Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Lebensstil

- Sprache: Englisch

Although it has been many years since the Triumph Spitfire was produced, the remaining number of functional examples that exist around the world is a testament to its ageless design and solid build quality. The Triumph Spitfire Restoration Manual is for anyone who has a keen interest in owning a Triumph Spitfire but has limited mechanical experience. It will steer any budding restorer through the many challenges encountered when maintaining and/or restoring such a classic and demonstrates the basic principles and simple techniques that would normally be learned by working alongside an experienced mechanic. Including helpful project tips and notes, which pass on a multitude of trade secrets.

Sie lesen das E-Book in den Legimi-Apps auf:

Veröffentlichungsjahr: 2024

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

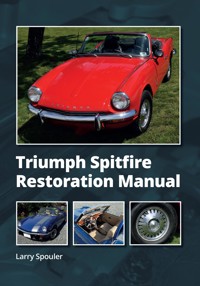

A 1974 Triumph Spitfire 1500 that the author and his son restored.

First published in 2024 by

The Crowood Press Ltd

Ramsbury, Marlborough

Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2024

© Larry Spouler 2024

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 0 7198 4329 7

Larry Spouler has asserted his right under the Copyright, Designs and Patents Act 1988 to be identified as the author of this work.

Disclaimers

Every reasonable effort has been made to trace and credit illustration copyright holders. If you own the copyright to an image appearing in this book and have not been credited, please contact the publisher, who will be pleased to add a credit in any future edition.

Safety is of the utmost importance in every aspect of an automotive workshop. The practical procedures and the tools and equipment used in automotive workshops are potentially dangerous. Tools should be used in strict accordance with the manufacturer’s recommended procedures and current health and safety regulations. The author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

Cover design by Blue Sunflower Creative

Contents

Preface and Acknowledgements

1Introduction to Restoring a Triumph Spitfire

2Finding the Project Car

3New Owner, Congratulations

4Getting Started

5Wire Harness Marking and Removal

6Fuel Tank Removal

7Emission Controls

8Door Interior Removal

9Seat Removal

10Soft-Top/Hood Frame Hinge and ‘B’ Pillar Cap

11Handbrake Removal

12Steering Wheel Removal

13Dashboard Layout

14Gear Shift Lever Removal

15Dash Pad, Demister System and Ashtray

16Windscreen Gasket and Glass Removal

17Wiper Posts and Wheel Box

18Heater Box and Water Valve

19Pedal Grouping

20Hydraulic Components and Lines

21Front and Rear Brake Mechanical Parts

22Electrical Harness Removal, Part 2

23Body Tub Removal

24Radiator

25Prop Shaft and Universal Joints

26Engine and Transmission Removal

27Engine Rebuild

28Clutch Assembly

29Transmission

30Steering Rack

31Suspension

32Bushing Replacement

33Rear End Differential

34Bare Chassis

35Hydraulic Lines

36Wheels on the Ground

37Body Tub Installation (Preparation)

38Fuel Tank Installation and Fuel Line Connections

39Wiper Posts and Cable Installation

40Heater Box and Water Hose Installation

41Pedal Grouping Installation

42Door Interior Assemblies

43Steering Column Installation

44Main Electrical Wire Harness Installation

45Master Cylinder Mounting

46Wiper Motor Installation

47Engine Bonnet and Rear Boot Lid Installation

48Exterior Body Paint

49Windscreen Frame Installation without Glass

50Interior Panels, Carpet, Soft Top and Tonneau Cover

51Windscreen Weatherstrip Gasket and Glass

52Soft-Top Tubular Frame

53Instrument Panel Installation

54Steering Wheel and Gear Lever

55Exterior Light Fixtures, Visors and Mirror

56Wiper Arm Installation and Movement Check

57Emblems, Badges, ID Plates and Mirrors

58Battery Installation and Ignition

59On the Road

Appendices

ITechnical Data: Mechanical

IITechnical Data: Electrical

IIITechnical Data: Dust and Water Sealing Areas

IVPaint Codes

Index

Preface and Acknowledgements

This book is intended to pass on a host of essentials and tricks I have found helpful when working on various models of a remarkable British sports car, the Triumph Spitfire. Many examples have exceeded their original production life cycle and in the process have outlived many of those who produced or purchased them when they came off the line.

In that time we have lost many experts who were once our primary source of parts, information and friendship. They came from a variety of mechanical backgrounds. Some of them worked on the production lines when these cars were made. Their knowledge and experience can never be replaced and it is unfortunate that their collective wisdom was not written down for future generations to share.

The focus of this publication is, I hope, to help the newcomer gain some confidence in owning a Triumph Spitfire. The manuals that were available when I started presumed the reader was experienced and had a good background in auto repair. The information was limited in scope and the photos were difficult to understand. Vehicle repair and servicing today revolves around computer diagnostics and module replacement, making it difficult to find an establishment that has personnel with the background to service these vintage vehicles. It has become more incumbent on the Spitfire owner to get to know their vehicle on an intimate level.

Some fortunate readers who have had past exposure to the subject may consider the basic material listed in this book to be trivial and unnecessary. I feel, however, that it is important to try to cater for everyone when taking on such a project, especially those with little or no experience.

I make no claim or presumption that the methods described here are the only ways to carry out a task, and I acknowledge that there are other acceptable ways to approach many problems. I have based the content on my personal experience, study of the published Repair Operations Manuals and consultation with a network of friends and associates who are presently active in the pursuit of keeping these classic British vehicles on the road. I hope that you will also enjoy the historic sales posters placed throughout the manual, which not only trace the course of the latest Spitfire technical advances, but help place these in the social context of that particular time.

ACKNOWLEDGEMENTS

This book, just like a restoration, takes the efforts of a great many people. The first and foremost mention is to my life partner of 45 years, my wife Linda. She has had to endure all the good and bad that come with this kind of hobby. She has become one hell of a navigator on our many road trips and shared in the driving on the Triumph Mayflower. She has always become involved with each and every car group we have become members with, and has never been one to be content sitting on the sidelines. Her energy, compassion and drive are infectious. She takes the ordinary and turns it into the exceptional.

I would also like to acknowledge Barrie, Andy and Doug, for their assistance in reviewing the different sections. The four of us have worked together on many a fine project. I wish to thank them for keeping me on track.

Special mention should go to Scott of Dun-Rite Performance, Guy of Western Starter and John of John’s Thistle Auto Ltd. Their technical expertise kept the presented material accurate and current.

The historic poster content has been provided courtesy of Harry Ilaria at Hi-Tech Software (www.htsoftware.com). The paint code chart and radiator fan photo are reproduced with the kind permission of Rimmer Bros (https://rimmerbros.com).

In the continuing pursuit of improving this book, if you have any recommendations or suggestions, please contact the publisher, who will forward your emails so I can act on your information.

Three Triumphs that have all been rebuilt with a full body-off restoration.

1

Introduction to Restoring a Triumph Spitfire

May I extend a welcome to all those considering restoring or fixing up a Triumph Spitfire. I hope this manual will help you in your project. I will be taking a position that the reader has little knowledge or previous experience of taking a car apart, and so will be offering recommendations and guidelines that I hope will make this process less intimidating. It will also help you maintain your Spitfire after it is on the road or until the time is right for a complete tear down.

The Triumph Spitfire was built for the average working person on a budget. Although it was not a luxury vehicle, it offers a great top-down sports car driving experience. It is simple to work on and maintain, although it goes without saying that you must always be ready to tinker with them as classic cars of this type are in need of constant attention. Even a full, frame-off restoration vehicle will require constant monitoring and a few spare parts in the boot when on a road trip. Part of the driving experience is to be challenged with some form of new noise or rattle while enjoying the car on the open road.

HISTORY

The Triumph Spitfire was in production from 1962 through to 1980. The body style was modified throughout this period and the engine size increased from 1296cc up to 1493cc. Like its namesake, the World War II fighter, the successive versions of the Spitfire car were designated as ‘Marks’. The first production Mark I was also named the Spitfire 4, in reference to its 4-cylinder engine. The following years produced the Mark II through to the Mark IV. By 1974 World War II was a more distant memory and the Mark designation was dropped. The last production version was simply named the 1500 in reference to the engine size, rather than the Mark V. A Spitfire 2000 was never produced as the factory engineers were concerned that its soft-top design might have issues with chassis strength. The only way to enjoy the 6-cylinder, 1996cc engine was to purchase a Triumph GT6 fast-back hard top.

REGIONAL VARIATIONS

What you are allowed to do when restoring a classic car to drive on the road, and how closely you must adhere to the original specification, may depend upon where you live. In the Canadian province of British Columbia, for example, there are strict rules governing the classification around collector licensing and the government insurance scheme offers a drastically reduced yearly rate for older cars kept in their period, manufactured state. Radio installation, steering wheel type and engine modification are monitored to keep the cars within the original manufactured options or recognised aftermarket improvements. This is done to ensure a period-correct restoration that does not incorporate modern technologies, such as digital radios or electric windows. In obtaining collector licence plate status one must stay within the parameters as listed by the insurance provider. We are, however, allowed to incorporate newer safety advancements without any penalty, such as fitting front disc brakes and an electric fuel pump, or replacing sealed-beam headlamps with LEDs.

You may find that your ambitious ideas to finish your car with fabulous modifications go beyond the changes permitted for classic or collector status. Before committing yourself, always check first with the local licensing agencies and make yourself fully aware of any restrictions or requirements that may need to be implemented in retaining a classic or period restoration classification.

I have found that Triumph vehicles, especially the Spitfire, remained very similar throughout their production years, with only minor variations for equipment placement and engine improvements.

The Spitfire is built upon a steel box frame to which everything is bolted. It can be stripped down systematically with each component taken off until eventually you get to the bare bones. The components can then be broken down, restored, repaired or replaced. All Spitfires were made in the UK and assembled using Standard National Fine (N.F.) thread, grade 5 bolts to hold everything together.

Spitfire 4 advertising poster, circa 1963.

The vast majority of parts fitted to those sold in North America are fundamentally the same as those installed on the UK models, except that all the Spitfire models shipped there were left-hand drive. In the later years of Spitfire production, however, California mandated new requirements that would require larger bumpers, engine emission equipment and the installation of an electronic safety system.

Always ensure that you approach your project in an organised way. Take lots of pictures of how things are put together. Like in any family, there are hundreds of photos of the firstborn child’s every little action, but far fewer of the second child. Treat this first teardown as if it were your firstborn. Keep a log book to record your findings and progress throughout the project. A computer file works even better as you can insert the photos as you go, record your discoveries, and note any repairs or replacements. You can also create a contact section listing the service shops and other persons of interest you have been introduced to during this project.

Triumph Spitfires, 1962–80

VersionEngineManufactureNumbers builtSpitfire 4 Mark I1147cc inline fourDec 1962–Dec 196445,753Spitfire 4 Mark II1147cc inline fourDec 1964–Jan 196737,409Spitfire Mark III1296cc inline fourJan 1967–Dec 197065,320Spitfire Mark IV1296cc inline fourNov 1970–Dec 197470,021Spitfire 15001493cc inline fourDec 1974–Aug 198095,829Triumph Spitfires, 1962–80

VersionYears of productionCatalogue part numberMark I–II1962–67 511682Mark III–IV1968–74 51628215001975–80RTC9110PARTS NEW AND USED

Do your research before you begin. Check out your local area for a Triumph Car Club and make contact with them. You will find this a great source of inspiration as you will probably be put in contact with Spitfire owners ready to share their personal experiences and offer advice on good sources of new or used parts. They may also know of someone thinking of selling their car or know where there is a forgotten project just waiting for a new owner. There are still some aftermarket part suppliers who can be approached for replacement parts, but they will not provide everything and you may need to visit a scrapyard to salvage that hard-to-find part. Another option is to purchase the factory parts catalogue, which provides an excellent reference tool to identify each part by number. These catalogues can be found online by searching for their own respective part number to locate the volume that matches the year of Spitfire you are working on.

BUDGET AND TIMETABLE

Know you own limitations, but do not be afraid to venture into new territory that will take you beyond your comfort level. Find out who are the experts in your area. I do all the disassembly and then the rebuild myself, but farm out the engine, transmission and rear end rebuilds if needed. I also use my local upholstery shop for the interior work. Chrome plating, media blasting, welding, radiator re-coring, body work and final body painting also usually require a specialist shop. The bodywork is the most challenging and expensive of all the restoration costs: allow at least 50 per cent of your budget for bodywork and paint.

You will need to decide how far you want to go in taking on a Spitfire restoration. The cost savings you can gain come primarily from your own labour in the disassembly and reassembly of the whole car.

If you have more mechanical talent than myself, you will realise even greater savings. A full body-off restoration would cost the average hobbyist in excess of £15,000–24,000 (US$19,000–30,000 or C$25,000–40,000). This kind of budget far exceeds the price that can be recouped once the car is completed and on the road. The average Triumph Spitfire 1500 in running order sells for about £5,000–10,500 (US$6,000–13,500 or C$8,000–18,000). As you can see, purchasing a Spitfire in excellent running condition has a financial advantage over a do-it-yourself project.

I am not trying to discourage you. The days are gone, however, when you could buy a car to fix up for a few thousand pounds or dollars. Labour and operating costs for businesses can elevate the restoration to a level well beyond your planned budget. Many owners have had their classic cars held to ransom at a workshop after little or nothing has been done, and a heavy financial sum has been demanded to release the car based on storage costs and so on.

The advantage of taking it apart and doing the reassembly yourself is that you will become intimate with all your car’s operating components. You will have the satisfaction of knowing that every underlying component has been inspected, properly repaired and/or replaced. There is an important safety factor in knowing that those hard-toget-at assemblies and bushings have been attended to. These deep-rooted problems are usually skipped over in a cosmetic clean-up. Remember that the Spitfire may now be approaching 50 or 60 years old. The rubber components and wiring are dried out and brittle, and will no longer function as intended. You will also have the satisfaction of knowing you have preserved a piece of history.

Allow plenty of time to take on this kind of project. How many years do you estimate you need? Be realistic in planning when you can work on the car. Plan your budget based on a yearly amount and not wait until you have the full amount saved up: my first TR4A project took six years due to family priorities while the kids were still at home and in school, with only a limited amount of extra cash available to spend on the car each year.

It is important to have somewhere suitable for the project with enough space, perhaps a double-bay garage that provides a secure, dry, well-lit area to do the work, including a bench and tables. Don’t forget about what to do with the parts as they are taken off. It is surprising how much room is needed to store all the parts once they are no longer assembled as a car. Windscreen, door glass, bumpers, seat frames, boot lid, wheels, engine, transmission, rear end, prop shaft and even the whole front bonnet are just some of the larger pieces that will need to be stored out of the way as you proceed with the tear-down.

BAG AND TAG

All the smaller components will need to be organised, labelled and stored so they will be ready for refurbishing. As items are removed, treat them as separate components: take lots of photos and make notes about their alignment and orientation on the car as they come apart. Store all the components in labelled, recycled plastic food containers. The old mounting bolts, screws and hardware can be organised in ziplock bags. Moisture-sensitive parts can be placed in containers alongside recycled water-absorbing pouches.

Various types of containers for components.

Moisture pouch.

Don’t throw all the bolts and screws into one large container thinking you will remember where they came from. You won’t. Be organised and bag each grouping of bolts. Mark each bag to identify where they came from and what diameter size they are, such as ¼in or ½in. Keep all the bags in one box in a sequential size order using cardboard dividers. After the car has been taken apart you can go to your hardware supplier with a full list of how many of each size and length of bolt you need. Make this type of inventory for the screws as well. Nyloc and regular nuts of the same size can be kept in the same bag. Flat and lock washers fitting the same bolt diameter can also be kept bagged together.

MEDIA BLASTING

The larger, heavier parts will later need to be sent somewhere for media blasting to remove the old paint and surface corrosion. In order for the blasting material to be effective you will first need to remove all the surface grease and dirt by scraping, brushing, wiping and sweeping up the layers of debris that have built up over 50 years. The type of media used is a personal choice, whether sand, walnut shells, ground glass or other abrasive material. Find out what services are available in your area, enquire whether the costs quoted include the application of a primer paint, and decide how the parts will be transported there and returned home.

TOOLS AND EQUIPMENT

In addition to standard sets of tools, such as screwdrivers, spanners, hammers, socket sets, wrenches and pliers, a number of more specialised tools will be necessary when tackling this type of project:

• Lifting jack and jack stands rated for the vehicle gross weight

• Wheel chock

• Wheeled dollies for ease of vehicle movement in tight spaces

• Penetrating fluid, paint thinner (white spirit), degreaser, old toothbrush

• Torch for heat application

• 4½in electric grinder with thin cut-off wheel

• Breaker bar for the socket set

• Ball-joint separator and gear-wheel puller

• Road spring-caged compressor tool for front shock assembly

• Tap and die set

• Torque wrench

• Screw and bolt extractors (Easy Outs)

• Alignment tool and nail punch set

• Personal protective safety equipment

• Digital photo device along with a computer to establish a written and photo log

• Clean recycled plastic food product containers in various sizes, plus ziplock bags

• Felt tip marker, paint pens, labels and masking tape

• Dielectric grease

• Anti-seize paste

• Heat shrink tubing of different colours and diameters

• 30–60cm (12–24in) length of jump wire with alligator clips at each end.

Spitfire Mark II advertising poster, circa 1966.

2

Finding the Project Car

Selecting the project car depends on how far you intend to go with the teardown. I look for a vehicle that has not been modified and still has almost all its original parts and wiring harness intact. Because of their age I expect to replace or rebuild everything throughout the car, so I am more interested in having the original parts for reference than their ability to work or function at the time of inspection. The important thing is the general solid condition of each component, and especially the frame and body tub. The candidates should be solid and straight without any rust perforation.

FIRST IMPRESSIONS

As mentioned in the previous chapter, the local Triumph Car Club may be able to put you in touch with someone wanting to sell their Spitfire or knowing where there is one for sale. When you go to have a look at a Spitfire, take a torch, a good earth magnet, a couple of clean rags, a hand-cleaning solution or gloves, and ask permission to take photos. Body condition is the most important aspect to consider when deciding to purchase an appropriate candidate. Surface rust should be expected, but perforation rust is very expensive to repair and may affect body tub stability. Inspect the floor panels by rolling back the carpet and examining the very front floor firewall area, especially the left and right corner areas. Here you will see one of the main body tub mounting bolts to the frame. Pay particular attention to the ‘A’ and ‘B’ pillar areas as they support the body tub at the door openings. The rocker panel below each door sill is also a key point in ensuring body tub stability.

Check the door operation for movement and poor alignment. Take a moment to observe the door gap at the ‘B’ pillar. The gap should be relatively even from top of door to bottom. A tighter gap at the door top with a wider gap at the bottom could indicate a sagging chassis. Also check for an even gap across the top of the rocker sill panel. Ask permission to use the magnet on the door panel and rocker panels to see if there is any body filler under the paint. Always ask permission first as some owners may object to this process. Placing some tape on the surface of the magnet may provide the reassurance the owner needs to allow you to place the magnet on the car’s painted panels. Wiggle the seats and observe the anchor points of the seat rails to the floor panels for excessive movement. Does the seat slide along the rails? It may be stiff but function is all that matters. Tip the seats forward to view the area under the seat and the rail condition. The 1500 Spitfire has a release lever at floor level behind the seat, which can be a bit fussy to pull upward, and tilt the seat. There is also a seat back adjustment lever, located at the base of the seat back, which can be used to adjust the seat back position from forward to a recline.

A likely candidate: a 1962 Spitfire 4.

1974 Spitfire 1500 candidate.

Location of the rocker sill panel, ‘A’ and ‘B’ pillars.

IN THE DRIVER’S SEAT

Check the interior door panels for wear and all door levers and window winders should be fully operated to note their action, restriction or absence. Door glass can be viewed when fully exposed. The dash pad area below the windscreen may contain splits and or cracks. Check the condition or absence of the air vent louvres and ashtray. Make sure that the instrument gauges are in good condition with no broken glass or excessive rust on the external chrome-plated metal rings. Ask whether the gauges and switches are original and if they operated when the car was last used. Does the gear lever have a knob? Check the rubber boot at the base of the gear lever base, making sure that it is in place and not torn. Press in the clutch and go through the gear selections, including shifting into reverse. Do your research in advance so that you know the proper gear lever operation for selecting and shifting into reverse gear on the Spitfire model and year you are viewing: a push down or pull up are commonly needed prior to moving the lever into the reverse direction. Disengage and then re-engage the handbrake lever to check its movement and release.

Ensure the paddles are on the ends of the lever switch arms.

The steering column has two lever switch arms from the escutcheons. The left one is for signals and the right for headlamp, flasher (where legally permitted) and running lights. Pulling back on the headlamp lever should engage the headlamps (flasher) even with the ignition off. Note whether the paddles are still present at the ends of the lever arms, as they are not available for purchase as a separate part. Also check that the headlamp lever paddle is a different shape to that of the signal lever.

Try the headlamp lever to see if the lights come on and then pull the headlamp selector lever towards you to activate the flasher feature. Also check whether the instrumentation lights come on. Note that the signals will not operate without the key switched on.

The horn button should be in place and audibly working. Grab the steering wheel in both hands at the 3 and 9 o’clock positions. With a firm but gentle force, push down and pull up on the wheel, as well as try to lift and push 90 degrees to the left and right of the wheel. Any free play or clunking sounds will indicate issues with bushing or connection. Take your time having a good look around the interior before getting out of the car.

UNDER THE BONNET

Lift up the engine bonnet and inspect the top, front and underside of the whole bonnet for rust or signs of collision damage. Have a good look at the bonnet hinges and tubular frame structure. Inspect the headlamp buckets for perforations and wiring splices. Are both horns present? Inspect the radiator mounting and its general condition. If the radiator is cool, ask to open the radiator cap and view inside. The engine bay can be viewed easily. Does the engine turn over and will it run? Note the general condition of the water hoses and confirm whether the wiring harness is original and unaltered.

Spitfire 4 firewall, right side.

Spitfire 4 firewall, left side.

The earlier Marks of Spitfire had a generator whereas the later Marks used an alternator. Is this Mark positive or negative earth? The steel frame can be inspected for perforations and cracks by wiping away any excess oil and a build-up of grease with the rags you brought with you. Look closely at the front suspension anchor points to the frame. Use the torch to examine the rack-and-pinion steering boots for perforations and tears, which may have exposed undersurface parts to corrosion. The firewall area has a helpful utility shelf used to house a great many components. The battery box floor area has a history of corrosion, which can result in lots of perforation, so look closely and ask the owner about the age of the present battery. The wiper motor mounting, heater mixing valve, voltage stabiliser, horn, starter relay, starter solenoid, ignition coil and the hydraulic master cylinders can all be easily checked over. Look over the engine to identify whether the carburation type is SU, Stromberg or perhaps Weber, as you may have a personal preference. Don’t worry too much about the rubber water hoses as they will all need to be replaced anyway due to their age.

If the car you are looking to choose comes with wire wheels you should ask to remove one wheel. Check the splined hub for wear. The outermost edge of the actual splines should not be worn into a sharp pointed tip or be bent. Does the hub still have the low-profile lug nuts? Are the original steel wheels and studs included with the car, and what tools come with it to remove the spinner?

REAR BOOT AND SUSPENSION

Inspect the inside of the boot (trunk) for rust perforation. Check out the tail lamp wiring harness for splices and connections. Also ensure that the rear cardboard bulkhead panel is in place covering the fuel tank, and then ask to remove it to view the fuel tank, filler hoses and sender unit. Check that the spare tyre mounting bracketry is still intact and that the emergency jack and tyre iron are present.

How does the boot lid fit to the body tub? Check that the boot latch catch pin is in place, as they have a habit of going missing or being damaged. Will the latch engage and secure the boot lid? Are there extra holes where a luggage rack was once installed? Examine the surface condition of the boot lid hinges. Are they rusted and all pitted out or do they just need to be replated or buffed up again?

Use the torch under the car to check the rear suspension anchor points to the frame and body tub for signs of perforation or excessive corrosion. The rear suspension has a radius arm/rod from each wheel to a body tub mounting bracket. Pay attention to where these radius arms/rods attach to the body tub. These are critical areas and it can be expensive to have them rebuilt due to the importance of strength and stability needed for safe vehicle operation. Look at the rear wheel backing plate to see if there is any evidence of a brake slave cylinder leaking. Look at the parking brake cable connections and return springs.

The front suspension has upper and lower ‘A’ arms. There is also an anti-roll bar that connects both front lower ‘A’ arms. Check the mounting points at the lower ‘A’ arms, making sure that no mounts have torn away from the ‘A’ arm area. The connecting rods, links and bushings are available from suppliers and can be replaced during the restoration or regular maintenance.

Inspecting the rear boot area of the future project Spitfire 4.

Rear boot latch catch pin as fitted to Spitfires from Mark I to Mark IV.

Check the radius arm/ rod connection points.

Front anti-roll bar connection.

You should expect to see some oil, mixed with road dirt, coating much of the frame and undercarriage parts. Look for excessive oil drips on the oil pan, transmission housing and differential case. Use your rag and torch to get a good view of what’s underneath the grime and grit. There is always more to view – be careful, take your time and be thorough.

If you take it for a test drive, ask the owner to go with you to answer any questions you may have while out on the road. Gear shifting noises or the transmission popping out of gear may indicate a synchro ring issue (see Chapter 29 on the transmission). Without a full inspection it could be worse: you might otherwise be tearing the car apart, so being able to drive it home will save you the cost of a flat-bed or trailer rental.

3

New Owner, Congratulations

You have made an executive decision and purchased a car. It has been towed, trailered or driven to its new home. Now is the time to find out all you can about its origins and specification.

IDENTIFICATION NUMBERS

The first task is to locate the various stamped identification and commission numbers. As they are found, a photograph should be taken and the details recorded in the log.

The lettering prefix for the engine numbers indicates the engine size and car type, as opposite:

Inserted into the lettering you may find a ‘C’ (California compliance), a ‘U’ (US Federal compliance), an ‘L’ (left-hand drive) or an ‘O’ (a vehicle with overdrive).

The body plate number is used for vehicle registration and is located on the left-hand body bulkhead, where it is visible when the bonnet is lifted. North American cars would have the plate located inside the left door, on the ‘B’ pillar next to the striker plate. There is also an additional smaller commission number plate visible through the left side windscreen pillar.

You should also take photos of all the decals located throughout the car. Replica decals and blank metal commission plates can be obtained from parts suppliers to be fitted after the paint job is completed to add that proper professional touch to the car. Keep all the old identification plates in a safe secure place.

Spitfire 4 engine block number.

Engine number location.

Gearbox number.

Body plate.

Differential number.

Spitfire 4 advertising poster, circa 1963.

Spitfire Mk 2 advertising poster circa 1966.

FM and UE on the engine number indicates a North American Spitfire 1500;

Commission plate location on North American Spitfires;

Commission plate on windscreen pillar.

Grade 5 bolt markings vs Grade 8 bolt markings.

Various speed nut types.

HARDWARE: THE NUTS AND BOLTS

Spitfires were built using Standard National Fine (N.F.) grade 5 bolts. Some of the basic principles for choosing National Fine thread are:

• A fine thread bolt will be less likely to loosen off under vibration

• They are stronger in tapped hole applications and result in a higher clamping force

• Stronger in both shear and tension force loading

• Better joint tightness and clamping force

• Stronger than the coarse thread bolt equivalent in size and hardness.

I prefer, however, to use N.F. grade 8 bolts throughout my rebuilds. They are altogether stronger and are appropriate for the suspension parts. Avoid using stainless-steel bolts for any load applications, such as the suspension, although they are fine in the non-critical, cosmetic assemblies. Anti-seize paste is to be used on threads and all bolt shafts as you slide them through bushings and other connecting points on the car. This will help prevent rust forming in the future, ensure bolt movement and rotation through the bushings, and allow easier disassembly should a repair be needed years after your completed rebuild. Apply antiseize paste to the thread ends of a bolt that is being threaded into a tapped area or threaded to a regular nut with lock washer. Any critical structural bolt should be replaced without question as your resources are unlikely to run to magnaflux testing to check for minute cracking.

As a general rule any nyloc nut removed from a suspension or critical structural bolt should not to be reused but discarded. This even applies to those that are brand new. These joints rely on a tight connection afforded by the nyloc grabbing the bolt, and should not be compromised by placing them on, taking them off and putting them back again.

Speed nuts will be found throughout the car at various openings in the body tub. They come in a variety of sizes, shapes and materials, and include both slide-on and insert types. As you remove screws and take off a part, take a photo of the speed nut in use and remove, bag and tag.

PAINT COLOUR CODES

The paint number codes stamped onto the identification plate can be referenced on the chart to determine if the car you are inspecting or have purchased is in its original colour. The trim colour code can also be referenced to the colour code chart. If you do not like the Spitfire’s current colour, one of the factory colours listed in Appendix 4 would make a proper substitute.

SAFETY IN THE WORKSHOP

It is important to work safely the whole time you are involved in this project. Proper personal safety equipment should be used at all times when there is a risk of exposure to injury. Purchase a quality pair of safety eyewear, which should be worn any time you are drilling, grinding, chipping, banging, working with a spinning wire wheel or working under the car – grit falls down as you look up. Nitrile mechanic gloves (not medical exam gloves) must be worn to protect you from the dirt, rust, grease, oil, petrol, radiator fluid and chemicals necessary to take you through the project. An N95 dust mask should be worn when working beneath the car, grinding, spraying paint or sweeping up dirt, rust and other materials. Hearing protection should be worn while performing any metal impact situations, which will generate high decibel sound levels. There should be no smoking in the workshop.

Invest in a pair of overalls that will keep your everyday clothes from being contaminated with dirt, chemicals and petroleum products. Shoes must be worn in the work area at all times. The overalls can be put on and taken off while in the work area, keeping all foreign material in the garage and out of the house. When the time comes to washing them, do so separately from any other family clothing.

Children are to be kept under adult supervision at all times. Once the rebuild gets underway, this area should remain out of bounds. Take photos of the kids sitting in the car when it is first brought home and before it is placed on jack stands. Once the project has started everything about it is just too tempting.

Adequate lighting is a must. Even with adequate overhead fluorescent lighting you will be under or inside the car, so portable lighting is essential to see what you are doing. LED rechargeable portable lights are great for this, but for some unknown reason they always tend to roll away from where you need to cast the light. A headband light is great for keeping the area lit and your hands free for the tools. LED lights on stands are really handy and can be easily adjusted to focus the light where it is needed. Do not use old glass incandescent bulbs as they shatter easily, scattering glass shards across the work area. They are also an unwelcome heat source. If you touch one accidentally in tight spaces it is instinctive to rapidly pull away, causing you to bang other body parts into solid metal objects, as I can vouch for by experience.

Spitfire Mark II advertising poster, circa 1965.

The work area should be properly ventilated to prevent any build up of fumes, vapours and gases produced when using a blowtorch or heat source when burning off paint, rubber, grease, oil or other chemicals. Any heating source used to keep you warm during the colder months should not present a fire risk or introduce an air contaminant into your workplace.

Power and hand tools should be used according to the manufacturers’ instructions. Do not use a tool for other than its intended purpose: screwdrivers, for example, are not pry bars. Ensure your power tools still have all the guards in place and that they are set correctly. Check that the rpm limits of your cut-off wheels or grinding disc match the rpm speed of your grinder.

Any lifting device, jack stand, lifting hydraulic jack or similar can be used if properly rated for the weights you are placing on them. Check the printed material that comes with the lifting product and mark them with their lifting limit using a felt tip or paint pen. Pulling an engine and/or transmission should be done using a properly rated lifting device and not a rope or chain wrapped around a roof joist.

When jacking up a car to position the jack stands, do it using incremental steps. Start by keeping the jack stand at full retraction and place one in each of the four corners of the car. Jack up one corner of the car and increase the height of each stand in small increments, until you obtain the working height required. This avoids the dangerous situation of having the car perched on one or two tall leg(s) while you attempt to jack up the next point of the car to that very tall height, possibly tumbling the car off the jacks. Prior to working under the car ensure all the lifting points are secure. Check that each jack stand is straight and taking part of the load. Place an extra stack of wood cribbing in one or two corners of the car at a load bearing point. This will add that extra margin of safety should that jack stand fall as you apply that extra level of torque force to get a stubborn part to release.

The floor surface of your work area should be kept clean and free from debris and any build-up of fluid. Painting the floor area prior to bringing the car home will help when finding dropped parts, make cleaning easier, and provide a more comfortable run when having to slide under the car. Spills should be cleaned up immediately and all soiled material properly disposed of according to national environmental regulations.

All the fluids from the car should be drained into appropriate labelled containers and disposed of at your local recycling facilities. Petrol tanks, once drained, should be allowed to continue to vent off the vapours. An empty petrol tank is a potential bomb and is to be treated with healthy respect. Radiator fluid may contain glycol, which is fatal when ingested by family pets. Do not put the fluids down the drain, flush them down the toilet or pour them into the garden. Do not leave the drained fluids in an open-top container allowing them to be easily spilt. Left open and unattended they will continue to vent gas into your work area. They may also be a potential hazard if children and/or animals are exposed to them. Proper containment and disposal protocols should be followed.

You will be using wire brush wheels on pedestal grinders or hand tools. Always use safety eyewear when running a wire wheel. You should be aware that wire wheel brushes shed tiny wire bristles that will penetrate your clothing and fly around the workshop in all directions. These bristles go undetected until you step on them. Never walk about the workshop in socks or bare feet (even it is just for a fraction of a second). Individual wire bristles will be thrown throughout the work area and can easily penetrate your foot. Not only is this painful but they are really difficult to remove, as the wire cannot be seen and requires an X-ray to locate. A local anaesthetic needle to the bottom of your foot, prior to local surgery, is one of life’s pleasures you can do without. The wire bristles will also become snagged in your clothing and will transfer to other family members’ clothing in the washing machine. I use a bar magnet attached to a pole (magnetic broom) to pass over the areas where the wire wheel was used. This will pick up most, but not all, of the released wire bristles. Clean up with a shop vacuum after the day’s work. It is amazing how much rust and debris will fall from the car. Establish a good housekeeping routine that will make it a pleasure to work on and under the car each day.

Set up an area as your small parts wash station. Use a shallow recycled plastic container as the tub and apply paint thinner or white spirit with an old toothbrush to clean old grease and oil off the smaller parts from various assemblies. When doing this always wear protective nitrile gloves and eyewear.

Bolt and screw heads can be painted safely when the shafts are inserted into a piece of cardboard.

Painting refurbished parts will also produce fumes. Establish an area where you can paint the smaller parts and have a fan to keep the air flowing. Allow for the overspray and establish a place to hang the parts as they dry. Wire coat hangers can be cut and bent to make great parts hooks. A small plastic turntable will do wonders when you need to get all around a small part without spraying paint over your gloved fingers.

A rolling seat stool with a lower parts tray is a wonderful accessory to have as you work around the car. A rolling parts/tool platform is a great help when you are working on the far end of the car away from the location of your tools and workbench. Selected tools can be placed on the tray for easy access from wherever you are working on the car. A magnetic tray also helps keep the nuts and bolts in one place until you bag and tag them.

Workshop equipment.

EMERGENCY PLANNING

Have an emergency system in place in case the worst scenario occurs. Mobile phones are now a part of everyday life: have yours available at all times. Remember that it’s difficult to pull the phone out of your pocket and dial when the car is on your chest. Let people know where you are and when you are starting. Estimate approximately how much time you will be in the workshop. Simple first aid supplies should be readily available for the standard cuts, scratches, pinches and whacks. Discuss with others about how you would get help if you are badly injured by a fall, or trapped under the car. Plan for a fire and how you would handle the situation. Make sure you have the appropriately rated extinguisher, discuss the method you will be using to raise the alarm and notify others, as well as keeping yourself out of danger and notify the emergency services if required.

I have tried to take a logical approach to the dismantling and reassembly process that is involved with such a project. As such, items are listed in a progressive manner. You may wish to take a different approach and work on components in a different order. That is totally up to you and your base of experience. You may wish to have a battery available to help check current flow and continuity during the early stages of the wiring installation. Again, it is up to your comfort level. Planning is a big part of any rebuild and sending out parts to a variety of outside agencies requires coordination and timing. You will want to have these parts finished and returned so the rebuild does not face undue delays. The main thing is to have fun and enjoy the project.

Project tip:

Avoid spraying any paint on bolt threads or into tapped threaded holes. Insert the shafts of bolts or screws into holes in a flat piece of cardboard, exposing only the area of the heads that need to be painted.

4

Getting Started

Start by making an inventory of any extra parts that came with your car purchase. No matter its condition, keep it all: you do not know what will turn up as your project comes apart. These old parts just might include an original you will need to help source the correct replacement instead of what was substituted on the car. Perhaps a workshop manual came with your purchase. If not, you can look for one to download through the various online marketplaces. Another option can be to contact the local club to see if there is an owner with your Mark of Spitfire, who may be willing to lend you his workshop manual. You can also order a Parts catalogue (seeChapter 1).

The objective is to strip out the body tub and engine bonnet so they can be removed from the frame, allowing easy access to the engine drive train and suspension parts. The body tub can be easily lifted off by four people and stood on its nose to stay out of the way until it is ready to be stripped and primed prior to any bodywork being done. The engine bonnet can be handled by two people and stood on its rear to take up as little space as possible while awaiting media blasting and priming.

The first task is to remove the battery. This will prevent any possible sparks from the live wire lead contacting a source to ground. Depending on the battery’s history and condition, it can be saved, recharged and placed back in the car when ready, or recycled at a proper facility. Note the post location and orientation for when a replacement is fitted, allowing your cables to connect properly. Record the battery dimensions, including its height, in order to maintain the top clearance needed so the posts do not contact the metal engine bonnet. If the old battery still holds a charge, it can be used to bench test several of the electrical parts. Make up a pair of jump wires with alligator clips installed on each end, with the wires coloured black (negative) and red (positive).

Spitfire Mark 2 advertising poster, circa 1967.

Place a pan under the radiator and remove the top cap from the radiator. Locate the drain plug and open it to allow the fluid to drain free from the car. It is important that you understand how toxic glycol is to household pets: they are attracted to it and it is deadly. Dispose of the fluid in an appropriate container at a proper recycle facility. Clean up any fluid spills immediately and keep the area dry.

REMOVING THE BONNET, BUMPERS AND GRILL

The next stage in the project is to prepare for the removal of the car’s larger parts: the engine bonnet, the boot lid and eventually the body tub. To do this we will be moving around and into the car and dealing with various components as they come off the car. We will also go into some detail on how to take these components apart and prepare them for a later installation. Keep the doors on the body tub. This avoids having to brace up the body tub when it is time to remove it from the frame. We will discuss the removal of the panels, glass, levers and windings later.

Spitfire 4 rear bumper.

Disassembled parts of the rear bumper.

Front and rear bumper details of the Spitfire 4.

Mark III rear bumper/light details.

Spitfire 4 front body valance is all in one piece.