8,49 €

Mehr erfahren.

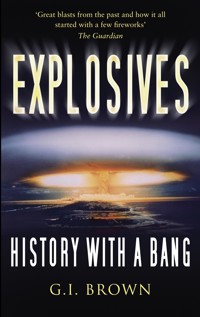

- Herausgeber: The History Press

- Kategorie: Fachliteratur

- Sprache: Englisch

This entertaining and informative book tells the dramatic tale of explosives from gunpowder to the H-bomb. Laying the emphasis on the lives of the people involved, on the diverse uses of explosives and on their social and historical impact, the author relates a story of remarkable international and human endeavour. Many of those involved - Roger Bacon, Guy Fawkes, Alfred Nobel, Robert Oppenheimer - are famed worldwide; others, such as C F Schonbein, William Bickford, Sir Frederick Abel and Charles E Munroe, though less well-known, also played critical roles. Alongside their achievements, this book highlights the uses and impact of explosives in both war and terrorism, and in civil engineering, quarrying, mining, demolition, fireworks manufacture and shooting for sport. In many cases explosives are seen to have had a significant historical impact as, for example, in the early use of gunpowder in the American Civil War, the defeat of the Spanish Armada, and the worldwide opening up of canals and railways.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Veröffentlichungsjahr: 2011

Ähnliche

For Barbara, Helen and Louise

Acknowledgements

The author would like to thank the following individuals and organizations for their help:

Argonne National Laboratory, USA; BASF; British Museum; Calladines (Stationery), Eton; Chemistry in Britain (The Royal Society of Chemistry); the librarian of Christ Church College, Oxford; Compair Holman Ltd; DuPont (UK) Ltd; Eley Hawk Ltd; the librarians of Eton College; Explosive Storage and Transport Committee of the Ministry of Defence; Faversham Society, Kent; Federation of Demolition Contractors; Greater Manchester County Record Office; Hagley Museum and Library, USA; Health and Safety Laboratory (Explosives Section), Buxton; Peter Huggins, ICI; ICI Australia Operations Pty Ltd; Imperial War Museum; Italesplosivi, Milan, Italy; Julian Cleeton; G.N.G. Tingey; Los Alamos National Laboratory, USA; National Maritime Museum; National Railway Museum; Oxford University Press; The Patent Office; Quarry Products Association; Robinson & Birdsell Ltd, Leeds; Royal Air Force Museum, Hendon; Royal Armouries, Leeds; Royal Artillery Historical Trust; Royal Collection Enterprises; Royal Commission on the Ancient and Historical Monuments of Scotland (RCAHMS); and the librarians of the Science Museum.

He is also grateful for help from Anne Marshall, Adam Hart-Davis and John Briscoe; to a number of friends who read the manuscript in its early days; and to his patient wife. She was a constant source of encouragement and provided both historical background and useful reminders when the technical matters became too much for her.

CONVERSION FACTORS

Contents

Title

Dedication

Acknowledgements and Conversion Factors

Foreword

1.The Invention of Gunpowder

2.Making Gunpowder

3.The Powder Trust

4.Testing Gunpowder

5.‘Crakys of War’

6.Mining and Civil Engineering

7.Gunpowder Modifications

8.Nitroglycerine

9.Dynamite

10.Guncotton

11.Smokeless Powders

12.Lyddite and TNT

13.Setting It Off

14.Nuclear Fission

15.The Manhattan Project

16.Nuclear Fusion

Appendix I: Names and Formulae

Appendix II: Energy and Power

Bibliography

Copyright

Foreword

When George Brown sent me the typescript of this book, my heart sank a little.I had plenty of work to do at the time, and the thought of having to read a treatise on the history of explosives filled me with gloom. However, feeling I should be polite, I started reluctantly at page 1 – and by page 3 found I was utterly hooked. I won’t say I couldn’t put it down, because in fact it was in a huge ring-binder that was so heavy I could scarcely pick it up, but I found the book completely fascinating. I read it right through, and now wait impatiently for a bound copy to read again, with all the excellent illustrations in place.

The first few pages give a fine flavour of The Big Bang, with the intriguing story of Greek fire, and how it was ousted by the new-fangled gunpowder. The struggles of so many people to make good gunpowder, the secret code of Roger Bacon, and the enigma of Black Berthold Schwartz had me on the edge of my seat.

I present a television series called Local Heroes, which celebrates pioneers of science, technology and invention, so I am always interested in stories about how people have ideas and introduce new technology. The Big Bang is full of such stories: in particular I recommend those of Bickford, Forsyth and Congreve. William Bickford, a Cornish currier in Tuckingmill, was so distressed by seeing the results of accidents with blasting powder in mines that he invented the safety fuse, which has scarcely changed till this day. Scottish minister Alexander Forsyth was frustrated when he tried to shoot ducks on the loch near his house at Belhevie north of Aberdeen, because the ducks saw the flash in the pan of his flintlock gun and flew away before the shot arrived; so he invented the percussion cap, which transformed military guns. Yet neither of these two made any money before they died. Colonel Sir William Congreve, by contrast, was much more successful with his rockets – even though they were more effective at terrifying horses than at damaging the enemy. However, he did manage to set fire to Boulogne by mistake, and his rockets blazed their way into the American National Anthem.

George Brown has done an exceptional job of weaving together the strands of history, biography, politics and science. I was fascinated to learn about the du Ponts, Alfred Nobel and Robert Oppenheimer; about Guy Fawkes and the Gunpowder Plot, about Count von Rumford and his extraordinary love-life, and about Chaim Weizmann and the national conker collection. I am most grateful to George for bringing these stories to my attention, and I hope you too will enjoy this splendid book.

Adam Hart-Davis

May 1998

CHAPTER 1

The Invention of Gunpowder

Fire can cause so much damage and create so much confusion, chaos and terror that it is not surprising that the use of incendiaries in warfare dates back to very ancient times. Fire-pots being thrown down on troops besieging a town are depicted in Assyrian bas-reliefs in the British Museum, dated around 900 BC, and early writers give detailed, and sometimes lurid, accounts of the use of incendiaries. Herodotus describes how arrows tipped with burning tow were used in the capture of Athens in 480 BC, and Thucydides tells how a huge bonfire was lit against the wooden walls of Platea1, in 429 BC. Even more remarkably, he describes the use of a blow-pipe in the attack on Delium in 424 BC:2

They took a great beam, sawed it in two parts, both of which they completely hollowed out, and then fitted the two parts closely together again, as in the joints of a pipe. A cauldron was then attached with chains to one end of the beam, and an iron tube, curving down into the cauldron, was inserted through the hollow part of the beam. Much of the surface of the beam itself was plated with iron … When this machine was brought up close to the city wall, they inserted into their end of the beam large bellows and blew through them. The blast, confined inside the tube, went straight into the cauldron which was filled with lighted coals, sulphur and pitch. A great flame was produced which set fire to the wall and made it impossible for the defenders to stay at their posts. They abandoned their positions and fled; and so the fortification was captured.

At first, almost any locally available materials which would burn were used as fuel but, with time, an unusual degree of sophistication crept in. A collection of supposedly contemporary recipes3 reveals a whole catalogue of witches’ brews. ‘Another kind of fire for burning enemies wherever they are can be made’, we are told4, ‘by taking petroleum, liquid pitch, and oil of sulphur. Put all these in a pottery jar buried in horse manure for fifteen days. Take it out and smear with it crows which can be flown against the tents of the enemy. When the sun rises and before the heat has melted it the mixture will inflame. But we advise that it should be used before sunrise or after sunset.’ In Arabian manuscripts, the unfortunate crows were apparently set on fire before launching; similar use of fire-birds appears in early Chinese works.

There were many other horrible formulations, all trying to outburn the others, but the use of incendiary materials entered a new phase in AD 673 when an architect called Kallinikos carried the secret of Greek fire from Heliopolis to Constantinople. That majestic city was the centre of the Byzantine Empire and Greek fire was to be the lynch-pin of the empire’s successful defence, against attacks from all quarters, for the next 800 years. It was an embryonic napalm, the Palladium of the Empire and, without doubt, the greatest deterrent of the day.

But quite what Greek fire was must remain something of a mystery. The name itself is widely used, or misused, for almost any incendiary mix, and may be used synonymously with wild-fire, wet-fire, sea-fire, maritime-fire, automatic-fire or incendiary oil. In Britain, where the incendiary was first introduced towards the end of the twelfth century, the term wildfire was generally preferred, and has remained in usage in the phrase ‘to spread like wildfire’. The fact that Greek fire did spread very rapidly over the surface of water gives some indication of its nature. It was always described as a liquid or semi-liquid material; it could be propelled through tubes; it floated on water; it was very difficult to extinguish; and it was possible, somehow, to keep the secret of its manufacture within Constantinople for many years. The secret was, indeed, very well protected by the Official Secrets Act of the day. The Emperor Constantine VII decreed that enquirers were to be told that it had been revealed by an angel, and there were very stern warnings that any communication of it to the enemy was treasonable and sacrilegious, bringing with it divine retribution. Someone about to betray the secret, it was said, had been struck by lightning.

What was the secret? All the evidence suggests that the main component of Greek fire was made from rock-oil or naphtha. This is a black, sticky material which does not occur at all commonly on the earth’s surface but which is found, oozing out of the ground or floating on pools of water, in the region between the Black Sea and the Caspian Sea. Rock-oil does not burn very easily, nor is it a very good solvent. But, if it is distilled – and the great secret was probably how to do this safely – a lighter, more inflammable oil can be obtained. It was probably an oil like this, thickened by dissolving in it such substances as sulphur and resin, that made up Greek fire. An early recipe5 says ‘You will make Greek fire in this way. Take liver of sulphur, tartar, sarcocolla and pitch, boiled salt, petroleum oil and common oil. Boil all these well together. Then immerse in it tow and set it on fire. If you like you can pour it through a funnel. Then kindle the fire, which is not extinguished except by urine, vinegar or sand.’

On land, Greek fire was either hurled from ballistae in large tubs with the mixture already alight, or projected in pots and then ignited by incendiary arrows. At sea, it was ejected through tubes or siphons. An account of a naval battle between the Greeks and the Pisans in 1103 gives a good, general picture but is very short on technical detail. ‘Each of the Byzantine galleys’, it says, ‘was fitted in the prow with a tube ending with the head of a lion or other beast made of brass or iron, and gilded, frightful to behold, through the open mouth of which it was arranged that fire should be projected by the soldiers through a flexible apparatus.’6 It is not at all clear how all this could have been achieved in practice. Playing with fire is a dangerous business and the player can easily get his own fingers burnt. Nevertheless, the problems must have been overcome successfully, because Greek fire served the Byzantines extremely well. The empire flourished, in all, for eleven centuries and only fell in 1453, when the Greek fire was overpowered by the relatively newfangled gunpowder of the Turkish invaders.

* * *

For many hundreds of years, until well into the second half of the nineteenth century, gunpowder was the only explosive to be used both as a propellant in guns and for blasting in warfare, mining and civil engineering. It only began to lose its monopoly when so-called nitro-explosives, such as dynamite and guncotton, were discovered around 1850.

As it looks rather like soot, gunpowder is commonly called black powder. A typical modern sample contains 75 per cent of potassium nitrate (nitre or saltpetre), 10 per cent of sulphur and 15 per cent of wood charcoal (carbon), but early mixtures contained much smaller amounts of saltpetre. All three components must be finely powdered, and they must be well mixed.

Sulphur is a yellow solid which will burn in air with a rather feeble blue flame. Wood charcoal simply smoulders, as in a barbecue. Both will burn much more rapidly in an oxygen-rich atmosphere, particularly if they are finely powdered, and it is the potassium nitrate that holds the key to gunpowder because it provides the oxygen. When gunpowder, or black powder, is lit, the oxygen from the nitrate enables the sulphur and the carbon to burn rapidly, forming a mixture of hot gases containing mainly sulphur dioxide and carbon dioxide, so that there is a large, and rapid, increase in volume. But this will only lead to an explosion if the gunpowder is lit in a confined space such as a sealed container, a gun barrel or a borehole, so that the pressure can build up sufficiently.

The pressure rise with gunpowder is never as dramatic as it is with high explosives, such as dynamite or guncotton, and it is classified as a low explosive. It is not very effective in cutting through steel plate, but it is suitable for pushing projectiles out of gun barrels, or blasting rock when it is set off in a borehole. It is referred to as a propellant explosive to distinguish it from high explosives which have a much greater shattering effect. Dynamite delivers a knock-out blow; gunpowder gives a more prolonged, steady push.

Gunpowder is easy to handle, easy to set off (it only requires to be heated above 300°C) and very safe, so far as any explosive can be regarded as safe. If lit in the open it simply burns away very quickly, even in the absence of air. The major disadvantages are its lack of power, its production of a lot of nasty smoke and fumes when it explodes, and its failure to explode when it is damp. In the early days, setting off gunpowder always involved some sort of heat or fire – a hot rod, a flame, a spark or frictional heat – and the use of the word ‘fire’ has persisted in ‘fireworks’, ‘gunfire’ and ‘firing the gun’, even though modern guns are generally set off by the explosion of a very sensitive chemical by a sharp blow, or percussion, as in a child’s toy cap-gun.

* * *

Gunpowder is both the best known and the oldest explosive, but its origins are shrouded in some mystery. Any researcher is soon entangled in a web of mistakes, misinterpretations and misrepresentations and the chance of finding a definitive answer has always been rather bleak. But a few historians have continued the search, sifting through claims that gunpowder was first used in Persia, in India, in Arabia, and in China. The most authoritative modern view is that gunpowder was first made in China, in the middle of the ninth century AD, by Thang alchemists who were actually looking for the elixir of immortality – one of the most remarkable examples of inventing one thing while trying to find something else. The early Chinese literature refers to ‘fire-chemical’ and ‘fire-drug’,7 but it is not until 1004 that there is any specific mention of the composition of gunpowder and even then no information is given about the proportions in the mixture.

The earliest use of gunpowder was certainly in fireworks, for which the Chinese have always had a passion, but the possibility of making simple bombs and grenades was realized during the eleventh century. The military implications led the Chinese to place the production of sulphur and saltpetre under state control and in 1067 the emperor banned their sale to foreigners. The Chinese army was already well over a million men strong and it was necessary to arm it as well as possible to fend off attacks by the Mongols from central Asia.

No one knows with any certainty how the news of all this remarkable activity in the East reached the Western world, nor why it travelled so slowly, but it may have been carried by the Saracens – those middle-men between the Orient and the West – for Roger Bacon, who first told the tale in about 1260, could read Arabic.

* * *

Roger Bacon was born in 1214 at Ilchester in Somerset. An inscription placed in the Church of St Mary Major there ‘by a few admirers of his genius’ to commemorate the seventh centenary of his birth gives a sketch of his life and achievements. It reads:

To the immortal Memory of Roger Bacon, a Franciscan Monk and also a free enquirer after true knowledge. His wonderful powers as mathematician, mechanician, optician, astronomer, chemist, linguist, moralist, physicist, and physician gained him the title of Doctor Mirabilis. He first made known the composition of gunpowder, and his researches laid the foundations of modern science. He prophesied the making of machines to propel vessels through the water without sails or oars; of chariots to travel on land without horses or other draught animals; of flying machines to traverse the air. He was imprisoned, starved and persecuted by the suspicious ignorance of his contemporaries, but a fuller knowledge now acclaims and honours him as one of the greatest of mankind. Born at Ilchester in 1214. Died at Oxford in 1292.

The sentiments, as in many church inscriptions, may be a little fulsome, but there can be no doubt that Roger Bacon was a very learned and very unusual man, though he remains something of an enigma to historians. Some rate him as heralding the dawn of modern science almost single-handed amid the gloom of the thirteenth century; others have regarded him as a sorcerer and necromancer whose reputation hangs only on legend.

Little is known of his boyhood but he came from a wealthy family who, later in his life, sacrificed their fortunes to help King Henry III in his struggle with the barons. Roger was a pupil of Robert Grosseteste at Oxford, where he studied theology, geometry, arithmetic, music, astronomy, Greek, Latin and Arabic. After some time at the University of Paris, where he graduated so brilliantly that he was nicknamed ‘Doctor Mirabilis’, he returned to Oxford and became a Franciscan friar around 1250. He lived at a time when learning, independence and freedom of speech were not greatly encouraged, but when a new outlook was being forced on to Western Christendom by the impact of the recently imported translations of major works of Greek and Arabian philosophy.

Bacon, in common with all other Christians of his day, believed that the Bible contained, in one form or another, the whole realm of knowledge. In the preface to his Opus Maius, written at Pope Clement IV’s request in an attempt to reassess the changing situation, he states: ‘I wish to show that there is one wisdom which is perfect, and that this is contained in the scriptures. From the roots of this wisdom all truth has sprung. I say therefore that one science is mistress of all others, namely theology.’8 Yet within that medieval concept, he was a great advocate of careful observation and experiment; what would, nowadays, but in a very different context, be called experimental method. He regarded mathematics as the ‘gateway and key to all other sciences’ and he hoped to demonstrate that natural science, far from being a danger to Christendom, was a source of wisdom and power.

It was the beginning of the Science versus Religion controversy. In all his searchings for the ‘perfect wisdom’, Bacon applied his famous adage ‘sine experimentia nihil sufficienter sciri potest’ (‘nothing can be certainly known but by experience’). But such a new and independent outlook – not always expressed with great tact – brought him into conflict with other Franciscans, some of whom he attacked as conceited and corrupt pedants. So much so that, in the end, his writings and his freedom were restricted. One report says that Jerome of Ascali, the Minister General of the Franciscans in 1277, ‘by the advice of many friars, condemned and denounced the teaching of Roger Bacon of England, master of sacred theology, as containing some suspected novelties, on account of which the said Roger was condemned to prison, with the order given to all the brethren that none should hold his doctrine but avoid it as reprobated by the Order’.9

* * *

Bacon revealed the composition of gunpowder in a treatise entitled De secretis operibus artis et naturae et de nullitate magiae (‘On the marvellous power of art and of nature and on the nullity of magic’). It consists of eleven letters or chapters, and versions of it are known in Latin, French, German and English, though their validity and the dates of their publication have been much argued by scholars. The work attempts to prove that certain happenings, which at the time were attributed to evil magic, could be due to natural causes and could be imitated by experiment, and it was probably written to defend the author against the charge that he was guilty of magic. Bacon suggests that such unheard-of possibilities as submarines, aeroplanes, compasses, motor cars, suspension bridges and magic lanterns could all be made to exist by natural means and without any trickery at all. This was far advanced for 1260. Yet he is at pains not to reveal any secrets easily. He writes: ‘But I recall that secrets of nature are not to be committed to the skins of goats and of sheep [that is, vellum and parchment] that anyone may understand them’, and ‘a man is crazy who writes a secret unless he conceals it from the crowd and leaves it so that it can be understood only by the effort of the studious and the wise’. And, after explaining seven different ways of encoding secrets, he adds ‘I have judged it necessary to touch upon these ways of concealment in order that I may help you as much as I can. Perhaps I shall make use of them because of the magnitude of our secrets.’10

One of the secrets to be revealed was the composition of gunpowder. Bacon refers to a material by which ‘the sound of thunder may be artificially produced in the air with greater resulting horror than if it had been produced by natural causes’. He then gives cryptic accounts of how to purify ‘aerial stone’ or ‘stone of Tagus’ (meaning saltpetre) – a vital part of making gunpowder; refers to ‘certain parts of burnt shrub or willow’ (charcoal); and to ‘vapour of Pearl’ (sulphur). But the most famous passage in the book, not universally accepted as authentic, reads as follows:

Sed tamen salispetrae LURUVOPOVIRCANUTRIET sulphuris et sic facies tonitruum et coruscationem; sic facies artificium; Vides tamen utrum loquor in seneigmate, vel secundun veritamet. [‘But however of saltpetre LURUVOPOVIRCANUTRIET of sulphur, and so you will make thunder and lightning, and so you will make the artifice (or turn the trick). But you must take note whether I am speaking in an enigma or according to the truth.’]11

The phrase in capitals is unintelligible and it seems likely that the words at the end of the chapter12 – ‘Whoever will rewrite this will have a key which opens and no man shuts; and when he will shut, no man opens’ – applied to it. The key remained hidden for almost 650 years but it was deciphered, in 1904, by Lt-Col. Hime, a Royal Artillery officer who made a study of the history of Greek fire and gunpowder. He recognized the letters as an anagram and rearranged them as follows

RVIIPARTVNOVCORULVET

so that the recipe for gunpowder follows as: ‘take [R still means take in today’s doctors’ prescriptions] seven [of saltpetre], five of young hazelwood and five [of sulphur]’. This gives a gunpowder containing 29.4 per cent each of charcoal and sulphur and 41.2 per cent of saltpetre, which is very close to the composition of early gunpowder mixtures.

One can only guess why Bacon hid the details so carefully. Perhaps he was frightened of publicizing such a revolutionary and awesome product which might well be regarded as associated with magic; perhaps he feared the reaction of the Church and was all too aware of the recently founded Inquisition; perhaps he did it all in jest. The puzzle is all the odder given that within a few years he was writing much more openly about gunpowder. In the Opum Tertium, about 1267, he wrote: ‘There is a child’s toy of sound and fire made in various parts of the world with powder of saltpetre, sulphur and charcoal of hazelwood. This powder is enclosed in an instrument of parchment the size of a finger, and since this can make such a noise that it seriously distresses the ears of men, especially if one is taken unawares, and the terrible flash is also very alarming, if an instrument of large size were used, no one could stand the terror of the noise and flash.’13

There can be no doubt that Bacon knew quite a lot about gunpowder, however secretly he may have imparted his information, but the claim, sometimes made, that he invented it is certainly false. It had been known in China for almost 400 years before he wrote about it in the West.

* * *

Some even doubt Bacon’s claims to be the first to bring the news of gunpowder to the West, for other scribes were active around the same time. Count Albert of Bollstadt, better known as Albertus Magnus, and sometimes as Saint Albert the Great, was born in Lauingen, on the Danube, around 1200 and he lived until 1280. He, like Bacon, was a great scholar and wrote thirty-eight volumes on almost every aspect of contemporary knowledge, and he gave the composition of gunpowder in De Mirabilis Mundi (‘Marvels of the World’). Almost the same recipe also appears in Liber Ignum (‘Book of Fires’), a six-page pamphlet written about 1225 and generally attributed to Mark the Greek (Marcus Graecus), but little is known about who he might have been, even if he existed at all, and it is probable that he copied from Albertus Magnus, or vice versa.

Berthold Schwartz, commonly known as Black Berthold, is another mysterious figure on the scene. He is commemorated by a statue in Freiberg, which was an important centre for casting cannon and training gunners in the fourteenth and fifteenth centuries, and is portrayed in contemporary prints. The statue claims that he invented gunpowder and guns in 1353 and one copper engraving depicts him firing a charge of gunpowder with a flint of steel and has an inscription describing him as ‘worthy and ingenious’ and as a ‘Franciscan Monk, doctor, alchemist and inventor of the force of using firearms in the year 1380’. A less complimentary epitaph had him as the ‘most abominable of inhumans who, by his art, had made miserable all the rest of humanity’.14 Yet though he was obviously buried and revered with some ceremony and feeling, it is not clear whether he ever actually lived. Professor Partington, who investigated Schwartz’s claims in great depth, added him to the list of legendary figures alongside William Tell and Friar Tuck.

* * *

So, despite much very careful work by a few dedicated researchers, the questions ‘What is Greek fire?’ and ‘Who invented gunpowder?’ still cannot be answered with any certainty. Let Edward Gibbon sum it up in his elegant, but vague, eighteenth-century judgements. On Greek fire, he wrote: ‘The historian who presumes to analyse this extraordinary composition should suspect his own ignorance and that of his Byzantine guides, so prone to the marvellous, so careless, and in this instance, so jealous of the truth!’15 and on gunpowder, ‘the precise era of the invention and application of gunpowder is involved in doubtful tradition and equivocal language’.16

Notes

Where a short title is provided, more details are given in the bibliography here.

1.Thucydides, History of the Peloponnesian War, trans. Rex Warner (Penguin Books, 1954), p. 172

2.Ibid., p. 325

3.A six-page Book of Fires (Liber Ignum), attributed to Marcus Graecus (Mark the Greek), lists thirty-five recipes. Partington (Ch. II) and Hime, Artillery (Ch. III) give more detail

4.Ibid., recipe no. 3

5.Ibid., recipe no. 26

6.Partington, p. 19

7.Needham’s Priestley Lecture, p. 314.

8.School Science Review, vol. XLVII, no. 163, June 1966, pp. 630–1

9.Partington, p. 66

10.Davis, Article in Industrial and Engineering Chemistry, vol. 20, no. 7, July 1928, p. 773

11.Ibid., p. 774

12.Ibid., p. 776

13.Partington, p. 78

14.Ibid., Preface, p. xii

15.Edward Gibbon, The Decline and Fall of the Roman Empire (Methuen & Co., 1912), vol. vi, p. 10

16.Ibid., vol. vii, p. 85

CHAPTER 2

Making Gunpowder

Describing gunpowder in the seventeenth century, John Bate1 wrote that ‘the saltpetre is the Soule, the Sulphur is the Life and the Coales the Body of it’. Saltpetre, or nitre, is certainly the most important component. It was recognized as potassium nitrate by John Mayow, a friend of Robert Boyle’s, in 1674. Prior to that much confusion had been caused by using the word ‘nitre’ to mean what we now know as sodium carbonate. The difficulty arose because the various different salts known to the ancients were all remarkably alike in both appearance and taste. The biblical quotations in Jeremiah ii 22 – ‘For though thou wash thee with nitre, and take thee much soap, yet thine iniquity is marked before me, saith the Lord God’ – and in Proverbs xxv 20 – ‘As he that taketh away a garment in cold weather, and as vinegar upon nitre, so is he that singeth songs to an heavy heart’ – only make sense if nitre is interpreted as sodium carbonate. And Robert Boyle demonstrated in 1680 that a sample of Egyptian nitre, given to him by the British ambassador at the Ottoman court, was a carbonate and not a nitrate. He wrote: ‘When once I received the nitre that I have mentioned, I quickly poured upon it some vinegar, and found as I expected that there presently ensued a manifest conflict, with noise, and store of bubbles, with which experiment I afterwards acquainted some critics and other learned men who were not ill-pleased with it.’2 Around that time the Egyptian carbonate came to be called natron, and the word nitre was applied to potassium nitrate. In modern versions of the Bible, the term nitre is replaced by lye or soda.

The word saltpetre is derived from the Latin sal petrae, salt of stone, the name originating from the fact that the chemical was first encountered as a white encrustation on stones or walls or on the ground. In Egypt it was called ‘the flower of the stone of Assos’, or ‘Chinese snow’,3 as it looks like snow on the ground, but these names are no longer in use.

Until the middle of the nineteenth century all the saltpetre required for making gunpowder was obtained by dissolving it from earth in which it had formed naturally by the decomposition of animal and vegetable matter. It is now known that this decomposition involves the action of bacteria, and plentiful supplies of saltpetre can only build up where there is an abundance of nitrogenous organic matter in the earth, where the temperature is high so that the bacterial action is accelerated, and where there is a prolonged dry season so that the saltpetre does not get washed away as soon as it is formed. Alternatively, saltpetre can build up in cellars and stables sheltered from rain. Wherever it occurred in large quantities it was sought after like gold, for it was imperative for every country to have adequate supplies, particularly in time of war.

India, especially the states of Bihar and Bengal, was one of the largest suppliers, exporting around 30,000 tons of saltpetre each year in the first half of the nineteenth century. The rapid nitrification of the sewage-sodden earth around the villages and the material from the mud walls of houses or cow sheds, produced a crust very rich in nitrates. The nitrate-containing earth was collected into a pile, and then wood ashes, which contain potassium carbonate, were mixed in so that any calcium or magnesium nitrates which might be present would be converted into the required potassium nitrate, and water was allowed to trickle through. The solution which was collected was, subsequently, evaporated either by a fire or by the sun’s heat, to form crystals.

The first crop of crystals was not very pure but could be refined by recrystallization to yield a solid containing about 90 per cent potassium nitrate. Further purification, particularly the removal of deliquescent impurities, was essential before the saltpetre could be used in gunpowder, for deliquescent substances absorb moisture from damp air. This necessity had been recognized in an early test given in the Codex Germanicus, written around 1350: ‘When thou buyest or makest saltpetre and will find whether it be good or not, so thrust thine hand there-into. If thine hand become damp, then it is not good. Also touch thine hand with thine tongue; if thine hand be salty, then the saltpetre is not good; but if thine hand be sweet, then it is good.’4 Early methods of purification had also been described by Roger Bacon and by Marcus Graecus, but considerable chemical ingenuity, making use of the differences in salt solubilities, had to be applied before an entirely satisfactory method was developed.

The basic conditions for the formation of nitrates in the ground were considerably less favourable in Europe than in India so that, in spite of strenuous and sometimes rather ridiculous governmental efforts, home production of saltpetre in Europe was always difficult.

In England early saltpetre manufacture was controlled by the State. In 1558 Queen Elizabeth I granted an eleven-year monopoly for gathering and making the material to George Evelyn (grandfather of John Evelyn, the famous diarist) and others. The monopoly covered all of southern England and the Midlands, excepting the City of London and its environs. By 1625 King Charles I had empowered saltpetre makers to enter any premises to remove nitrate-containing earth wherever they could find it and, in the following year, he went even further, ordering that his

loving subjects … inhabiting within every city, town and village … shall carefully and constantly keep and preserve all the urine of man during the whole year, and all the stale of beasts which they can save and gather together whilst their beasts are in their stables and stalls, and that they be careful to use the best means of gathering together and preserving the urine and stale, without mixture of water or other thing put therein. Which our commandment and royal pleasure being easy to observe, and so necessary for the public service of us and our people, that if any person do be remiss hereof we shall esteem all such persons contemptuous and ill affected both to our person and estate, and are resolved to proceed to the punishment of that offender with what severity we may.5

There have been many ‘England expects’ announcements over the years, but this must surely be one of the most remarkable. It was all going too far, and the powers of the saltpetre searchers and gatherers were curtailed by an Act of Parliament in 1656.

An inadequate supply of nitrates was not the only problem with which English saltpetre manufacturers of that era had to contend. Wood ashes were always in short supply because they were required for making soap as well as gunpowder. The clash was resolved by the Lords of the Admiralty directing that the saltpetremen should have priority. Gunpowder was more important than soap!

The home industry was, then, never very successful and it declined, despite many efforts to keep it going, as soon as the East India Company began to import Indian saltpetre on a regular basis around 1630. By 1760 Indian supplies were four times cheaper than the home product.

Sixteenth-century nitre beds from a treatise by Lazarus Ercker, 1580. Wood ashes, from the wood piles (D), were added to nitrate-containing earth scraped from the beds (C). The mixture was treated with water in the leaching house (A) to extract the saltpetre. The solution was then heated in the boiling house (B) until it formed crystals on cooling.

In France an edict of 1540 granted salpêtriers even greater powers than their English counterparts, and many of them lasted until 1840. By 1630, 1,600 tons of saltpetre were being produced annually but this had halved by 1775 owing to the competition from Indian imports. To try to boost the home production, the salpêtriers were given even greater powers; the Paris Academie des Sciences offered a prize of 4,000 livres for improved methods of production; and the administration of the Ferme des Poudres, which had become corrupt and inefficient, was replaced by the Régie des Poudres, who appointed four commissioners, including Antoine-Laurent Lavoisier, to be responsible for gunpowder manufacture. M. and Mme Lavoisier went to live in the Arsenal in Paris where they presided over many dazzling social occasions and where he carried out his famous experiments on the nature of combustion.

All this was timely, because France had to rely entirely on home production of gunpowder during the British naval blockade of 1792. Needs must, and in one year more than 7,000 tonnes of saltpetre were produced in about six thousand factories all over the country. Much important research was carried out during the nineteen years in which Lavoisier was associated with the Régie des Poudres, and the quality of French gunpowder improved enormously, a fact which caused much concern in England. Yet in 1794, at the early age of fifty-one, Lavoisier was sent to the guillotine. He had been charged with attempting to supply gunpowder to France’s enemies and, in his capacity as a Fermier-général, concerned with the collection of indirect taxes, ‘of adding to tobacco, water and other ingredients detrimental to the health of the citizens’.6 In the general state of turmoil following the start of the Revolution in 1789, a tribunal found Lavoisier guilty and sentenced him to death, saying that ‘the Republic has no need of men of science’. But the Republic still needed gunpowder, and Lavoisier’s tragic demise was bemoaned by one of his many supporters, Joseph Lagrange, with the words, ‘It required but a moment to strike off this head, and probably a hundred years will not suffice to reproduce such another’. In 1840 the last of privileges granted to the salpêtriers were abolished, and by 1870 there were only two factories making gunpowder in the whole of France.

* * *

The decline in saltpetre manufacture in Europe and, eventually, in India was accelerated by the discovery of immense deposits of caliche in Chile at the start of the nineteenth century. The caliche, which occurs at a depth of between 0.5 and 4.5 metres in the Atacama region of Northern Chile, contains up to 70 per cent sodium (not potassium) nitrate, and has come to be called Chile saltpetre. The deposits are said to have been discovered

by a native woodcutter named Negreiros, of the Pampa of Tamataragul, by his having made a fire at a certain spot, which still preserves his name, and observing that the ground thereupon began to melt and run like a stream. He hastily reported this fact to his curé in Camina, who declared it to be hell-fire, and asked to be shown the spot so as to be able to deal with it. The curé took a sample of the salt and found that it was nitre. He threw the remainder into his garden, where, to his surprise, the plants now grew better than ever before. A British naval officer, visiting Tarapaca some time later, paid a visit to the curé and spread the news to Europe.7

For about a hundred years, starting in 1825, when the deposits first began to be mined, caliche played a very important part in Chile’s economy, providing almost all the world’s supplies of nitrates. These were mainly used as nitrogenous fertilizers and in making nitric acid, with much smaller amounts being used in making gunpowder.

The sodum nitrate in the caliche cannot generally be used directly as a component of gunpowder because, unlike potassium nitrate, it picks up moisture from a damp atmosphere (it is deliquescent). Conversion of the sodium nitrate into potassium nitrate could not be carried out on a large scale so long as the only readily available potassium compounds had to come from wood ashes, kelp, raw sheep’s wool or sugar-beet molasses (vinasse), but it became relatively easy when the vast deposits around Stassfurt in Germany, discovered in 1839, were mined for carnallite, which contains potassium chloride. Potassium nitrate made from sodium nitrate and potassium chloride was called conversion or German saltpetre. It first became important in the manufacture of gunpowder during the Crimean War (1854–6) when existing supplies from Europe and India could not meet the demand, and it was widely used thereafter.

* * *

Sulphur, commonly called brimstone (burning stone), is a yellow solid which melts at a low temperature. It has been known since ancient times and is mentioned five times in the Bible, for example in Genesis xix 24: ‘Then the Lord rained upon Sodom and upon Gomorrah brimstone and fire from the Lord of Heaven.’ Homer mentions its use as a fumigant in the Odyssey: ‘Bring sulphur, old nurse, that cleanses all pollution and bring me fire, that I may purify the house with sulphur’,8 and Pliny refers to its use in medicine, in bleaching cloth, in fumigating wool and in making lamp-wicks for easy kindling.

In early days sulphur was always surrounded by an aura of mystery, and it was regarded as a symbol of evil power, perhaps because of its occurrence in volcanic regions and because of the pungent smell it emits when it burns. Milton, Coleridge and Southey all associated it with hell or with the devil. But all such fantastic ideas are long since discarded, and sulphur was recognized as an element in 1809, since when it has become an essential raw material in the chemical industry.

It occurs in most parts of the world both as natural sulphur and in the form of metallic sulphides, such as fool’s gold, and sulphates, like Epsom salts and gypsum. Some natural sulphur is found alongside volcanoes and mineral springs, but the main supplies lie underground, mixed with gypsum and limestone. Until 1900 most of the world’s sulphur came from the volcanic regions of Sicily but it now comes from underground sources in Texas and Louisiana in the United States.

Refining sulphur, a sixteenth-century etching. The impure sulphur was heated in a small earthenware pot (A). This boiled the sulphur and the vapour passed into a larger pot (B), where it liquefied. The liquid was then run off, from the bottom, into another container in which it solidified.

In the early Sicilian process, sulphur-containing rocks were laid out in a flat bed on sloping ground and covered with earth and ash in what was called a calcaroni. The rocks at the top of the slope were lit and, as the heat moved downwards, it melted the sulphur in the lower part, which then ran down and could be collected. The process was very wasteful because about 40 per cent of the sulphur was burnt away, and the noxious gases produced devastated the countryside for miles around. But no satisfactory alternative fuels were available in Sicily. The crude sulphur from the calcaroni had to be refined before it was suitable for use in gunpowder, and this was done either on site at some gunpowder mills or by specialist refiners originally concentrated around Marseilles.

Sulphur production was revolutionized in 1894 by Herman Frasch, who had trained as a pharmacist in Germany. After emigrating to the United States, he turned to chemistry so that he could join the fast-growing oil industry, and by 1876, when he was only twenty-five, he had patented a process for removing objectionable sulphur from crude oil. This brought him into contact with the Standard Oil Company of Cleveland, with whom he signed a business agreement, which eventually led to him becoming their first director of research and development. Frasch took out sixty-four patents in his lifetime. Twenty were concerned with refining oil; others with making paint, washing soda, electric light filaments and waxed paper. But it is for his patented method of mining sulphur that he is best remembered.

The sulphur in Texas and Louisiana occurs in thick beds about 150 m or more below the surface. It is mixed with limestone and covered by quicksand, soil and rock, and it had resisted all conventional methods of mining for many years. Frasch patented the idea of using a pump, made up of three concentric pipes of diameters 150 mm, 75 mm and 25 mm, lowered down a hole drilled into the sulphur bed. Hot water, under pressure, was forced down the outermost(150 mm) pipe to melt the sulphur at the bottom of the pump. Hot, compressed air passed down the innermost (25 mm) pipe and forced the molten sulphur up the central (75 mm) pipe as a frothy mixture with water. Sceptics said it would not work, and Frasch wrote: ‘Everyone who expressed an opinion seemed to be convinced that this thing could not be done, one prominent man offering to eat every ounce of sulphur I ever pumped.’9 Later, he described the success of his first test, which ended on Christmas Eve 1894:

I had the heated water run down, under pressure, for twenty-four hours. Then the pumping engine was started on the sulphur line. More and more slowly went the engine, more steam was turned on – until the man at the throttle sang out excitedly, ‘She’s pumping.’ In five minutes the outlet valve was opened. A beautiful stream of golden fluid shot into the barrels we had ready. In about fifteen minutes the forty barrels we had were full. We threw up embankments quickly and lined them with boards to catch the sulphur that was gushing out… . When everything had been finished, the sulphur all piled up in one heap, and the men departed, I enjoyed all by myself this demonstration of success.I mounted the sulphur pile and seated myself at the very top.

The process was not immediately profitable because it was so expensive to heat the 20,000 litres of water required for each ton of sulphur, but economic success came within a few years, when it became possible to heat the water by locally discovered oil, and the industry has thrived ever since, contributing to the large number of millionaires in Texas.

Wood charcoal has been used as a fuel and in the extraction of metals from their ores for many centuries so that charcoal burning was well established as a craft long before the advent of gunpowder. Logs of wood were arranged regularly in large conical-shaped mounds with some sort of flue down the centre. All the spaces were filled as fully as possible with smaller pieces of timber to limit the amount of air and the mound was then covered over with turf and rubbish. A smouldering fire was started by forcing burning charcoal or wood down the flue which was then blocked. By making vent-holes around the surface of the mound, the smouldering was made to spread outwards from the centre to convert as much of the wood as possible into charcoal.

Gunpowder was originally made using this sort of charcoal but it became clear, as early as the fourteenth century, that it was necessary both to heat and select the timber much more carefully in order to produce higher quality gunpowder. The precise nature of the charcoal used greatly affects the properties of a gunpowder and choosing the right charcoal was one of the subtle arts of a manufacturer. A much improved charcoal could be made by heating the wood in iron cylinders so that the length of heating and the temperature could be controlled more carefully than in a pile; the product was known as cylinder charcoal and it made better gunpowder. Further improvement came with the correct choice of timber. Roger Bacon’s recipe had specified hazelwood, but dogwood, willow and alder were commonly used in England: dogwood for rapid burning, small-grain powder, as used in rifles and shotguns, and willow and alder for coarse-grain powders, which burnt more slowly and were used in larger guns and for blasting. In other countries, poplar, lime, yew, oleander, vine and hemp stems were all used, and beech and birch are satisfactory for cheaper gunpowders.

Wherever possible, the trees were grown close by the gunpowder mill. It was lucky that the amount of timber needed for making gunpowder was not very great because there were many competing demands. Much of the available timber was required for building ships, and charcoal was also needed in large quantities both as a fuel and for smelting iron. The resulting deforestation in many parts of the world caused a constant rise in the price of charcoal and led to various Acts by Queen Elizabeth I and other monarchs limiting the felling of trees for iron-smelting.

* * *

At first gunpowder was made simply by powdering the three components separately and then grinding them together in a mortar with a hand-operated pestle. Later, stamp mills were used, the mixture being pounded in wooden mortars by wooden-headed stamps which were moved up and down, originally by hand but, from the middle of the fifteenth century, by using horse- or water-power. The method was always hazardous because the friction and percussion from the pestle frequently caused the gunpowder to burn or explode. As a result stamp mills were banned in the United Kingdom by the 1772 Gunpowder Act, though they were still allowed to be used in making a particularly good sporting powder called Battle powder after the name of one of the places, in Sussex, where it was produced.