4,79 €

Mehr erfahren.

- Herausgeber: Pitkin

- Kategorie: Geisteswissenschaft

- Sprache: Englisch

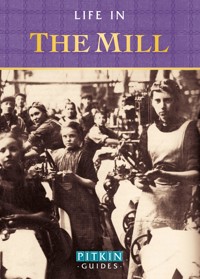

For centuries, most textile manufacturing relied on people working in their own homes. All that changed in 1761 when Richard Arkwright began construction of the first water-powered cotton mill in Derbyshire. The complex woollen industry was transformed as mills spread cross the north of England and into Scotland, with tasks taken out of the cottage and into the factory. This informative guide tracks the development of the textile manufacturing industry, from industrial power looms meeting with Luddite resistance, to the distinctive silk weaving workrooms. Mill towns sprung up around places of work, including special apprentice houses for children. Conditions were harsh and often dangerous, both in the mills and in woollen towns living under permanent palls of smoke. Packed with photographs and illustrations, this is a classic Pitkin guide to the everyday lives of the workers in this mills and towns, from their work to their time off. There was a time when Britain sent textiles around the world: this is the story of the workforce, mainly women and children, who made this possible - and created the factory age. Includes a list of mills, museums and visitor centres to visit.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Seitenzahl: 52

Veröffentlichungsjahr: 2013

Ähnliche

LIFE IN

THE MILL

ANTHONY BURTON

Pitkin Publishing

The Mill, Brimscombe Port

Stroud, Gloucestershire, GL5 2QG

www.thehistorypress.co.uk

This ebook edition first published in 2013

All rights reserved

Text © Pitkin Publishing, 2013

Written by Anthony Burton. The right of the Author, to be identified as the Author of this work has been asserted in accordance with the Copyrights, Designs and Patents Act 1988.

Edited by Gill Knappett

This ebook is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorized distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

EPUB ISBN 978 0 7524 9440 1

Original typesetting by Pitkin Publishing

CONTENTS

Important Dates

The Textile Revolution

A Cottage Industry

Arkwright of Cromford

Years of Invention

The Apprentices

Owen of New Lanark

The Luddites

Power for the Mills

Spinners

Weavers

Finishing the Cloth

Silk Mills

Mill Towns

Time Off

Mill Buildings

Places to Visit

Glossary

IMPORTANT DATES

1589 The Revd William Lee invents a machine for knitting hosiery.

1724 Thomas Lombe establishes a mill in Derby for spinning silk.

1733 John Kay invents the flying shuttle that greatly speeds up work on the loom.

1764 James Hargreaves invents the spinning jenny, which enabled one operative to do the same amount of work as many workers using the traditional methods.

1771 Richard Arkwright establishes a cotton mill at Cromford in Derbyshire, using his newly invented spinning machinery powered by waterwheel. Cromford becomes the fìrst mill town.

1779 Samuel Crompton invents the spinning mule, a machine that combines the best features of Hargreaves’ and Arkwright’s machines.

1786 Dr Edmund Cartwright invents the fìrst automatic loom.

1788 The first steam engine is installed to provide power for a cotton mill at Papplewick, Nottinghamshire.

1798 Robert Owen arrives to take over the cotton mills at New Lanark in Scotland and begins a social experiment to improve the conditions of the workers.

1801 Joseph Marie Jacquard invents a new type of loom for the silk industry that uses punched cards to create elaborate patterns.

1806 Gas lighting is introduced into cotton mills for the fìrst time.

1811 The beginnings of Luddism: framework knitters in Nottingham and Leicester begin smashing machines, with the movement’s leaders appearing under the name of ‘General Ludd’.

1819 The Cotton Mills and Factories Act makes it illegal to employ mill apprentices under the age of nine and limits working hours to 16 a day.

1828 The ring spinning frame is invented in America; by the 20th century it dominates factory spinning.

1833 The Factory Act becomes the fìrst general legislation on the work of children in every industry, limiting the age at which they can start and the hours they can work.

1847 The Ten Hour Act is passed.

1856 William Henry Perkin develops the fìrst aniline dye for silk.

1861 The start of the American Civil War causes a cotton famine in Lancashire.

1904 Courtaulds acquire the UK rights to Cross and Bevan’s cellulose treating process and use it to develop the artificial fibre, rayon.

1937 W.H. Carothers develops a new artificial fibre, nylon.

1950 Introduction of the Sulzer shuttleless loom.

1983 First electronic Jacquard loom introduced in Milan.

2001 New Lanark and the Derwent Valleys are made World Heritage Sites in recognition of their importance in the textile revolution.

THE TEXTILE REVOLUTION

Traditionally the British textile industry was based on wool. At the beginning of the 16th century the human population of England was estimated at three million, but the country supported eight million sheep. Most of the wool went for export, with merchants coming from as far away as Italy to buy fleeces; areas such as the Cotswolds and East Anglia grew prosperous on the trade. The results can still be seen in the magnificent ‘wool churches’ that even quite modest towns and villages were able to afford to build. A proportion of the wool was kept in Britain for making into yarn, to be used for knitting or weaving. Some cotton cloth was also produced, but it was mostly for comparatively modest uses, such as linings for the better class of garments. All that began to change when the British began trading with India.

By the middle of the 17th century cotton cloth was being imported into Britain. Not everyone approved of the importing of foreign cloth: the author Daniel Defoe ridiculed the new fashion, writing caustically of ‘ladies of quality dressed in Indian carpets’ which previously their chambermaids would have thought ‘too ordinary for them’. However, the new, brightly patterned material called calico, after the port of Calicut, proved hugely popular with many people. British manufacturers were beginning to think that they could make far bigger profits by importing the raw cotton instead of finished cloth, and spinning and weaving it themselves. This called for improvements in productivity to meet the increased demand.

The first step forward came in 1733 when John Kay of Bury, Lancashire, invented his flying shuttle. The shuttle carries the weft thread, and is passed from one side of the loom to the other, interweaving with the fixed thread, the warp. Kay’s invention replaced the human hands of the weaver with mechanical hands, operated by cords, and the shuttle ran on wheels. It enabled one weaver to do the work of two. What was needed now was new machinery to increase the production of yarn. Solving that problem began an industrial revolution.

A COTTAGE INDUSTRY

T