Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Lebensstil

- Sprache: Englisch

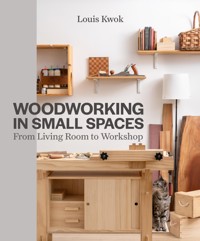

A common misconception of woodworking is that it requires a spacious workshop filled with expensive tools and machines. However, with the right approach, you can set up a fully functional woodworking studio in your home, even with limited space and resources. Whether you are a beginner or an experienced woodworker looking to adapt to a smaller space, Woodworking in Small Spaces proves that woodworking in a small apartment or dwelling is practical, rewarding and easier than you think.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 236

Veröffentlichungsjahr: 2025

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

CONTENTS

CHAPTER 1 | Planning Your Space

CHAPTER 2 | Knowing Your Material

CHAPTER 3 | Tools and Equipment

CHAPTER 4 | Tool Maintenance

CHAPTER 5 | Your First Work Surface

CHAPTER 6 | Woodworking Basics

CHAPTER 7 | Making a Toolbox

CHAPTER 8 | Your First Workbench

CHAPTER 9 | Adhesives and Finishes

CHAPTER 10 | Projects

Bibliography

Useful Links and Resources

Index

CHAPTER 1

PLANNING YOUR SPACE

S pace is always a luxury, especially when you live in an apartment. Every square foot (or metre) is counted towards your rent – or your mortgage, if you are fortunate enough to own your place. Identifying a suitable area for your woodworking needs is the first step on your journey to apartment woodworking. What is crucial is not how big the space is, but how creatively you are able to visualise and make use of the limited space that you have.

My current workspace is somewhere between the living room and the bedrooms.

SPACE MANAGEMENT

If you are just starting out, I would suggest a spot where it is possible to put your tools away in a neat manner, where you can sweep up easily and keep the space relatively clean. Nobody likes a messy and cluttered workspace and having one will further discourage you from doing any actual woodwork.

There are some who convert their kitchen top or their dining table into their worktop when they want to do some woodwork and after they are done for the day, restore the area to what it was. There is no limit to where to start, but I strongly believe in being able to pack and clean up the area after each session of planing wood or cutting joints. I even know of someone who first used his bathroom as his first workspace!

Having a larger space is definitely great, but it means a bigger space to manage. It also tempts you to buy more equipment and to hoard more materials. Learning to grow organically has taught me to be a little more prudent in my purchases and to be creative in the tools and materials that I already have. I started with the only unoccupied space I had in my apartment a roughly 2 × 1m (6 × 3ft) area on the balcony.

Aside from managing the space in your apartment, you might want to factor in the access points to your apartment as well. If you are living in a building with an elevator, be sure to know what is the longest or widest piece of timber you can carry into it. If you are living in a walk-up type of apartment, consider the angle of your stairwell. I inherited an old hand trolley from a shop that was closing down and found that it was excellent for transporting narrower boards of timber.

My first workspace was on a balcony with a used kitchen island as a workbench.

When designing your workspace, be ready to have some space assigned for material storage. Most people will think of the actual working area, but fail to organise a place to store materials and equipment. As woodworkers, our material can be rather bulky and potentially take up precious space. Depending on where you are venturing into the world of woodworking, you can quickly see your space being overcrowded by timber (or lumber) after trips to the timber/lumber yard or salvaging from other places. So, be sure to dedicate a space to house your material.

Ideally, we would want at least two working surfaces; one to do actual woodworking on, and one to put tools and other materials on. It can be very frustrating while working on multiple pieces with limited work surfaces and you end up putting stuff all over the floor which can very quickly become a safety issue. Keeping the floors relatively clear is good practice; loose power cables and wires can be a tripping hazard in the already limited work area. Wall-mounted shelving options such as the peg boards or the French cleat system are modular and can be adapted as you grow in your craft.

A WORD ON STORAGE

Always be creative with storage. I always look above and beneath when I need to find somewhere to store material. This is because the last thing you want is to play a game of tetris and to move things around just to get to what you need or to be able to start working. I have found that I can store long pieces of wood and large sheets of veneers lying flat on top of shelves or cabinets. You can also consider modifying existing pieces of furniture to suit your needs.

My second workspace was a converted bedroom in the apartment with wall-mounted shelves and a French cleat system to increase storage space.

LIGHTING

It is essential to see what we are doing, especially more so in woodworking because we are dealing with sharp chisels and saws. I generally work during the day because I enjoy using mainly natural light when I work. However, whenever that is not possible due to geographic locality or the location of the workspace, I do suggest having sufficient lighting in the work area. This could be in the form of overhead lights or portable clip-on lights. There are comparisons to fluorescent lighting, LEDs (light emitting diodes) and even tungsten lights. Which type is brighter, better for the eyes, or even cheaper to maintain?

I would suggest first using what you have before spending on a dedicated lighting system. When I first started, I used a table top lamp which uses screw-on bulbs. Screw-on bulbs like E14, E26 and E27 are convenient, because they are easily replaceable and offer various options to choose from.

There are a few things to consider when choosing your lights:

Bulbs Most bulbs come with a base. I like to use the screw-in types like E27s, but there are many others like the pin types, plug-ins or twist and lock types – even highly custom ones for special applications. This was my choice because I used what I already had, which was a table lamp that uses E27 bulbs. These screw-in types of bulbs come in a variety of brightnesses based on the wattages and lumens which you can purchase. Do consider LED (light emitting diode) bulbs as compared to CFL (compact fluorescent) or incandescent bulbs, as they require less energy and are longer lasting.

These screw-in E27 light bulbs come in a variety of brightness and colour temperatures and can be easily replaced.

Colour temperature In the simplest terms, colour temperature is how warm (orange) or how cool (blue) the light is. Daylight has a colour temperature of around 5,000 to 6,500K (Kelvin is the measure of colour temperature). Some people prefer working in a temperature similar to daylight because it is easier to see colours and tones. This is important when the colour of an object is critical, like when working with paints or dyes or various types of polishes.

Examples of different colour temperature light bulbs on the same lamp. Warm lighting on the left and cool lighting on the right.

I tend to prefer to work in a slightly warm tone lighting environment because I feel that it is more comfortable to my eyes. The colour temperature of a workshop is highly subjective because depending on what you are working on, the requirements vary. Because of this, I outgrew my table top lamp after a few years and when I was setting up my new studio, I decided to invest in LED lighting strips, which have the option to change their brightness and colour temperature, as well as them being remote controlled. It is a little luxurious but it fulfilled all my needs.

There are colour- and brightness-controllable LED screw-in bulbs available. These are very convenient and can easily convert your incandescent lamps into work lights without buying into a whole new system.

A WORD ON LIGHTING

When it is not possible to manoeuvre your lights to shine at hard-to-reach spots, get creative by using portable battery packs with USB-powered LED lights – some of these lights come with articulating arms so you can easily manipulate them into your desired position. I use old battery packs that may not be as powerful as newer ones but are still efficient in powering these small LED lights.

I affectionately call these portable battery pack lights my ‘snails’.

DUST AND VENTILATION

I live with four cats, and their lungs are more sensitive than those of humans. So I try to be a responsible cat parent and also have their general health and wellbeing in mind.

I cannot stress how important our lungs are. It is also difficult to ‘see’ what we breathe in. Micro dust particles can be extremely dangerous when inhaled for long periods of time. I highly recommend having your set up somewhere with proper ventilation, like near open windows. If no windows are present or if it is not suitable to have the windows constantly open, then I would suggest getting at least an air purifier.

The good news is that when using hand tools, most of the wood particles produced when sawing or planing are larger as compared to using machines. This means it is possible to have most of the larger debris land on the floor, making it easier to sweep up. Some form of slip-resistant, covered footwear can help prevent injuries from falling tools and wood, or stepping over wood chips.

However, when doing any sanding or dealing with any finishes or chemicals that have fumes, it is important to wear the appropriate masks and eye protection. Some masks will only help filter out dust particles while others filter fumes and harmful gases. Invest in a good system with replaceable filters or have some disposable ones to hand.

I invested in a general purpose vacuum cleaner to clean up the rest of the dust. After each day or in between various intervals of the day, it is important to take note of how much dust is being produced and where it has accumulated on the surfaces around you. This is an indication of how the air flows (or does not) in your workspace, and how often you need to clean up. I have tried installing and using a one-horse power extractor in my home studio, but I found that it was unnecessary and was far too loud for my liking. I never have more than one power tool running at the same time, and I do not produce enough volume of dust to justify the extractor’s footprint (and amount of sound it makes) in the studio.

Cats and other indoor pets have different tolerances from humans when it comes to dust, fumes and other airborne particles.

Apart from masks, eye and ear protection is essential in woodworking.

POWER MANAGEMENT

Make sure there are enough power points for lights, possible hand-held power tools and for charging other items.

It is always convenient to have access to power points near the area you are going to be working in. This will be great for charging batteries for battery-powered tools or the portable lamp that you might be using whilst you work and even your mobile device. Just make sure you do not overload each socket and ensure that the electrical device is compatible with the power output of the country that you are in. I moved from a country which uses 220V to one which uses 110V and had to make sure I had the correct transformers.

The internet has made ordering equipment so easy across countries, so make sure you are purchasing one that is suitable with the power output that you have wherever you may be. There is some equipment which is dual voltage, which is usually denoted with ‘110V–220V’ or ‘100V–240V’. This means that it can be used in whichever country you are in.

Dual voltage appliances mean that they can be used in most parts of the world without fear of damaging your equipment.

A WORD ON POWER

With so many options on power tools, consider getting a system that uses battery packs. Cordless technology has improved tremendously over the years and at the time of writing this book, most corded power tools already have their cordless counterparts readily available. Battery power packs are also typically designed to be interchangeable among the power tools.

Battery-operated tools are very convenient and eliminate the need for cords and extensions, which can become a tripping hazard.

SOUND MANAGEMENT

One of the first considerations I had when I first set up my apartment workshop was how not to annoy my neighbours. The last thing you want is to have unhappy people living around you. I used to live in an apartment with three other neighbours on the floor that I was on. Thankfully none of our walls were adjacent with any of them. However, in the next apartment that I moved into, I shared an adjacent wall, so I had to take that into consideration when I was planning my workshop. The current apartment I am renting has an adjacent wall in the living room, so I have chosen the furthest room (with no adjacent neighbours) to be used as my studio.

There are two main aspects when I plan for sound.

Volume Even moving wood around will create sound. But what is an acceptable amount of sound? I take general household appliances as my guide. Using a decibel meter on my phone, I could get a rough gauge of what is generally acceptable in an apartment. Of course this varies from countries, cultures and societies and you will have to decide what is considered too loud before you start annoying someone else. The ambient sound in my area averages around 40db.

The loudest sound-emitting appliance I have is possibly my vacuum cleaner and perhaps a juice blender – their operating sound generally ranges between 70–80db.

On occasion I use a handheld router and an electric drill. Their operating sound also ranges between 70–80db. In my opinion, this puts me in an acceptable range as long as I do not use it for prolonged periods of time. I think short bursts of usage is acceptable and this also encourages you to plan your working sequence when working on a project.

For larger, fixed appliances like the vacuum cleaner (or dust extractor), you could consider making a simple sound box for it. Even a simple cardboard box with some packing foam boards will help dampen the sound quite a fair bit; you only need to make sure you leave an opening for air flow and also remember not to use it over prolonged periods to prevent overheating.

Vibrations In addition to sounds, the act of hammering, knocking or using a power tool will produce vibrations as well. I have found the use of rubber mats rather helpful in absorbing vibrations. I started laying out thin exercise mats under my workbench but found that it only helped minimally. So while setting up my second workspace, I decided to lay the entire room with a layer of 4mm natural rubber sheet as well as 18mm birch plywood. At that point in time, I wanted to make use of the sound absorption properties of the rubber mat, but also wanted the look and feel of a solid hardwood floor surface. In hindsight, it was a little overkill, but it did the job. The only problem was that, when I was moving out, the rubber mat left a stain on my beautiful terrazzo stone floor, which needed professional cleaning. If I were to apply this combination again, I would consider putting an underlay first before putting the rubber mat directly over the original flooring. This is especially important if your apartment is rented.

A simple plywood box lined with some thick foam boards can effectively reduce the sound of the vacuum cleaner by about 10–15 decibels.

One of the best options I have used and am still currently using is thick gym mats used for weight training. These mats usually come in sheets measuring 500 × 500mm (24 × 24in) with thickness of around 2–3 inches. If people at the gym can drop their heavy barbells directly on them without causing any problems, then I am pretty sure it is good enough for the striking of my chisels!

To start off, you can choose to purchase a few pieces to put under working areas like the workbench or saw horses. You can then choose to extend the coverage to a larger area when you feel you have the need to.

Thick gym mats are great for sound absorption, as well as protecting your tools should you accidentally drop them!

For my workspace in apartment number two, I put a combination of rubber sheets and plywood over the terrazzo floor to further reduce sound.

SUMMARY: MANAGING EXPECTATIONS

Woodworking in an apartment has its limitations. I may not fit a sliding table saw through the doors of my flat, but I am still able to cut sheets of plywood using other methods such as using a hand-held plunge circular saw. There are hand tools and hand-held power tools that are able to do the same job, with a slightly different result and possibly more time to do so.

In summary, I would like to touch on the things that are possible to do, things that seem a little difficult, and things that I still have not found a solution to.

Firstly, there will always be a constant struggle with space. I have learnt much earlier that I am not able to do very large pieces like dining tables or large cabinets. But if you are a little creative with the design, you might be able to get some similar pieces done. Perhaps design them as ‘knock-down’ furniture, or modular systems that can transform in terms of size and shape. Because of my lack of space, I have taken some ideas found in designs from nineteenth-century campaign furniture. There are also many new types of hinges or hardware that can extend or collapse your workpiece. So, do not be limited by what you think you can do, but continue to seek solutions and this will also aid growth in your creativity.

Secondly, you might be limited by your budget. Expect to spend some money to start your woodworking journey, but do not be too eager and buy into every type and brand of tool that you think you might want. Learn to grow organically and start with a set of decent, good-quality tools. From my personal experience, cheap tools fail fast and do not do what you expect them to do. Trust me, you will end up frustrated, upset and probably feel that you wasted your money. As the saying goes, buy cheap, buy twice, or buy good, buy once.

Thirdly, it is great to be ambitious and be inspired by what you see in books, magazines and on social media. A lot of the time, the processes are overly simplified or sped up to entice viewers. Therefore, before you attempt complex joinery work, or use highly complicated and expensive products, try with simple basic joints and use organic finishes such as beeswax just to start off. Learning from the basics forms a good foundation to begin your journey. Even if you have dabbled with woodworking in the past or are already an accomplished maker, it is always good to revisit the basics; the solution to most of our most complex problems can sometimes be found there.

Lastly, try not to hurry. Rushing through a project to completion is just a quick road trip to disaster. As much as we would like to see a finished piece, it is better to have a well-made one. The act of rushing will often lead to either an accident, or a sloppy and slipshod piece of work. Have some pride in your work and make sure that the materials are used properly and respectfully. You want to make something that you will be proud of and that begins with taking time to carefully plan and execute each step properly.

There are many types of extensions, hinges, locks and other hardware that can be used in your projects.

The first few boxes that I ever made were not the prettiest, but meant the world to me.

CHAPTER 2

KNOWING YOUR MATERIAL

F or a start, we can all agree that a tree is a tall plant that has a thick stem which we call a trunk. This supports the tree and usually comes with branches sticking out with leaves on them. The material they are made from is generally referred to as ‘wood’. When trees are felled for the purpose of harvesting, the meaty trunk and larger branches are called ‘logs’. They will eventually be sent to the sawmill for further processing.

Living and breathing, the main material for our craft is finite and should be treated with care and respect.

TREES, WOOD, LOGS, TIMBER, LUMBER

Depending on where you are in the world, some of these words have different meanings. In the United States and Canada, ‘timber’ and ‘lumber’ have their own definitions. ‘Timber’ is used for wood that has been cut down but has not yet been processed. ‘Lumber’ is used for wood that has been processed at the sawmill, possibly cut down into more manageable sizes and prepared for other purposes. In British English, the term ‘timber’ can be used for both processed and unprocessed wood.

Regardless, wood is the one important resource that makes us woodworkers who we are. Without this material, we are very much not ‘woodworkers’ anymore. Therefore, respect and consideration is important and an understanding of this finite resource should be cultivated, taking great care to ensure that it is not being exploited.

From tree to…

There are tens of thousands of species of trees in the world, but only a small percentage of them are harvested for their wood.

The process of felling a tree and turning the raw material into usable wood is a highly complex and demanding process. Thankfully, all of this work is done by trained professionals and we woodworkers have only the task of selecting milled boards, ready to be used in the comfort of our workshop. Not all trees are the same and it is good knowledge to understand their general classifications and properties.

We start by dividing trees into two categories: hardwood; deciduous trees and softwood; coniferous trees. The terms ‘hardwood’ and ‘softwood’ can be misleading because not all hardwoods are physically hard and vice versa. This classification is based on their botanical attributes. One such example is ‘poplar’ – a pale-coloured hardwood that is actually relatively soft and easy to use with hand tools.

Deciduous trees are angiosperms, which means that they have their seeds enclosed and covered in flowers and fruits. They have broad leaves that usually change colour and eventually drop from their branches during the colder months of winter. Deciduous trees nearer to the tropics with fewer seasonal changes lose their leaves in drier months of the year to conserve moisture.

Coniferous trees are gymnosperms which are plants with naked seeds. They are cone-bearing plants and have needle-like leaves and will usually retain foliage throughout the year.

The beauty of wood is in its range of colours, textures and even smell.

Examples of hardwoods commonly used in woodworking are: Oak, Walnut, Cherry, Ash, Maple, Birch, Rosewood, Beech and Mahogany.

Examples of softwoods commonly used in woodworking are: Pine, Cedar, Cypress and Spruce.

In general, hardwood species are slower growing and therefore are denser and stronger than softwoods, which grow faster. There are many exceptions and this shows the beauty and diversity of our fauna world.

Depending on where in the world you are, there will be wood varieties and species that are unique to your locality. I am from Singapore, a tropical island nation in south-east Asia located near the equator. Local trees include Angsana (Pterocarpus indicus) and Tembusu (Fagraea fragrans). The timber yard I frequent also has wood varieties from the rest of the region. This included Balau (Shorea laevis), Nyatoh (Palaquium spp.) and Meranti (Shorea spp.) to name a few. Their names often reflect the local languages and may be identified differently elsewhere. In some cases, similar-looking species are renamed and marketed by clever salesmen to make them more sellable. One such example is renaming the common rubberwood (Hevea brasiliensis) to ‘Malaysian Oak’ to make them sound more luxurious and desirable.

During my travels, I often encounter species that I have never seen before let alone worked with. One thing I learnt is not to limit your wood selection to the few commonly used ones. There is no harm in experimenting with what is available to you locally or using recycled material. Now that I am living in Taiwan, I am being introduced to species like Camphor, Taiwanese Cypress and Longan. New smells, colours and textures excite me and I am always on the lookout for interesting species that I could potentially work with.

On a slightly serious note, be mindful that illegal logging and deforestation is still an ongoing issue around the world. While it may be difficult to ascertain the true sources of our timber suppliers, we can try our best to ensure that our material comes from sustainable sources by asking the right questions and being acquainted with the ever-growing CITES list of protected species. Once again, this precious material takes years to grow and mature and we should strive to always maximise its potential and create less waste.

WHAT IS IN THE TREE?

The cross-section of a tree shows valuable information.

1) The outermost layer of the trunk is the bark, a protective layer that keeps the moisture within the tree.

2) The cambium is a thin reproductive layer that continuously grows and gradually adds to the width of the tree.

3) The sapwood is the lifeline of the tree, carrying water and minerals from the roots to the other parts of the tree.

4) The heartwood is sapwood that has matured and hardened with the formation of extractives.

5) The growth rings show the age of the tree, with the space between each concentric ring representing a year of growth. Medullary rays carry and store nutrients horizontally across the tree. They are more pronounced in some species like white oak.

6) At the very centre of the tree is the pith. This is the oldest part of the tree and normally not used in woodworking, as it can be very unstable and will often split apart.

Reading the rings

We have often been told that each concentric ring represents a year of growth, but what does this really mean?

During the warmer months with lots of sunlight and water, the tree grows rapidly, producing larger, thin-walled cells that allow for efficient water transport. This results in lighter-coloured rings.

In contrast, during the colder dormant months, the tree growth slows significantly or stops altogether and enters dormancy. As it heads towards the end of the growing season, the tree produces dense, smaller cells and thicker walls, resulting in a darker-coloured ring. Therefore, the combination of one lighter ring and one darker ring makes up one calendar year.

However, this might differ in trees from different geographical locations. Trees grown in temperate regions with more distinct seasonal changes have more defined annual rings as compared to trees grown in tropical regions, where the ring patterns are less apparent.

Cross-section of a tree and their main components.

CONVERTING WOOD

There are several ways in which a log is sawn into smaller boards. Even though we are normally at the mercy of how timber yards process raw wood, it is good to understand and identify the types of cuts available and how they react to the environment during our selection process.

The most common way is known as through-and-through sawing. This is the fastest and easiest way, as the log is fed through a large band saw from one side to the other in increments without any rotation at all. This method of cutting produces a range of cuts, but are mostly flat-sawn boards.