Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The History Press

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

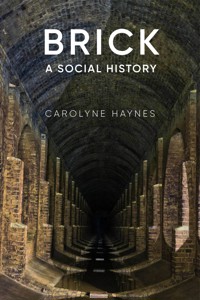

Bricks – such small and seemingly uninteresting things – have helped to build the way we live as society has evolved, from the feudal system of early Britain right up to today. Originally very expensive, bricks were only used by those who could afford them. This gradually changed with the Great Fire of London in 1666 when legislation decreed that the city must be rebuilt with non flammable materials, and bricks came into their own. A few centuries later bricks formed the infrastructure of industrial Britain as the need for canals and railways grew. But bricks are also associated with some of the worst slums this country has ever known, with poor bricks and sandy mortars indirectly causing misery for thousands of people. Our love affair with bricks continues today, with exposed brickwork being used to decorate both exteriors and interiors. But how are bricks made? What are they made of? Who made them and how have they changed through time? In Brick Carolyne Haynes answers these questions and reveals the surprising social history of bricks in Britain.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 450

Veröffentlichungsjahr: 2019

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

First published 2019

The History Press

97 St George’s Place, Cheltenham,

Gloucestershire, GL50 3QB

www.thehistorypress.co.uk

© Carolyne Haynes, 2019

The right of Carolyne Haynes to be identified as the Author of this work has been asserted in accordance with the Copyright, Designs and Patents Act 1988.

All rights reserved. No part of this book may be reprinted or reproduced or utilised in any form or by any electronic, mechanical or other means, now known or hereafter invented, including photocopying and recording, or in any information storage or retrieval system, without the permission in writing from the Publishers.

British Library Cataloguing in Publication Data.

A catalogue record for this book is available from the British Library.

ISBN 978 0 7509 9359 3

Typesetting and origination by The History Press

Printed in Turkey by Imak

eBook converted by Geethik Technologies

CONTENTS

Introduction

Acknowledgements

1 A Very Brief Chemistry Lesson

2 Clay

3 A Roman Holiday

4 An Influx of Religion

5 One Last Invasion

6 A Medieval Brickyard

7 Wool, War and Wealth

8 Fear of Fire

9 Keeping up with Demand

10 A Time of Transition

11 The Search for Perfection

12 The Classical City

13 The Pace Quickens

14 A Victorian Love Affair

15 ‘The March of Bricks and Mortar’

16 The Poor are Always with Us

17 Working Life in the Brickyards

18 Decline and Resurrection

Appendix A: Buriton Chalk Pits

Appendix B: Bursledon Brickworks

Bibliography

INTRODUCTION

It would be hard to live in much of Britain from around the 1660s onwards and not know about bricks. Certainly, today they are woven into the fabric of our lives. People like to live in brick houses – it makes them feel secure. Mortgage providers also like people to live in brick houses, as it makes them feel secure as well. I remember trying to persuade a well-known building society that they should give me a mortgage for a timber-framed house back in the early 1990s, and being met with incredulity. It didn’t seem to matter that a large number of the houses being built by the big house builders were technically timber-framed – they were clad in brick so they were fine. Cladding is not structural but I couldn’t make the lass behind the desk see that. The bricks were all that mattered.

Whilst we love the idea of bricks it is perhaps true to say we take little notice of them. Questions such as how they were made, why they are the colour they are, how old they are, are rarely pondered. I know this as a result of running a museum based on bricks. On the whole, our visitors fall into two camps: those who have an interest in all things industrial – steam especially – and those who are being dragged along for the ride. The heartening thing is how many leave with a very different impression. We constantly get feedback saying things like ‘who would have thought a brick could be so interesting’ and ‘I will never look at a brick the same way again’. Which is excellent.

Bricks do not stand alone, they work best with a sticky material to bind them together. So, wound into this story of bricks is an exploration of the use of lime. If bricks are mostly ignored, lime is rarely mentioned at all. Even the literature about it is thin on the ground, and yet arguably it is right up there as one of the most important chemicals in our history. Still widely used today, lime was the material that allowed us to build our houses, fortifications, churches and other structures for hundreds of years. Without lime it would have been very much harder to make brick walls strong. There are alternatives. We could have stuck them together using clay, but lime is long lasting, versatile, relatively easy to use and surprisingly strong. It’s an unsung hero that played a huge part in our history and I think that it is time that we took a bit more notice of it.

Both materials have a long pedigree in our country. They came with the Romans and apart from a few gaps, some of which were quite lengthy, they have remained with us ever since. Their history is one of need.

When we didn’t need bricks, we didn’t make them – and this might last hundreds of years. When we did need them, we learned how to make them again, and when we needed millions of them, we learned how to do that as well. The same applied to lime. It has a more continuous history than bricks, without the long gaps. Also, lime had the advantage of being fairly easy to make and so was more useful to both the Celts and the Anglo-Saxons. Today we continue to make both and, although the processes are now more mechanised, the ones used are similar to those introduced nearly 2,000 years ago.

This book would have been considerably more difficult to write without the help of two old industrial sites: Buriton Chalk Pits and Bursledon Brickworks. Buriton Chalk Pits were once a lime working situated near the village of Buriton in Hampshire. They manufactured lime from about 1860 to 1935. My involvement with the Chalk Pits was part of a project that would preserve both the natural history and the archaeological history of the site. With the help of a Heritage Lottery Fund award, the old lime workings have been saved as a nature reserve. An important part of the project was to pull together all the history that was known about the site. This included the work of Buriton Heritage Bank, who had already collected oral testimonies and photographs. From here began my interest in lime and the lime industry.

A little later, I was asked for help in finding a viable way forward for Bursledon Brickworks. The Brickworks near Southampton are a unique survivor and are, as far as is known, the only remaining Victorian steam-driven brickworks in the UK. Located on the muddy estuary of the River Hamble, they started to manufacture bricks in 1897 and ceased in 1974. At peak production, the works manufactured 20 million bricks a year. With help from the Heritage Lottery Fund, they are now The Brickworks Museum.

Both of these industrial sites were started by Victorian entrepreneurs. In the mid to late 1800s, Britain was a country at the height of its powers. The Empire was still in place, markets were booming, the population was growing and there was seemingly a bright future ahead. Bricks and mortar created the backbone for these changes. Without the humble brick, railway engineers would have struggled as, in order to work, they needed the infrastructure. Similarly, without improved mortars, there wouldn’t have been canals. To build a lock needed a mortar that could set under water, and there weren’t any available at the time of the first canals. It was the ever-increasing demands of the marketplace that led to the expansion of both industries. For bricks, the most challenging issue faced by the manufacturers was to increase the numbers being made, whilst for lime it was to create mortars that really worked. It was an exciting time and these two small enterprises were right there in the thick of it.

As a result of all of the above, the idea for this book arose. It sets out to be a study of our long involvement with both bricks and mortar, from retro-fitting chimneys into timber-framed houses through to the first tunnel under the Thames. I try to explore what it was like for both the people who made the materials and those who lived in or worked with the results. The history spans a timescale from the Iron Age right up to today. Tempting though it is to include bricks from all over the world, this would have been an impossibly large task, and so the focus has been on Great Britain. My hope is that after reading this book you will start looking at walls in a different way. Even if you live in a predominantly stone area such as Bath, you can admire the thin mortar joints.

I was once in Milwaukee with my old friend Frank Lloyd Wright who was attending a conference there. He began: ‘Ladies and gentlemen, do you know what a brick is? It’s trivial and costs 11 cents: it’s common and valueless but possesses a peculiar characteristic. Give me a brick and it becomes worth its weight in gold.’ That was perhaps the only time that I had heard in public, stated clearly and bluntly, what architecture really is. Architecture is the transformation of a worthless brick into something worth its weight in gold.

(Alvar Aalto remembering Frank Lloyd Wright, quoted on the Phaidon.com website in an article celebrating the publication of William Hall’s Brick book: ‘Even modernist Mies loved Bricks…’)

ACKNOWLEDGEMENTS

The writing of this book would not have been easy without the help and support of the teams that have worked on Buriton Chalk Pits and Bursledon Brickworks. The large amount of research undertaken by Doug Jones and the Buriton Heritage Bank group into the history of the village is impressive and covers much more than the lime workings. More information can be found on their website: www.buriton.org.uk.

Working with Hampshire Buildings Preservation Trust and Bursledon Brickworks Museum Trust has also been invaluable. The gradual piecing together of the history of the site has taken many years as all the original paperwork was destroyed. Luckily, early testimony was taken in the 1990s and reached back as far as 1915 – only eight years after the works started. Since then, all kinds of people have come forward to relate their experiences of working in the yard, adding layers of detail to what had been quite sketchy information.

Both of these sites had Conservation Plans researched and written by Fred Aldsworth. The methodical research undertaken by him in the formation of these documents was incredibly useful in understanding their histories and the wider historical context.

Lots of people have helped me along the way, including Alyn Shipton, who was brilliant at helping to turn a vague idea into a project, all the knowledgeable people on the Facebook page ‘Brick of the Day’ for their serendipitous approach to the subject, Bob Chase for an impromptu (and knowledgeable) tour of Titchfield, and Amy Rigg and the team from The History Press who saw something in the idea and ran with it.

Finally, I would like to thank my very long-suffering family and friends for putting up with me for the last few years. I think I have managed to convert most of them to the delights of bricks, but of course they might just be humouring me.

I would also like to thank the following for allowing me to use images taken at the various locations:

Emma Keen, Weald and Downland Living Museum, West Sussex

Julia Edge, Amberley Museum, West Sussex

Helen Woollison, Dr Johnson’s House Museum, London

Rob Symmons, Fishbourne Roman Palace Museum, West Sussex

Darren Bevin, Chawton House, Hampshire

Julie Ryan, Bader International Study Centre, Herstmonceux Castle, East Sussex

Helena Harris, The Roman Baths, Bath, www.romanbaths.co.uk

Karen Davis & Elizabeth Thomson, The Black Country Living Museum

Nicola Thorogood, St Mary’s Church, Polstead, Suffolk

Rob Young, St Mary the Virgin, Silchester, Hampshire

Laura Cox, Blakesley Hall, Birmingham Museums Trust

Rachel Bingham, Butser Ancient Farm, Hampshire

Historic Environment Scotland, Skara Brae, Orkney

Amy Taylor, The Landmark Trust

Every effort has been made to trace all copyright holders, in the event of any omission please contact the publisher.

1

A VERY BRIEF CHEMISTRY LESSON

Should our civilization crash, should a new dark age come, clay will still be here, and we can, each of us, scoop it from the earth and use it for our most basic needs, the preparation of food, and for shelter.

(Clay, Suzanne Staubach)

Bricks

We don’t make bricks entirely of clay, but without clay we couldn’t make bricks. It is the ‘glue’ that holds the brick together and the squishy bit that moulds it into shape. Clay is a very tactile material that has the ability to be both malleable, or plastic, and hard. It was once, many billions of years ago, stone. Over time the stone was worn away by the action of weather, water and, to a lesser extent, vegetation and it changed in nature. This chemical change was part of a very long and complex process that culminated with the formation of the ingredients needed to make clay: alumina, silica and chemically bonded water. The resulting particles then took two distinct routes. Some didn’t travel far and were laid down in layers that became almost as rock-like as the rocks that they were formed from. This is called shale and feels too hard to conform to our standard idea of what clay is, but it is too soft to be stone – you can usually pick it off in layers. The other particles travelled further and were distributed widely by the action of wind and water to form layers of sediment. This eventually formed the sticky kind of clay we are more familiar with and find when digging in the garden in many parts of Britain. The period in which the clay was formed resulted in it being suited to making different types of bricks. Here is a quick summary to give an understanding of the complexities involved:

The Holocene period – 11,700 years ago up until today – formed the alluvial clays, examples of which can be found all down the east coast of the country. They were the earliest clays to be used for brickmaking in Britain and arguably the easiest as they were close to the surface and already a mixture of sand and clayey silt.

Pleistocene clays – 2.6 million to 11,700 years ago – were formed in east Suffolk, most of northern England and eastern Wales.

Eocene clays – 54.8 million to 33.7 million years ago – give the bricks a blotchy purple colour. The most notable examples can be seen all round Reading, but also in the type of clay known as London clay.

The Cretaceous period – 142 million to 65 million years ago – formed the Wealden clays, running in a swathe all along West Sussex to Dorset. Also Gault clays, which were limited to Kent and Cambridge and gave bricks a pale ‘white’ colour.

The Jurassic period – 205 million to 142 million years ago – formed the Lias and Oxford clays.

Triassic clay – formed 248 million to 205 million years ago – was a reddish brown sort of mudstone that could be found all around Leicestershire and Nottinghamshire.

Carboniferous clays – 354 million to 290 million years ago – were a form of shale associated with coal. It was important for the Staffordshire tile and brick industries and today’s Flettons that are made in the Peterborough area.

For hundreds of years superficial deposits of clay were all that were used for pottery and brickmaking. There was so much available that there was no need to quarry down to find more.

The particles that form clay have an important attribute – they are almost two-dimensional in shape, giving them a tendency to slip across each other when wet. It is this slipperiness that makes clay plastic. It means that you can take a lump of it, add water, squeeze it between your fingers, form any shape you like and it will hold that shape. It gets stickier as you add water until it turns into a slurry. Often the clay we dig will happily stick to anything that it touches – your spade, your boots, your hands – with great tenacity. If you take a lump of clay and make a shape out of it, then leave it somewhere dry, it will, once excess water has evaporated, go hard. The molecules will hold rigidly onto each other but only until they get wet again.

So, we have a plastic material that is easy to form into shapes and will dry hard. This makes it very suitable for the forming of adobe, or mud, bricks but it has the awkward habit of turning back into a sloppy mess when wet. A material that was plastic enough to form a shape but then could become permanently hard would be a huge improvement – and clay is also that material. Although the molecules slip happily over each other when there is water present and will slip less happily when dry, they undergo a big change when heated strongly. If clay is taken to a temperature in excess of 900°C, then the material changes in nature and creates strong interlocking molecular bonds. A burnt brick is a new material and is both strong and very long lasting. You can leave a burnt brick out in the rain for hundreds of years and still have a brick.

Clay used on its own generally makes very poor bricks. Too pure and it will shrink excessively, crack or warp as it dries. So, although we tend to say that bricks are made from clay, they are in fact made from a mixture of clay and other substances, and the old term of ‘brick earth’ is more accurate. If you are lucky, the mixing has already been carried out for you by nature; if not, you have to mix in other substances by hand – usually sand, ash and to a lesser extent, chalk. Nearly all the clay we dig out of the garden contains some sand. If you are prising the earth off the spade and it comes away in clean slices, then you are blessed with a lot more clay than sand. If the soil runs through your fingers, you probably have more sand. Sand, or silica, stops shrinking and cracking by bulking out the clay with a relatively neutral filler. It has the added advantage of being able to vary colour and texture in the finished bricks, but it can cause problems. Too much sand and bricks are not strong enough, and if taken to too high a temperature the sand turns to glass, spoiling the brick.

Ash is a viable alternative to sand as long as there are large sources available. The coal fragments left in the ash help the brick to burn. A naturally occurring fuel appears in the carboniferous clays mentioned above. This clay has a high level of organic matter in it, forming a kind of oil. When taken up to a high temperature in the kiln, the oil acts as an additional fuel source in the same way as particles of unburnt coal do in the ash.

If you were lucky, nature did the mixing for you. It is unsurprising that many of the early brickyards were based near river estuaries. The sand from the sea would form layers with the silts washed down by the river to create the perfect mix.

In the early days of brickmaking, trial and error was behind much of the science and it was only with experience that good bricks could be made. Mistakes would have happened throughout the process by getting the initial mix wrong, not letting the bricks dry out enough before burning, and then not reaching the right temperature when in the kiln. A bad batch of bricks for whatever reason was a nightmare for the brickmaker, as it was a waste of so much invested manpower. When the Whitgift Hospital (Croydon, South London) was built in 1596, the bricks were commissioned specially for the job. Sadly for the brickmaker, the first batch were rejected. A very early document describes the exchange between the maker and his client with cringing accuracy that anyone who has ever been involved with putting up a building will recognise today. It starts off with the brickmaker trying to defend himself:

he would have excused himself but his handiwork spake against him; and we were so rounde with him, that he burst into tears, saying it was never the lyke served in anie worke he was ashamed of it; he could not excuse it …

Before blaming it on his materials:

The site of a small nineteenth-century brickyard that once made bricks using the silt formed by the tidal River Hamble. Located near Manor Park, Hampshire. (CMH)

it was the wickedness and deceitfulness of the yearth and albeit he not thoroughly make amends, yet he could be contente to do what lay in him; but not of that yearthe.

(Nathanial Lloyd, A History of English Brickwork, H. Greville Montgomery, 1925, p.18)

To go into a large amount of detail about the types of clays and brick earths would be too big a diversion here, but it is useful to give a brief description of a few of the varieties of materials and methods that can be used to make bricks and the different effects created. Common clays are often called either strong or mild. Milder clays are those that have already sufficient additives to make them work quite well, whilst a strong clay is nearly all clay. As we have noted above, the latter cannot be used alone and has to be mixed with something else. Marl is a name given to the weaker mixes of clays, those that already contain a naturally high level of chalk or sand and are ideal for brickmaking. They still need to be used with care, as there may be large pieces of chalk or shell (bigger than a pea) in them that can cause problems in the firing of the brick. If bigger bits do get left in, they can blow apart in the heat, causing damage to the bricks. The colour of the clay is not necessarily an indication of the resulting colour of the brick. A dark red clay may only be this colour due to vegetation, which will burn off giving a much paler brick. Clays from different layers or areas of the quarry can be mixed before making the bricks to ensure the correct colour.

Minerals in the clay can also have an effect on the colour. A mixture of iron oxides and lime compounds will give a red brick, if burnt on a lower heat, because of the iron. However, if the heat is raised the lime will react with the iron and a ‘white’ (pale grey/yellow) brick is formed. The type of sand used in making the brick or the amount of oxygen available when firing can also vary the colour. With oxygen present, iron compounds make a red brick, but if oxygen levels are reduced the same mixture creates a black or ‘blue’ brick. The firing of a kiln would often end up with three qualities of bricks. Those that have burnt perfectly, those that got too hot, and those that have not got hot enough. A perfect brick rings true when you take it from the kiln. This is difficult to describe in words, but such perfect bricks make a satisfactory ‘tink’ when tapped together. If there is a fault with them they go ‘dunk’! Perfect bricks shun rain, look good, face frosts with impunity and generally are a delight to work with. These are more expensive to buy. Bricks that did not get hot enough in the kiln are cheaper and they are cheaper for a good reason, because they aren’t as good. They can be used for internal walls or in places where quality isn’t such an issue, but used where the weather can get to them they start to misbehave quite quickly. They absorb moisture, react badly to frost and decay faster than a brick should. However, from time immemorial unscrupulous builders have tried to cut corners when it comes to materials, and so these substandard bricks will often be found in external or loadbearing walls when really they are not fit for purpose.

The bricks that get too hot can be used in walls but it depends on how hot is too hot. If the sand has fused into a mass, then it is unlikely that the brick is the right size (they usually expand), or the proper shape or the right colour. These bricks are really only fit for breaking up and using as hard core. However, it is possible to create what was once a very desirable effect by getting the bricks a little bit too close to the fire. Tudor brickwork often incorporated the use of ‘black’ bricks to make a diamond or nappy-shaped pattern. These black bricks were formed by placing the short end (or header) of the brick close to the wood being burnt in the kiln. If they got hot enough then the sand combined with the wood ash to make the shiny – partly glazed – black surface. This is harder to achieve with modern kilns as they burn so hot and so cleanly.

Lime

Although most people know something about bricks, not so many have any clue as to what lime is, or why it is so important. Lime, like clay, is a material that can change from being malleable to hard. It is also very corrosive and although this makes it difficult to work with, both of these properties have been found to be valuable.

Lime is made from calcium carbonate. There are a number of types of rock rich in calcium carbonate in Britain, including limestone and chalk. Chalk is a white stone of medium strength found in large deposits across the country, for example, the hills of the South Downs in Hampshire and Sussex. Limestone is a harder stone and found in a swathe that runs roughly from the Bath in the south-west up to Lincolnshire in the north-east. It isn’t difficult to know whether you are in a chalk or limestone area because the houses will tend to be built of the respective stones. Calcium carbonate is a stable material but it can be broken down if heated strongly (up to 1,100°C), whereupon it loses one carbon and two oxygen atoms. These are given off in the form of the common gas carbon dioxide, leaving a whitish crumbly substance, calcium oxide, also known as lime or quicklime. This is strongly alkaline and is very reactive with water, creating a fizzing, violent reaction that gives off considerable amounts of heat. This reactivity with water makes it horrible to handle, as it seeks out the moisture in the skin and the result causes burns. It is so corrosive that one of its many uses over time has been to dissolve bodies in mass graves. Once water has been added, the calcium oxide turns into calcium hydroxide (hydrated or slaked lime). In this state it is a little easier to handle and is less reactive. From the moment it is made lime will try to slowly absorb calcium dioxide from the air and set hard, turning back into calcium carbonate again. The cycle is then complete. It isn’t as strong as the original stone but it is strong enough to bond walls together or form concrete, and it is this property that has made it so important to the history of building.

The main skill required to make lime is to ensure the right temperature has been reached. Without temperature gauges it could be a bit hit and miss and if a filled kiln didn’t burn hot enough, rectifying the problem was hard. It is not very easy to empty a badly burnt kiln and the waste of man-hours and the high cost of the fuel made it an expensive undertaking. Having said that, making lime was certainly easier than making bricks. There were not so many things that could go wrong and if they did, then at least the stone could be reclaimed and burnt again. By contrast, once bricks have been fired in a kiln it is impossible to go back. Even if the clay hasn’t burnt properly it will have changed enough to ensure it isn’t plastic any more. Losing a whole kiln of bricks was really hard, and even with modern technology it still happens.

Once the lime was made it was destined for a wide variety of processes. In the early days it was used more or less equally for agriculture and construction, but with the rise in demand for buildings that came with the industrial revolution larger quantities were needed for construction. Lime was used to create mortar. This is a mixture with the constituency of a soft butter that can be spread on a layer of stone or brick before putting another layer of stone or brick in place. You don’t have to have mortar between joints and many buildings have been built without it, relying instead on the weight of stone to hold walls in place. However, mortar helps to bind smaller stones together and thinner walls can be built, thereby saving on the amount of masonry used. It also saves time as the selection of stones can be more casual – the mortar filling up any gaps in the joints. A dry-stone wall – without mortar – has to be laid with care and the right stones selected to fill up each space.

Lime mortar mixed and ready to use. (CMH)

In order to make mortar, lime needed to be slaked. The first step was to put the lime into a shallow trough before adding water slowly. The lime would start fizzing, creating enough heat to boil the water. More water was added until all the lime had broken down. You could tell when this had happened because the lumps of lime would crumble as they reacted. Eventually, this formed a lime putty and from this point on it would try to combine with any carbon dioxide it could, in order to become the stable form, calcium carbonate, again. Hydrated lime is lime that has had water added but is in the form of a powder rather than a putty. This is so dry that it won’t start reacting with carbon dioxide until more water has been added. In order to make a mortar, the lime putty or the hydrated lime is mixed with sand and any additional water needed, until it is the right texture. Once mixed it is much easier to handle, although still corrosive.

Lime was valuable for other industries as well. It was used to ‘sweeten’ water. If water was a bit hard, lime was added to help improve the taste. Twyford Water Works near Winchester had limekilns to process chalk for their own use. The demand for palatable water to drink developed alongside plumbed water supplies. Lime is still added to water today. Lime in agriculture was used as manure and to neutralise acid soils. The corrosive properties of lime were valuable to parchment makers. They soaked sheepskins in lime for weeks to remove the wool. Finally, as mentioned, quicklime has always been useful for getting rid of bodies. Whether it was in plague pits that were too full and needed something to speed up decomposition, or getting rid of evidence of mass murder, the lime was used to dissolve the flesh off bones.

In the following chapters, the focus will be on our use of both materials for building. Our involvement with lime and clay has been both long and successful, starting with the simplest of adobe buildings through to the complexities of today’s structures. Clay and lime have facilitated the journey.

2

CLAY

Houses have been made of straw, sticks, skins, bark, stones, fired and unfired bricks, and piles of mud for thousands of years. What material is used is usually dictated by what is most available, and the way the inhabitants live …

(Clay, Suzanne Staubach)

The making of pots starts back in the mists of time in the Middle East and, possibly independently, in other parts of Asia. It took millennia to filter across Europe and then even longer to get across the sea to British shores. We don’t know how making pottery was first discovered, but it is highly likely that it began as a result of people playing with the sticky mud that can be dug out of riverbanks. As we saw in Chapter 1, this mud – as long as it had some clay in it – could be squished into shapes and would then hold its shape. Perhaps someone left the objects they’d made by the fire and realised that they set hard with time. Maybe then they went on to experiment with putting them into the fire to see what happened. Who knows? What we do know is that by the time our Neolithic ancestors were learning about pottery, the techniques for producing it were well advanced.

Like all good ideas it spread, but only when there was a need. It wouldn’t matter how often you picked up your neighbour’s beautifully made pot and admired it; if you didn’t actually need a pot, it is doubtful you would go to all the trouble of learning how to make one. This all changed at roughly the same time that we, in the British Isles, stopped being hunter-gatherers and started to settle down. Nomadic peoples tend to travel light even today. Anything made from clay is going to be heavy and difficult to transport – lightweight and less fragile baskets or animal skin ‘bottles’ work better. Once we had started to settle – around 4000 BCE – our needs began to change. Perhaps at this point people realised clay pots were worth making and were willing to learn the skill and invest the time. We can only guess of course, as we don’t really know. What we do know is that Neolithic woman, or man (but my guess is that it was the women), knew how to take clay, mix in enough sand or ground shells to make it work well and form it into a pot. They knew how to dry it and then burn it in a fire until it became hot enough to turn it into terracotta (the name given to unglazed, fired clay).

A good terracotta pot will keep out vermin, hold liquids reasonably well and keep water at a good temperature because of the continual evaporation from the surface. Any one of these attributes would make it useful. Couple this with being a handy cooking utensil, one that can even cope with the high temperatures needed for smelting iron, and it became invaluable. The making of pots was a skill that spread quickly from community to community. There were differences in the end design but the basic technology underpinning them was the same. By the mid to late Neolithic period, people were throwing their broken pots away all over the country and these shards were to become one of the most common finds in archaeological digs.

Settled communities also started to create more permanent dwellings. These were more structural than the tents of the nomads. Although archaeological evidence for the pre-Neolithic period is not clear, we do know that the hunter-gatherers were travelling around leaving their rubbish (and a few prized artefacts) behind them, but there is generally little sign of what they were living in. From the rubbish piles we know that they often returned to the same places each year but were probably using temporary dwellings of some kind. The only evidence left of what they were living in is the absence of anything permanent. It is probable that they were creating what we would today call ‘benders’, made from a ring of thin posts stuck into the ground and bent over to meet at the top and then covered with skins. Completely demountable, nomads could take them wherever they were travelling next, rather like an ancient version of the Mongolian yurt. Once settled, however, folk no longer needed to dismantle their homes every few days or weeks, but stayed in one location.

Farming in a cold climate with a long winter put demands on people. They required somewhere warm to live, somewhere to overwinter enough animals to start breeding them the following spring, and sufficient food to keep both humans and animals alive over the winter months. As temporary dwellings evolved into more complex permanent ones, the knowledge that clay is sticky when wet but dries hard was to come in useful. These new dwellings continued to be round but were often much larger. They had structural conical roofs and short walls around the perimeter, made of vertical sticks stuck into the ground with smaller sticks woven between them horizontally. If the building was big enough to need it, there was then a ring of large posts set into the earth a little way into the interior. This formed the structural support for the roof timbers, creating an aisle round the edge, thereby further dividing and defining the space inside. The conical shape gave the structure stability and it didn’t need a central post, leaving room for the hearth right at the heart of the building. The roofing material was likely to have been turf or thatch and this thatch could have been the stalks of the newly developed cereal crops or, if available, reeds.

This was a simple way of building that was to last many hundreds of years. It is arguable that the temporary buildings recorded in the early 1900s for charcoal burners, hunters and the like, were direct descendants of this method of construction. Particularly in more rural areas, it is possible that people continued to use much of what our Iron Age ancestors would have recognised. Why would we have changed it if it worked or was enjoyable? Laurie Lee reminisces in one of his short pieces about springtime entertainments in the Slad valley, describing a dance that a village would do each year. It involved linking together to form a long serpentine chain and weaving their way around the dwellings. With Iron Age settlements in the area it seems incredibly likely that this kind of activity continued year after year without interruption.

Large Iron Age round-houses were quite lovely inside. If you ever have the chance to go into one – there are several sites across the country where they have been recreated – you will find they are surprisingly majestic. Big enough to accommodate more than one family, their roofs fade away into the dark above you. The walls encircle the space and the focus is all on the hearth in the middle. For a thatched roof it was wiser to leave no chimney hole in the roof. It wouldn’t work as it would draw far too much air in and risk sparks rising up to the thatch and setting it alight. The conical roof is usually big enough to catch most of the smoke and it isn’t uncomfortable at ground level. There would be plenty of gaps for the smoke to get out eventually. There is only one opening, usually to the south-east, forming the main door and what light there is comes from this and the hearth. The large ring of posts helps to define the interior layout, creating one zone that is out of the main living area and one focused on the middle. Storytelling in one of these spaces is quite magical. Perhaps this, and the long winter nights, helped us to form an oral rather than a written tradition during this period of our history.

The woven walls alone would not keep the weather out. They could have been lined with skins but for longevity a clay or chalk mix was used. These materials were mixed with water into a putty and then pushed onto the timbers from both sides to form a solid reinforced wall – an early version of medieval wattle and daub. Additionally, the clay or chalk dust could be mixed with all kinds of things including cow dung. Using the materials that were to hand, trial and error would have quickly shown what worked well and what didn’t. Adding hair or chopped straw helped to bind these simple renders together. Neither material was fired – so it was adobe or chalk, not brick or lime mortar. The large overhanging conical roofs threw rainwater well away from the adobe walls and there is evidence of drains being dug round the dwellings helping to keep everything dry. They would have lasted for years like this, with only the occasional need for patching. In Britain we still make buildings using timber frame, adobe and chalk, although rarely. It works well as it is insulating, uses materials that are readily available, is easy to patch and repair and is long lasting. It also, using today’s jargon, touches the earth lightly, as it dissolves away when not wanted any more.

Stone was also used during the Neolithic period – 4000 to 2500 BCE – with some magnificent examples remaining in Northern Ireland and Scotland. Stone was heavy to move around and was really only built with where it could be easily found and where there were few alternatives. For the rest of the country there was usually a ready supply of wood, including the large straight trunks needed for the main posts and roofing timbers, and mud or chalk dust. That people were building quite large settlements towards the end of the Iron Age – roughly 1000 BCE – can be identified in both archaeological remains and in snippets of old Celtic stories. The Celts were a society that told stories and they related them over and over again. Whilst there are bound to be changes over time, the essence of the stories is likely to hold true. Thus in ‘The Cattle Raid of Cooley’, which is one of these early sagas, there is a paragraph that describes at least three different built structures:

Sualtaim went to Emain, and cried out to the men of Ulster: ‘Men have been murdered, women stolen, cattle plundered!’ He gave his first cry from the slope of the enclosure, his second beside the fort, and the third cry from the Mound of the Hostages inside Emain itself.

(Quoted in Britain BC, Francis Pryor, p.377)

The settled communities of the Iron Age would have had more security both in terms of food and politics – encouraging population growth. As the communities grew so did their settlements, and towards the time of the Roman invasion there were several quite large ‘towns’. They included places for the manufacture of goods, dwellings, cemeteries and religious sites. There were earthworks defining such zones and they might sprawl over quite large areas, a bit like the suburbs of a modern town. This relaxed approach to the built landscape may well have been symptomatic of Iron Age social hierarchies. Unlike many other parts of the world, the Celts seem to have adopted a truer form of democracy than anything we manage today. It was only towards the end of the Iron Age that more distinct hierarchies appear to have begun. Certainly, by the time the Romans were trying to take over, there were tribal leaders.

One of the houses that is part of the Neolithic village, Skara Brae, Orkney, Scotland. The houses made use of the local stone to build both the walls and ‘fitted’ furniture inside. The stones were laid on top of each other without the use of any form of mortar. (Photo by CMH, with thanks to Historic Environment Scotland)

As we shall see in the next chapter, the Romans were good at building over the earlier Celtic towns, making it difficult to tease the two different styles apart. However, what we do know is that the methods of building adopted by these early ancestors of ours were robust enough to withstand several hundred years of Roman intervention without changing much. This is fairly remarkable considering the temptations that some aspects of Roman life must have offered them. It is hard to imagine what the experience of a Roman bath would have been like to someone who had never had any notion of such a luxury beforehand. It is possible that the Romans eventually succeeded because of their ability to heat up water and then wallow in it. If all you had ever experienced was a chilly British river or sea, this must have been quite something. How tempting to adopt Roman lifestyles, if only on the outside, just to have a taste of it all! However, as we shall see, all the Roman sophistication in building techniques washed over our Celtic ancestors and after 400 years of occupation they left us more or less where they found us.

3

A ROMAN HOLIDAY

… a medley of villas, workshops, public buildings, warehouses, shops and temples.

(Description of Roman Londinium, Roy Porter, London: A Social History)

Firing bricks marked a significant step forward in the history of building and started around 3500 BC. Although they were recognised as being a useful building material, this didn’t make bricks an overnight success, and the use of them was patchy for a very long time. Bricks were always going to be far more expensive than their adobe equivalent because of the fuel costs involved. Good weather and a stable political background helped. It would be difficult to justify the time bricks take to make if enemies were likely to come along and destroy or steal them. This need for a secure environment is an important factor in the history of brickmaking and probably a significant one as to why the manufacturing of bricks took time to spread.

Once fired, the bricks could be built into walls without any need for a mortar. Such walls would need to be several bricks thick, but the subsequent mass of masonry was capable of holding the whole structure together. However, fired bricks are expensive to make and so thinner walls using fewer bricks would become the preferred option. These thinner walls needed a mortar. It was possible to use clay to stick the bricks together. It would set hard and hold the bricks in position. The snag with using clay was that it was vulnerable to being washed out by water. The most practical solution was to use a mortar based on something that would resist water – lime. The history of burning lime is less easy to chart than that of bricks. We know that plasters were being made as far back as 7000 BCE. At that time gypsum (a soft sulphate mineral) was used as the main base but later lime was found to be more durable. This lime was most probably burnt in simple kilns – or more accurately clamps – which were to leave minimal traces behind for future archaeologists. The main proof that lime was being made is its presence in early mortars.

By about 1000 BCE the Romans were building with fired bricks bonded together with lime mortars. They learnt the techniques from others, mainly the Greeks who were keen advocates of the use of both bricks and lime, but the Romans quickly became adept themselves. If this book was a history of world bricks then a chapter on Roman bricks would be very long. They were key players in both the development of making bricks and the improvement of mortars; furthermore, they took their technology with them all over Europe. In a few countries of the Roman Empire the techniques for both burning lime and bricks were adopted and used continually, even after the Romans had gone. For others, Britain included, it came at the wrong time and was largely ignored. During the 400 years of Roman brickmaking in Britain, there is little evidence of indigenous peoples making bricks, and this continued to be the case for some considerable time after the Romans had left. It is possible that the Celts did find learning about lime more interesting but the evidence is patchy. The burning of limestone leaves so little archaeological trace that any evidence as to whether walls were lime washed or even lime plastered would also have been obliterated over time.

For the Romans, firing clay roof tiles was probably the main driver behind the making of bricks and it is certainly true that their roof tiles and bricks were similar. Clay roof tiles were extremely long lasting and could provide a waterproof roof for decades with only small amounts of maintenance needed. The cost of the extra fuel involved was insignificant when compared to the life of the material. The Roman roofing system commonly used in Britain relied on two tiles – the tegulla and the imbrex (sometimes called a vallus). The tegulla was essentially a plain flat tile. The soft clay was pushed into a mould, emptied out and then laid on the ground to dry, or it could be rolled out like pastry and then cut to shape. Sometimes they were given a ridge on the underneath of the upper end to help hold them in place on the roof by hooking over a batten. They often had footprints in them made by people or animals walking over the drying tiles, creating a personal connection with the makers and their animals.

They even scratched graffiti into their surface:

Austalis dibus XIII vagatur sibcotidum.

Translation: Austalis has been going off by himself everyday for these thirteen days.

(Plumridge & Meulenkamp, Brickwork: Architecture and Design, p.18)

The imbrex were half-round sections that covered the joints between the tegullae. Both the tegullae and the imbrices lapped each other to help guide water down the roof slope. Because it was more difficult to make, an imbrex was priced at four times the cost of a tegula.

The Roman brick was in essence a tegulla, and it was primarily used as a way of holding walls together. In a masonry wall they used rubble stone for the inner and outer faces and filled up the middle with a mix of mortar and rubble (an early form of concrete). The tegullae were then laid right across the wall from front to back every few courses (a course is one layer of stone or brick). This gave the wall considerable strength. The bricks and tiles were made where they were needed by skilled workers. Each team would have a mark they could stamp on the back to identify who had made it. The authorities insisted that both bricks and tiles were marked with the date, place of manufacture and the name of the person who had made them – the joys of bureaucracy starting early. The maker’s stamp was called a figlina, and in some parts of the Empire this could even be used to trace tiles or bricks to a specific brickfield. For historians, the figlina is a gift as you can identify which legion went where, e.g. in York there are bricks bearing marks of the 6th and 9th legions. Recent archaeological finds in Silchester have included a tile with a stamp on it that was used to date the building to the very early days of Roman occupation.

A fragment of clay tile showing the print of a foot made before the clay dried. On display at Fishbourne Roman Palace near Chichester. (Photo by CMH, with thanks to Fishbourne Roman Palace Museum)

Roman bricks needed to be big and flat in order to span the whole width of the wall. They couldn’t be too thin or they would break too easily, or too fat, which would make them difficult to manufacture and be very heavy to use. The optimum thickness was between 1.5–2in. These flat bricks were also called cocti or coctiles and came in many sizes. Some were based on palms:

Lydian – four palms by five palms

Tetradoron – four palms square

Pentadoran – five palms square

And some were based on feet:

Bessalis – ⅔ of a Roman Foot square (approx. 20cm)

Bipedalis – 2 Roman Feet square (approx. 58cm)

Thus everything was related back to the size of a person. Our modern obsession with millimetre accuracy has lost sight of this when building. Once, our buildings fitted us quite precisely.

When built in walls, tegullae looked like long thin bricks. Jumping forward a few centuries, this was to become a desired effect, leading to specialist ‘Roman’ bricks being created for architects such as Frank Lloyd Wright, who liked the way they looked. However, for the Romans the bare brick was not appealing and they usually covered their walls inside and out with plasters or renders. Hiding the materials meant that less care could be taken when laying them, thereby speeding up the process. It also meant the mortar layer could be quite thick, saving on more costly materials.

One of the major sources of information on Roman building techniques was Vitruvius; or to give him his full name, Marcus Vitruvius Pollio. He was an architect and engineer who flourished in the first century BCE and wrote a treatise called De Architectura. It was originally written as a handbook for Roman architects but was still being referenced when I was training as an architect in the 1970s. His knowledge was based on his own experience and on the works of Greek architects before him; in fact, he was really looking backwards all the time and extolling the virtues of Greek architecture, and not looking to contemporary practices much at all. Divided into ten parts, it covered a wide range of subjects from urban planning to building materials. He described how to use bricks to hold walls together, what the proper coursing should be and how to bond the bricks so that you wouldn’t get vertical joints (alternate joints increase the strength of brickwork enormously). It is often difficult to know if he was talking about adobe bricks or fired ones. As he praised them for keeping walls both strong and true (perpendicular) far longer than other walls, in this instance, it was probably fired bricks. He does add a caution, though, and one that we shall see carried on throughout history. It was very difficult to tell the quality of a brick until it had been in a wall and exposed to the elements for a while.