carefully remove the scored strips of laminate. It is key that these are removed gently, by pushing the laminate downwards along the scores, with the panel flat on the table; otherwise it can get damaged. Remove spare threads as the strips are removed.

Remove the pink cover of double-sided tape (DST) on the 1cm fabric strip, then fold it onto the laminate. Add another piece of the DST to the other end, but on the fabric side. Do not remove the pink cover yet. Cover the rings with DST, in the middle of the rings, let it meet at the end (not overlap). Smooth it down firmly. Take off the cover, starting with the utility ring – you can stand this up while removing the tape off the plain ring.

Lay the panel fabric-side down, with the extra folded end at the far end. Decide if the lampshade is to be for a ceiling (position the utility ring at the top of the panel) or a lamp base (place the utility ring at the base of the panel). Position yourself in front of the panel and the rings on the edge of the laminate; place them so that the gimbals are not by the front edge.

Roll the rings forward slowly. It is key not to have the rings either on the fabric or with the laminate edge showing. It can help to move one ring a few centimetres first and then the second, and repeat. It can help to turn the panel round towards you for accuracy once you get started. Once the panel has been completely rolled onto the rings, check there is no laminate sticking proud of the rings; unstick and re-roll if there is. Place the lampshade on its side, and smooth down the fabric around the rings.

On top of the gimbals, place scissors under the fabric and snip to the edge, not the top, of the ring. Now push the excess fabric under the rings: pull it up and over, and select either the tool in the kit or an old store card or small rounded-end knife to push the fabric under; position the tool onto the edge of the fabric and push it under – be firm. Leave the seam area until the end, otherwise it may result in a bowed-in seam.

Close the seam area by removing the cover of the DST, placing the seam of the lampshade on the table, and pressing it firmly together. The tabs are needed as there is so much fabric to tuck in around the seam, especially if using a thick fabric. Trim away as much of the tab as needed, then carefully pull up and tuck under the ring.

Using Separate Components to Make a Drum Lampshade

The advantages of not using a kit include:

• the lampshade can be made as tall as required

• a complete pattern in the fabric design can be included

• the ability to remake lampshades using new cut-to-size laminate (seeChapter 3 for the remaking tutorial)

•