Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The History Press

- Kategorie: Fachliteratur

- Sprache: Englisch

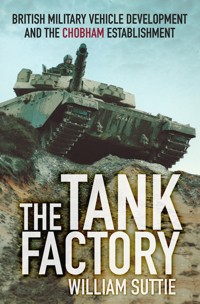

Despite being the inventor of the tank and responsible for campaign-winning tactics, by the start of the Second World War the United Kingdom had fallen well behind other nations in the design and build of armoured vehicles. Here, William Suttie uncovers the history of tank design from a government perspective and the decisions and failures that led to that state of affairs, and details the formation of the Fighting Vehicles Research and Development Establishment at Chertsey. Known as the Tank Factory, the Chertsey establishment sought to ensure that the United Kingdom became world-leading in the field of military vehicle research and design, and that the British Army would never be underprotected or outgunned again. Drawing on unpublished sources and photographs, this fascinating book reveals the establishment's history, its groundbreaking research and its inventions and designs, including first-hand insights from those who worked there.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 354

Veröffentlichungsjahr: 2015

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

ACKNOWLEDGEMENTS

This book was compiled with inputs, encouragement and support from many people who worked at or had associations with the establishment. Particular mention is made of the following people for their contributions:

Ian Burch

Brian Clark

Alan Cooper

Simon Davis

Paul Fenne

Thomas Forbes

Dave King

Colin Newell

Richard Rawlins

Neil Service

Neil Sparshott

Derek Talbot

Julian Walker

CONTENTS

Title

Acknowledgements

Author’s Note

Abbreviations

Introduction

1 The Birth of the Tank

2 British Tank Development Following the First World War

3 Vehicle Testing in the Interwar Years

4 Rearmament

5 Tank Development in the Second World War and the Role of the DTD

6 Vehicle Testing During the Second World War

7 Chobham Common

8 Post-war Evolution of the Chertsey Establishment

9 Development of the Chertsey Site

10 Chertsey Facilities

11 Equipment, Concepts, Designs and Development

12 Survivability Research and Development at Chertsey

13 Mobility Research at Chertsey

14 Fighting and Subsystem Research at Chertsey

15 Special Devices

Appendix A: Genealogy of Chertsey

Appendix B: Lineage of Director MVEE

Appendix C: Longcross Test Track Facilities

Bibliography

Copyright

AUTHOR’S NOTE

This book has been compiled using information from a significant number of documents and resources; the key open-source documents are listed in the bibliography. Most importantly, I have been able to have access to a significant number of MOD reports, and hence I include much information that has never been published before and ensure that, as far as possible, all the information within this book is correct. A large number of MOD reports used are still classified and, therefore, are not listed in this book. Where open-source literature and Internet sources have been used, information has been checked for coherence with information from official reports. An interesting aspect of compiling this document is to see how in these days of the World Wide Web incorrect ‘facts’ become widely repeated and quoted on different websites until they are assumed to be right.

Some of the best, and most interesting, inputs have been provided by ex-members of staff who have sent me stories, facts and pictures. It was the staff who made the Chertsey establishment the successful place it was, and so these personal inputs are valued.

This book contains a large number of pictures never before published. Many come from MOD reports and are used with permission, but others have been sent by ex-members of staff, or are pictures from my own collection. Some of the pictures are of poor quality, having been taken from electronic scanned copies of old documents, but these have been included because they are of specific interest.

The resulting document is likely to have many omissions and despite the checks may have some errors. Any additional information or corrections are always welcome.

I am grateful to the Ministry of Defence, and the Defence Science and Technology Laboratory in particular, for permission to publish this document and to use information and pictures from MOD sources.

ABBREVIATIONS

ACAVP

Advanced Composite Armoured Vehicle Programme

AD

Assistant Director

AEV

Armoured Engineer Vehicle

ALPS

Advanced Land Platform System

APC

Armoured Personnel Carrier

APDS

Armour Piercing Discarding Sabot

APFSDS

Armour Piercing Fin Stabilised Discarding Sabot

ARRV

Armoured Repair and Recovery Vehicle

ARV

Armoured Recovery Vehicle

ASC

Army Service Corps

ASPAT

Air-portable Self Propelled Anti-Tank

AT

Anti-Tank

ATDT

Automatic Target Detection and Tracking

ATSA

Army Technical Support Agency

AVLB

Armoured Vehicle Launched Bridge

AVR

Armoured Vehicle Reconnaissance

AVRE

Armoured Vehicle Royal Engineers

BAC

British Aircraft Corporation

BAOR

British Army Of the Rhine

BARV

Beach Armoured Recovery Vehicle

BTID

Battlefield Target Identification Device

BEF

British Expeditionary Force

CAC

Climatic and Altitude Chamber

CER

Controller Establishments and Research

CET

Combat Engineer Tractor

CHIP

Chieftain/Challenger Improvement Programme

CIA

Chief Inspector of Artillery

CR1

Challenger 1

CRARRV

Challenger Armoured Repair and Recovery Vehicle

CTDP

Component Technology Demonstrator Programme

CVCC

Complete Vehicle Climatic Chamber

CVR(T)

Combat Vehicle Reconnaissance (Tracked)

CVR(W)

Combat Vehicle Reconnaissance (Wheeled)

DD

Duplex Drive (Swimming Tank system)

DD

Deputy Director

DD(M)

Design Department (Mechanical)

DD(V)

Design Department (Vehicles)

DERA

Defence Evaluation and Research Agency

DFWES

Direct Fire Weapon Effects Simulator

DIT

Driver In Turret

DLO

Defence Logistics Organisation

DO

Drawing Office

DOE

Department Of the Environment

DRA

Defence Research Agency

DRIFT

Driving Remotely In Following Truck

DSEi

Defence Systems and Equipment International

Dstl

Defence Science and Technology Laboratory

DTD

Department of Tank Design

DTD&E

Department of Tank Design and Experimentation

ECU

Engine Control Unit

EMC

Electromagnetic Compatibility

EM gun

Electromagnetic gun

EOD

Explosive Ordnance Disposal

ETL

Engineering Test Laboratories

FCR

Fire Control Rig

FCTP

Fire Control Technical Programme

FLAV

Future Light Armoured Vehicle

FMBT

Future Main Battle Tank

FRES

Future Rapid Effects System

FV

Fighting Vehicle

FVDD

Fighting Vehicles Design Department

FVPE

Fighting Vehicles Proving Establishment

FVRDE

Fighting Vehicles Research and Development Establishment

GS

General Service

HE

High Explosive

HEAT

High Explosive Anti-Tank

HESH

High Explosive Squash Head

hp

Horsepower

HQ

Headquarters

IDCE

Integrated Driving Control Experiment

IED

Improvised Explosive Device

IFCS

Improved Fire Control System

IFV

Infantry Fighting Vehicle

KE

Kinetic Energy

kW

Kilowatt

LCS

Landing Craft Ship

LCT

Landing Craft Tank

LP

Liquid Propellant

MAID

Mobile Autonomous Intelligent Device

MARDI

Mobile Advanced Robotics Defence Initiative

MBT

Main Battle Tank

MEE

Mechanical Experimental Establishment

MEXE

Military Engineering Experimental Establishment

MCV80

Mechanised Combat Vehicle 80

MGB

Medium Girder Bridge

MGO

Master General of the Ordnance

MICV

Mechanised Infantry Combat Vehicle

MLRS

Multi-Launch Rocket System

MMP

Mean Maximum Pressure

MOD

Ministry of Defence

MT

Motor Transport

MVEE

Military Vehicles and Engineering Establishment

MWEE

Mechanised Warfare Experimental Establishment

MWSD

Mechanical Warfare Supply Department

NBC

Nuclear Biological Chemical

NEC

Network Enabled Capability

NGP

Nominal Ground Pressure

ODP

Operational Demonstrator Programme

OF

Ordnance Factory

PANTILI

Panoramic Thermal Imager Laser Integrated

PE

Procurement Executive

PERME

Propellants Explosives and Rocket Motors Establishment

POL

Petrol Oils and Lubricants

PPP

Public Private Partnership

PSA

Property Services Agency

R&D

Research and Development

RA

Royal Artillery

RAC

Royal Armoured Corps

RAF

Royal Air Force

RARDE

Royal Armaments Research and Development Establishment

RASC

Royal Army Service Corps

RE

Royal Engineers

REME

Royal Electrical and Mechanical Engineers

RMG

Ranging Machine Gun

RNAS

Royal Naval Air Service

ROF

Royal Ordnance Factory

ROVA

Road Vehicle Autonomous

RSRE

Royal Signals and Radar Establishment

RTC

Royal Transport Corps

RUDA

Reduced Update Driving Aid

SAE

Special Armour Establishment

SC

Shaped Charge

SCAR

Signature Classification And Reduction

SID

Signature Integration Demonstrator

SITV

Sprung Idler Test Vehicle

SP

Self Propelled

SP70

Self Propelled Gun 70 – Joint UK-German project

SPAT

Self Propelled Anti-Tank

SRV

Suspension Research Vehicle

STAMPLAR

Sight, Thermal, Armoured, Periscope, Laser Ranging

STT

School of Tank Technology

SVDC

Special Vehicle Development Committee

TD&E

Trials Design and Experimentation

TDU

Trials and Development Unit

TED

Tom Elliott Detector

TICM

Thermal Imager Common Module

TOG

‘The Old Gang’

TOGS

Thermal Observation and Gunnery Sight

TS Dept

Tank Supply Department

TVA

Test Vehicle Aluminium

URV

Unmanned Research Vehicle

VE

Vehicle Engineering

VSI

Vehicle Systems Integration

WASAD

Wide Area Surveillance and Aided Detection

WSD

Weapon System Demonstrator

WVEE

Wheeled Vehicles Experimental Establishment

INTRODUCTION

There is currently a triangle of land on the north-east corner of Chobham Common in Surrey enclosed by a security fence. It is bounded on one side by the M3 between junctions 2 and 3 and on another by the Reading-to-Waterloo railway line at Longcross station. On the site can be seen a mixture of buildings including modern brick-built offices, corrugated iron hangars and, by the station, a large industrial-looking concrete-built building. The site is currently used by film and television crews as a set, but it has been sold for redevelopment and so soon all traces of the current buildings are likely to disappear. Once that happens there will be nothing left to indicate the significant activity that went on there for over fifty years when it was the centre for British military vehicle Research and Development (R&D).

A government research and development establishment for military vehicles existed on this site at Chobham Common from 1942 through to 2004, when the last government employees were relocated. Although on Chobham Common it was always referred to officially, and by staff, as the ‘Chertsey’ site due to its postal address. The establishment went through various name changes, but for most of its life it was known as the Fighting Vehicles Research and Development Establishment (FVRDE) and then the Military Vehicles and Engineering Establishment (MVEE). The locals simply called it the ‘Tank Factory’. To the wider world it is known as ‘Chobham’, the name given to the game-changing armour technology developed there.

Through the time it existed the Chertsey establishment became world leading in the field of military vehicle research and design, and could claim many ‘firsts’ in military vehicle technology. This document attempts to capture some of the history of UK Government involvement in tank design and testing, the factors that led up to the formation of the Chertsey establishment and its subsequent roles and activities. Above all it is intended as a tribute to those who worked there and their world-leading achievements.

The first part of the book provides an overview of tank development in the United Kingdom up until the end of the Second World War, with a focus on the role of government and the various bodies and establishments that form the lineage of Chertsey. The rest of the book focuses on Chertsey itself, describing how the structures and roles changed, the development of the site and the facilities, and finally the vehicles and technologies studied and developed there.

1

THE BIRTH OF THE TANK

The first attempt at setting up a government organisation in Britain for the procurement of military transport was in 1645 when Oliver Cromwell appointed a comissionary to hire or requisition coaches, wagons and carts for the troops in the New Model Army. Then in 1664 the Royal Carriage Works was set up at Woolwich to build wagons and gun carriages for the army, the design and build of gun carriages being a skilled activity if a robust and stable firing platform was to be provided. The comissionary was answerable to the Treasury, not the army, and this remained the situation until 24 January 1855 when a warrant was signed for the formation of the Land Transport Corps. This was set up primarily to support the Crimean campaign and had its headquarters at Horfield Barracks in Bristol.

Mechanisation in the British Army came slowly. In 1769 a French military engineer, N.J. Cugnot, built a steam-powered wheeled vehicle for towing guns, but it was much later in Britain, in 1845, that the Inspector General of Fortifications suggested that steam-powered engines could be used for military purposes. Therefore in 1855 trials of a Boydell traction engine were undertaken at Woolwich Arsenal where it towed a 68pdr gun weighing 8 tons. There are some suggestions that Boydell traction engines were deployed during the Crimean War (1853–56) to haul heavy guns into position. In 1855 James Govan suggested that a Boydell Tractor could be fitted with a cannon and an armoured cover. This was one of the first practical proposals for an armoured fighting vehicle, but the idea was rejected by Lord Palmerston as being ‘uncivilised’, particularly as the design included rotating scythes fitted to the wheels. In 1857 the Superintendent of Machinery at Woolwich Royal Carriage Department undertook a trial in which a Boydell Traction Engine was driven from Thetford to Woolwich. The 15-ton traction engine towed a load of 29 tons, the 99½-mile journey taking thirty-two hours and consuming 91cwt of coal. Having demonstrated their utility, military traction engines, including armoured Fowler engines, were deployed by the British Army in South Africa in 1885 where their uses included towing road trains.

In 1900, following some trials of petrol-driven cars and lorries for the army, a ‘Mechanical Transport Committee’ was set up. This consisted of interested branches, the Royal Artillery (RA), Royal Engineers (RE) and the Army Service Corps (ASC), who co-ordinated requirements and conducted trials. Requirements included vehicles for mobile searchlights and to tow guns.

Fowler Armoured Traction engine, as used in the Boer War around 1900. (Crown Copyright-MOD)

Key to the ultimate success of tanks was the development of tracks. The first known patent of a track-like system dates from 1713. It was filed by a Mr d’Herman at the Royal Academy of Sciences and had a system of interconnected rollers. British Patent 953/1770 of 15 February 1770, which was filed by Richard Lovell Edgeworth, proposed the use of ‘portable railways’ in which ‘several pieces of wood are connected to the carriage which moves on in regular succession in such a manner that a sufficient length of railway is constantly at rest for the wheels to roll on’. In 1826 Sir George Cayley patented a scheme for a continuous track. An ‘endless railway wheel’ was patented by a British Engineer James Boydell in 1846 and this was used on the traction engine that took part in the Woolwich trials. An Australian, Mr J.B. Hughs, reported back to his government some observations of those trials, noting that when working in the rain the wheels of the engine, which weighed 12 tons, did not sink into the ground, but those of wagons weighing 2 tons did sink.* The Boydell system, sometimes called ‘Boydell’s Girdle’, consisted of a number of plates attached to the wheels. Similar schemes of plates or feet attached to wheels included the ‘Tippings Plates’ system used for launching lifeboats across soft beaches and the Diplock Pedrail system. A Pedrail traction engine was tested at Aldershot in 1905 and the ‘Boydell’s Girdle’ system was used on some heavy First World War artillery pieces to improve mobility when being towed. In the USA, Alvin Lombard was granted a patent for a tracked log hauler and in 1901 built the first of eighty-three machines. In 1903 Benjamin Holt bought the patent rights from Lombard and in 1906 started to build the world’s first commercially successful vehicle to use tracks – the Holt Tractor.

Boydell Traction Engine. From a 1944 School of Tank Technology document on the history of Tracks by E. Micklethwaite. (Crown Copyright-MOD)

Meanwhile, in Britain in 1899 F.R. Simms fitted a Maxim machine gun with armoured shield to the handle bars of a Beeston Quadricycle powered by a 1.5hp de Dion engine. This he called a ‘Motor Scout’ and he demonstrated it at Richmond in Surrey. He went on to develop concepts for armoured cars and was asked by Vickers to design a ‘war car’, which they then built. Although such armoured cars had also been proposed by others, for example by the American E.J. Pennington in 1896, Simms was the first to turn his ideas into a fully functional prototype vehicle. It had a 16hp engine giving a speed of 9mph, was armed with two machine guns and a 1pdr gun, and had 6mm armour. It was displayed at Crystal Palace in April 1902 and offered for sale to the British and European governments without success.

In 1903 The Strand Magazine published a story by H.G. Wells, called ‘The Land Ironclads’, in which he described the battlefield of the future dominated by steam-propelled, iron-clad vehicles running on large Pedrails. During the war he was taken to visit a factory in Birmingham where tanks were being built to see how his vision of future warfare was becoming reality.

In 1907 the War Office offered a prize for a cross-country vehicle that could tow a howitzer for 40 miles without refuelling. The prize was won by a tracked petrol-driven tractor designed by David Roberts and built by R. Hornsby and Sons, who had been working on tracked tractor designs since 1905. Although it had fragile tracks with wooden shoes, a Major Donoghue suggested that it could mount a gun surrounded by an armoured shield. Another suggestion submitted to the War Office came from Australian engineer L. de Mole in 1912, who proposed an advanced tracked, armoured machine with suspension and steering through the use of bowed tracks.

The Hornsby Tractor. From a 1944 School of Tank Technology document on the history of Tracks by E. Micklethwaite. (Crown Copyright-MOD)

Although these ideas for armoured vehicles were not taken forward, mechanisation (or Mechanicalisation as it was then called) was underway in the British Army. In 1903 it had been agreed that the Army Service Corps would take over responsibility of mechanical transport from the Royal Engineers. In 1905 the ASC set up a Motor Transport Repair Depot at Hurley, near Henley-on-Thames, to support manoeuvres to test the suitability of mechanical motor transport and by 1906 a training establishment had been set up in Aldershot.

In 1914 the Admiralty purchased 100 Rolls-Royce cars for use by the Royal Naval Air Service (RNAS) for base protection. Some of these were subsequently provided with armour protection. The RNAS also carried out trials of the Killen-Strait tractor. This had tracked running gear in a tricycle arrangement and after successful trials and a demonstration on 30 June 1915 a contract was placed the following month for an armoured version with a Delaunay-Belleville armoured body. This is claimed to be the world’s first tracked, armoured vehicle that was actually built and tested.

In September 1914 Lieutenant Colonel E.D. Swinton RE (Assistant Secretary of the Committee of Imperial Defence) suggested that the US Holt Agricultural tracked tractor, then in use to tow 8in guns, could be used as the basis for an armoured vehicle. This suggestion was turned down as it was assumed that such a vehicle would be too vulnerable to artillery fire. Swinton did, however, discuss his ideas with Lieutenant Colonel M. Hankey, who was the secretary of the Committee of Imperial Defence. As a result, in February 1915, a demonstration was made to that committee of a Holt tractor towing an armoured trailer. The demonstration was considered unconvincing by the army, but Winston Churchill, as First Lord of the Admiralty, passed Swinton’s ideas on to the Admiralty Landships Committee. When Swinton met with Albert Stern, the secretary of the Landships Committee, he was said to remark, ‘Lieut. Stern, this is the most extraordinary thing that I have ever seen. The Director of Naval Construction appears to be making land battleships for the army who have never asked for them, and are doing nothing to help. You have nothing but naval ratings doing all your work.’ Swinton went on to play a key role in generating interest in tanks in the army.

Rolls-Royce Armoured Car. (Copyright W. Suttie)

The Landships Committee had only just been formed, with support from Winston Churchill, and on 24 February 1915 Mr Eustace Tennyson d’Eyncourt, a naval architect, had been appointed as Chairman. Winston Churchill had already written to Mr Herbert Asquith, the Prime Minister, complaining about the lack of efforts on behalf of the army to address the problems associated with trench warfare and modern firepower. He suggested:

It would be quite easy in a short time to fit up a number of steam tractors with small armoured shelters, in which men and machine guns could be placed, which would be bullet-proof. Used at night, they would not be affected by artillery fire to any extent. The caterpillar system would enable trenches to be crossed quite easily, and the weight of the machine would destroy all wire entanglements.

Originally the Landships Committee was housed in offices over Admiralty Arch. It is interesting to note that some members of that team had a long association with tank development. Mr N.C. Tervet worked as a draughtsman on early tank designs and at the time of his death in 1952 was working in the running-gear branch at Chertsey. The Landships Committee looked at a range of ideas for armoured vehicles suitable for crossing rough terrain. One was the Bramah Diplock ‘Pedrail’, which had evolved from a system of large pads around a wheel into a continuous track solution. In 1913 Pedrail Transport Ltd of Fulham had displayed a 10-ton petrol-driven truck that demonstrated the principle of the ‘Diplock Patent Anti-friction Self-contained Railway’. This was used as the basis for an articulated vehicle with two pairs of tracks on each side, which was assessed by the Landships Committee. The design was driven by a requirement to carry a trench-storming party of forty men stood side by side in two rows, but it was soon realised that the long length of the vehicle would cause problems.

Another vehicle was the Tritton Trencher. This had wheels on a long chassis extension to reach across a gap so that planks could then be emplaced for the rest of the vehicle to cross; this design was dropped after trials in June 1915 as it proved too cumbersome.

Even less practical were concepts that used very large wheels to cross rough terrain. A concept for a device with 40ft wheels and powered by an 800hp submarine engine was developed and a design contract placed with Messrs Foster and Company of Lincoln. The contract was soon stopped when full-size mock-ups were being built as it was realised that such a large vehicle would provide an easy target for enemy artillery.

By 23 June 1915 the Landships Committee was in possession of a Killen-Strait tractor, two Diplock experimental 1-ton wagons and two Giant Creeper Grip tractors purchased from the USA. A test site had been acquired at Burton-upon-Trent and the Ministry of Munitions Experimental Ground at Wembley was also used for trials. Appointed to provide support to the committee was 20 Squadron of the Royal Naval Armoured Car Division because at that time the army was unable, or unwilling, to provide support. Two ‘Land Battleships’ were under construction, one based on the Pedrail solution and the other using the ‘creeper grip’ tracks from the USA. A more practical solution was based on armouring a US Bullock-tracked tractor and an RNAS team commanded by Lt Walter G. Wilson conducted trials of this machine at Burton-upon-Trent. The development work on the Bullock tractor had been carried out by Fosters of Lincoln who made wheeled tractors for the artillery and had already been involved in the big-wheel concepts.

D’Eyncourt asked Fosters to design a machine that had ‘strong armour, powerful guns and the ability to cross trenches and other obstacles’. On 15 June 1915 Swinton issued a specification for such a machine, which included the ability to climb a 5ft bank, cross a 5ft gap, be proof against armour-piercing bullets, carry a quick-firing gun and machine guns, and have a speed of around 4mph. A number of complex and ingenious solutions were considered, but in the end it was recognised that a simple robust solution was needed. Finally in response to the requirement they built Lincoln No. 1 – the world’s first true tank. Designed by William Tritton, and so also called the ‘Tritton Machine’, it used a pair of 9ft Bullock tracks. The actual contract for the vehicle was placed on 29 July 1915 and it ran on 6 September 1915 with trench crossing trials first carried out on 19 September. The vehicle was constructed using available parts including the Bullock tracks and the engine and transmission used in heavy howitzer tractors. It was built of boiler plate of the correct weight and had a dummy turret also of the correct weight. Although it demonstrated the ability to cross a small trench, the tracks were inadequate.

Design of a second vehicle had started before the first was completed, and a wooden mock-up was viewed by members of the Landships Committee on 26 August. Key to improvements with the second vehicle was the development of a new track based on pressed-steel plates designed by Tritton and Lt W.G. Wilson. This vehicle, called Little Willie, retained the same hull but had longer tracks of the new design and was completed in December 1915. The September trials had highlighted mobility limitations and so, with the input of Swinton’s ideas, Fosters had immediately started work on concepts that evolved into a new design. This was variously called the Wilson Machine, Centipede, Big Willie and finally Mother. The term ‘Tank’ was used for the vehicles at this time as part of secrecy measures. The requirement for a suitable name had been recognised as the term ‘Landship’ was thought to be too descriptive. Mr d’Eyncourt suggested the term ‘Water Carrier’ as the cover name, but as government departments tended to be referred to by their initials this idea was rejected and the name ‘Tank’ adopted; hence the Landships Committee became the Tank Supply, or TS, Committee.

Although the design of Little Willie was obsolete before the vehicle was completed it actually formed part of the UK defences in the Second World War, initially as a static strongpoint north of Bovington camp before moving to enhance the defences of a Gloucestershire airfield. Such uses of this and other vehicles in the Bovington museum collection prevented them from being melted down for much needed scrap metal.

‘Mother’ introduced the classic rhomboid shape of First World War heavy tanks, which was driven by the requirement to climb over high walls and parapets. A full-size mock-up was quickly completed and displayed at Wembley on 29 September, and despite reservations from some army officers instructions were given to Tritton to build a prototype as soon as possible. ‘Mother’ was ready for its first run at Lincoln on 3 December 1915. There was concern about the impact of firing the main weapon on the sponsons in which they were mounted, and on the crew, and therefore soon after it was ready Mother was taken to a nearby field for a test firing of one of the QF 6pdr guns. The first shot was a misfire and when the crew were still examining the breach the round went off. As the direction the shot went in was not known there was initial concern for the safety of Lincoln Cathedral, which was only a mile away, but after searching for two hours the shot was eventually found and no damage had been done. Mother left Lincoln on 26 January and was taken by train to Hatfield Station where it was unloaded at night and driven to Hatfield Park.

Instructions had been given by Lord Kitchener on 29 December 1915 for a trial of the sample machine being built, stating that, ‘the first thing … would be to test its practical utility under field conditions; without such a test we may be wasting material and men uselessly.’ Hatfield Park had been lent by Lord Salisbury for the trials following an arrangement made with Mr d’Eyncourt in the previous October as Wembley was considered inadequate for full testing and demonstration. A working party consisting of men of the 3rd (Mid Herts) Battalion Herts Volunteer Regiment and a company of engineers, lent by the War Office, began to construct trenches and obstacles early in January 1916. The machine successfully negotiated the resulting course on 29 January and the following day Mr d’Eyncourt informed Lord Kitchener that the ‘Centipede’ could be demonstrated on 2 February.

The official demonstration took place in the presence of Lord Kitchener and officers of the General Staff, War Office, Officers of the Staff of the Commander-in-Chief, the First Lord and other members of the Admiralty and the Minister of Munitions. Soon afterwards, on 8 February, the machine was demonstrated to the King. The demonstrations were in three parts, negotiating obstacles that reflected the official performance requirements, a test course representative of assumed combat use and finally negotiating obstacles that demonstrated the full capabilities of the vehicle. The official test obstacles included a parapet 4ft 6in high followed by a gap 5ft wide. The representative test course included gaps and parapets, wire entanglements, two shell craters, water-logged ground and typical German defences. The demonstration of actual capability included a 5ft 6in parapet and a 9ft-wide gap, which were successfully navigated. On 14 February Mr d’Eyncourt wrote to Mr Churchill describing the success of the vehicle stating:

Wire entanglements it goes through like a rhinoceros through a field of corn. It carries two 6-pdr. guns in sponsons (a naval touch) which can fire right ahead and enfilade the trenches on the broadside. It is proof against machine-gun fire. It can be conveyed by rail (the sponsons and guns take off, making it lighter), and can be put together ready for action and proceed independently at short notice … The wheels behind form a rudder for steering a course and also absorb the shock over banks, but are not absolutely necessary.

Following the successful demonstrations on 12 February, Lloyd George, Minister for Munitions, signed a Charter for the TS Committee to deliver 100 tanks, with a request that they be available within six months. This was followed on 3 April by orders for a further fifty tanks. Orders for fifty Mark IIs and fifty Mark IIIs followed. Of the first 100 tanks twenty-five were built by Fosters and the rest by the Metropolitan Carriage, Wagon and Finance Company at Wednesbury. Armour plate was ordered from Cammell Laird, Vickers-Armstrong and Beardmore. The Mark II and Mark III versions had a number of minor improvements over the Mark Is and the Mark IIIs had improved-quality armour to defeat the German anti-tank rifle. There had been ongoing work to improve the quality of armour since it had been discovered that some German bullets could easily penetrate the plates used on armoured cars. Further improved armour materials to defeat the German armour-piercing bullet were developed with help from the ‘Armour-Plate Design Department’ of Messrs Beardmore.

In March 1916 the forerunner of the Tank Corps was formed under Colonel Swinton as the Heavy Section of the Machine Gun Corps, initially based at Bisley. The Machine Gun Corps had itself been formed in October 1915 with Infantry, Cavalry and Motor branches. The Motor Branch brought together the Motor Machine Gun Service, which had been administered by the Royal Artillery and equipped with motor cycle mounted machine guns, and the armoured car squadrons from the Royal Naval Armoured Car Service. Therefore when the Heavy Section was formed there was a mix of officers and men from the Royal Navy and the motor trade as well as from the army. In addition to initial training at Bisley, the Naval Gunnery School at Whale Island provided training in the use of the 6pdr guns. The Heavy Machine Gun Corps with forty-nine vehicles took part in the first operational use of tanks at Flers-Courcelette on 15 September 1916.

Mark IV Tank. (Copyright W. Suttie)

By August 1916 a training camp for the Heavy Section had been set up at Elveden Camp in Norfolk. The training area there was well guarded to keep people away and the presence of Royal Engineers, to build trenches and earth works for realistic training, led to a rumour among the local populous that it was the site of a tunnel being built to Germany. In October 1916 the Heavy Section was relocated to Bovington Camp near Wool where the ‘Tank Centre’ was set up under the command of Brigadier Anley. This had been used as an Infantry Training Area since 1899 but had expanded significantly at the start of the war in order to train the many new recruits who had responded to Lord Kitchener’s call for volunteers. Thus began the association of Bovington with armoured vehicles, which still continues today. In November 1916 the Heavy Section became the Heavy Branch.

Even after the success of the first tanks work continued on the Pedrail concept. A Major A.R. Glasford made some proposals in a paper on the ‘neutralisation of the trench as an obstacle’, forwarded through G.H.Q. France on 3 September 1915. The paper suggested that it would be possible to ‘carry the attack with lethal gases right into the enemy hues by means of a Pedrail caterpillar, of which the main armament would be a liquid, such as hydrocyanic acid, deadly in effect but not so persistent as to hamper the attacking infantry’. The design and manufacture of a Pedrail machine carrying a flame-projector was then already in progress, in line with requirements agreed at a conference held on 28 August 1915. Construction of the parts of this machine was largely completed by 17 February 1916 but it lacked a solution for armour, which would have been too heavy due to its size. The machine, which was commonly called the ‘Trench Warfare Caterpillar’, was finally ready to leave the works on 22 July 1916. As completed it ran on two Pedrail units arranged in tandem and driven by Aster engines. The frame was 33ft 4in long by 9ft 4in wide. It was sent to Porton for trials early in August 1916, but development stopped due to problems with the Pedrail feet when running on roads.

In order to streamline processes with the focus now on production, the TS Committee became the Tank Supply Department. The TS Department had offices at 17 Cockspur Street, London and trial grounds at Dollis Hill in North London and Oldbury in Worcestershire. The Department continued design work and, seeing the need to maintain design and manufacturing capabilities pending new orders for tanks, started work on designing a gun carrier for 5in howitzers. Design work started in April 1916 and the design modified following review in June 1916. An order was placed for fifty, the last two of which were completed as ‘Salvage Tanks’ to aid the retrieval and dismantling of damaged or destroyed tanks.

The initial successes of the first tanks led to an order for a further 1,000 placed on 19 September 1916, just a few days after the first operational use. However, this order was cancelled by the Army Council just twenty-one days later on 10 October. Only the direct intervention of Lloyd George, then Secretary for War, enabled the order to be reinstated the very next day. The order resulted in the delivery of 1,015 of the Mark IV version, which had a number of improvements, particularly to crew conditions, and included thicker armour, an exhaust silencer (to give the enemy less notice of approach) and provision for an un-ditching beam. In February 1917 an additional 205 Mark IV tender tanks were ordered for carrying supplies to the fighting tanks. The Mark IV was adopted as the standard heavy tank at that time with earlier Marks being returned to the UK to be used for training.

In order to manage the task of building 1,000 new tanks, acceptance testing and delivery along with the supply of spares, the TS Department became the Mechanical Warfare Supply Department (MWSD) reporting to the Ministry of Munitions. Key staff from the TS Department continued to work in the MWSD with Sir Albert Stern as Director and Sir Eustace d’Eyncourt as the Chief Designer.

Building 1,000 tanks was challenging not least because the Ministry of Supply had stated that Tanks were the fifth priority after aeroplanes, guns and ammunition, mechanical transport and locomotives. This meant that the supply of men and materials for construction was constrained and a request to the Ministry of Labour for 2,000 men to be engaged in building tanks resulted in just 275 being provided. Initially there were even problems getting men working on tanks issued with ‘War Lapel Badges’ – these indicated that they were undertaking critical work in support of the war effort thus preventing criticism that they were avoiding active duty. Despite the problems, by May 1917 tanks were being produced at a rate of sixty a month.

The demand for tanks meant that as the war progressed the number of companies involved in manufacture increased and included the Metropolitan Carriage, Wagon and Finance Company in Birmingham, the Coventry Ordnance Works and three factories in Glasgow: Mirlees, Watson Co. Ltd and William Beardmore Co. Ltd. The MWSD set up the ‘Tank Testing Section’ based at Newbury Racecourse and all vehicles were sent there for testing before being shipped to France.

The need to train crews for the large number of new tanks had prompted the move of training to Bovington. It was stated that, ‘The wooded country around Bovington is particularly adapted to the training of tank battalions, the rolling downs, the woods and the small streets being very similar to and as equally deserted as the battlefields of France.’* A range of training courses was developed for the new crew members including driving, maintenance, gunnery, signalling, reconnaissance and the care of pigeons. Carrier pigeons were carried by each tank for passing messages, but it is said the birds were often groggy due to the fumes in the vehicle and sometimes became emergency rations. To enhance driver training a range of courses and obstacles were built including trenches, bogs and areas of ‘no man’s land’ created with explosives. Initially the desire to keep the new ‘secret weapon’ under wraps had an impact on local residents, especially when the vehicles were driven from Wool station to the camp. People who lived on the route were required by the Military Police to close their blinds and pedestrians were told to stand in a field with their backs to the road while tanks passed. How effective these precautions were is open to question; Mr James Spicer who owned Bovington Farm told the military authorities that he had no objections to trying to help keep tanks secret but requested the removal of one that had broken down and had been towed into his farmyard and left there for forty-eight hours.

On 3 March 1917 an exhibition of vehicles was held at the Oldbury test area. In addition to British military and civilian VIPs there was a delegation from France, where they were developing their own tanks. The vehicles demonstrated included a Mark IV Heavy tank, Tritton Chaser (Prototype Medium A), the gun-carrying tank and a number of Mark IVs with alternative transmissions. These were:

1. Williams-Janney Hydraulic transmission

2. Wilson Epicyclic transmission

3. Daimler Petrol-Electric transmission

4. Westinghouse Petrol-Electric transmission

5. Wilson Multiple Clutch transmission

In July 1917, based on experience from the Battle of Arras, it was agreed that the Heavy Branch should be expanded and become the Tank Corps, but in September 1917 the expansion was cancelled only to be revived again the next month. The Mark IV was the tank used at the Battle of Cambrai on 20 November 1917 when they were deployed as originally envisaged by Colonel Swinton – in large numbers across a wide front in a surprise attack across suitable ground. In comparison with previous offensive operations, spectacular advances were made but were not exploited due to lack of sufficient infantry reinforcements to secure the ground. Even after the success at Cambrai the Tank Corps still faced difficulties with ongoing debates on how best to organise the Corps. In April 1918 expansion of the Tank Corps was again suspended, but following the victory at Hamel in July 1918 General Headquarters requested more tanks. On 31 July 1918 a branch called SD7 was created under the Director of Staff Duties in the War Office to carry out the expansion. SD7 addressed manpower and training issues along with the need to improve facilities at Wool; however the expansion was still being implemented when the Armistice came.

In addition to serving in Western Europe, eight Mark I and II tanks were sent to Egypt in January 1917 and were used against the Turks at Gaza. Mark IV tanks were also sent to Egypt in November 1917.

Development of the heavy tanks continued with the Mark V, Mark VI and Mark VII. The Mark V was the first tank that could be driven by one man; previous versions required the co-ordinated efforts of the driver, commander and two gearsmen to change direction. Over 1,000 Mark Vs of different variants were manufactured including ‘stretched’ versions, which were 4ft longer to increase trench-crossing capability. The Mark VI was designed by Major Wilson and a wooden mock-up was built by Fosters. It was to have a lower ground pressure and be faster than existing tanks, but it did not go into production due to the urgent need to mass produce existing designs. The Mark VII was longer and had an improved transmission but only three were built. Improving the mobility, protection and fightability of tanks, as reflected in the early development work, remained an ongoing theme and was the subject of extensive research many years later at the Chertsey site. The Mark VIII was a completely new design and was intended as an Anglo-American vehicle although only three prototypes of the UK version were built. The US version was powered by a derivative of the Liberty aero engine and the same engine formed the basis of that used in a number of Second World War cruiser tanks, including the Crusader. The overall design did find fame as the basis of the tank in the Indiana Jones film The Last Crusade, although the producers requested that a turret be added! When it was being designed the builder of this vehicle sought advice on tracked vehicle steering from a member of Chertsey staff.

‘Indiana Jones’ Tank based on the Mark VIII. (Copyright W. Suttie)

The final model in the family of heavy tanks was the Mark IX, which was not a tank but a purpose-designed stores or infantry carrier. Only thirty-five were built by the end of the war and they did not see action.

Even before the first tanks were fielded there was ongoing research to improve capabilities. The question of protecting tanks against shell fire was taken up after the first order was placed, and a double-skin solution was tried. It was discovered that a 1in plate with half the metal stamped out, thus halving the weight, and placed 1ft in front of the base armour, would detonate a German high-explosive shell and prevent any damage. The idea was not taken forward at that time, but more than eighty years later the Defence Science and Technology Laboratory (Dstl) demonstrated a cost-effective method for manufacturing perforated high-hardness armour steel to provide weight-efficient protection solutions.

Research was also undertaken into different solutions for roof protection. Other experiments assessed different means of communications including signal lamps, wireless and semaphore. An experimental plough was developed for laying telephone cables as the tanks advanced.

An important area of research and development was transmissions. It was realised that the initial system was inadequate and a number of alternatives were tested including a Daimler Company petrol-electric transmission, a British Westinghouse electrical tramway transmission, a Williams-Janney hydraulic transmission and the Ilcle-Shaw Company hydraulic transmission. In addition the Metropolitan Company built epicyclic and multiple-clutch transmissions designed by Major Wilson, and the St Diamond Company in France arranged to have their petrol-electric transmission installed in a hull, which was sent to them.