18,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Fachliteratur

- Sprache: Englisch

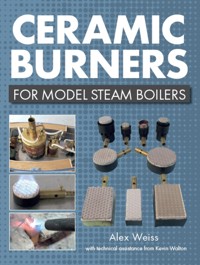

This book covers the materials needed to make ceramic burners and explains how to silver solder them. It discusses LPG and holding tanks, as well as connecting pipework and electronic and mechanical automatic gas-control systems to monitor the boiler pressure. In addition, there is advice on how to set up, install and operate each burner to provide optimum heating to the boiler. A summary of the Boiler Test Code Volume 3 that applies to home-made gas tanks is included, together with a list of useful suppliers with their contact details. This book provides all the information you need to build and operate: three burners, with one variant, for boilers with 42mm, 35mm and 28mm horizontal flues; two round burners for vertical boilers with fire boxes; two different sizes of rectangular burner, with one variant, for use in horizontal water-tube or pot boilers and finally, one small round and one tiny oblong burner for use in Mamod and Wilesco boilers. The burners described are straightforward to make and simple to use to heat the water in boilers that meet the 3 bar litre limit in the UK Boiler Test Code.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 151

Veröffentlichungsjahr: 2020

Ähnliche

CERAMICBURNERS

FOR MODEL STEAM BOILERS

CERAMICBURNERS

FOR MODEL STEAM BOILERS

Alex Weiss

With technical assistance from Kevin Walton

First published in 2020 byThe Crowood Press LtdRamsbury, MarlboroughWiltshire SN8 2HR

www.crowood.com

This e-book first published in 2020

© Alex Weiss 2020

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

ISBN 978 1 78500 766 8

DISCLAIMER

Safety is of the utmost importance in every aspect of metalworking. When using tools, always follow closely the manufacturer’s recommended procedures. However, the author and publisher cannot accept responsibility for any accident or injury caused by following the advice given in this book.

CONTENTS

Acknowledgements

WHEN I WROTE THE book Building Small Boilers for Gas Firing in 2013, each of the four larger boilers, the three vertical fire-tube ones, and the horizontal water-tube one, was fitted with a commercially available ceramic burner. These burners were either round or rectangular and worked extremely well. They were also quite expensive to purchase.

This led me to wonder whether I could make my own burners with similar dimensions. I discovered that the jewellery trade uses ceramic honeycomb for manufacturing decorative items. This honeycomb material is hard, resists crumbling, and has proved to be ideal for making ceramic burners. Furthermore, the plumbing trade provides a large variety of end caps that are suitable for use as housings for all the circular burners, together with the occasional length of copper tube. All the burners need short lengths of brass rod for the gas-jet holders and housings, and the rectangular burners require small flat sheets of copper or brass, widely available from the suppliers to model engineers. The success of these designs led to the production of some even smaller burners, suitable for Mamod, Wilesco and similar-size small boilers.

I must thank my friend Kevin Walton, who has provided much of the technical input and detailed recommendations that have made possible the building of the burners described in this book. He has also helped with the construction of all the burners, and has solved some significant problems relating to how they were built and in their operation.

Finally, I must mention my appreciation of my wife Lynda, who has had to put up with all the work involved in making the burners, testing and photographing them, as well as the many months writing up and organizing the results on my computer.

Introduction

HEAT HAS ALWAYS BEEN an essential for humans. Its earliest use was in the form of wood fires used to keep warm and to cook food. For some people, oil or tar emerged from the surface of the ground and was also found to burn well. It was particularly useful for providing torchlight at night. The first steam-powered device dates back to ancient Greek times, but it wasn’t until the start of the industrial revolution that useful work was obtained from steam engines.

There is something incredibly appealing about operating model steam engines. They may require a heat source and a boiler to generate the steam, but they produce almost silent power, normally without the need for gear changes to drive their load. And they are a glorious reminder of the golden age of the industrial revolution.

Steam engines, as originally envisaged by Newcomen, Trevithick, Watt and others, have become the life blood of many preservation organizations, but the steam turbine, invented by Charles Parsons, is still happily turning the generators in power stations that produce electricity, as well as propellers in some ships. The steam generators for these turbines may be heated by coal, gas, oil or a controlled nuclear chain reaction.

FIG. 1A Stuart beam engine powered by a 108mm (41⁄4in) vertical fire-tube boiler heated by a 67mm round ceramic burner.

FIG. 2A 76mm (3in) horizontal water-tube boiler fitted with a 70 × 50mm rectangular burner steaming a single-cylinder mill engine.

Running a model steam engine on compressed air is neither good for the engine nor in any sense realistic. Running on steam from the right size of model boiler is exhilarating, and with a displacement lubricator, feeds small amounts of oil through the valves into the cylinder to minimize wear to the valve gear and on the cylinder/piston combination.

There are many ways of heating the water in a model steam boiler. They include using coal, liquefied petroleum gas (LPG), paraffin, methylated spirits, impregnated pellets and historically petrol, although petrol is not considered a safe option in the twenty-first century. This is because petrol vapour is explosive, and as a result, using a petrolfuelled blowlamp to heat a boiler has, fortunately, all but disappeared.

Each source of heat comes with its own set of problems. With coal, the fire requires a stoker, normally human, to add coal regularly to the firebox. Starting the fire with kindling can also be a time-consuming task. On the other hand, LPG gives a virtually instantaneous heat and can provide a high heat output. However, it does require a safe gas tank and care in handling the gas. Paraffin or kerosene is not a very volatile liquid and is difficult to vaporize ready for burning. Methylated spirits will produce relatively small amounts of heat, and again will require a safe spirit container. The flame is virtually invisible and the storage tank must be protected from the heat.

However, neither methylated spirits nor LPG need an operator in attendance. They are thus suitable for installation in model vehicles and steam boats – but take care to ensure the heat source is exhausted before the boiler water has run out. The same warning applies to stationary installations. A boiler that has run out of water is readily destroyed if the heating is not turned off.

Over the past ten years, the author and Kevin Walton have designed and built nine different boilers of a variety of shapes, sizes and configurations, but all within the 3-bar litre limit detailed in the UK Boiler Test Code 2018 Volume 2. Some years ago Building Small Boilers for Gas Firing was published by Camden Miniature Steam Services, giving detailed instructions on how to build these boilers. The majority of the boilers were heated by commercial ceramic burners, but some subsequent experiments led to fitting new home-made burners to most of these boilers, and writing about how to make the burners in a typical model engineer’s workshop, and also how to operate these burners.

As a result, this book describes a range of easy-tomake ceramic burners for the home builder. They all burn a propane/butane gas mixture, two of a range of LPGs that are widely available. These burners provide high heat outputs from burners of relatively small size, are clean to operate, and that may be powered from small disposable gas cylinders or from easy-to-purchase refillable ones. However, do take care when using these gases. They are heavier (denser) than air and will therefore pool in any enclosed area – the floor of a workshop, the hull of a model boat or even the interior of a car. With air they form a volatile mixture that can readily be ignited by either a spark or a naked flame. While this sounds a very severe area for concern, provided you are careful, their use as a fuel presents no problems, and it is worth remembering that they are widely used for camping stoves.

There are several different commercially available designs of small burner for model steam boilers currently on the market. Some use a ceramic element, and there are several different types of ceramic element, while some use a metal disc with holes drilled in it. Of burners that plug into a horizontal flue, some have secondary air holes, some do not. The same is true of the similarly configured burners described in this book. All the burners described in this volume use a hard ceramic element of the type used by the jewellery trade, rather than the softer type that is more prone to damage.

FIG. 3An 89mm (31⁄2in) vertical fire-tube boiler heated by a 54mm round burner.

FIG. 4Construction details are given for all eleven of these ceramic burners.

Three different configurations and nine different sizes of burner are described in detail in this book, together with two minor variants. They are shown in Figure 4. They are all suitable for use in boilers that are below the 3-bar litre limit covered in the UK Boiler Test Code 2018. Such boilers face a less stringent testing regime than larger boilers. Three different-size burners are suitable for fitting in the centre flues of boilers, and there is one variant for any boiler where the end of the flue is flush with the boiler end plate. The other six burners fit in a firebox and are suited to heating vertical fire-tube or horizontal water-tube boilers, or even just pot boilers. There are three different sizes of round burner, and likewise three rectangular ones, again with a variant made from brass sheet instead of copper.

The nine larger designs work well, are quick to build, and maintain steam pressure in suitably sized boilers, typically vertical ones varying in size from 51mm (2in) to 108mm (41⁄4in) diameter. Horizontal boilers with 28mm, 35mm or 42mm flues should not exceed 108mm (41⁄4in) diameter or 250mm (10in) long. The same size limitations apply to horizontal boilers with a firebox below.

FIG. 5This Mamod traction engine will run well with a small round burner fitted in the firebox.

FIG. 6A squat 108mm (41⁄4in) boat boiler with a 67mm round ceramic burner on a test rig steaming a twin-cylinder Marcher engine.

FIG. 7The Stuart 4000 boiler running at 30psi (2 bar) with a 42mm burner and brass adapter ring, driving a Stuart Double 10 engine turning a small generator powering the overhead light.

The two smallest burners, one round and one rectangular, also perform extremely well and have been specially designed to heat the boilers of Mamod, Wilesco and similar static steam plants, as well as their steam rollers and traction engines such as the one in Figure 5.

All burners require both primary and secondary sources of air if the gas is to burn efficiently. Primary air passes through holes drilled in the gas-jet housings of all the burners, and the jet can be moved by undoing the locking bolt in its holder and moving the jet further in or out of the housing. For the two larger burners that fit in flues, the secondary air comes with the primary air, while the holes in the outer shell of the two smallest burners provide secondary air. All the vertically mounted burners draw their air through holes in the boiler firebox.

FIG. 8The 67mm round burner is well alight and showing blue cones.

FIG. 9The large rectangular burner provides plenty of heat and is burning well.

FIG. 10The smallest rectangular burner provides excellent heat for its size, and has blue cones visible on the top of its ceramic element.

FIG. 11The 42mm burner well alight with the jet correctly adjusted to provide a good hot flame.

To make any of these burners some fairly basic skills in drilling, tapping and turning will be required. The small number of parts that will be needed can be made using a lathe, but for the smallest 28mm burner you will really need access to a milling machine and a rotary table. For all the burners, you will also need to gain the ability to carry out simple silver soldering, a skill that many model engineers have already learned. This can be done with a relatively small, self-contained MAP (methylacetylenepropadiene) torch or a larger propane gas torch with a modest-size head. Some firebricks, heat-resisting blocks or Vermiculite board will also be needed to support the work being soldered.

The seven round burners are made using copper plumbing end caps of the appropriate dimensions. The rectangular ones use folded copper or brass boxes. The right size gas jet for each particular burner will be required, and a jet holder with pipe that can be connected to the valve of a small gas container. These are available from a number of model engineering suppliers, listed at the end of this book, or you can turn a holder yourself from brass rod. All the burners then need a short length of tube turned from brass rod to provide primary air and to act as a housing for the gas-jet holder.

The two large round burners and the three larger rectangular ones need two gas-diffusing components: a short length of stainless-steel spring of 1⁄2in or 12mm diameter in their bodies from the primary air tube to the other end of the burner body, and a small strip of stainless-steel mesh of twenty holes per inch. You will also need a small block of ceramic material that can be easily cut and filed to size and shape. The spring, the mesh and the ceramic material can be glued in place with high-temperature adhesive filler such as Ceramix, Vitcas or Mapeflex. The smallest rectangular burner needs a 3⁄8in or 10mm spring and the same mesh.

FIG. 12A 35mm burner provides plenty of heat for this 108mm (41⁄4in) horizontal boiler to drive a Stuart mill engine.

You may choose to finish copper burners with high-temperature paint, but this will not work for brass as there are no high-temperature etch primers. Therefore as an alternative, the burner jet housings and the brass bodies can be polished.

FIG. 13The author’s workshop is well equipped with a lathe, milling machine and pillar drill with X/Y table. The lathe is the only machine tool necessary for making all but one of the ceramic burners.

FIG. 14Kevin Walton’s workshop also has three similar machine tools, but making the ceramic burners has largely been completed on the Chester lathe.

You may already have a well-equipped workshop such as those shown in Figures 13 and 14, but as long as you have access to a lathe, you can make all but one of the burners without any other workshop machinery.

ABOUT THIS BOOK

Since the main components used to make the burners are metric sizes, metric dimensions are used but with equivalent imperial measurements where these are practicable. In some cases, there is no imperial equivalent. For example, gas pipe connectors require 1⁄8in copper pipe and 3mm pipe would not be suitable. Likewise, gas jets are threaded 1BA and therefore this imperial thread has to be used in any gas-jet holder.

Each chapter commences with a short summary of its contents. The first chapter starts with an explanation of the various material and tools, including some basic machine tools that you will need. It is followed by details of how to silver solder the relatively small burner bodies and gas pipes. This chapter also includes information on the types of gas torch you will need for this task, and the LPG they use. There is then a description of three burners, with one variant, for boilers with horizontal flues. These burners fit 42mm, 35mm and 28mm flues, but details are given of how to make an adaptor to fit slightly different-size flues.

Construction details follow for two round burners, one larger than the other, for vertical boilers with fireboxes. There are also instructions on how you can build two different sizes of rectangular burner for use in horizontal water-tube or pot boilers, with a variant for the larger one. This is followed by an account of building a small round and a diminutive oblong burner for use in Mamod and Wilesco and similar boilers. The next chapter deals with the provision of LPG for the ceramic burners and the tanks to hold it, as well as the connecting pipework and necessary valves and connecters.

Then there is advice on how to set up, install and operate the burners in your boiler to ensure optimal heating, and for burners that fit in a firebox, advice on how to avoid blowback and how to repair a burner if blowback occurs. The following chapter looks at a number of electronic and mechanical automatic gas-control systems that monitor the boiler pressure you have set, and adjust the gas flow to try and maintain the desired pressure. They will help to reduce gas consumption and simplify the operation of gas-fired boilers in model boats and land vehicles. This is followed by some conclusions.

Finally, the Appendix provides a concise summary of the UK Boiler Test Code 2018 Volume 3 that deals with making LPG tanks under 250ml capacity. A list of the addresses of useful suppliers detailing the relevant items they can supply is provided at the end of this book. There is also a comprehensive index.

WARNING

Please ensure that you read and understand the advice on using liquefied petroleum gas (LPG) given in Chapters 2 and 6 before silver soldering any of the gas burners described in this book, and before operating them.