20,99 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

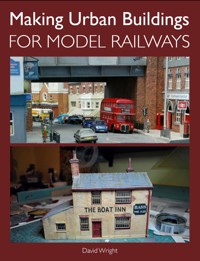

This fascinating book is aimed at all those modellers who wish to create a model railway set in an urban landscape. It covers the selection and the construction of a wide range of urban buildings, and presents many detailed photographs of real buildings from which the modeller can gain ideas, identify specific features and draw inspiration. Special attention is paid to modelling architectural details and to the effects of weathering. Scratch-building techniques and materials, as well as ready-to-plant buildings and kits are covered. In addition to the buildings themselves, the author also considers the urban setting and infrastructure, and demonstrates how to construct roads and pavements, create authentic street scenes, and make realistic models that accurately reflect, for example, urban decay and dereliction. Finally, consideration is given to persepctive modelling, a concept that provides the modeller with an opportunity to make much better use of a limited amount of space.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Veröffentlichungsjahr: 2013

Ähnliche

Making Urban Buildings

FOR MODEL RAILWAYS

David Wright

THE CROWOOD PRESS

First published in 2013 byThe Crowood Press LtdRamsbury, MarlboroughWiltshire SN8 2HR

www.crowood.com

This e-book first published in 2013

© David Wright 2013

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication DataA catalogue record for this book is available from the British Library.

ISBN 978 1 84797 569 0

DedicationI would like to dedicate this, my second book, to a good friend and fellow modeller, John Gaskin, who sadly passed away with prostate cancer while I was compiling it.

DisclaimerThe author and the publisher do not accept any responsibility in any manner whatsoever for any error or omission, or any loss, damage, injury, adverse outcome or liability of any kind incurred as a result of the use of any of the information contained in this book, or reliance upon it.

CONTENTS

INTRODUCTION

CHAPTER 1: INDUSTRIAL BUILDINGS

CHAPTER 2: DOMESTIC HOUSING

CHAPTER 3: COMMERCIAL AND SERVICE BUILDINGS

CHAPTER 4: CREATING THE URBAN SETTING

CHAPTER 5: PAINTING AND WEATHERING

CHAPTER 6: THE URBAN MODELLER’S SKETCHBOOK

APPENDIX 1: SUPPLIERS OF EQUIPMENT, MATERIAL, KITS AND OFF-THE-SHELF MODELS

APPENDIX 2: MUSEUMS AND INDUSTRIAL HERITAGE CENTRES OF INTEREST TO THE URBAN MODELLER

APPENDIX 3: ORGANIZATIONS, SERVICES AND FURTHER INFORMATION

INDEX

INTRODUCTION

Before we look at constructing models of urban buildings for your model railway, it is worth spending some time considering what you may realistically aspire to achieve and what will be physically possible. It is so easy to get carried away in attempting to build a model beyond the capability of one person. Before you start you should ask yourself:

● What spare time can I realistically allow myself to build the model?

● Do I have the physical space?

● Do I have the physical capability?

● Can I realistically afford the expense?

● Am I looking to build a true representation of an actual railway and location, or do I just want to run trains through an urban landscape without a specific authenticity?

● Will I achieve full satisfaction from building this model?

These questions are not intended to put you off, far from it, but it is important to ask them during the planning stage. So many model railways have been or never will be finished because this has not been addressed properly. By definition a model railway set in an urban scene will always lead to grand ideas to create something larger than one in a rural setting. It might, for example, be worth considering only a small urban station or leaving one out altogether. I will endeavour to cover this subject in detail in Chapter 4, where I will look at both planning and setting a model railway into the urban landscape.

Ivatt 2P 2-6-2 tank 41296 awaits to go onto the shed on the 7mm ‘Wychnor-on-Trent’ layout. Photo: John Hancock

The magnificent arch of the Iron Bridge, spanning the River Severn. The first cast iron bridge has become an enduring symbol of the birth of the Industrial Revolution. The valley is now a World Heritage site.

As with all aspects of railway modelling, if we are hoping to build miniature versions of urban buildings it helps to have some knowledge of their history and the materials used to construct them.

In this book I will concentrate on urban development following the Industrial Revolution and up to the present day. This was a period of mass expansion and change that included the development of the railways and other forms of transport.

Close examination of a town will reveal the history of its development from an early nucleus around a market place or square. Before the Industrial Revolution, most were originally market towns that supplied all necessary trades to the surrounding rural areas. This economic model, however, was transformed during the eighteenth and nineteenth centuries. Abraham Darby’s introduction of a coke smelting method in 1709 enabled him to manufacture pig iron of a higher quality and more cheaply than previously. He used deposits of local coal to produce coke to fuel the furnaces at Coalbrookdale in the gorge of the River Severn. The valley soon became a centre of mass production. The gorge today is a UNESCO World Heritage site with a collection of museums describing its industrial past, symbolized by the magnificent Iron Bridge erected in 1779, which spans the river with one enormous arch and gives its name to the complex.

Ex. Midland Class 3F 43244 awaits its next turn of duty to shunt the brewery exchange sidings on the ‘Wychnor’ layout. Photo: John Hancock

LMS Class 4F 44558 returns on the the shed after working brewery traffic. Photo: John Hancock

Cromford Mill was the first successful water-powered cotton mill. It was here that Richard Arkwright pioneered the water frame in 1771, originating the factory system.

Water became the first source of power to operate the new mills and factories. The Industrial Revolution would see these occupying many of Britain’s river valleys and turning them into centres of industry.

A busy goods yard is depicted in this photograph of ‘Wychnor-on Trent’. Photo: John Hancock

The three-storey building in stone is the weavers’ workshop at Cromford Mill. Here hand-loom workers were employed to work up the yarn. This building would make a very interesting subject for a model.

An industrial landscape is modelled to perfection. The photograph shows the goods and coal yards in the station area at ‘Eccleston’. The layout is the work of Martin Nield. Photo: Martin Nield

Another textile mill along the banks of the River Derwent in Derbyshire was built by Thomas Evans at Darley Abbey to produce high-quality cotton thread. Pictured is the oldest building in the complex, the Long Mill, which dates from 1790. The wooden sash-window frames and ‘X’-shaped tie-bar plates should both be noted. A new village was also constructed to house all the workers.

The impressive frontage of Richard Arkwright’s Mason Mill, standing between Cromford and Matlock Bath. It was built from Accrington red brick set on gritstone foundations, with Venetian windows flanking a tier of lunettes. The bell tower was provided to call the workers in for the shift.

The Silk Mill on the banks of the River Derwent was the first factory in the country. Only the foundations and the tower survived a fire that destroyed the original eighteenth-century building, however, the building shown here is a smaller reconstruction that is now the home of Derby’s Museum of Industry. The famous Midland Railway model exhibit is housed on the first floor and the author was responsible for constructing a good number of its buildings and structures.

The Industrial Revolution also saw the introduction and development of machinery for producing textiles, beginning with the Spinning Jenny developed by James Hargreaves. The water-powered spinning frames that Richard Arkwright installed in a mill at Cromford, Derbyshire, were closely followed by others using water power from the River Derwent. Like the Iron Bridge Gorge, the Derwent Valley has now been granted UNESCO World Heritage status.

The new industries required power to keep the machinery running. The first source was water and all the early mills were built along the course of a river to supply this. Later factories and mills would be powered by steam, which required the mining of large quantities of coal. The task of sinking deep pits for this was itself assisted by the development of steam-powered beam engines for draining the mines. With the pumps in place, deep mines started to appear in areas of the country with rich coal measures. Other minerals would be mined and quarried to provide the raw materials required. Coal and its by-products helped to fuel other industries and the mass production of goods from iron, copper, tin and steel. Besides the manufacturing industries, coal would be used for services and to process raw materials to produce food and drink products. This period would see the expansion of the brewing industry from a local activity to the creation of major breweries supplying beer to the world.

Alongside this rapid industrial expansion there was an immediate need to house all the people moving into the towns and cities to provide the essential labour. Most of the labour moved from the country, drawn by the promise of higher wages and a better standard of living. The Victorian era saw towns considerably enlarged as massive areas were covered with terrace rows of back-to-back houses, the most effective way of producing homes quickly for the ever growing population. In addition it was necessary to ensure services to educate, entertain and provide health services and provisions as well as to serve the religious beliefs of the workers and their families. These houses and services would require coal as a fuel to provide all the heating and cooking requirements.

All this industry and housing also required an improved transport system to bring in raw materials and distribute the finished products around the country and abroad. The late eighteenth century would see the construction of a canal network to transport these goods. The first railways were developed to serve the mines, but it was not long before this method of transport was established all over the country to carry both goods and passengers.

In this book I will look at how our urban towns and cities developed and take a detailed look at the various buildings belonging to this era. Both industrial buildings and domestic housing will be examined, together with buildings that were provided for services and transport. As we take a look at the prototypes, I will endeavour to describe how miniature versions can be constructed for our model railways.

A row of original weavers’ cottages at Lea Mills, Derbyshire.

A Duchess rounds the curve and crosses the canal, drifting into ‘Wychnor-on-Trent’ station with an express from the north. Note how this corner of the layout has been filled with the industrial brewery cameos. Photo: John Hancock

TOOLS AND MATERIALS

The following section provides guidance regarding the selection of tools, equipment and basic materials that you will need in order to build models of urban buildings as described in this book. For all the modelling techniques used, I would strongly recommend the wearing of safety glasses.

When measuring large industrial buildings you will need to acquire the longest tape measures you can find. Short tapes are handy for measuring items such as the windows and doors.

While impact adhesives are fine for gluing most materials, they can dissolve some of the foam used in the core of foam board. When you are bonding foam board together it is better to use a universal polyvinyl acetate (uPVA) adhesive.

Bostik is an impact adhesive suitable for most of your modelling needs.

Das modelling clay can be used to create a skin for any stone buildings or to fill gaps on other masonry where embossed styrene sheet has been used.

No More Cracks, a ready-mixed plaster filler made by Unibond, can be used to fill gaps and create rendered and pebble-dashed finishes.

Some of the drawing equipment required to produce a working drawing.

Extra drawing equipment is needed to produce windows with arched or curved tops.

A short metal ruler and small square will come in handy for many stages of model making.

Good quality double-sided tape can be used as a cleaner alternative to glue when fixing slates and roof tiles.

An embossing tool can be used to produce bolt and rivet heads on door hinges and for riveted plates on water tanks, oil tanks and gas holders.

Milliput epoxy putty is used as a filler and to create the flaunching holding the chimney pots to the stack.

A compass cutter comes in handy when cutting arched or curved window apertures.

Embossed plastic building sheets from the Wills range.

Wills corner quoins and brick arched lintels.

A selection of laser-cut industrial window frames from York Modelmaking.

Industrial metal-framed windows with centre-pivoted opening lights. These were commissioned to be etched from drawings by GT Models.

Plastic pipes and valves, such as these supplied by Knightwing, will come in handy when modelling a gasworks or brewery.

Square-profiled downpipes with hoppers produced in resin for 7mm scale by Skytrex Models.

The results of scribing planking on card and then adding the colour by using a Pro-marker pen.

CHAPTER ONE

INDUSTRIAL BUILDINGS

In this chapter I will look at some of Britain’s first industrial buildings as well as those from later periods. The first factories were textile mills. Initially the machinery was powered by water, but this was eventually superseded by steam and finally electricity. Mills became a common feature of the urban landscape, especially in the northern counties of Derbyshire, Yorkshire and Lancashire, although they could be found elsewhere: mills for processing wool, for example, were built in the Cotswolds (Stroud, Chipping Norton and Bradford-on-Avon) and in Devon (Buckfastleigh).

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!

Lesen Sie weiter in der vollständigen Ausgabe!