45,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

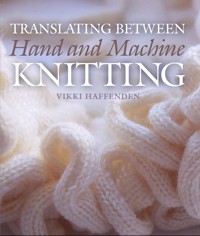

Knitting is an enduringly popular and creative craft, but many associate the techniques primarily with hand knitting, believing machine knitting to require arcane knowledge. However, machine knitting is formed from the same stitch structures and is equally versatile. Translating between Hand and Machine Knitting rediscovers the potential of domestic machine knitting to open up new possibilities for dedicated knitters, offering an equally creative yet timesaving method of crafting new designs. With over 500 images, this comprehensive guide offers detailed step-by-step explanations of techniques in both hand and machine knitting, whilst also offering inspiration and design advice. Dr Vikki Haffenden, a highly experienced knit designer, technical knitter and educator, shares the knowledge and understanding she has accumulated over a career designing for the knitted textile and knitwear industry and as a lecturer in knitted textile design.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Veröffentlichungsjahr: 2018

Ähnliche

TRANSLATING BETWEEN

Hand and Machine

KNITTING

VIKKI HAFFENDEN

THE CROWOOD PRESS

First published in 2018 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2018

© Vikki Haffenden 2018

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of thistext may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 432 2

Dedication

For my mother, Molly, who ran out of time her own book.

Cover photo: Simon Canning

CONTENTS

Acknowledgements

List of Abbreviations

Suggested skill levels

Introduction

1Materials and equipment

2Stitch constructions

3Hand-and machine-knitting techniques

4Surface texture

5Working with colour

6Creating shapes and three-dimensional shaping

7Translating patterns between hand and machine knitting

Appendix 1

Appendix 2

Appendix 3

Glossary of Terms

List of Suppliers

Bibliography

Index

ACKNOWLEDGEMENTS

That you are reading this book is due in huge part to my patient and constantly supportive husband, Ross, without whom it would never have been completed. He has continually provided cooked dinners, tea and sympathy and has always been prepared to listen as I talk things through, never doubting that I would get there. He and my sons, Jack, Ben and Tom, have carried knitting machines, tripped over yarns, soldered electronics, delayed holidays and put up with being displaced from their rooms by an expanding array of knitting equipment, for which I thank them all wholeheartedly.

I am indebted to my stalwart knitter, Rachel Graham, who coped so well with vaguely drawn graphs and draft instructions; any irregularities in the knitting are my fault alone. I own a debt of gratitude to the talented graduates and students of Knitted-Textile Design from the University of Brighton Department of Fashion Textiles, who have so generously permitted me to include their designs in this book: Marie-Claire Canning, Megan Doggett, Nell Downes, Rachel Graham, Juliet Hilder, Ilana Avital, Sigita Kaleth, Rachel Lynch, Becca Middleton, Emily Powell and Lily Rodgers. I wish them all the best for their future careers.

Thanks are due to my former colleague, and font of all knitting knowledge, Toni Hicks, for allowing me to use photographs from her knitting-related adventure in South America. Rachel Driver, Toni Hicks and Lara Evans proofread early drafts and provided me with insightful professional feedback. My friends Elly Donovan, Gail Kennington and Frances Tobin gave me the confidence to continue, whereas Mary Mussett and Sue Pringle took me walking so that I didn’t become subsumed by knitting. I would also like to thank the team at Crowood Press for offering me the opportunity to write the book that has been in my heart and mind for many years, and for their patience with my concern over details.

Finally, but not least, thanks must be given to all of those people who have so generously enabled me to accumulate such a rich store of knowledge of and skills in textiles and knitting, especially Professor John Miles, who started me on my journey.

Without all of you, this book would not be as it is.

LIST OF ABBREVIATIONS

COL

carriage on left (machine)

COR

carriage on right (machine)

DK

double-knit

EON

every other needle (machine)

HP

holding position (machine)

k1b

knit into the stitch below

k2tog

knit two stitches together (hand)

k2tog tbl

knit two stitches together through back of the loops (hand)

kfb

knit into the front and back of a stitch (hand)

LC

left cross cable, also known as front cross (hand)

LH

left-hand

ll1

left-lifted increase (hand)

m1

make one increase (hand)

m1l

make one left (hand)

m1r

make one right (hand)

NWP

non-working position (machine)

p2tog

purl two stitches together (hand)

p2tog tbl

purl two stitches together through the back of the loops (hand)

pfb

purl into the front and back of a stitch (hand)

RC

right cross cable

RC

row counter (machine)

RH

right-hand

rl1

right-lifted increase (hand)

RS

right side

s1

slip one stitch

s1, k1, psso

slip one stitch, knit one stitch and pass the slip stitch over (hand)

s1, p1, psso

slip one stitch, purl one stitch and pass the slip stitch over (hand)

SB

single bed (machine)

ssk

slip two stitches knitwise, one by one, and knit them together through the back of the loops (hand)

ssp

slip two stitches knitwise, one by one, and purl them together through the back of the loops (hand)

UWP

upper working position (machine)

WP

working position (machine)

wpi

wraps per inch (in)

WS

wrong side

wyib

with yarn in back

wyif

with yarn in front

yo

yarn over (hand)

yfwd

yarn forward (hand)

ypp

yards per pound (lb)

SUGGESTED SKILL LEVELS

These definitions of suggested skill levels for working techniques and patterns in this book have been included purely to inform and guide and are in no way intended to deter knitters from trying any technique or stitch pattern. After all, trying something new is the best way to improve your skills. You may find one technique easier than another, so play to your strengths, and, most of all, enjoy practising.

Please note, the star rating may be different for hand and machine knitting of the same technique or stitch pattern.

Green

Suitable for all levels

Techniques: * minimal stitch manipulation, no machine settings required

Stitch patterns: a good starting point in either method of knitting, only simple techniques used.

Yellow

Intermediate

Techniques: limited stitch manipulation, very little manual intervention or machine settings required.

Stitch patterns: may involve a combination of techniques/machine settings. Basic use of punchcards/electronic machine patterning*.

Red

Advanced

Techniques: stitch manipulations, and/or combinations of machine settings required.

Stitch patterns: involve combined techniques and machine settings, may involve interruption or creation of punchcard*/digital pattern.

Purple

Challenging

Techniques: require concentration and patience, even from experienced knitters.

Stitch patterns: more complex combinations of techniques and colours. Will involve combinations of machine settings, manual interventions and/or creation of punchcards*/digital patterns.

May need practise to succeed.

*Machines without punchcards will require manual selection of needles from a chart.

INTRODUCTION

Free experimentation (with materials) can result in the fulfillment of an inner urge to give form and to give permanence to ideas, that is to say, it can result in art, or it can result in the satisfaction of invention in some more technical way.1

Anni Albers, 1937

Anni Albers, the famous twentieth-century textile artist, wasn’t writing specifically about knitting, but this paragraph embodies the underlying philosophy of this book. She so clearly expresses the urge to create, possibly without final purpose, for the joy of materials and making from the perspective of technical challenge, as well as aesthetic reward. Albers also said that, when she worked with threads, she ‘learned to listen to them and to speak their language. I learned the process of handling them.’2 To me, Anni Albers is describing how, through practice, we develop a preference for specific needles, a type of machine, a particular technique or a favourite fibre or yarn with which to work.

Manually woven textural motifs on a machine-knitted background. Brushed wool fibres. Designed and knitted by Becca Millington.

Textiles are fundamental to human existence, providing warmth and shelter, but they also satisfy our need for adornment and comfort and convey social messages. The latter is not always positive; uniforms as a tool for subjugation, and economically motivated sumptuary laws that stigmatized segments of the population both come to mind.

Current, urgent environmental issues are forcing us to question the sustainability of a fast-fashion cycle and a throwaway attitude to cheap clothing that is mass-produced from limited resources by a low-paid workforce. Knitting and, to some degree, knitters are complicit in this; therefore, even more thought should go into what we hand produce, and in this I include hand knitting and knitting by hand on a knitting machine.

Dramatically cascading ruffles formed into a semi-circle by the stitch construction. Machine knitted with wool on a standard-gauge machine. Designed and knitted by Marie-Claire Canning. Photograph by Simon Canning.

Beautiful and rewarding textiles for clothing, accessories and our homes can be knitted, and, in the process, we can achieve personal satisfaction from the act of making. If we can use sustainable and durable materials whilst doing this and make the items well, so that they have longevity, it becomes a win–win situation.

Wool dyed with avocado pits. At the top is hand-spun fleece from Jacob sheep, in the middle are commercially spun, organic, wool yarns and at the bottom is foraged fleece, gathered during walks on the South Downs.

Not everyone has the time or inclination to work complicated stitch patterns, but knitting doesn’t have to be complicated. Simple techniques worked with carefully selected, attractive, unusual, and mixed materials can produce individual and satisfying results. Others may find working with colour difficult but love a technical challenge.

Stocking-stitch and garter-stitch intarsia, worked with carefully balanced colours. Introducing textural yarns adds depth, and small areas of monofilament add transparency to the knitting. Designed and knitted by Rachel Graham.

Recycled copper wire, knitted on a Brother 230 chunky-gauge machine. Copper is very malleable, so it will take the bend of the stitch. Do take care and use finer wire on standard-gauge machines, because the needles are less robust.

Machines make very even stitches, which is often desirable, but some people may wish to subvert this. Understanding the attributes and behaviours of the fibre and stitch with which you are working enables fabrics to be developed with a specific look and handle. The felting of wool is a good example of this, because it softens colours and adds density to the fabric; when worked with suitable colours, it can give a homespun appearance to the finished textile.

The knitter found this piece to be a complicated technical challenge, requiring considerable concentration: the short rows had to be calculated and knitted precisely, and the delicate yarn had to be managed carefully to avoid looping and catching. Designed and knitted by Marie-Claire Canning. Photograph by Simon Canning.

Felted, knitted textiles. Combining textural yarns during and after knitting, but before felting, means that, when washed, the fibres blend and the colours meld together. Designed and knitted by Juliet Hilder.

Hand knitting is all about manual intervention between needles and yarn, and there are good reasons to consider combining hand and machine knitting in one piece, so that the strengths of each can be exploited to the full. That is the aim of this book, to encourage and enable the use of the most appropriate tools for the task, so that knitters can realize their passion and release their joy of making.

A riotous, joyful sample in which the knitter has mixed techniques and yarn weights, with a considered use of colour. Designed and knitted by Emily Powell

Hand knitting

Like many people, I was introduced to hand knitting by my grandmother, a prolific and precise, if plain, hand knitter, whom I remember knitting her own bedjackets and cardigans in pastel colours. My mother was a more utilitarian knitter, concentrating on school jumpers, and knitting as a way of contributing to the family finances. Again, like many beginners, I became frustrated with the slowness of achievement, so I put hand knitting aside until my twenties. Whilst I was working as a designer in a Yorkshire knitting mill, I discovered cones of beautiful and irresistible chunky Italian yarns forgotten in the store room, and it was these that inspired me to drag my part-remembered skills out of retirement. Starting with sloppy-joe-style jumpers in stocking stitch, I rapidly broadened my repertoire and progressed to stitch structures, Fair Isle patterns and intarsia.

At the time, I was part way through a degree in knitted-textile design, which was almost totally machine-based, and my work at the mill was designing immediately on to industrial machinery. Pre-internet, I began to fill my bookshelves and improve my technical knowledge of hand knitting, alongside that of the emerging electronic knitting-design systems, both domestic and industrial, that also fascinated me. From this point onwards, transferring and adapting between hand and machine knitting became part of my continuing design practice.

Machine knitting

My earliest memory of machine knitting is of when I was about five and my mother had a machine on which she knitted garments to order for a London boutique. My mother’s was a single-bed machine, finished in a glorious metallic green, which I believe might have been an early Passap model, but please don’t hold me to that. It had what I now know to be sinkers, which rise up and down in a wave as the carriage passes over the needles and hold the stitches down so that little or no weighting is required.

My brother and I delighted in the way that the carriage glided across and caused this wave. Not comprehending (or possibly caring) that this knocked the knitting off the machine and ruined all of her hard work, we were callously oblivious to my mother’s dismay when we did this.

My own first experience of really using a knitting machine (as opposed to zooming the carriage along for fun) was during the summer before I took up my place on an art foundation course in the 1970s. At some point, my brother had acquired a second-hand, Singer knitting machine and somewhat misguidedly thought that, as our mother now hand knitted for pleasure, the gift of a knitting machine would thrill her. Unfortunately, as so often happens in these circumstances, she discreetly hid it away under the bed, and the machine was forgotten; until I found it.

Machine-knitted Fair Isle. The irregular pattern has long floats, and an elastane yarn has been used as the second colour. This technique not only creates complex surface texture but also increases the elasticity of the fabric, a technique common for knitted fabric used for active sportswear. Shetland-wool and elastane yarns knitted on a standard-gauge machine. Wet finished.

Machinery and mechanical processes have always fascinated me, so, once I discovered the machine, I quickly assembled it, between working to save for college. Learning how to operate it took a little longer. There were of course no instructions, because, as we all know, machine manuals have legs and the ability to disappear without a trace. The Singer was a purpose-built, double-bed machine, packed in a matching green suitcase (probably the Singer DB, I now realize, but sadly it is no longer with me), and, as with the Passap of my childhood, its glowing, golden needle beds and kitsch green, plastic end plates were irresistible to me.

Gathering together all of my long-suffering mother’s odd balls of hand-knitting sock and four-ply yarn, I found enough to knit a rather roughly shaped, short-sleeved, striped jumper; this surprised both me and my mother. This was probably a fundamentally significant point in my career, but of course who realizes this at the time?

Art college in the 1970s was fun with a capital F, but I managed to keep my focus and secured a place on a textile-design degree course, after which it didn’t take long to decide that I wanted to concentrate on knitting. Following my brief but passionate love affair with the Singer machine, and whilst working as a designer in the same Yorkshire knitting mill where I embraced a new relationship with hand knitting, I also discovered not only that I was fascinated with machinery but that I was prepared to invest the time to understand it, and to use that knowledge to develop knit designs. It is this understanding of aesthetics, of yarn, colour, texture and the three-dimensional human body shape, combined with practical knowledge of technical knitting, that supports my design practice and teaching. My desire whilst researching and writing this book has been to share my knowledge with others, so that they too may move freely between different methods of knitting.

Many knitters seem to make a clear, and sometimes disadvantageous, distinction between hand and machine knitting, but I don’t believe that this is sensible or beneficial to either craft skill when there are clear benefits to both. Machine knitting offers speed, constant tension and even knitting, plus automatic, repeatable patterning via punchcard or digital means. Meanwhile, hand knitting is portable, flexible and more sociable. There is also evidence to suggest that hand knitting may have some positive therapeutic benefits for health and well-being.

I obviously practise both methods, and I switch between them flexibly and thoughtfully to suit circumstances or achieve the results that I require. If I want to relax and watch TV, I will hand knit, and, when I go on holiday, I always take a hand-knitting project; however, making garments, large panels in particular, is mostly a machine job. I have a continuing personal and professional interest in the diversity of the three-dimensional human body shape, and this is influential when I am designing knitted-garment shapes.

Electronic machines are quite common, and I own three of these (put me down as an avid collector), but I am still convinced that mechanical, punchcard machines are the mainstay of domestic machine knitting. Machines designed and manufactured in the 1980s are still going strong. The capabilities of the latest mechanical models may have been finessed, but they are fundamentally not that different. These machines are sturdy, reliable and relatively simple to understand and maintain, and second-hand models can be bought for a reasonable price. Punchcards themselves are concrete, and the relationship between the punched pattern and the stitch pattern is easy to interrogate visually without any additional steps.

There is little confusion, once the basics are understood, unlike the situation with electronic machines that require a combination of computer savvy, special pens, software, cables and a different understanding of how to work with patterns, not to mention a considerable financial investment. Don’t get me wrong; I am deeply excited by electronic machines for their patterning flexibility and responsiveness, particularly when teamed with design software, but I won’t be getting rid of my punchcard machines any day soon.

As with hand knitting, for which there are numerous choices of equipment available to a diverse pool of practitioners, there are many types of machine knitters and knitting machines. Try not to let any preconceptions influence your choices as you explore the possibilities. There are numerous myths attached to machine knitting: ‘knitting by machine is cheating’, ‘machine-made fabric is of inferior quality’, ‘knitting machines are complicated’, ‘knitting machines destroy creativity’ … need I go on? Alternatively, you may have been told that machines knit only acrylic or synthetic yarns and, therefore, are no use for natural fibres or homespun yarns. None of this is true. Knitting by machine is as skilled as hand knitting and requires equal knowledge and understanding of yarn and structure, and aesthetic appreciation. In addition to this, a knitting machine is a fearsomely effective design tool. What’s not to like in being able to knit a sample in five minutes and rework it in two different yarns or colourways in fifteen minutes? By either method, it is the design, quality of material and skill of the knitter that will make or break the final product.

I believe that the foundation of these myths may lie in the knitting machine’s historical connection to industry and Luddite working practices, although this seems to be peculiar to knitting, as little criticism is given to the use of a loom or sewing machine instead of the handworked counterpart.

A Brother standard-gauge punchcard machine with a ribber attached.

Closely packed fringing, manually woven on a standard-gauge domestic machine. Designed and knitted by Rachel Lynch.

History

The histories of both hand and industrial knitting are the subject of many books and cannot be covered in detail here, but it may dispel some myths if a little of the history of the knitting machine is known. We have William Lee to thank for the first knitting frame, which he is credited with inventing in 1589. The first wooden knitting frames, with upright bearded needles (looking like a shepherd’s crook), were heavy and physically demanding to operate, so framework knitters were predominantly male, and knitting then did not have the female connotations that developed in the late 1800s. These skilled craftsmen produced mainly stockings, but, as the technology of the frame developed, they progressed to shaped stockings and delicate lace knitting. Powered, industrial knitting machines displaced the domestic framework knitters during the Industrial Revolution, and this is where I believe these prejudices against knitting machines began. Prior to this, framework knitters had been respected for their skill, although it is true that hand-knitted stockings were still highly prized by the wealthy classes.

A circular, industrial knitting machine. The yarns are fed into the needle dial from above. This machine knits garment-length pieces, but some knit only continuous fabric.

Before electronic needle selection and computer-controlled feeder selection, powered V bed machines such as this Dubied JDR used a system of steels to select the needles (seen along the front of the machine) and pasteboard cards (on the right) to control the feeders. Catalogue from the author’s private collection.

During the Industrial Revolution (approximately 1760 to 1840), and throughout the remainder of the nineteenth century, the types of industrial knitting machines became more diverse and included circular machines, flat frames and, latterly, V beds. The innovative latch needle, widely held to have been invented in France by Pierre Jeandeau in the very early part of the nineteenth century and developed further by Matthew Townsend of Leicester, contributed significantly to these developments.

The needle bed and cam box (carriage) of a modern, industrial V bed machine.

Circular machines, the first model of which was invented by Marc Brunel in 1816, have a round dial of vertical needles (originally bearded, now mostly latched), flat frames have bearded needles and V beds are so named from a literal description of the way in which two horizontal beds of latch needles face each other, looking like an inverted V from the side.

Each type of machine has different strengths, and, although too simplistic an explanation, to be brief, flat frames can knit shapes, but they do not rival the V bed’s surface-pattern capabilities (these machines can also shape with manual intervention), and circular machines, by their very nature, produce a tube that has to be cut into a garment shape and sewn together. Of the three types, V beds are more akin to the domestic machines that we know today, with latch needles and horizontal beds.

Small-dial, hand-operated, circular machines were distributed from the mid-to-late 1800s onwards to just after the turn of the century to home workers to knit socks, stockings and even modular garments. This model has a second dial of horizontal needles, so it can produce ribs as well as stocking stitch. The dial rotates either way, and the needles can be blocked from rising to WP, so short rows can be worked to shape the heel and toe of the sock. Many of these machines have survived as museum pieces, but some remain in domestic use. Photograph by webqueen, https://pixabay.com/en/old-knitting-machine-singlecylinder-1588883

Circular machines are extremely fast, and, from early in the twentieth century, some models have been able to knit ribs and garment lengths. Not long afterwards, stitch- and colour-pattern mechanisms were introduced. Although outside the scope of this book, circular machines are likely to be of interest to any machine knitter.

Recueil de Dessins et Points de Fantaisie “Dubied”, a knitting instruction manual from the early 1900s for working stitch patterns on V bed knitting machines. The patterns are created through combinations of semiautomatic needle selections, cam settings and manual manipulations. Book from the author’s private collection.

One cannot discuss the history of knitwear without mentioning Coco Chanel and her innovative use of jersey in the early 1900s. Although mainly cut and sewn from circular jersey, her emancipating, simple silhouettes were nonetheless knitted and introduced to knitwear a new concept of fabric formerly used for underwear as outerwear that is still being explored today.

Mass-produced, commercial knitwear became increasingly popular, for example, the pervasive twinset of the 1950s, but it lacked the edge that hand-knitted garments could offer in combinations of colour and texture patterns alongside shaping. The fashion for Fair Isle sweaters in the 1920s called for hand knitting, and several significant revivals of hand-knitted fashion in the late 1930s and 1970s illustrate this. Although there are few who will remember the Paris atelier knitting of the 1930s, described so well by Montse Stanley, some will remember the ‘excitement of the new’, inspired by Patricia Roberts’s brightly coloured popcorn knits and Kaffe Fassett’s remarkable intarsia designs.

Tennis dresses designed for machine knitting. Chanel’s influence and the natural stretch of knitting made the tennis dress an ideal subject with which knitting companies could promote their machines, Recueil de Dessins et Points de Fantaisie “Dubied”, Edouard Dubied & Cie, circa 1923.

I have in my collection a charming industrial knitting manual for V bed machines from the early 1900s, which clearly illustrates the surface patterns and garment shapes achieved on these machines. What qualities the products of industrial machines lacked compared to those of hand-knitted equivalents, the machines made up for in mass production (particularly for fine-gauge fabric), providing affordable fashion clothing for the high-street consumer.

Following a series of developments, probably the most significant of which enabled efficient automatic stitch transfer, there remained the problem of communicating complex stitch selections to the automatic machines. Finally, digital programming caught up with the engineering abilities of the machine builders, and the new technologies mean that innovatively shaped, totally seamless knitwear can be produced with complex colour and texture patterns.

So, what does this potted history tells us? To me, it explains some of the prejudice against machine-made knitting, because so much industrial knitwear was badly made and of poor quality materials. Whilst studying an archive of mass-produced knitwear from the early to mid-1900s, I was amazed at the irregular overlocking, botched seam matching and horrible yarn handle of most of the garments. Manufacturers of these garment made use of new fibres such as rayon that emulated silk (but quickly became misshapen) and Courtelle® that boasted washability and durability but did not feel pleasant close to the skin. Commercially made knitwear was created for reduced price points, and this lowered its profile.

For domestic machine knitting, a similar process seems to have been taking place. In the 1960s, when my mother was knitting on her Passap, she worked with wool, for high-end stores. However, the increasing popularity of domestic machines, combined with the wide availability and lower cost of synthetic yarns, meant that domestic machine knitting rapidly became subject to the same influences as commercial knitwear: speed and economy.

A range of machine-knitted samples knitted with wool yarns. The textiles have been felted after embellishments have been applied by hand. Designed and knitted by Juliet Hilder.

Whilst some of the knitting techniques discussed in this book are placed in historical context where appropriate, this is not a historical study of knitting, but, having looked briefly at the history of machine knitting, it is only fair to turn to that of hand knitting. There are many books that cover specific historical aspects of knitting techniques and knitwear, and other authors have made valuable and detailed studies of hand knitting’s long history; therefore, there is little need to repeat this information. I will, however, give some recommendations for further reading for those interested in this history. No precise date has been identified as the birth of the craft, so the origins of hand knitting are still in dispute. However, we know from studies of art and artefacts that it has been practised for many hundreds of years, and, according to Richard Rutt, was probably worked on double-pointed needles, in the round.3 Sadly, although some ancient fragments have been found in Egypt and Syria, because of its very nature, little physical evidence of very early knitting has survived. The Victoria and Albert Museum in London has knitted garments dating from the fourth and sixth centuries in its collection, including knitted caps, socks and stockings, as well as some extremely fine jackets. Anyone wishing to study the history of hand knitting further should read Richard Rutt’s A History of Hand Knitting, whilst Montse Stanley’s chapter in Disentangling Textiles gives an excellent snapshot of the 1930s heyday of couture knitting.4 I also direct the reader who is keen to learn more about knitting history to Sandy Black’s comprehensive longitudinal text, Knitting: Fashion, Industry, Craft.5

Moving on to more-modern times, in the first half of the twentieth century, hand knitting was still a necessity for many people. This was something done in the home, mainly by women, and yarns were workaday and uninspiring.

In the 1970s, designer Patricia Roberts’s elaborate, brightly coloured hand-knitting patterns were a game changer, and Rowan Yarns emerged in the UK market in the early 1980s, offering not only yarns but fresh approaches to the design of hand-knitted garments. A new generation of hand- and machine-knitting designers developed through the 1970s and 1980s, Kaffe Fassett with his use of rich colour combinations in beautifully composed intarsia knitting being one of the most influential designers.

Covering bikes, trees, telephone boxes and lampposts was, and still is, part of the new approach to knitting that emerged at the very end of the twentieth century. Photograph by cocoparisienne, https://pixabay.com/en/bike-matureclose-lady-sbike-247394/

The success of Debbie Stoller’s Stitch ’n Bitch in 1999 heralded a fresh focus for hand knitting. Stoller’s approach was inclusive and endorsed knitting in public. Knitters were encouraged to have a go, to not be intimidated by the need to achieve perfection and to take an essentially female activity into public places, holding knitting groups in coffee shops, in pubs and on public transport. Knitting came out of the boudoir (or church hall) and became a social activity rather than women’s work.

Joanne Turney writes that hand knitting became ‘an activity of choice rather than necessity’, but, in 1999, as in Western societies today, hand knitting is unlikely to have been widely undertaken from true necessity.6 Notwithstanding this point, hand knitting enjoyed another revival that took it public; yarn bombing (a form of street art in which private items and surfaces in shared spaces are decoratively covered with yarn, knitting or crochet) became popular with knitters.

Stimulated by demand, new yarns appeared on the market, and even more choice exists today. Increasing commercial availability of a wider and more sophisticated range of hand-knitting yarns has been one of the contributing factors to stimulating the current burgeoning hand-knitting revival that we hear so much about. The continuing growth of online yarn shops and communities such as Ravelry have created and support an international community of both hand and machine knitters. In 2015, the importance of the craft of knitting to British society was formally recognized when hand-knitting designer Debbie Bliss received an MBE for her services to hand knitting and the craft industry.

Public spaces, including this square in Trieste, are ideal candidates for yarn bombing. The Picknitartcafe group organized people to send in their own crocheted squares, with the aim of producing the largest crocheted blanket in the world. The blanket was sewn together in the town square on 20 June 2015, and it was over 3,000 square metres (33,000 square feet) in area. Photograph by 3674664, https://pixabay.com/en/italy-trieste-europe-carpet-knits-1797274

Whilst hand knitting enjoyed a rebirth at the end of the 1980s, the British knitting industry was shrinking, with major retailers moving production overseas. This was followed by a declining interest in domestic machine knitting in the UK, and, by the time Brother stopped making machines at the end of the 1990s, innovation had ceased, and domestic machine knitting was entering the doldrums. The once-prolific yarn suppliers to this market disappeared, and quality coned yarns became harder to find for domestic use. Conversely, throughout this time, industrial machine knitting became increasingly versatile, supported by progressively sophisticated digital programming.

When knitting production first moved to the Far East, domestic knitting machines were used commercially, and machines are still made there, as can be seen in the lively online trade in parts and generic accessories. Throughout this time, British textile education has continued to train knitted-textile and knitwear designers, and graduates are in demand as well-rounded, technically knowledgeable designers. That this could occur is due to the survival of Silver Reed knitting machines, and their continued support for older Knit-master models, and the backing of the contracted, but still active, UK knitting industry. It also pays homage to the longevity of punchcard machines, and that of their semi-industrial double-bed counterparts as used in most educational institutions’ knitted-textile workshops. It is also due to my colleagues and those in other colleges and universities who, like myself, cut our teeth in the knitting industry and continue to share our accumulated knowledge with the generations that will take knitting into the future.

Hand-knitted intarsia worked with different fibres, weights, and textures of yarn. Hand embellished with leather thongs. Designed and knitted by Sagita Kaleth.

Why do we knit? We enjoy it, it gives us pleasure, it rewards us aesthetically and it gives a sense of achievement. This is true of hand and machine knitting, despite any lingering prejudice towards machine knitting. Both are aspects of the same craft; there need be no conflict between these methods. Stitches, fibres and rewards are the same, and the level of craft skill is equal, so, when they are combined, a particular magic can take place.

Don’t buy a knitting machine if you are, primarily, intending to make money from its use. Although some designers do make their living doing this, it would be wrong of me to say that this is common, and those who do make money knitting (as opposed to designing) may not make significant amounts relative to the hours spent knitting. The boom period for domestic machine knitting for profit has long gone.

A modern, industrial, computer-controlled Shima Seiki knitting machine. All of the operations of the machine are controlled by electronics, and stitch patterns and garment shaping are programmed exclusively via a computer design interface.

Machine-knitted short rows, with stripes accentuating the swirling effect of the knitting. Ladders, which lighten the fabric and add an ethereal quality to the knitting, have been made to run along the hem. Designed and knitted by Rachel Clements.

It is also true to say that making knitwear yourself is no longer a financial saving, as fashionable, perfectly adequate, everyday clothing can be bought so cheaply in the high street. However, when you look at higher-priced, more-individual items, the cost difference narrows, and it is here that I believe domestic knitting comes to the fore, particularly if and when you combine the advantages of machine knitting with those of hand knitting. Consider, for example, working a rib by hand and picking up its stitches on a machine to knit the larger panels, or knitting the body of a garment on a machine and the yoke by hand. There is no limit to your creativity and experimentation when working with a knitting machine, because a swatch of an idea can be so quickly worked for evaluation of yarn and effect.

It can be fun and informative to go window shopping in higher-end shops to find shapes and styles that you like and which match your shape preferences. Don’t be afraid of trying things on, taking photos and making notes over a coffee afterwards. Look at the fibre content on the label, and, if possible, lay the garment flat so that you can see the shape of the component parts. Often, the shapes are quite simple. The main difference is likely to be in the gauge of knitwear fabrics. Many commercial garments are produced on fine-gauge machines, sometimes with up to eighteen needles per inch, and this weight of knitting cannot be reproduced domestically. However, fine-gauge, domestic machines and thin yarns can help to take a step towards this, and even a standard-gauge machine can produce lightweight, airy fabrics with fine yarns.

Elastane yarn knitted into short rows draws this machine-knitted cotton sample into a partial seersucker effect. On the left is a machine-knitted eyelet-lace mesh worked with substantial cotton yarn. Designed and knitted by Megan Doggett.

Let us look a little deeper into the reasons for knitting an item yourself. By adjusting the length, waist, bust or shoulder width to suit your body shape, garments can have a better fit for your figure. Styling details that are fashionable or more flattering can be included, such as making a deeper scooped neckline instead of a high, round neck.

Purchasing machine-knitting yarn on cones is often cheaper than buying 50g balls, although of course the choice is more limited. Consider mixing handknitting balls with coned yarns to reduce the outlay. Mixing yarns is especially practical for mid-gauge and chunky-gauge machines, whilst using fine industrial yarns in multiple ends works well on all machines.

Hand-spun, sequinned, wool yarn, striped with a commercially spun and dyed, thick, cotton yarn. Knitted on a chunky-gauge machine by using a garter-bar accessory to turn the knitting.

In our centrally heated homes and workplaces, we no longer need thick knitwear, but layers are an excellent way to cope with temperature fluctuations. Although the ubiquitous fleece is commonly worn for leisure activities, wool is increasingly being recognized as a valuable and important fibre for sportswear. In addition to this, your own designs add individuality and style beyond the reach of mass-produced items.

When I have been writing, instead of relaxing and knitting, I have been asked ‘Why did you decide to write this book?’ The answer is on my bookshelf; one only has to look at the publication dates of the authoritative machine-knitting books listed in the bibliography to realize that an up-to-date and comprehensive new book that combines the two craft skills of hand and machine knitting is timely.

When I was approached to write this book, the undertaking seemed to be a straightforward matter of describing how to translate stitch patterns from hand knitting to machine knitting, but, as it developed and I delved deeper into how to do this, I realized the huge task that I had taken on. It is only recently that I learned that Susanna Lewis took five years to research and write A Machine Knitter’s Guide to Creating Fabrics, a fact that has given me considerable comfort.

Short rows, worked part way across the bed with elastane yarn, draw the heavy wool knitting that surrounds them into dramatic but surprising regular folds. Minimal use of colour emphasizes the texture of the knitting. Designed and knitted by Megan Doggett.

Firstly, I had to define what types of knitting could be included, because clearly some focus was needed, otherwise I would be writing for many years. There are several ways to hand knit, including circular methods, but finally I decided to concentrate on hand knitting back and forth on straight needles and flat, single-bed, domestic machine knitting. That is not to say that the stitches and techniques discussed are exclusive to straight-needle hand knitting and single-bed machines, but there is only so much detail possible to include in one book without it becoming impenetrably complex. Once you have mastered the basics of flat knitting, why not explore the possibilities of circular knitting by hand and on a machine?

From that point on, I decided to write based on the assumption that more people hand knit than machine knit and that the reader is likely to have some knitting knowledge already. Although materials and equipment are discussed at the start, advice and asides on these will also feature throughout the book where appropriate. As much relevant information as possible to help the reader has been included in the text and captions, because there is nothing more annoying than having to flip backwards and forwards to find information in order to follow instructions. Abbreviations have been used in the text and are explained at the beginning of the book.

Because I have assumed some level of knowledge, you will find that the content order is not as in most knitting manuals. The first instructions are not how to cast on; instead, the basic stitch structures are explored and put in the context of hand and machine knitting. It is not until Chapter 3 that the beginner will learn how to cast on by hand or machine. You could of course skip the first two chapters. That’s fine with me; I too am impatient when I get a new book, but do return to the earlier chapters once you have started some knitting, because this book has been arranged so that the reader can progress (relatively painlessly) through to the final chapter, which explains methods for translating garment shapes.

Machine-knitted beaded lace, positioned as a widely spaced motif. Silk-noil yarn knitted on a standard-gauge machine.

Many step-by-step, illustrated instructions accompany the text, because my aim was that this book should be accessible to a wide audience. This includes hand knitters who may be deciding whether they should purchase a machine, hand knitters who already own a machine but want to use it more, and machine knitters who are looking for advice and information to develop their knitting and design skills.

Stitch structures are explained in detail, alongside hand- and machine-knitting instructions, and are accompanied by design suggestions. Therefore, this book is ideal for students undertaking educational courses in textiles or those individuals who independently wish to develop their design and making skills and are looking for a knitting reference book to keep at their side. Anyone who may be considering purchasing a knitting machine and wondering what a machine can produce will also find this book valuable and informative.

Written from a perspective that aims to exploit the advantage of speed that machine knitting has over hand knitting, the detailed information in this book will enable you to make choices about which method suits what project at a specific time. I am not a great fan of hand manipulation on a machine, because I prefer to work on standard-gauge or finer-gauge machines; hand manipulation, therefore, is a lengthy process, and dropped stitches are hard to recover in finer yarns. However, I am aware that many knitters work on mid-gauge and chunky-gauge machines, for which hand manipulation is a more viable option, so this has been included where it may be helpful, appropriate or necessary to achieve a stitch or effect. I own rather too many types and gauges of knitting machine (my long-suffering family will attest to this), and one of my favourites is a mid-gauge machine that has been used to knit some of the samples in this book. Mid-gauge machines can knit with the double-knit (DK) yarn used for the hand-knitted samples, so, where possible, it made sense to make truly direct translations.

Chenille yarn knitted as a background, with knitted strips of cotton woven through the fabric to give a threedimensional surface. The stocking-stitch edges of the overlapping areas have been embroidered by hand to eliminate their natural curl. Designed and knitted by Becca Millington.

Over the years, many of my students have bought their knitting machines from people who had been given them because they enjoy hand knitting, which are circumstances that are reflected in my experience with my mother’s Singer machine. Of course, a machine can knit faster, but this misguided and misplaced generosity completely misses the point. Hand knitting and machine knitting are different activities, with their own pleasures and advantages. Hand knitting is portable, and can be sociable, whereas machine knitting requires that the knitter be at the machine. Machines cost more than needles, and space to work is essential, and it is preferable to not have to take the machine off the dining-room table at every meal time. Apart from these practical distinctions, both hand and machine knitting require varying, but equivalent, levels of concentration, preparation and finishing.

This book explains how to translate knitting stitches and techniques between hand and machine methods. It will explore the commonalities between hand and machine knitting by examining basic stitch constructions and knitted fabrics for both methods. Similarities and differences between technique and terminology will be discussed to encourage experimentation across these two methods of knitting. After establishing terminologies and definitions, techniques less often considered suitable to transfer between hand and machine knitting will be explored within the scope of single-bed machine knitting.

The technical detail

There are many makes and models of knitting machines, not all of which can be included here, and I apologize in advance if your model is not mentioned. Standard-gauge Knitmaster SK700 punchcard and Silver Reed SK840 and Brother 950i electronic machines, plus a mid-gauge Knitmaster HK160 machine, were used to knit the samples and demonstrate and explain the machine-knitting techniques in this book. However, the knitting instructions can be related to all single-bed knitting machines, including fine- and chunky-gauge machines, both electronic and manual, but should be adjusted to suit your model and be used in conjunction with the relevant machine instruction manual. For example, on models without automatic patterning, needles will have to be manually selected according to the chart or punchcard template, and those without certain pattern-selection settings or abilities may need to have stitches such as lace holes and purl stitches manually manipulated.

Directions for Silver Reed/Knitmaster and Brother machines are included throughout, and it will be highlighted when it is possible to produce a technique using only a particular make or type of machine.

Instructions are directly transferable to brands of machines that work in the same way as the main two types described, and most machine techniques are possible on other makes of machine: Brother, Toyota, Singer, Studio, Knitking, etc. For exact translation to these machines, you will need to refer to the specific machine manual. Passap owners will find many of the techniques applicable to their machines by using its single bed only. I hope that owners of double-bed machines will see the potential for developing their own translations through those explained here.

Machine-punchcard graphs will be included where appropriate. Some techniques are possible even on machines without punchcard patterning, but hand manipulation is not the focus of this book and will mainly be included as an addition to automatic methods. Whichever machine you own, this book will provide insights and ideas to enable you to make your machine sing.

I am optimistic that this book is at the forefront of a new wave of enthusiasm for machine knitting and that it will also contribute in a small way to the entrepreneurial spirit of emerging micro- to mid-scale knitting-related businesses.

1Black Mountain College Bulletin, 5, 1938. Reprinted in College Art Journal III:2, January 1944, pp.51–54; and in Anni Albers: On Designing, 1959 and 1971.

2 Albers, A. The Art/Craft Connection: Grass Roots or Glass Houses, College Art Association’s 1982 annual meeting. February 25, 1982.

3 Rutt, R. 1987. A History of Hand Knitting. Interweave Press. pp.44–50.

4 Stanley, M. 2002. ‘Jumpers that Drive you Quite Insane’: Colour, Structure and Form in Knitted Objects. In Disentangling Textiles, (ed.) M. S. A. C. Boydell, pp.23–32. London: Middlesex University Press.

5 Black, S. 2012. Knitting: Fashion, Industry, Craft. V&A Publishing.

6 JoanneTurney. 2004. The Culture of Knitting. Oxford: Berg Publishers. p.145.

CHAPTER 1

MATERIALS AND EQUIPMENT

Yarn is your paintbox; needles are your brush

This analogy is an excellent design prompt when developing ideas, but even the most creative designer needs to understand their tools and materials. It may be a chicken-and-egg situation for many knitters, but, in those cases where a luscious yarn prompts a new project, it is helpful to know which needle or machine is likely to enable the most successful work. It is equally important to understand the properties of fibres and yarns, especially when choosing materials to knit into a specific weight or fabric construction.

Equipment and materials for hand and machine knitting, and some that are common to both knitting methods.

This chapter will discuss both hand- and machine-knitting equipment, explore the sources and properties of common and unusual fibres and discuss the diversity of yarns produced from these fibres, whilst debating the merits of fibres and yarns in the context of both knitting methods.

Essential equipment for both types of knitting

Scissors (or yarn cutter)

A knitter’s close companion is a pair of sharp scissors. Using blunt scissors, or trying to break yarn with your hands, leads to pulled edges and sliced fingers.

Tape measure

For taking body measurements and checking progress as you work.

Ruler

For measuring stitches and rows to establish stitch and row gauges; a ruler is more accurate than a tape measure for this purpose.

A collection of needles in a range materials and sizes allows responsive sampling, thus enabling design decisions.

Basic items that a knitter will always find useful. Sharp needlework scissors, pins with glass or plastic heads, and different sizes of crochet hooks for picking up stitches and finishing yarn ends.

Row counter

If you lose your way in a pattern, it can be difficult to count the rows exactly, and even experienced knitters can make mistakes. Clicking a row counter at the end of each row will save you time, energy and frustration, but do be consistent and don’t rely blindly on this little gadget. If you absentmindedly forget to click or can’t remember if you did, disaster could await. Placing a marker every so often, when you are sure that you have clicked, is helpful, and learning how to identify the stitches and rows in a stitch pattern will enable you to verify that the counter is indeed correct. Machine knitters may feel a little smug here, because the carriage automatically clicks the inbuilt counter each time that a row is worked, but I have been caught out so many times by forgetting to wind it back after unravelling rows or forgetting to lock it if working an empty row.

Stitch markers

Marking salient stitches is as important as keeping track of rows, and a collection of split, openable stitch markers and closed stitch markers is useful.

Hand-knitting accessories, clockwise from bottom left: magnifying stitch counter with needle gauge, vintage metal needle gauge, tie-on label (for identifying a sample), rosewood double-pointed needles, rosewood and metal cable needles, sharp and blunt large-eyed sewing needles, stitch holders, machine needles (or latch tools or crochet hooks, for picking up dropped stitches), ruler, tape measure, stitch holder and intarsia bobbins. In the centre are various stitch markers and row counters. The scissors were, as usual, not to hand when this picture was taken, but we all know that they are the most important accessory.

Pins

For pinning out pieces of knitting before blocking.

Large-eyed bodkin needle

For sewing in yarn ends and creating seams. A needle with a blunt point is best, because it is less likely to split the yarn.

Crochet hook, latch tool or spare knitting-machine needle

For quickly picking up dropped stitches and tidying loose ends of yarn.

Using markers for hand and machine knitting

Home-sourced versions include rubber O washers, safety pins and paper clips. Coloured paper clips are particularly useful for colour-coding groups of stitches. A blob of epoxy glue will turn these into closed markers if required. These markers lie between stitches, but, to mark an actual stitch, short lengths (8–10cm, or 3–4in) of contrast-colour yarn are the simplest type of marker to use.

When hand knitting, lay the contrast-colour yarn over the stitch before knitting that stitch with the main yarn; similarly, when machine knitting, lay it behind the latch of the appropriate needle before knitting the stitch (or row) that you wish to mark. In both cases, the contrast-colour yarn will be caught into the stitch and can be pulled out when the work is complete.

If you prefer a more secure marker when machine knitting, slip a knotted loop of contrast-colour yarn on to a single-point transfer tool (these tools will be discussed further on in this chapter), and take the stitch that you wish to mark off of its needle and on to the transfer tool. Lift the top of the loop of contrast-colour yarn off the end of the tool but over the head of the stitch, so that the stitch is pulled through it. Re-place the stitch on to its needle. When the markers are no longer required, they can be carefully snipped out of the knitting.

If you find that the whole row-counter thing breaks your hand-knitting rhythm, you might prefer to use beads to mark rows. Thread beads on to a separate length of slippery yarn that is twice the intended length of your knitted fabric, and attach a bead or button at each end to secure the marking beads on to this yarn. Keeping the beaded yarn at the back of the knitting, work to the row you wish to mark. Work part of this row, and then bring the beaded yarn forwards between two stitches. Work to the end of the row, and work the next row to the point where the beaded yarn is positioned, then take the beaded yarn to the back between the two stitches at the marking position, leaving one bead on the front of the work. Continue with the knitting, taking the beaded yarn back and forth as described to thread it through the knitted fabric.

When the knitting is completed, snip the beaded yarn (being careful not to snip your knitting yarn), and slip it from between the stitches. The beads will fall off for you to reuse.

Hand knitting – useful additional accessories

Needle gauge

A needle gauge is useful if you own, as I do, a collection of needles garnered from relatives and second-hand shops that you want to match across the different sizing systems.

Cable needle

A short needle (usually bent) for holding stitches whilst working cables.

Stitch holder

Open stitches can be slipped on to this accessory for later use, for example, whilst working a pocket.

Yarn bowl

This accessory is not a necessity, but there are so many attractive ones that I couldn’t resist drawing attention to them.

Hand-knitting needles

Any seasoned hand knitter will have a comprehensive collection of needles, whilst those knitters with less experience will be starting to build such a collection. I can’t be alone in having spent precious time sorting and organizing an ever-growing needle collection, even making a spreadsheet of sizes and types in the hope of maintaining control and not repurchasing the same size. I have lovingly sewn padded needle cases for particularly special wooden needles and bought numerous pots to organize needles by size and material, but I still end up jamming needles unceremoniously into the wrong pot at the end of a project.

A yarn bowl can keep your hand-knitting yarns clean and tidy, whilst looking attractive in your living room.

Let us accept from the start that everyone keeps their needles in their own personal way, and I am not going to argue or try to convince you to do otherwise because your way works for you. Assembling a collection of sizes and types of needles is, however, a key step for making your knitting process more comfortable and efficient.

A quick look through any needle collection will demonstrate the diversity of materials used for knitting needles, and a range of materials is helpful for working with different fibres, yarns and knitting techniques, thereby producing a wider variety of fabrics. In my experience, apart from some practical issues discussed further on, needle material is often a matter of personal choice and an individual order of preference, based on availability, budget and physical needs.

Yarn attributes will affect the choice of needle material. When working with soft-spun yarns that split easily, for example, you are likely to find one type of needle easier to work with than another. Make a note of this on the relevant pattern or, better still, in a technical notebook, for future reference.

A visit to a good yarn shop or an internet search will throw up numerous brands of needles, but, when choosing new ones, select by project and make choices based on your budget.

Having a range of materials in your needle collection eases the ability to knit with different yarns and stitch patterns. From left to right: hardwood, bamboo, anodized metal, vintage tortoiseshell plastic, rosewood and utilitarian plastic.

Needle sizes

A mistake commonly made by beginners is to think that thick yarn and big needles will be the easiest to work and learn with. Sadly, this isn’t the case, and I would recommend using 5mm-diameter needles with plain, light-coloured, aran-weight yarn as an ideal starting combination. Experienced knitters may have a personal preference for a particular needle size and yarn weight, but they will still be able to work across different combinations with ease. The accompanying table will help you when matching yarns to needles, but always knit a test sample to check that your stitch gauge matches that of the pattern or the desired fabric handle. Too large a needle size for the yarn will result in an openwork structure that will not hold form; too small a needle size will produce a very firm knit that may take away a soft characteristic of the yarn. Neither is wrong as such, but recognizing the effect that you desire is essential.

Needle sizes and suggested yarn weights (including US terms)

Needle sizes

Suggested yarn weights

Yarn weight symbol

Knit fabric suggestions

Metric

Old UK

US

(Craft Council of America)

2mm

2.5mm

14

13

0

1

Lace, 1–2 ply, fingering, cobweb

Lace, Best left until some experience has been gained

2.7mmm

3mm

3.25mm

12

11

10

2

-

3

Baby, 2–3 ply, fingering, superfine spun

Baby clothes, fine knit socks and shawls

3.5mmm

3.75m

4mm

-

9

8

4

5

6

Baby, 4 ply, sport weight (US), fine spun

Lightweight jumpers and cardigans, baby clothes and accessories, socks

4.5mm

7

7

Double knit, light worsted (US)

High versatile, baby, children’s wear, lightweight adult garements, accessories, blankets

5mm

5.5mm

6

5

8

9

Aran worsted (US)

Adult garments, accessories, blankets

6mm

6.5mm

7mm

8mm

4

3

2

0

10

10 ½

–

11

Chunky, multiends, thick self-made yarns

Home accessories, jackets, winter weight clothing

9mm

10mm

00

000

13

15

Super chunky, bulky (US), roving, multi-ends self-made yarns

Home accessories, thick scarves. Yardage is low per ball

Table of needle sizes to enable translation between metric, old UK and US sizes.

Needle length

Needle length is often a balancing act of practical necessity and personal choice. Whilst knitting the front or back of an adult garment, you will need a longer needle to hold all of the stitches and be able to work them evenly, but smaller items being made with the same yarn can be worked on shorter needles of the same diameter.

My own preference is for shorter needles, but everyone has their favourites; my grandmother, for example, liked to knit with long needles, tucking the right-hand (RH) needle under her arm for stability. This method is reminiscent of historical knitting practices as described by Michael Pearson in Traditional Knitting