69,99 €

Mehr erfahren.

- Herausgeber: John Wiley & Sons

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

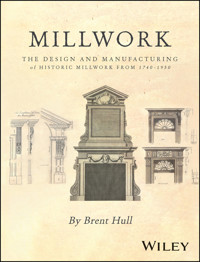

Historic millwork expert Brent Hull provides a one-of-a-kind, comprehensive reference of millwork elements found in historic homes from the 18th to 20th centuries. Millwork: The Design and Manufacturing of Historic Millwork from 1740–1950 is organized by type of millwork for ease of reference and includes rare illustrations, hard-to-find drawings, and diagrams from the 19th century, many of which are sourced from out-of-print catalogs in Hull’s private collection.

Explore the classification and definition of doors, windows, moldings, mantels, paneled walls, built-ins, and other millwork elements through a historical lens. Learn how architectural millwork elements were designed, manufactured, and constructed during the hand-made (pre-industrial) era and how they changed after World War II. Millwork: The Design and Manufacturing of Historic Millwork from 1740–1950 is a unique and valuable reference for architects, designers, historians, preservationists, builders, or anyone interested in restoring historic homes.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 347

Veröffentlichungsjahr: 2025

Ähnliche

Table of Contents

Cover

Table of Contents

Title Page

Copyright

Preface

CHAPTER 1: Introduction

The Classical System

Manufacturing History

CHAPTER 2: Moldings 1740–1950

Intro

1740–1850

Conclusion

CHAPTER 3: Doors 1740–1960

Intro

Preindustrial Doors

Post‐Industrial Doors

CHAPTER 4: Windows 1740–1960

Intro

Window Glass

Preindustrial Windows

Post‐Industrial Windows

CHAPTER 5: Stairs 1740–1960

Intro

Preindustrial Stairs

Post‐Industrial Stairs

CHAPTER 6: Mantles 1740–1950

Intro

Preindustrial Mantles

CHAPTER 7: Cabinetry‐Built‐ins 1740–1960

Intro

Preindustrial Cabinetry and Built‐ins

Post‐Industrial: Cabinetry and Built‐ins

CHAPTER 8: Wood and Best Practices

Choosing the Right Wood Today

Index

End User License Agreement

List of Illustrations

Chapter 1

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

Chapter 2

FIGURE 1.

FIGURE 2.

FIGURE 2A.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

FIGURE 10.

FIGURE 11.

FIGURE 12.

FIGURE 13.

FIGURE 14.

FIGURE 15.

FIGURE 16.

FIGURE 17.

FIGURE 18.

FIGURE 19.

FIGURE 20.

FIGURE 21.

FIGURE 22.

FIGURE 23.

FIGURE 24.

FIGURE 25.

FIGURE 26.

FIGURE 27.

FIGURE 28.

FIGURE 29.

FIGURE 30.

FIGURE 31.

FIGURE 32.

FIGURE 33.

FIGURE 34.

FIGURE 35.

FIGURE 36.

FIGURE 37.

FIGURE 38.

FIGURE 39.

FIGURE 40.

FIGURE 41.

FIGURE 42.

FIGURE 43.

FIGURE 44.

FIGURE 45.

FIGURE 46.

FIGURE 47.

FIGURE 48.

FIGURE 49.

FIGURE 50.

FIGURE 51.

FIGURE 52.

FIGURE 53.

FIGURE 54.

FIGURE 55.

FIGURE 56.

FIGURE 57.

FIGURE 58.

FIGURE 59.

FIGURE 60.

FIGURE 61.

FIGURE 62.

FIGURE 63.

FIGURE 64.

FIGURE 65.

FIGURE 66.

FIGURE 67.

FIGURE 68.

FIGURE 69.

FIGURE 70.

FIGURE 71.

FIGURE 72.

FIGURE 73.

FIGURE 74.

FIGURE 75.

FIGURE 76.

FIGURE 77.

FIGURE 78.

FIGURE 79.

FIGURE 80.

FIGURE 81.

FIGURE 82.

FIGURE 83.

FIGURE 84.

FIGURE 85.

FIGURE 86.

FIGURE 87.

FIGURE 88.

FIGURE 89.

FIGURE 90.

FIGURE 91.

FIGURE 92.

FIGURE 93.

FIGURE 94.

FIGURE 95.

FIGURE 96.

FIGURE 97.

FIGURE 98.

FIGURE 99.

FIGURE 100.

FIGURE 101.

FIGURE 102.

FIGURE 103.

FIGURE 104.

FIGURE 105.

FIGURE 106.

FIGURE 107.

FIGURE 108.

FIGURE 109.

FIGURE 110.

FIGURE 111.

FIGURE 112.

FIGURE 113.

FIGURE 114.

FIGURE 115.

FIGURE 116.

FIGURE 117.

FIGURE 118.

FIGURE 119.

FIGURE 120.

FIGURE 121.

FIGURE 122.

FIGURE 123.

FIGURE 124.

FIGURE 125.

FIGURE 126.

FIGURE 127.

FIGURE 128.

FIGURE 129.

Chapter 3

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

FIGURE 10.

FIGURE 11.

FIGURE 12.

FIGURE 13.

FIGURE 14.

FIGURE 15.

FIGURE 16.

FIGURE 17.

FIGURE 18.

FIGURE 19.

FIGURE 20.

FIGURE 21.

FIGURE 22.

FIGURE 23.

FIGURE 24.

FIGURE 25.

FIGURE 26.

FIGURE 27.

FIGURE 28.

FIGURE 29.

FIGURE 30.

FIGURE 31.

FIGURE 32.

FIGURE 33.

FIGURE 34.

FIGURE 35.

FIGURE 36.

FIGURE 37.

FIGURE 38.

FIGURE 39.

FIGURE 40.

FIGURE 41.

FIGURE 42.

FIGURE 43.

FIGURE 44.

FIGURE 45.

FIGURE 46.

FIGURE 47.

FIGURE 48.

FIGURE 49.

FIGURE 50.

FIGURE 51.

FIGURE 52A.

FIGURE 52B.

FIGURE 53.

FIGURE 54.

FIGURE 55.

FIGURE 56.

FIGURE 57.

FIGURE 58.

FIGURE 59.

FIGURE 60.

FIGURE 61.

FIGURE 62.

FIGURE 63.

FIGURE 64.

FIGURE 65.

FIGURE 66.

FIGURE 67.

FIGURE 68.

FIGURE 69.

FIGURE 70.

FIGURE 71.

FIGURE 72.

FIGURE 73.

FIGURE 74.

FIGURE 75.

FIGURE 76.

FIGURE 77.

FIGURE 78.

FIGURE 79.

FIGURE 80.

FIGURE 81.

FIGURE 82.

FIGURE 83.

FIGURE 84.

FIGURE 85.

FIGURE 86.

FIGURE 87.

FIGURE 88.

FIGURE 89.

FIGURE 90.

FIGURE 91.

FIGURE 92.

FIGURE 93.

FIGURE 94.

FIGURE 95.

FIGURE 96.

FIGURE 97.

FIGURE 98.

FIGURE 99.

FIGURE 100.

FIGURE 101.

FIGURE 102.

FIGURE 103.

FIGURE 104.

FIGURE 105.

FIGURE 106.

FIGURE 107.

FIGURE 108.

FIGURE 109.

FIGURE 110.

FIGURE 111.

FIGURE 112.

FIGURE 113.

FIGURE 114.

FIGURE 115.

FIGURE 116.

FIGURE 117.

FIGURE 118.

FIGURE 119.

Chapter 4

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

FIGURE 10.

FIGURE 11.

FIGURE 12.

FIGURE 13.

FIGURE 14.

FIGURE 15.

FIGURE 16.

FIGURE 17.

FIGURE 18.

FIGURE 19.

FIGURE 20.

FIGURE 21.

FIGURE 22.

FIGURE 23.

FIGURE 24.

FIGURE 25.

FIGURE 26.

FIGURE 27.

FIGURE 28.

FIGURE 29.

FIGURE 30.

FIGURE 31.

FIGURE 32.

FIGURE 33.

FIGURE 34.

FIGURE 35.

FIGURE 36.

FIGURE 37.

FIGURE 38.

FIGURE 39.

FIGURE 40.

FIGURE 41.

FIGURE 42.

FIGURE 43.

FIGURE 44.

FIGURE 45.

FIGURE 46.

FIGURE 47.

FIGURE 48.

FIGURE 49.

FIGURE 50.

FIGURE 51.

FIGURE 52.

FIGURE 53.

FIGURE 54.

FIGURE 55.

FIGURE 56.

FIGURE 57.

FIGURE 58.

FIGURE 59.

FIGURE 60.

FIGURE 61.

FIGURE 62.

Chapter 5

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

FIGURE 10.

FIGURE 10A.

FIGURE 11.

FIGURE 12.

FIGURE 13.

FIGURE 14.

FIGURE 15.

FIGURE 16.

FIGURE 16A.

FIGURE 16B.

FIGURE 17.

FIGURE 18.

FIGURE 19.

FIGURE 20.

FIGURE 21.

FIGURE 22.

FIGURE 23.

FIGURE 24.

FIGURE 25.

FIGURE 26.

FIGURE 26A.

FIGURE 27.

FIGURE 28.

FIGURE 29.

FIGURE 30.

FIGURE 31.

FIGURE 32.

FIGURE 33.

FIGURE 34.

FIGURE 35.

FIGURE 36.

FIGURE 37.

FIGURE 38.

FIGURE 39.

FIGURE 40.

FIGURE 41.

FIGURE 42.

FIGURE 43.

FIGURE 44.

FIGURE 45.

FIGURE 46.

FIGURE 47.

FIGURE 48.

FIGURE 49.

FIGURE 50.

FIGURE 51.

FIGURE 52.

FIGURE 53.

FIGURE 54.

FIGURE 55.

FIGURE 56.

FIGURE 57.

FIGURE 58.

FIGURE 59.

FIGURE 59A.

FIGURE 60.

FIGURE 61.

FIGURE 62.

FIGURE 63.

FIGURE 64.

FIGURE 65.

FIGURE 66.

FIGURE 67.

FIGURE 68.

FIGURE 69.

FIGURE 70.

FIGURE 71.

FIGURE 72.

FIGURE 73.

FIGURE 74.

FIGURE 75.

FIGURE 76.

FIGURE 77.

FIGURE 78.

FIGURE 79.

FIGURE 80.

FIGURE 81.

FIGURE 82.

FIGURE 83.

FIGURE 84.

FIGURE 85.

FIGURE 86.

FIGURE 87.

FIGURE 88.

FIGURE 89.

FIGURE 90.

FIGURE 91.

FIGURE 92.

FIGURE 93.

FIGURE 94.

FIGURE 95.

FIGURE 96.

FIGURE 97.

FIGURE 98.

FIGURE 99.

FIGURE 100.

FIGURE 101.

FIGURE 102.

FIGURE 103.

FIGURE 104.

FIGURE 105.

FIGURE 106.

FIGURE 107.

FIGURE 108.

FIGURE 109.

FIGURE 110.

FIGURE 111.

FIGURE 112.

FIGURE 113.

FIGURE 114.

FIGURE 115.

FIGURE 116.

FIGURE 117.

FIGURE 118.

FIGURE 119.

FIGURE 120.

FIGURE 121.

FIGURE 122.

FIGURE 123.

FIGURE 124.

FIGURE 125.

FIGURE 126.

Chapter 6

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

FIGURE 10.

FIGURE 11.

FIGURE 12.

FIGURE 13.

FIGURE 14.

FIGURE 15.

FIGURE 16.

FIGURE 17.

FIGURE 18.

FIGURE 18A.

FIGURE 18B.

FIGURE 18C.

FIGURE 18D.

FIGURE 19.

FIGURE 20.

FIGURE 21.

FIGURE 22.

FIGURE 22A.

FIGURE 22B.

FIGURE 22C.

FIGURE 22D.

FIGURE 23.

FIGURE 24.

FIGURE 25.

FIGURE 26.

FIGURE 27.

FIGURE 27A.

FIGURE 28.

FIGURE 29.

FIGURE 30.

FIGURE 31.

FIGURE 32.

FIGURE 33.

FIGURE 34.

FIGURE 35.

FIGURE 36.

FIGURE 37.

FIGURE 38.

FIGURE 39.

FIGURE 40.

FIGURE 41.

FIGURE 42.

FIGURE 43.

FIGURE 44.

FIGURE 45.

FIGURE 46.

FIGURE 47.

FIGURE 48.

FIGURE 49.

FIGURE 50.

FIGURE 51.

FIGURE 52.

FIGURE 53.

FIGURE 54.

FIGURE 55.

FIGURE 56.

FIGURE 57.

FIGURE 58.

FIGURE 59.

FIGURE 60.

FIGURE 61.

FIGURE 62.

FIGURE 63.

FIGURE 64.

FIGURE 65.

FIGURE 66.

FIGURE 67.

FIGURE 68.

FIGURE 69.

FIGURE 70.

FIGURE 71.

FIGURE 72.

FIGURE 73.

FIGURE 74.

FIGURE 75.

Chapter 7

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

FIGURE 8.

FIGURE 9.

FIGURE 10.

FIGURE 10A.

FIGURE 10B.

FIGURE 11.

FIGURE 12.

FIGURE 13.

FIGURE 14.

FIGURE 15.

FIGURE 16.

FIGURE 17.

FIGURE 18.

FIGURE 19.

FIGURE 19A.

FIGURE 20.

FIGURE 21.

FIGURE 22.

FIGURE 23.

FIGURE 24.

FIGURE 25.

FIGURE 25A.

FIGURE 25B.

FIGURE 25C.

FIGURE 25D.

FIGURE 25E.

FIGURE 25F.

FIGURE 25G.

FIGURE 25H.

FIGURE 25I.

FIGURE 26.

FIGURE 27.

FIGURE 28.

FIGURE 29.

FIGURE 30.

FIGURE 31.

FIGURE 32.

FIGURE 33.

FIGURE 34.

FIGURE 35.

FIGURE 36.

FIGURE 37.

FIGURE 38.

FIGURE 39.

FIGURE 40.

FIGURE 41.

FIGURE 42.

FIGURE 43.

FIGURE 44.

FIGURE 45.

FIGURE 46.

FIGURE 47.

FIGURE 48.

FIGURE 49.

FIGURE 50.

FIGURE 51.

FIGURE 52.

FIGURE 53.

FIGURE 54.

FIGURE 55.

FIGURE 55A.

FIGURE 55B.

FIGURE 55C.

FIGURE 55D.

FIGURE 55E.

FIGURE 55F.

FIGURE 55G.

FIGURE 55H.

FIGURE 55I.

FIGURE 55J.

FIGURE 55K.

FIGURE 55L.

FIGURE 55M.

FIGURE 55N.

FIGURE 55O.

FIGURE 55P.

FIGURE 56.

FIGURE 57.

FIGURE 58.

FIGURE 58A.

FIGURE 58B.

FIGURE 58C.

FIGURE 58D.

FIGURE 58E.

FIGURE 58F.

FIGURE 58G.

FIGURE 58H.

FIGURE 58I.

FIGURE 58J.

FIGURE 58K.

FIGURE 58L.

FIGURE 58M.

FIGURE 58N.

FIGURE 59.

FIGURE 60.

FIGURE 61.

FIGURE 62.

FIGURE 63.

FIGURE 64.

FIGURE 65.

FIGURE 66.

FIGURE 67.

FIGURE 68.

FIGURE 69.

FIGURE 70.

FIGURE 71.

FIGURE 72.

FIGURE 73.

FIGURE 74.

FIGURE 75.

FIGURE 76.

FIGURE 77.

FIGURE 78.

FIGURE 79.

FIGURE 80.

FIGURE 81.

FIGURE 82.

FIGURE 83.

FIGURE 84.

FIGURE 85.

FIGURE 86.

FIGURE 87.

FIGURE 88.

FIGURE 89.

FIGURE 90.

FIGURE 91.

FIGURE 92.

FIGURE 93.

FIGURE 94.

FIGURE 95.

FIGURE 96.

FIGURE 97.

FIGURE 98.

FIGURE 99.

FIGURE 100.

FIGURE 101.

FIGURE 102.

FIGURE 103.

FIGURE 104.

FIGURE 105.

FIGURE 106.

Chapter 8

FIGURE 1.

FIGURE 2.

FIGURE 3.

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

Guide

Cover

Table of Contents

Title Page

Copyright

Preface

Begin Reading

Index

End User License Agreement

Pages

iii

iv

vii

1

2

3

4

5

6

7

8

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

173

174

175

176

177

178

180

181

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296

297

298

299

300

301

302

303

304

305

306

Millwork

The Design and Manufacturing of Historic Millwork from 1740–1950

BRENT HULLHull Homes ‐ Hull Millworkbrenthull.comFort Worth, Texas. USA

Copyright © 2025 by John Wiley & Sons, Inc. All rights reserved, including rights for text and data mining and training of artificial technologies or similar technologies.

Published by John Wiley & Sons, Inc., Hoboken, New Jersey.Published simultaneously in Canada.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, scanning, or otherwise, except as permitted under Section 107 or 108 of the 1976 United States Copyright Act, without either the prior written permission of the Publisher, or authorization through payment of the appropriate per‐copy fee to the Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923, (978) 750‐8400, fax (978) 750‐4470, or on the web at www.copyright.com. Requests to the Publisher for permission should be addressed to the Permissions Department, John Wiley & Sons, Inc., 111 River Street, Hoboken, NJ 07030, (201) 748‐6011, fax (201) 748‐6008, or online at http://www.wiley.com/go/permission.

The manufacturer’s authorized representative according to the EU General Product Safety Regulation is Wiley‐VCH GmbH, Boschstr. 12, 69469 Weinheim, Germany, e‐mail: [email protected].

Trademarks: Wiley and the Wiley logo are trademarks or registered trademarks of John Wiley & Sons, Inc. and/or its affiliates in the United States and other countries and may not be used without written permission. All other trademarks are the property of their respective owners. John Wiley & Sons, Inc. is not associated with any product or vendor mentioned in this book.

Limit of Liability/Disclaimer of Warranty: While the publisher and author have used their best efforts in preparing this book, they make no representations or warranties with respect to the accuracy or completeness of the contents of this book and specifically disclaim any implied warranties of merchantability or fitness for a particular purpose. No warranty may be created or extended by sales representatives or written sales materials. The advice and strategies contained herein may not be suitable for your situation. You should consult with a professional where appropriate. Further, readers should be aware that websites listed in this work may have changed or disappeared between when this work was written and when it is read. Neither the publisher nor authors shall be liable for any loss of profit or any other commercial damages, including but not limited to special, incidental, consequential, or other damages.

For general information on our other products and services or for technical support, please contact our Customer Care Department within the United States at (800) 762‐2974, outside the United States at (317) 572‐3993 or fax (317) 572‐4002.

Wiley also publishes its books in a variety of electronic formats. Some content that appears in print may not be available in electronic formats. For more information about Wiley products, visit our web site at www.wiley.com.

Library of Congress Cataloging‐in‐Publication Data Applied for

Hardback ISBN: 9781394168453

Cover Design: WileyCover Images: The Art of Drawing, and Working the Ornamental Parts of Architecture, Batty Langley, Published by Samuel Harding 1741.The Practical Builder; or Workman’s General Assistant, London: Printed for I. and J. Taylor at the Architectural Library 1787.The Practical Builder; or Workman’s General Assistant, William Pain, London: Printed for I. Taylor 1774.

Preface

The origins for this book started 30+ years ago when I started at the North Bennett St. School in the North End of Boston. North Bennett St. School is a trade school, the oldest in America, and my program was preservation carpentry. It was a hands‐on historic preservation program. We learned how buildings and homes were built 250 years ago and I haven't stopped learning since.

My first book was Historic Millwork, focusing on the period 1870–1940. I was then fortunate to learn a great deal at the Winterthur Museum with my good friend Christine Franck. We wrote the book Traditional American Rooms. Winterthur exposed me to woodwork and architectural interiors from before the Industrial Revolution. These rooms, collected by Henry DuPont, represent the finest collection of American interiors and rooms in the world.

At the same time, I have also been a practitioner of the trades through my companies Hull Millwork and Hull Homes. Our millwork company restores and builds new millwork to match the historic millwork by copying profiles and matching joinery. Our Homes company works on pre‐1940 homes and builds new‐old houses. Working out of Fort Worth, Texas, and consulting around the country, we have worked on some amazing historic homes, schools, courthouses, and depots.

Despite all this experience and training, I'm convinced that I am not fully qualified to write about this subject. It is so broad and varied that to write definitively about doors, windows, and moldings is merely providing guidelines for what may have been.

One thing that makes this task difficult is knowing what is original even when going into an historic house. Red Herrings is what my instructor at North Bennett St. School called items installed in houses that were never there originally. These confusing items that may have come from an earlier Georgian house are confusing in a federal home.

Furthermore, there are regional differences, processes, and advancements like the steam‐powered planning mills that show up on the east coast as early as 1840 but aren't a reality in the Midwest for 20 more years.

Consider the railroad and the near‐immediate advances in millwork that happen to houses and architecture in our country. A recent home we were working on, built in 1881, had original, hand‐built mantles that looked very similar to a mantle design from Shaw or Lafever in one of their 1850s pattern books. Yet, there was also oak mantle, made with quarter‐sawn oak veneers and very similar to mantles available in 1890 manufacturer catalogs. A quick history of the town showed that the railroad first arrived there in 1887.

The arrival of the railroad changed the architectural interiors of the home, and the sophistication and quality of the millwork were quickly advanced. It was confusing for me when we were trying to date the millwork of the home because the owner wanted an accurate restoration after years of neglect and quick fixes.

The mantles were crude, the Sanborn maps were not definitive, and there were confusing elements. But this is why I wanted to write this book. It is to help those preserving and restoring buildings to understand what was available, how doors change, and what windows should look like. For those looking for more information, for those looking to fill in holes of information, I’m hopeful this book is a start.

I also wrote this book with the hope that we can build better. It is my belief that millwork was better crafted than what is made today. Moldings are a good example. Moldings of the Georgian and Federal era are generally larger and more thoughtfully designed than moldings today. If today’s builders and craftsmen simply improved the quality of moldings they installed in their homes, we would have better houses.

There is a great deal we can learn from the past, and my research has only encouraged this resolve. Read this book and learn about the past and see the great resolve and focus on beauty, scale, and proportion that was once such an integral part of building. This book is a start.

I would like to thank the team at John Wiley for their help in putting this new book together. Thanks to my staff at the Brent Hull companies for my time researching and looking for clues that took me away from work. Thanks to those who encouraged me in this work and felt it was a worthwhile endeavor. I hope you enjoy the discovery as much as I have.

Brent Hull

CHAPTER 1Introduction

This book is organized by type as opposed to by period. Though this was an early discussion with my publisher, it was quickly determined that a chapter on doors was more useful than a chapter on Georgian interiors. Further, we really only deal with interiors and not with the exterior millwork like door surrounds/porticos, porches. Maybe that is another book.

I originally started by looking at historic buildings, well‐known historic properties, but found that many of these are not perfect specimens for study because many of these have been changed over time.

I ended up settling on the pattern books and printed material. Though again this isn’t a perfect way to study woodwork and millwork, it did provide a framework for discussing woodwork in each period.

There many different types of books and these types change over time. We start with period pattern books, and end with manufacturer catalogs. Any and all books that give insight into woodwork and millwork were fair game. I have used a few studies of historic pricing guides, as these give the clearest insight into the process and pricing of historic woodwork.

Knowing which historic pattern books to read and use was made easier because of 2 studies of pattern books in early America, one by Helen Parks and a later study by Janice Schimmelman. These scholars did a deep dive into American history and by using advertisements, book dealer lists and even book inventories at the death of craftsmen they have provided a glimpse into which books were used and which books were influential in America.

The period of the master builder’s pattern book end in the mid‐19th century and are replaced by architectural design books by house plan designers. These books offer a glimpse into design and what was popular. Lastly, after the civil war, manufacturer catalogs take hold and provide a clear glimpse into what was sold and what was popular.

I chose the dates of 1740–1950 for a couple of reasons. First, it is my belief that good houses in America start around 1740/1750. Peter Harrison’s redwood library is an early example, but also Mount Airy, Carter’s Grove, Gunston Hall, and Drayton Hall are all good examples and early flourishing of architectural style and taste in America. It is also when we first see these architectural pattern books by Batty Langley, Abraham Swan, and others being sold.

I have ended at 1950 because of the rise of production builders who learn to build in a cheap and fast method that results in aluminum windows and hollow core doors. Essentially the millwork we study in this book changes so much, that it would require a different book to chronicle the changes.

Here is a list of the books I used for this study. I tried to find and use books in 10 year increments. Books and sources of information on millwork changes over time. The builder and architect written pattern books are most popular in the preindustrial era. Before 1860, they are the primary source. After this time, it shifts to architectural design books, the difference being there is less emphasis on building how‐to. Less building instruction and more emphasis on architectural details. After 1890, the manufacturer catalogs provide the most information. These catalogs are hardcover books with high production quality and wonderful illustrations.

Before 1797, the builder pattern books are written by English authors. Research by Parks and Schimmelman show few French books in America. Asher Benjamin’s book The Country Builder’s Assistant is the first American‐authored pattern book.

These preindustrial pattern books have a long shelf life. These books go through many editions and iterations. They spread across the country and influence builders and buildings. Abner Cook was a master builder working Austin in the 1850s. He built the Governor’s mansion as well as many other homes. He was influenced by both Minard Lafever’s book as well as Asher Benjamin’s. In our restoration work on Abner Cook homes, those books are great clues to what was original and how the home was built.

Early pattern book author’s “borrowed” and were influenced by one another. Sometimes they took details from one another, and each new edition was an opportunity to create new elements. Styles too changed with the author. Asher Benjamin started out designing Federal style homes but clearly changed over to the Greek Revival by 1830.

Most of the preindustrial books I use are builder focused. This is in contrast to the architectural books written for the Gentleman architect. Andrea Palladio’s 4 books of architecture is very influential but may not be as relevant to a builder/craftsman. In the 18th and early 19th century, men of learning and taste considered the study of architecture an important body of knowledge.

One thing that needs to be understood is the difference between a Gentleman architect and a master builder. The Gentleman architect is the homeowner, or wealthy patron who studied architecture and design as a hobby or general interest rather than as a trade. These might be wealthy owners and patrons who encouraged the design and building of great homes.

Thinking about great houses like Drayton Hall, or Gunston Hall, Elias Derby in Salem were all wealthy owners who had or owned books of architecture and influenced and practiced building.

The Master builder was generally someone who grew up in the trades, apprenticed as a craftsman or builder, and actively built homes, millwork, etc. This was their profession and skill. While they might share the same enthusiasm for building as the patron/gentleman architect, they actively designed, built, and constructed homes, often with their own hands.

This distinction is important because some pattern books were written for gentlemen architects like James Gibb or Colin Campbell, while others were written for builders and craftsmen like Batty Langley and Asher Benjamin.

It’s confusing because today we might term them all architects because they were involved in design, but in truth, the practice or actual work creates the separation between the two.

1730: William Halfpenny,

Practical Architecture

: 5th edition. 1968 reprint.

1736: William Solmon,

Palladio Londonesis

.

1740: Batty Langley.

The Builder’s Jewel and Builder’s Chest

book.

1750: Abraham Swan.

The British Architect

.

1757: Abraham Swan.

A Collection of Designs in Architecture

Vol 1 & 2.

1760: Batty Langley.

A Builder’s and Workman’s Treasury of Design

.

1766: Batty Langley.

A Builder’s Complete Assistant

.

1778: William Pain.

The Practical Builder

.

1786:

The Rule book for the Carpenter’s Company of the City of Philadelphia

. Reprint.

1786: William Pain.

British Palladio

.

1797: Asher Benjamin.

The Country Builder’s Assistant

.

1799: William Pain.

Practical House Carpenter

.

1826: Asher Benjamin.

Builder’s Companion

.

1832: Edward Shaw.

Civil Architecture

.

1833: Minard Lafever.

The Modern Builder’s Guide

.

1836:

American Builder’s Price Book and Estimator

.

1838: A. Pugin.

Gothic Architecture

.

1841: Asher Benjamin.

Practical House Carpenter

.

1849: Minard Lafever.

Beauties of Modern Architecture

.

1851: Asher Benjamin.

The Practice of Architecture

.

1852: Edward Shaw.

Civil Architecture

.

1854: Edward Shaw.

Modern Architect

.

1854: Oliver P Smith.

Domestic Architect

.

1865: Paley’s.

Gothic Moldings

.

1868: Cummings and Miller.

Architecture‐Designs

.

1873: A. J. Bicknell.

Detail

,

Cottage and Constructive Architecture

.

1873: M. F. Cummings.

Architectural Details

.

1881: William T. Comstock.

Modern Architectural Designs and Details

.

1892: Book of Designs of M. A. Disbrow & Co catalog published by Rand McNally.

1893: Construction Details: prepared for the use of the students of the Mass. Institute of Technology. By F. W. Chandler.

1898:

American Architect and Building News

.

1903:

Farley Loetscher Catalog

.

1914:

Curtis Millwork Catalog

.

1914:

Kitchen Design

book—Hoosier Kitchen contest.

1920:

Curtis Millwork Catalog

.

1921:

Morgan Catalog

‐

Assurance of Design

.

1927:

Universal Design Catalog

.

1931:

Woodwork Institute of California

.

1936:

Curtis Catalog

.

1942:

Iriquois Morgan Catalog

.

1949:

Morgan Sectional Cabinets

.

1951:

Iroquois Millwork Catalog

.

1956:

Quigley Millwork Catalog

.

The Classical System

It is hard to study historic millwork without understanding the design ideal that influenced the moldings, room proportions, and mantle designs. Essentially all the millwork we will study is grounded in a classical tradition. If you want to master historic design and room proportions, you need to be familiar with the classical approach. The moldings, room proportions, layout, and even vocabulary all start here.

The classical system refers to the ancient Greek and Roman method of design. This method, developed by the Greeks, was grounded in the perfection of nature and the human form. What developed was a series of proportioning systems (we now call orders) that was each based on the scale and proportions of the human body. The Greeks developed the classical model and the Romans added to it. Together, those 2 cultures left us amazing buildings and temples that we still study today.

After the fall of the Roman empire, there is a pause in building but during the renaissance, this classical system is rediscovered when the only ancient book on architecture is found. Written by Vitruvius, we know it today as the 10 books of architecture. Vitruvius inspired the renaissance world including Leonardo Di Vinci who drew the famous Vitruvian man image 1, which expressed the wonder, beauty, and proportions of the human form (Figure 1).

FIGURE 1.

The Renaissance world rediscovers the magic of classical architecture which stood in ruins all around them. Piranesi’s etchings and prints capture the ancient world and his print Campo de vasi, or cow field, shows us how the renaissance world experienced the Roman ruins. Amazingly, roman buildings were once covered in marble but this was taken down over many centuries by scavengers and often burned to make lime (Figure 2).

FIGURE 2.

Perhaps no master builder and architect is more famous than Andrea Palladio. Palladio was trained as a stone mason but caught the eye of a wealthy statesmen who trained and educated Palladio. Palladio traveled to Rome as was struck by the ancient buildings and longed to understand their scale and proportion. He studied the ancient ruins and then developed or adapted these details to a new form of architecture, a kind of classical country house.

These homes built for the wealthy farms in Vicencia (outside of Venice) were working farms with work areas below and living quarters above. He adorned these homes with temple fronts and classical details and proportions. His book, the 4 books of architecture, was profoundly important in history but also in America as well. Thomas Jefferson, for instance, considered Palladio his bible for building. Monticello is grounded in classical design ideals and is inspired by Palladio’s work.

Fast forward to the 18th century America and we see this classical teaching in every pattern book and design book available at the time. It was as if the writers were saying, if you want to build right, you must understand the orders of architecture. Virtually every builder book from 1730 into the 1850s starts with an explanation of at least 3 of the orders; Doric, Ionic, and Corinthian (Figure 3).

FIGURE 3.

The orders and these proportioning methods not only drove the exterior facade of the home, but especially the interiors, the walls, and the moldings (Figure 4).

FIGURE 4.

Just like the orders are laid out with pedestal, column, and entablature, the walls are laid out with wainscot or chair rail that act as the pedestal. The paneled wall that acts as the column and then the crown or cornice that acts as the entablature. The Lancaster room and Cecil Bedroom (figures 5 & 6) are 2 rooms at Winterthur that show how classicism was used in American interiors.

FIGURE 5.

FIGURE 6.

The Lancaster room is from Virginia built in 1802. In the right corner you can see the classical parts laid out with pedestal, column, and entablature that wraps the room.

The Cecil bedroom is a 1740 room built in Maryland and express the columns and entablature in a rural manor. Note how the architrave is lifted above the column capitol, not directly on top. There is an effort from early craftsmen and builders to build better and with more sophistication. Building in the classical tradition was an attempt to show culture and taste. In this case the column, and entablature, expresses an understanding though not perfect representation of the classical style.

The Georgian and Federal eras express classicism differently. Georgian rooms are heavy and bold, Federal rooms are lighter and dainty. And even though the ornamentation changes the classical proportions and scale are still followed. Going into the Greek Revival era, authors like Shaw and Lafever push and encourage the Greek Revival style by eschewing the chair rail and building in the Greek tradition. Moldings are bold and more stone like, and the ornamentation takes on a Greek flavor.

This adherence follows through the Victorian period, although you might see some wildly creative interpretations of moldings, crowns, and columns. Firms like McKim, Mead and White, renew the classical push and much of their work is inspired by buildings of the classical era. A good example is their collegiate work where you see the Pantheon inspired buildings like the Low Memorial Library at Columbia University.

The classical framework is present in moldings throughout our period of study. Even the modern Art Deco movement holds to classical proportioning expressed in creative ways. It is really European modernism and the influence of Mies and others who steer design away from classicism. Most of the changes to moldings and interiors happened after 1950, but it is important to realize, especially when designing new spaces, what the design ideal was in the past. It will help you design better today.

As to the parts and pieces, here is how the system works.

Each of the orders of architecture are a proportioning system. They use the traditional post and beam building blocks as the framework for design. Thus, the column, which supports the beam above becomes the frame for each order. Each order, like the human body, have a correlation between width and height. This was measured at the base of a column and compared to the overall height.

The Doric order is associated with a male form and has a proportion of 1:7. The Ionic is associated with the female form and has a proportion of 1:8. This ratio or proportion is seen in the size of the column. 1 being the width at the base of the column and 7 is the height of the column. Thus, column is 7 widths tall. Then, each part of that order is proportioned based on the width or diameter at the base often called “D.” Figure 7 is from the Institute of Classical Architecture and Art. Note how the parts and pieces represent a proportion of D. The base for instance is 1/2 D.

FIGURE 7.

FIGURE 8.

Practically this works that if the diameter of the column is 12″ wide, then the base height at 1/2 D equals 6″. While I caution using the math in the design of a room, when you’re just learning the system, the math is crucial to understanding the original intent of the system. For me, it explains why many new moldings fall flat today, chair rails too tall, moldings the wrong size, because we’ve forgotten how it all goes together.

Manufacturing History

There are 2 distinct eras in this book. The preindustrial era when things are made by hand using hand tools. And the post‐industrial era where machines do a great deal of work speeding up production and increasing the variety of woods used in construction. I conclude this study at 1950 because a third era is growing and that is the era of production building. Hollow core doors and aluminum windows show the new mindset in the builder and manufacturer that really changes how millwork is even thought about.

This chapter is a brief glimpse into the world of woodwork and millwork over a 200 year period. I make the distinction because, technically millwork needs to be made in a mill. Yet, before the industrial era, there were no mills with powered machinery.

Let’s define the preindustrial era as 1740–1850 and the industrialized era as 1850–1950. I’ll add that there is clear overlap between eras. Industrialization progresses slowly over a 30–60 year period. There are records of early planning mill flyers as early as the 1830s and 1840s. The Woodworth planning mill (which we’ll discuss below) is patented in 1827. At the same time, the sales of hand planes peaks in the 1890s and sell into the early 20th century. This seems to be a dichotomy as hand tools and machine tools seem to work closely side by side for many decades.

During the preindustrial era, doors windows and moldings would have been made by hand using hand tools. Essentially, everything in this era is custom made. There are production shops or specialized makers of sash for instance, but that would have only happened in larger cities like Philadelphia. Donna Rilling’s book, Making Houses, Crafting Capitalism, a study of builders in Philadelphia 1790–1850, does a great job of showing how home building happened. Yet, this is not the way houses were built in smaller towns and rural areas.