28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

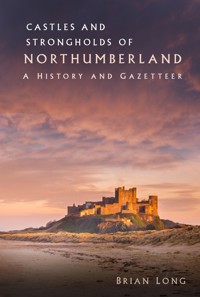

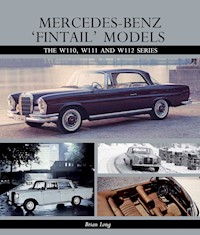

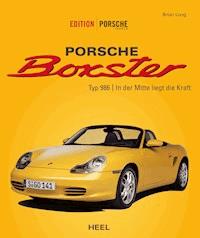

The Zero Carbon Car examines the hundreds of ways in which car manufacturers are trying to reduce our carbon footprint, and the adaptation of the automotive industry to changing technology in a world where environmental issues are becoming ever more prevalent. The book's in-depth research into green car technology shows that manufacturers make concerted efforts, but sometimes also defeat the gains of their innovation. Topics covered include: What is meant by the terms 'global warming' and 'green', and how these can be defined; An account of the long history of green automotive technology; Alternative fuels, including diesel and hydrogen; Developments in environmentally friendly engine technology; Electric cars; Environmental issues in material usage and car body manufacture. A wide-ranging survey of the hundreds of ways in which car manufacturers are trying to reduce our carbon footprint.Written in an easy-to-understand manner, the book enables the reader to fully understand what is meant by 'global warming'. Examines alternative fuels, material usage and the motive power options available to us. Superbly illustrated with 350 colour photographs.Brian Long is a professional writer and motoring historian with over sixty books to his credit.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 505

Veröffentlichungsjahr: 2013

Ähnliche

The Zero Carbon Car

Green Technology and the Automotive Industry

Brian Long

Copyright

First published in 2013 by The Crowood Press Ltd, Ramsbury, Marlborough, Wiltshire, SN8 2HR

www.crowood.com

This e-book edition first published in 2013

© Brian Long 2013

All rights reserved. This e-book is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

ISBN 978 1 84797 514 0

Frontispiece image courtesy Nissan.

CONTENTS

INTRODUCTION

The dreams of men have for centuries posed problems for engineers. Humans had looked skyward for hundreds of years, hoping to soar through the skies like a bird. The dream became a reality first through balloons and gliders, and then, just over a century ago, the world witnessed the beginnings of powered flight. Flying between continents is now something we take for granted, and even space travel is not beyond us.

Closer to the ground, Stephenson’s ‘Rocket’ harnessed the power of steam to become the world’s first successful steam train. By the 1920s, steam trains such as ‘The Flying Scotsman’ were hitting 160km/h (100mph) in Britain, and the elegant streamliners that followed in the next decade would continue to take speeds higher. After the war, the wonders of electricity brought a whole new generation of high-speed trains into being, and now linear motors promise previously unheard-of levels of performance.

A fine piece of Mercedes-Benz advertising from 1994, stating that an automobile needn’t cost the Earth. A play on words, but the ‘Green’ message comes through loud and clear. Daimler AG

As for cars, those early horseless carriages that used to chug along at a snail’s pace soon evolved into practical machines that could enter in town-to-town races, with drivetrain and chassis refinements being introduced on an almost daily basis once motoring had become accepted by the masses. Nowadays, even the average road car is faster than a works rally machine from the early 1970s, and, generally speaking, certainly a whole lot more reliable.

The latest problem facing engineers is not so much about following dreams – creating machines capable of defying the laws of gravity, covering huge distances or possessing stunning levels of performance – but how to develop motor vehicles suitable for everyday use that leave as small a carbon footprint as possible.

Global warming, along with ozone-layer depletion, is something that concerns us all, and not just polar bears. Even if we look the other way now, claiming there’s nothing to worry about in the immediate future, there’s certainly cause to be worried for the generations to come, including our children. In a number of countries the warning signs are already there, with air pollution creating a very real threat to health and the environment today. Motor vehicles have been singled out as a significant source of the problem, and while cynics such as myself ask why the same level of fuss isn’t made over deforestation for logging, or beef production for fast-food chains, the fact is that cars and trucks are simply not ‘clean’ machines.

Having ignored the risk to the planet’s atmosphere – and therefore our own well-being in general – for far too long, we are now rushing to find all manner of ways to clean up the environment. The automobile industry is making a sterling effort to do its part through advanced engineering aimed at reducing emissions and our carbon footprint, all the way from the manufacturing stage to the recycling of a product once it has served its purpose.

In the background, the pace of research on sustainability is being picked up, with alternatives to fossil fuels finally being investigated with an open mind. In fact the second generation bio-fuels could be the answer to a lot of our problems. At the end of the day, engineers can only go so far – they are not capable of miracles, and cleaner, more eco-friendly fuels are therefore an important part of the overall ‘Green’ picture.

After starting the research for this book, ploughing through a political minefield along the way, even a car-crazy guy like me has to admit that something needs to be done quickly – and it’s mildly comforting to record that something is – maybe not as much as could be done, but it’s a start.

Putting things in historical perspective – which in itself should bring forth more than a few surprises for the casual observer – this book sets out to outline some of the progress being made in this relatively new field of technology. It also – in order to give balance – sets out to explode some of the myths, to simplify the science into layman’s terms to help the reader decide what is and what isn’t eco-friendly in the real world, and to break down some of the propaganda in the process.

After all, ‘Green’ sells in today’s marketplace, and with careful wording in the promotional paperwork and snazzy television adverts, some things are made out to be far better for the environment than they are in reality. Car companies, and certain countries as a whole, often push ecology issues for good PR, but mainly for financial reasons and/or political gain, often having little interest in going all the way down the Green or Blue path to tackle problems in a proper fashion. The quandary facing our planet is not new, but it will also be found that some of the solutions have been available to us for decades.

Brian Long Chiba City, Japan

CHAPTER ONE

ZERO CARBON: WHAT EXACTLY DOES IT MEAN?

Nowadays we hear or see the phrase ‘zero carbon’ on an almost daily basis, used by government departments and manufacturers in fields as diverse as house building through to the motor industry. But what does it actually mean, both in the literal sense and, just as importantly, in the real world?

Every day we are subjected to ‘Greenwashing’ – people jumping on the eco bandwagon to further their image or cause. But saving the planet is important. It’s also our moral duty, as it’s the only place mankind has to live. NASA-JPL

Basically, zero carbon (sometimes referred to as ‘carbon neutrality’) describes a nett emissions goal, aimed at significantly reducing, and ultimately eliminating, the release of greenhouse gases (often shortened to the initials ‘GHG’) that cause damage to the planet’s delicate ozone layer. Some of these gases build up and trap the radiation that should bounce off the Earth’s surface into space (the greenhouse effect, leading to global warming), while others deplete the ozone layer, leaving us exposed to harmful UV B rays from the sun.

Carbon dioxide (CO2) is recognized as the main culprit in upsetting the balance of the ozone layer, but worldwide controls are being called for on the discharge of other radiative greenhouse gases, such as methane (CH4), nitrous oxide (N2O), chlorofluorocarbons (CFCs), hydrochlorofluorocarbons (HCFCs), hydrofluorocarbons (HFCs), sulphur hex-afluoride (SF6), and perfluorocarbons (PFCs).

After water vapour in the atmosphere, over which we have little control, carbon dioxide is classed as the largest contributor to the greenhouse effect. For clarity, all greenhouse gases are given a ‘CO2 equivalent’ (CDE) rating, to bring their damage levels into perspective. Methane is less of a threat by volume, but its global warming potential (GWP) is said to be seventy-two times higher than carbon dioxide over a twenty-year timescale, while nitrous oxide is some 289 times higher. Certain chemicals outlined in the Kyoto Protocol are several thousand times more likely to have a long-term radiative effect, which would ultimately accelerate global warming.

Burning fossil fuels is recognized as being responsible for creating around 21 billion tonnes of carbon dioxide each year, not to mention being a chief cause behind other forms of air pollution. It is the speed with which we are upsetting the balance of nature that frightens scientists, with the eco-system unable to absorb the levels of emissions we are producing.

In the background, the sustainability question also has to be raised. Even though it is a rather different problem to global warming, our current energy policies mean the two are related. As James Zachos of the University of California recently said: ‘With fossil fuels today, we’re taking what took millions of years to accumulate and releasing it in a geological instant.’

A drawing showing how an increase in GHGs can expedite global warming. NASA-GSFC

Satellite image of the hole in the ozone layer over the Antarctic. This series of shots was taken in 1979, 1989 and 2006, with dark blue and purple showing the worst affected areas. NASA-GSFC

One should also bear in mind that CFCs and HCFCs, commonly found in refrigerants, aerosols and solvents, have the ability to destroy the ozone layer, as do other gases which are either man-made or occur naturally as part of the mechanism of the eco-system. We talk about the delicacy of the ozone layer, but it’s hard to imagine just how flimsy it is. To give the reader some idea of the scale, if it were compressed down to air pressure at 0ºC, it is only 3mm (0.12in) thick, yet it absorbs around 98 per cent of the sun’s UV B rays, protecting the planet and its inhabitants. Since the 1970s, ozone-layer depletion has been recorded at a rate of about 4 per cent every decade. Due to the unusually cold weather, ozone loss over the Arctic was so severe in 2011 that scientists reported an ‘ozone hole’ like the one that already exists in the Antarctic.

A hole-punch cloud, or a fall-streak hole, photographed by the author in the summer of 2011. This form of cloud seeding is thought to relate to jet aircraft activity, but, being a totally new phenomenon, the exact science behind it, and its impact on local climate, is as yet unknown. B. Long

GLOBAL WARMING

In historical terms, global warming has become a top news item only recently. The greenhouse effect has been recognized for well over a century, but it wasn’t until 1974 that ozone depletion was first recognized by scientists. Even then, no one really took any notice, and as a result, the layman had never really considered it to be an issue. Now, of course, in this age of electronic communication, one is bombarded with ‘facts’ citing gloom and doom, and counter-facts that tell us not to worry.

Certain governments have deliberately employed scientists to challenge established data, saying industry and current lifestyle practices are not the cause of global warming. This is simply a case of politicians pandering to lobbyists who are only interested in protecting their livelihood and short-term profit margins.

Yes, the world may be warming up naturally due to sunspot activity, and it’s easy to point out that Earth has been through phases before, which have taken us through from a world in the tropics to the Ice Age – but to ignore the damage being done by the planet’s inhabitants is foolish in the extreme. For instance, the smog that shrouds London, Madrid, Milan and Athens from time to time, as well as Mexico City and highly populated parts of California and Japan, now covers huge chunks of China on a daily basis, and is entirely of our own doing.

The British government appointed a ‘Royal Commission on Noxious Vapours’ in 1876. The smog over Britain today (this picture was taken in April 2011, when the brownish haze hovering over the capital triggered an air quality alert) cannot be blamed on the Industrial Revolution. MODIS Rapid Response Team at NASA-GSFC

We may or may not be able to stop the polar ice caps melting little by little – an unlikely situation in the Antarctic, as it happens, and not really a big problem in the Arctic beyond wildlife concerns, as this is floating ice – though we definitely need to avoid the ice sheets of Greenland melting away, otherwise sea levels could rise by as much as seven metres! However, we can certainly reduce ozone-layer damage, and we can certainly make an effort to keep the air we breathe as clean as possible.

We have the tools to address the problem, but it seems that politicians often feel they have to look after those who funded their rise to power before they think of their children’s future. They often appear to be too selective, creating taxes that hurt the ‘little man’ in a bid to look ‘Green’ on the surface, whilst happily turning a blind eye towards the real villains in the equation, coming up with wondrous schemes such as ‘carbon offsetting’, which allows polluting countries to continue gushing out emissions to the same degree as before. It may ease the minds of certain people in government or within a big corporation to know that a tree is being planted somewhere, to show that they have ‘done their bit’ in saving the environment, but the bottom line is that without further thought regarding the use of commodities and construction materials, waste control and recycling, nothing has changed to any great extent.

Meanwhile the motorist has been an easy target for taxation for decades. People resist less when they are told that the money they are handing over is for the benefit of the planet – but the reality is that cars are only a small part of the problem. Factors such as deforestation, coal-powered electricity generation, cement factories and air travel do far more harm. Even meat production for fast-food chains has a massive impact, accounting for around 20 per cent of the world’s CO2 equivalent emissions – it has been said that to get enough meat for one hamburger produces about the same amount of greenhouse gases as an average car driven for ten miles!

That’s not to say finger-pointing is the answer, with certain industries being given an easier ride because they pollute less than others. That is simply sidestepping the issue, something which has been done for far too long already. Something constructive – taking in the big picture – needs to be done on all fronts, from stricter emission controls for all nations (regardless of their ‘developed’ or ‘developing’ status) to improving roads and public transport systems.

Strange weather patterns are becoming the norm. There are those who are happy to pass this off as a separate issue to global warming, but records show that El Niño and La Niña have been occurring more frequently and with greater intensity since the 1970s. NASA-JPL

SELLING GREEN

In this day and age there’s no doubt that turning attention towards ‘Green’ issues can be a great selling point, bringing popularity to companies and individuals alike, even if the words they put forward are empty. We only need to reflect on Al Gore’s comeback from the political wilderness after taking up the subject of climate change to see how easily public opinion can be swayed.

It wasn’t always this way, however, with presentation being as much a part of the problem as the lack of scientific data to back claims up. In reality, the early British ‘Green’ movement probably did more harm than good, shouting its cause from beaten-up Morris Minors that obviously hadn’t been maintained since the day they rolled off the line at Cowley. People more often than not dismissed them as a bunch of scruffy eccentrics – although they did have a point, in that it takes a huge amount of energy to create a new car from scratch (releasing as much as 15 tonnes of CO2 along the way, according to some estimations), so it’s therefore greener to run a vehicle that already exists, assuming that it’s still in good all-round condition.

Had the Green brigade said the same thing from a gleaming, in-tune Minor whilst wearing sharp suits, maybe more folks would have listened, and forced British makers to buck up their ideas. Introducing new technology to answer the critics at that time, developing new cars that were attractive, fuel-efficient, eco-friendly and reliable, instead of plodding along with warmed-over running gear from the 1950s, might just have saved the bulk of the UK industry. Who knows?

On saying that, projects with the noble aim of reducing our carbon footprint had of course been tried before, with the Porsche-developed FLA ‘Long Life Car’ being a perfect example. It featured mechanical components designed to last a minimum of ten years, and corrosion-free body panels made of stainless steel and aluminium (easier to recycle than plastics at the time). Ironically there was so much opposition from within the car industry that the designs were shelved almost four decades ago.

AN IMPOSSIBLE DREAM?

So is the idea of a zero-carbon car an impossible dream? For the time being, at least, it’s not easy to achieve, mainly because of our not particularly eco-friendly sources of electrical power, employed not only to create an automobile from scratch (from the manufacture of raw materials to the end of the production line), but to keep what should officially be the cleanest of all cars – the electric vehicle (EV) – charged up and ready to roll.

Solar power gives a close-to-ideal scenario from a ‘Green’ point of view, assuming the necessary equipment can stay in service for a fairly long period of time (say, twenty-five to thirty years), and panel production techniques are properly monitored, but there are still very few houses equipped with solar panels. Wind energy just isn’t practical, so we end up coming back to traditional methods of generating power, which are far from eco-friendly, as is evident from the data table.

CO2 Emissions by Energy Source

Half of America’s electricity comes from coal-fired plants, which may be 80 per cent cleaner than they were in 1970, but the release of CO2 into the atmosphere is still very high, while a third of the UK’s electricity is made that way. The zero emissions performance of an EV is therefore wiped out during the battery-charging process, unless the grid is hooked up to a hydro-electric plant (all too rare, often damaging to a local eco-system, and sometimes set up in such a way as to waste as much electricity as it produces!) or a nuclear facility.

Coal-fired electricity plants can bring a question mark over the ‘Green’ credentials of EVs. Wknight94/Creative Commons

Nuclear power is a relatively clean and widespread source of energy in certain countries (possibly even cleaner than wind energy with all things taken into account, and certainly thousands of times more practical), but the recent disaster in Japan has raised many questions, and a wave of public mistrust has swept across Europe, putting plans for further nuclear power stations on hold; it has also provided the US government with an ideal excuse not to invest in its infrastructure while funds are tight, meaning the burning of fossil fuels will continue for many years yet. With coal plentiful and half a million US jobs depending on it, the chance of changing to a cleaner energy is very slim at best.

More chilling, perhaps, is the fact that around 80 per cent of China’s electricity is produced using coal-fired plants; moreover, China has no intention of changing its energy policy any time soon (it will probably stay much the same until at least 2020), as coal is still cheap and plentiful in this vast country. It’s not so much the recharging of electric vehicles that bothers us here, but the sheer number of components made in China, aptly nicknamed ‘the world’s factory’. Add this into the equation, along with further damage caused to the environment by long-distance shipping, and unless outsourcing policies within the automotive industry change dramatically, a true zero-carbon car may forever be out of the question.

Engineers may be striving to design more eco-friendly cars and components, but accountants can undo their work in minutes by having parts made thousands of miles from assembly sites – cargo ships are a huge source of pollution, more often than not using low-grade bunker fuel, which has 2,000 times the sulphur content of road transport diesel. The largest ships burn 350 tonnes of fuel a day, creating 300,000 tonnes of CO2 over a year, and SOx emissions that add up to the equivalent of 50 million cars. FEMA Photo Library/Robert Kaufmann

The Spread of Energy Generation in Selected Countries

We also have to consider things such as battery production and disposal, and whether the high costs involved in changing battery packs on ageing vehicles will simply put another serviceable machine off the road prematurely. Yes, the motor industry needs to make and sell new cars, but the energy used in creating and recycling a vehicle is huge. And where does all this energy come from?

ZERO CARBON IN TODAY’S CAR WORLD

In reality, the term ‘zero carbon’ mainly concerns the energy efficiency of a product after it has been built, but many highly responsible companies with an eye on the future are now making rigorous efforts to reduce their carbon footprint during the build process as well. It is a question of balancing the release of harmful gases with renewable energy and zero-emission technology.

In the automotive engineering world, reaching zero-carbon goals can be done in many different ways, but by far the most popular approach at the moment is the reduction of exhaust emissions – something actively tackled by countries such as Japan and the US state of California for several decades, albeit with mixed results in the early days, as car manufacturers sought to comply with regulations without reducing performance levels – until very recently, marketing muscle and glamour came before highlighting ‘Green’ issues.

Cars are very much a fashion statement – we’ve come to expect a little glamour from our steed. And who can blame us? A car is recognized as the second biggest purchase we’ll ever make in our lives; for those not interested in housing, it usually becomes number one! At the end of the day, manufacturers make what we demand – very few will have the nerve to try and re-educate us, telling us what we should be buying. Ultimately, the car business is a market-led industry. GM and Alfa Romeo

THE FUTURE OF OIL RESERVES

Thinking about the environment is something that concerns us all, as outlined in the section ‘Global Warming’ at the beginning of this chapter. But there’s another reason why we have to consider different fuels or alternatives to traditional car engines, and that is the future oil reserve situation.

While Saudi Arabia has for the last couple of decades had around 250 billion barrels of oil reserves in hand, which accounted for almost one-fifth of the world’s reserves, recently Venezuela has found a rich heavy crude deposit in the Orinoco Belt. This may or may not be easy to recover, but suddenly Venezuela could be sitting on 300 billion barrels of reserves, as compared to 100 billion four years earlier.

Using the current proven figures (as opposed to estimates and recent finds that may yet yield very little, despite their great potential, due to a combination of extraction costs and technical reasons) – which, by the way, give Venezuela a 7 per cent share of global oil reserves – at the current rate of production and consumption, the world could actually run out of oil in about sixty-five years. This may sound a long way off, but other estimates bring the day of reckoning decades sooner, and can you remember where the last ten years went?

It is also important to consider the rapid growth of motoring in China and developing countries, which would almost certainly bring a faster drain on reserves than any savings that can be made through improved technology. Furthermore, the current wave of global anti-nuclear feeling following the huge M9.0 earthquake off the Japanese coast may also deplete reserves that much more quickly.

Ironically, after all these years of making certain oil-producing countries rich beyond imagination, talk within the motor industry of moving over to renewable alternative fuels and the more efficient forms of hybrid engineering already has OPEC members calling for compensation for lost earnings! So much for the planet, but it also gives a realistic view of what most corporations, and the countries that house them, really consider to be the most important thing, despite the nice PR handouts. When it comes to a choice between the environment and short-term gain, I’m afraid to say that money wins out every time.

Top Fifteen Countries Ranked by their Oil Reserves

There’s a limit to the amount of oil we can drill for, which, in addition to environmental concerns, gives us another reason to use wisely what’s available. As well as thinking outside the box with motive power units, we have to start developing alternatives to petroleum products that serve our needs with true long-term benefits, as opposed to short-term visions and hype. No one is saying it will be easy, but time is against us. Genghiskhanviet

Looking back as a motoring historian, one can conclude with a certain amount of cynicism that the various Middle East crises were responsible for sparking off a dramatic rise in gasoline prices, and that this was often the root cause behind the introduction of more energy-efficient vehicles, rather than concerns for the planet. In addition, stricter safety rules, especially those imposed by America – as well as fashion trends in certain countries (a 2011 survey by Tesco’s in the UK, for instance, found that the school run car of dreams was the BMW X5, showing the mindset of ordinary people and the power of image marketing) – brought ever bigger and heavier vehicles into being. As a result, in many cases when one analyses model development, most of the gains that could have been made in creating cleaner, environmentally friendly vehicles were severely compromised.

Returning to the twenty-first century, it’s fair to say that combustion technology is being refined all the time on both petrol and diesel engines, as is the development of alternatives to fossil fuels, and electric power, the latter often combined with a petrol powerplant to create a hybrid vehicle. Efforts are also being made to create lighter, more aerodynamic bodies, and across the globe, production techniques and material usage are under constant revision to try and reduce the impact on the planet during the entire manufacturing stage.

Even at the end of a product’s useful lifespan, engineers and designers have put in place ways to recycle component parts easily – the role of the traditional scrapyard crusher, used to flatten or sometimes compact a car down to the size of a small cube, is rapidly becoming outdated in the majority of developed countries, with each piece of the vehicle being marked with an international code for separation by material type, which then enables more efficient recycling. Only when a bare steel bodyshell is left does the crusher come into play, with the metal almost certainly being used once again after it has been melted down and re-formed into a useful shape. Recycling steel uses less energy than making steel from iron ore, by the way, so the environment benefits in this way, too.

IN SUMMARY

For numerous reasons, both technically and, most likely, politically, due to certain countries refusing to pull their heads out of the sand, a true zero-carbon industry is probably a long way off. Being totally realistic, it’s something that may not be an achievable goal even within our lifetime. But at least problems have been acknowledged, and after decades of ignoring, or skirting around issues at best, the first serious steps – for better or worse – are at last being taken towards making current and future motor vehicles more environmentally friendly. The chapters that follow look into what is being done, with a historical overview to put things into context, before a final section that tries to gaze into the decades ahead.

CHAPTER TWO

THE DIESEL BOOM

In recent years, one can safely say that in any number of major European cities, literally half the new cars on the road are powered by a diesel engine. This is probably as good a time as any to admit that I’ve never been a fan of diesel, and only a decade ago it would have taken the best salesman in the world to convince me that I should have embraced this technology with the same verve as seemingly every other person in Europe!

In some respects the way diesel has been considered over the years is like tobacco – we all know the health issues, not just for smokers but for innocent bystanders too, but governments continue to support sales due to the huge tax revenues they generate in the short term. Likewise diesel has its problems, but powerful lobby groups, from America to India, somehow kept them off the agenda at times when the damning data should at least have been aired. That said, the author will strive to outline the good and bad points of diesel fairly and objectively (both from today’s perspective and historically), pointing out the vast improvements that have been made in emission control, and will try to assess exactly how diesel engines can help reduce our carbon footprint in the future.

Happily it looks as if there is an answer in the pipeline, and one that will silence even the strongest critics. Ironically, in addition to recent leading-edge technology such as the remarkable ‘BlueTec’ system, part of the equation has been there for almost a century, its benefits left largely untapped thanks to the political wont of certain countries for whom oil is a symbol of wealth and world power.

THE BIRTH OF THE DIESEL ENGINE

Gasoline engines, or at least readily recognizable versions of the breed, had already been around for over a decade before the first diesel powerplant appeared. Interestingly it was Germany that led the way in petrol engine technology, with Gottlieb Daimler refining the four-stroke Otto-cycle principle to make a series of practical units fed fuel through carburettors, while Wilhelm Maybach and Carl Benz provided, respectively, the necessary cooperation and rivalry to keep development moving at a fast pace in these pioneering days of automotive engineering.

The diesel power unit, named after its inventor, Rudolf Diesel, was a completely new concept in internal combustion engines, using the compression stroke to cause ignition of the fuel-air mixture rather than an electrical spark. This meant a reduction in parts, and with ignition components notoriously delicate at the turn of the twentieth century, combined with the promise of better fuel economy, the new motor – often referred to as a CI unit, the initials standing for ‘compression ignition’ – therefore held great appeal as the first real alternative to the gasoline engine.

Rudolf Diesel was born in Paris in the spring of 1858 to Bavarian parents, but following the outbreak of the Franco-Prussian War in the summer of 1870, he moved to the land of his ancestors to settle with his family in Augsburg. Diesel quickly showed an interest in engineering and then promptly displayed a talent for the subject, both academically and practically: a large number of patents were filed in his name in Germany and France. After working with steam engines, he studied thermodynamics whilst laid up in hospital, and then moved on to develop his own type of powerplant based on the mechanics of the four-stroke cycle – the diesel engine.

Rudolf Diesel, inventor of the diesel engine. Born in March 1858, he died in mysterious circumstances at sea in September 1913. Some have pointed to a conspiracy theory involving German nationalists, as Diesel had close links with France, Britain and the United States, but an accident or suicide seems a more likely explanation for his death. This German stamp was released to celebrate the 100th anniversary of his birth. Deutsche Bundespost

Diesel first published a book containing an outline theory and proposal for the construction of what he termed a ‘rational heat engine’ in 1893. This was the basis for the diesel engine that followed – although it has to be said that without the continued help of MAN AG, the project may never have come to fruition. Notwithstanding, more patents were filed in Europe and America in Diesel’s name, and by 1898 his patents had made him a millionaire, as diesel power proved to be far superior to steam in terms of mechanical efficiency – up to seven times higher on paper, although closer to five times higher in reality. Even using the latter figure, it was a significant improvement on the steam engines that had given birth to the Industrial Revolution.

An early diesel stationary engine. MAN Diesel & Turbo

THE OTTO CYCLE

The Otto cycle is another name for the four-stroke system applied to internal combustion engines. The name ‘Otto’ comes out of respect for Nikolaus August Otto, father of the four-stroke principle, while the four-stroke moniker describes the four piston movements necessary to complete one combustion cycle in conjunction with suitable inlet and exhaust valve operation, a method of igniting a measured fuel-air mixture, and a crankshaft with offset crankpins to keep pistons moving in the desired direction. The four ‘strokes’ can be summed up as follows:

Intake: As the piston moves down the cylinder, a suitable fuel-air mixture is drawn into the combustion chamber through the open inlet valve. The exhaust valve is closed at this stage.

Compression: Both valves are closed, allowing the fuel-air mixture to be compressed within the combustion chamber as the piston rises in the cylinder.

Power: With both valves closed, the fuel-air mixture is ignited either by a spark or an increase in heat through extreme pressure (via a higher c/r, as in the diesel engine), the resulting controlled explosion pushing the piston back down again.

Exhaust: As the piston starts to rise again, the inlet valve remains shut, but the exhaust valve opens, allowing burnt gases to exit the combustion chamber.

At the start of the next chapter a series of drawings shows the four strokes and the way the engine’s internal components move in relation to them.

Slowly but surely replacing stationary steam engines around the world, the diesel engine – in four-and two-stroke guise – became popular in maritime applications after the turn of the century, and then made inroads as the motive power unit for railway locomotives, trucks and buses. It was even being put forward as the powerplant of the future for road cars, with a 1931 article in Popular Mechanics of America predicting that by 1940, maintenance-free diesel engines would be the norm.

France was quick to take up diesel engines for production vehicles, with Citroën offering 1750cc Ricardo-developed CI units in family cars from the early 1930s. Peugeot wasn’t far behind, although development was delayed due to the outbreak of World War II. Meanwhile Mercedes-Benz had launched this car, the 260D, at the 1936 Berlin Show, seen here in chassis form. It would go down in history as the world’s first commercially successful diesel passenger car. Daimler AG

A few prototypes were built on both sides of the Atlantic in the late 1920s, and by the 1930s, 4-cylinder versions were starting to find their way into production passenger cars, such as certain models of the Citroën Rosalie (service trials of the 40bhp engine had started in the summer of 1934), and the Mercedes-Benz 260D, introduced at the 1936 Berlin Motor Show. The Hanomag Rekord was another oil burner announced at the same German event, when diesel was literally half the price of petrol, while Peugeot, who had been working on CI engines behind the scenes since 1921, released a limited number of diesel 402Bs for the 1939 season.

Naturally road car development was interrupted during World War II, but diesel engines powered entire armies and navies, and were also used in a number of aeronautical applications. By this time, fuel delivery systems had long since been perfected via Bosch injection and the later Cummins’ common-rail system, and turbochargers had already put in an appearance.

Following the end of hostilities, interest in the diesel engine continued to rise, and any remaining restrictions on private use were gradually withdrawn. Although some countries had been quicker to warm to diesel than others, virtually all ships and railway locomotives used diesel power within a few years of the war ending; agricultural machinery and heavy-duty generators provided another lucrative market for diesel-engine manufacturers. The road haulage business was yet another huge outlet, of course, with technology being introduced at a rapid rate in this particular field. This, in turn, gave rise to the idea of reviving diesel passenger cars on a more serious, mass-production basis.

POST-WAR DIESEL CARS

The promise of superior fuel consumption (allied to cheaper fuel costs at the pumps in the first place) and power-unit longevity helped give the four-stroke diesel engine a foothold in the passenger car market. Many manufacturers looked at the unit’s potential, including the likes of Volkswagen, whose VW Beetle was already known for fuel efficiency – but as the 1950s rolled on, it was still a rare sight in regular automobiles, offered by only a handful of makers around the world: the petrol engine was still king in this sector of the market.

Even so, whilst most technological advances with regard to diesel engines were found in the commercial vehicle field – enhancing power and torque output, improving fuel consumption figures, and eventually reducing emissions – diesel passenger cars were starting to filter through as makers from Britain (Standard, Rover and Austin) and Italy (Fiat) joined the traditional diesel strongholds of Germany and France in offering customers an option to petrol engines.

As the 1960s dawned, in the wake of the Suez Crisis more manufacturers started looking at diesel-engined vehicles as a viable alternative to the bubble cars and microcars of the previous decade, as a means of reducing the cost of motoring. Even Japan joined the diesel game at this stage, with Isuzu listing a diesel Bellel model alongside the petrol-engined derivatives.

The Standard Motor Company was Britain’s first car manufacturer to offer a diesel engine option, fitted to the Phase II Vanguards from February 1954 onwards. Standard

The Peugeot 204 was revolutionary in many ways, but it should perhaps be remembered as the car that, more than any other if we use production figures as a gauge, brought diesel power into mainstream motoring. It really paved the way for the small VWs. Peugeot

The Mini had shown that interior space could be combined with compact exterior dimensions if the packaging were right, and Peugeot took the FF concept a stage further in 1968 with the introduction of a diesel version of the 204 model. With a 1.3-litre capacity, the transverse engine was the smallest diesel unit available in a road car, and around 150,000 diesel 204s were built, although a high percentage of them found use as commercial vehicles, being sold as estates or vans – those customers who went for diesel cars usually opted for larger models, such as the Mercedes 200D or 220D, which could be readily pressed into service as a taxi.

Notwithstanding, DAF attempted to bring out a small air-cooled diesel engine in 1973, but the company’s financial woes put an end to the project, and all future cars came via Volvo, and all with petrol engines until well into the 1980s. As a result it was left to Volkswagen to make the compact diesel car popular on a global scale, first with the EA111 four in the VW Polo, and more successfully with the EA827 series units in the VW Golf (or Rabbit in the States) from 1976 onwards.

This was an era when America was stunned by the two oil crises of the 1970s, and forced to rethink its car policy – the outcome was the downsizing of domestic vehicles, increased popularity in small import models, and a fresh look at frugal diesel powerplants. This tempted General Motors to join the fray, albeit for a limited period – diesel passenger-car engines were still very much a European speciality.

For a little while, even America caught the diesel bug. The LF9 Oldsmobile V8 diesel engine, introduced in 1978, was used in other GM brands, too, including Cadillac. GM

At the other end of the scale to the Golf there were large saloons such as the ubiquitous Benz W115- and W123-series, and the Peugeot 504 (fitted with an enlarged 2.1-litre engine for the 1977 season, which was also adopted in the contemporary Ford Granada), while the 1979 Model Year 604 was one of the first passenger cars to receive a turbo-diesel (TD) unit – the 2.3-litre XD2S, endowed with a modest 80bhp.

As it happens, the French maker was only a year behind Mercedes-Benz in getting a TD to market. On the Benz (sold only in North America), it was unusual in another respect, having an in-line 5-cylinder configuration – while turbocharging had been common on trucks for some time (even before the war), it was something new on cars, and the straight-five diesel was a world first, although Audi were very close behind, the Ingolstadt firm having already made the first production 5-cylinder petrol engine. Interestingly, sales of diesel Mercedes were so strong in the grip of the oil crisis that there were thoughts of launching a turbo-diesel R107 SL at one time, but falling petrol prices brought back a sense of reality.

The 3-litre turbo-diesel used in the US market Mercedes 300SD model, announced in February 1977, although full-scale production didn’t start for over a year. Daimler AG

Behind the scenes, the Peugeot-Citroën empire (the PSA Group) was readying its legendary XU D power-unit, which would go on to sell in its millions. First used in the face-lifted ‘Mk II’ Peugeot 305 and the contemporary Talbot Horizon, it was in the Peugeot 205 that it gained real recognition, and later in the 405 and Citroën BX. More than any other engine, it is fair to say that the 4-cylinder XU D indirect-injection (IDI) unit was responsible for making diesel a truly desirable option in Europe. It’s ironic to think that the top end was based on technology used by Citroën in the early 1930s, when the famous British consulting engineer, Sir Harry Ricardo, designed the Comet cylinder head (with high charge turbulence to encourage better combustion) for the Paris maker.

Over in Japan, in 1977 Toyota made the country’s first domestic diesel power-unit designed specifically for passenger cars – a 2.2-litre four. Meanwhile, Isuzu was exploring the possibilities of using ceramics in diesel engines, joining Kyocera in a technical cooperation agreement. Ultimately, heat is developed whenever an engine is run, but once it becomes excessive, a cooling system of some sort is needed, to take the heat away. However, heat is energy, and the people at Isuzu knew that an engine could be made more efficient if the heat was allowed to build up to higher temperatures.

The use of modern ceramics seemed to provide the solution. Traditional ceramics are far too brittle to be of use in automotive applications, despite their excellent resistance to heat, friction, chemicals, corrosion and wear, but the 1970s saw a new generation of ceramics, such as silicon nitride and silicon carbide, and with a suitable type of mixing or fibre reinforcement, these can actually be made stronger than iron and just as tough. Other ceramics, such as alumina and zirconia, allowed more specialized components to be made.

The Peugeot 405 was one of several cars to make good use of the legendary XUD engine. Peugeot

Bosch’s EDC system, first used by BMW. Bosch

The first car to carry the TDI badge was the Audi 100 of 1989 vintage. This is the estate (or Avant) version. Audi

Ceramic glowplugs were introduced by Isuzu in 1981 (sparkplugs had used ceramics for decades, after all), although there were far more ambitious plans afoot, finally taking shape in the form of the P306Y engine – a turbocharged diesel unit with no radiator or cooling fins that delivered 30 per cent more power and fuel economy thanks to the adiabatic properties of the ceramic valves, piston surfaces and rings, and combustion chamber walls, allowing the engine to operate at a highly efficient 800°C.

Announced in 1985, during testing the P306Y engine showed that it was capable of lasting five times longer than a cast-iron lump, and it was naturally a substantial amount lighter than its metal counterpart, too. Sadly, technical difficulties, including machining time and cost, put an end to the dream of the ceramic engine, but today, many small components are produced in ceramic materials, with Kyocera still at the forefront of this technology.

Coming back to more conventional engineering, Bosch introduced the EDC (electronic diesel control) module in 1986, an engine management ‘black box’ that we take for granted now, but which at the time was cutting-edge technology, the control unit gathering data from a number of sensors to ensure smoother engine running, as well as lower emissions and fuel consumption. First seen on the BMW 524TD – the diesel powerplant was a new venture for the Munich concern, starting in 1983, although the unit also found its way into the Lincoln Continental Mk VII – EDCs would quickly find use throughout the industry, being updated on a regular basis in an age of staggering progress in the electronics field.

Bosch was also responsible for the injection system on the first Fiat Croma, released in the mid-1980s. This was the world’s first passenger car with a direct-injection (DI) turbo-diesel engine, although it’s fair to say that the VW-Audi Group (with its signature TDI moniker) brought this technology into the mainstream, increasing the efficiency of diesel powerplants a huge amount by injecting the fuel directly into the cylinder rather than into a prechamber.

The TDI trademark is synonymous with the Volkswagen brand. This is one of the first Mk IV Golfs, introduced for the 1998 season. Volkswagen

The first generation CRD system from Bosch. Bosch

A major difference between the Fiat and Volkswagen/Audi engines was the use of electronically controlled injection on the German models, giving superior performance and tighter emission control. According to Peugeot’s figures for their latest HDI (high-pressure direct-injection) engines, the benefits of DI add up to a 20 per cent reduction in the release of carbon dioxide, a 40 per cent drop in carbon monoxide, hydrocarbon emissions halved, and a 60 per cent reduction in particulate matter compared to the old XU D unit.

A common-rail diesel (CRD) system – which basically uses the ‘rail’ that runs the length of the engine as a high-pressure fuel reservoir – had been patented by Clessie Cummins during World War II, although CRD-type arrangements had appeared on marine engines as early as 1916. The Swiss took the idea a stage further in the 1960s, but it was left to the Japanese to bring CRD to the marketplace – Nippondenso (now known as Denso) making the injection system for the 1995 Hino Ranger truck series. Not long after, in 1997, the first common-rail diesel passenger car appeared – the Alfa Romeo 156 JTD, available in two versions and fitted with a Bosch CRD system that had originally been born as the Magneti Marelli Unijet, designed under Dr Rinaldo Rinolfi of the Fiat Group.

A Mercedes-Benz common-rail diesel set-up from 1997. Daimler AG

DIESEL FUEL REFINING AND GRADES

A recognized ‘barrel’ holds 159ltr (35 Imperial/42 US gallons) of crude oil, although it generally ends up providing about 5 per cent more product by volume due to the modern refining process. Nowadays, once the crude oil has been refined into various types of petroleum-based fuels and other by-products, petrol accounts for almost half of the barrel’s volume, diesel a quarter, and aviation fuel about 10 per cent.

The refining process is basically the distillation of crude oil into its component elements (or fractions) by the application of extreme heat, as the different hydrocarbons that make up crude oil each have different boiling points, and later, further refining can take place through the so-called ‘reforming’ and ‘cracking’ processes, which use a combination of heat, catalysts and pressure to manufacture more profitable products from less useful liquids such as naphtha. Impurities are taken out along the way, with the removal of sulphur being a key part of the diesel fuel production process.

Whilst fuel with a low sulphur content is kinder to catalytic converters (sulphur poisons cats and NAC – NOx Absorber Catalyst – units) and the environment in general (PM – diesel soot, or particulate matter, often shortened to the initials PM – is dramatically reduced), sulphur removal has been blamed for the escalation in the price of diesel, which now costs more than petrol in Britain, and North America, too. This wasn’t always the case – quite the opposite was true for decades, until diesel cars started to become popular in the UK and threatened to become popular in the States, as if by an amazing coincidence. One can also make allowances for the fact that, compared with gasoline, less diesel is produced per litre of crude, and, to a lesser extent, acknowledge that more is spent on marketing diesel fuel than petrol.

As it happens, the manufacture of LPG is by far the most efficient use of crude oil if one takes as the gauge the amount of product that can be made from a set volume. More realistic, though, is to compare petrol and diesel, and here we can see that for every 100ltr (22gal) of diesel produced, 118ltr (26gal) of premium gasoline could be made, or 123ltr (27gal) of regular. Of course, before reaching the pumps, numerous additives find their way into the equation, and modern diesel often has a significant amount of bio-fuel added to reduce emissions and improve lubrication.

But even after taking all these things into consideration, it is strange that Japan – where diesel isn’t at all popular for private passenger vehicles, and steps to reduce the sulphur content were introduced as early as 1994 – can sell it for 117 yen a litre, compared with 139 yen for regular gasoline, and 150 yen for the premium grade. This is the kind of price differential UK customers were used to before diesel car sales started booming.

The basic refining process, the crude oil being superheated by steam to about 600°C before entering the distillation column. The heavier products stay lower down in the column, while the lighter ones are separated off as they rise. The temperature is roughly 20°C at the top of the column. US DoE

Making Sense of the Cost of Fuel

Interestingly, a House of Commons report shows that British taxes (fuel duty) have steadily increased on diesel in line with the diesel engine’s popularity as a road car powerplant (a real spike in demand for diesel fuel started in 1982, and continued to rise sharply until 1998), and are now the same as for petrol, whereas they used to be fractionally lower. On the Continent, meanwhile, diesel is still far cheaper than petrol in virtually all the mainland European countries due to the significantly lower taxes applied to the former.

In fact most countries didn’t call for reduced sulphur content until the turn of the century, with Bill Clinton making the first steps in America in a May 2000 speech, for instance. It took several years for proposals to filter through, however, and the EU ended up being slightly ahead of the game, but still a fair way behind the likes of Japan.

The basic, pre-low-sulphur diesel is still sold today, though it is officially reserved for off-road, farm and construction vehicles. Known as ‘red diesel’ in Britain, due to the dye used to identify it (as opposed to ‘DERV’, or ‘white’ diesel), it is included in a significantly lower tax level, which also tends to attract shady dealing. A police clampdown found as many as one in five private cars using red diesel in certain areas of the UK, thus completely negating the original idea of improving the air we breathe.

Further reductions in the amount of sulphur contained in diesel fuel led to ‘ultra-low sulphur diesel’ (ULSD) becoming the norm in most parts of the world from about 2006 onwards. Lowering the sulphur content in diesel helps PM filters work more efficiently, and also reduces certain exhaust emissions that contribute towards the buildup of acid rain. However, sulphur helps lubricate engine components, so bio-fuels are generally added to replace the sulphur’s properties. It therefore seems ironic that so few countries are willing to take the leap and make pure bio-fuels available on the service station forecourt.

Other additives include succinimide-based detergents to reduce deposits on injectors; olefin copolymers to stop diesel freezing so easily; cetane enhancers, which can improve the self-ignition properties of poor quality fuel, being of particular help in terms of reducing noise and improving cold-start efficiency; and certain organo-metallic compounds to reduce smoke, although the latter have been found to promote emissions of ultra-fine PM and their use is therefore under review. Incidentally, Swedish diesel is specially blended to be kinder to the environment, with a lower aromatic hydrocarbon content, and carries a slight price premium as a result.

Alfa Romeo brought a sporting twist to the diesel saga with the 156 JTD. Only a decade earlier, the words ‘sporting’ and ‘diesel’ used in the same breath would have been unthinkable. Bosch

The lightweight Ford Prodigy was another mild hybrid, with an electric motor providing an idle-stop facility and assisting the 1.2-litre turbo-diesel engine under hard acceleration. Based on the P2000 LSR (with LSR standing for low storage requirement), the car made its debut at the 2000 Detroit Show, which opened on 29 December 1999. Ford

As the twenty-first century dawned, it seemed as if demand for diesel cars had peaked a long time ago in the States as cheap petrol virtually killed off the breed, with only Mercedes-Benz and Volkswagen offering CI models in America, although Europe’s unquenched thirst for diesel vehicles made up for the lack of interest across the Atlantic. Indeed this popularity, combined with recent calls for more stringent emission controls in the EEC, has led to great leaps in technology. With America also warming to diesel again, to meet more challenging CAFE (‘corporate average fuel economy’) figures averaged across an entire maker’s range, engineers are now busy refining the diesel engine as never before.

The ESX-III was the second Chrysler PNGV concept to feature a mild hybrid drivetrain – an electric motor assisting the 74bhp diesel engine when necessary. The ESX-II model had been released in 1998, with the ESXIII following in 2000. Cost was one of the main factors in the project not being developed further, with a $7,500 premium hard to justify when prices at US pumps were so cheap. Chrysler

JUST HOW ‘GREEN’ IS DIESEL?

From a greenhouse gas point of view, according to popular beliefs based on the evidence put forward, diesel emissions are considered far cleaner than those of an equivalent petrol engine, as CO2 levels released from the exhaust are generally accepted as being lower – but in direct comparison (gallon for gallon), they are actually higher. According to figures released by the Irish government in August 2010, burning a litre of petrol generates about 234 grams of CO2, while burning a litre of diesel produces 270 grams.

However, broadly speaking, diesel gives far better fuel-consumption figures (litre for litre on engine size), which tends to promote and reinforce the point on CO2 emissions over a vehicle’s life. It also helps preserve oil reserves – at least in theory, although it takes more crude oil to produce a gallon of diesel fuel than it does a gallon of gasoline, which wipes out a lot of the latter advantage. And another black mark for diesel from a ‘Green’ perspective is the huge escape of methane gas during the oil drilling and refining process, so the more crude needed equals more methane released into the atmosphere.

In addition, the diesel engine’s superior thermal efficiency is largely due to the use of higher compression ratios compared to a gasoline unit, although some modern petrol engines boast an extremely high c/r, helping to significantly improve fuel consumption, which again closes the gap.

Perhaps more importantly, a large number of corporations and certain governments have concentrated far too much PR effort on the reduction of CO2 emissions to create a cleaner planet, thereby making us – and them – fail to see a lot of the big picture. Even the recently proposed EU bill to have car manufacturers allocate a huge amount of space in each advert to Green issues only really calls for fuel consumption and CO2 emissions to be given any real prominence.

One of the problems is that although we consider nitrous oxide (N2O) a greenhouse gas, increasing in volume largely through modern farming practices, NOx emissions (a combination of nitric oxide and nitrogen dioxide) seem to escape the spotlight to a great extent, despite occurring every time there is combustion involved, and despite both component parts (NO and NO2) being recognized air pollutants which can dramatically affect the balance of the ozone layer – depleting it in certain conditions, or reacting with it to increase ozone (O3) levels closer to the Earth’s surface to form smog in urban areas; nitric oxide also has the potential to create acid rain. Some of this oversight is due to confusion over which gas is which, and what its effects are, while some of it is a question of ‘don’t ask, don’t tell’. Even when new, compared to their petrol counterparts, NOx emissions are significantly higher on CI engines running on conventional diesel fuel due to the extremely high compression ratios involved (as high as 18.5:1 even today, with over 20:1 being common in the past, before direct injection became popular), and that surely undermines the ‘Green’ marketing angle to a great extent, especially when we take the GWP (global warming potential) of nitrous oxide into account.

A wonderful Volkswagen UK advert from 1990. Volkswagen

A modern diesel particulate filter unit, this one fitted to the 2004 MY Audi A8. DPFs were still a real rarity at this time. Audi

There is also the level of engine tuning and condition to consider. Diesels can be seriously dirty unless they are given the correct fuels and regular servicing. We’ve all followed trucks and buses belching out clouds of black smoke, and certain dubious operators have been known to continue running vehicles that are pumping out clouds of blue and/or white smoke. The damage to the environment – and people’s health – is increased exponentially as the state of engine tune deteriorates.

Certainly petrol engines emit higher levels of noxious carbon