Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

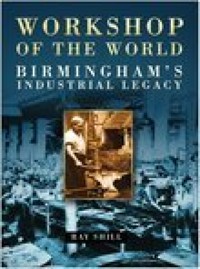

- Herausgeber: The History Press

- Kategorie: Sachliteratur, Reportagen, Biografien

- Sprache: Englisch

Researches Birmingham's industries - primarily the manufacture of components, paints and varnish, plastics, toys, aircraft components, and the food industry. This book interweaves company history and product development with descriptions of technical processes, as well as including site visits. It is also illustrated with a wide range of pictures.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 401

Veröffentlichungsjahr: 2006

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

WORKSHOP

OF THE WORLD

BIRMINGHAM’S

INDUSTRIAL LEGACY

RAY SHILL

First published in 2006

The History Press

The Mill, Brimscombe Port

Stroud, Gloucestershire, GL5 2QG

www.thehistorypress.co.uk

This ebook edition first published in 2013

All rights reserved

© Ray Shill, 2006, 2013

The right of Ray Shill to be identified as the Author of this work has been asserted in accordance with the Copyright, Designs and Patents Act 1988.

This ebook is copyright material and must not be copied, reproduced, transferred, distributed, leased, licensed or publicly performed or used in any way except as specifically permitted in writing by the publishers, as allowed under the terms and conditions under which it was purchased or as strictly permitted by applicable copyright law. Any unauthorised distribution or use of this text may be a direct infringement of the author’s and publisher’s rights, and those responsible may be liable in law accordingly.

EPUB ISBN 978-0-7509-5416-7

Original typesetting by The History Press

ACKNOWLEDGEMENTS

Special thanks must go to the staff of Birmingham Public Libraries (Archives, Local Studies), The National Archives (Public Record Office), Warwickshire Record Office, and to Hudson’s Whistles, Llewellyn Ryland and Kappa SSK.

CONTENTS

Introduction

ONE

Sewing Machine Manufacture

TWO

Wire & Nails

THREE

The Brass Trade

FOUR

The Bedstead Trade

FIVE

The Gas Industry

SIX

Paints & Varnishes

SEVEN

The Plastics Trade

EIGHT

The Chemical Trade

NINE

Beer & Liquor Engine Makers

TEN

Paper Making

ELEVEN

The Toy Trade

TWELVE

Brickmaking & Aggregate Trades

THIRTEEN

The Aircraft Industry

FOURTEEN

Exhibitions for the World

Conclusion

Sources

INTRODUCTION

The inventiveness of Birmingham manufacturers was quite remarkable. Their ability to take on new products and adopt modern methods enabled the introduction of a wide range of different trades and established Birmingham as an important manufacturing centre. They were fortunate to be able to draw on the skills of local people, whose assistance was essential to the continued success of any company. Many firms showed versatility and the ability to adapt and pursue lucrative lines and there was a ready market for their products not only in Britain but also throughout the British Empire and indeed the world. It was no small wonder that when the British Association held their Exhibition in Birmingham in 1886, they credited Birmingham as the Workshop of the World.

Specialist crafts were interwoven with metal fashioning abilities that were to be found in Birmingham and surrounding communities located in the Black Country, Coventry and Redditch. Metal working has remained an important skill through to the present day. The methods might have changed, as have the tools and machines and techniques needed to accomplish the task. Yet metal fashioning is needed as much today as it ever has been.

The first forms of mechanical power entailed the use of water- and wind-powered mills. Water power, in particular, proved invaluable to the development of local industry. The rivers local to the Birmingham district were the Cole, Rea and Tame. They provided a natural, but hard-won power source. Watermills were arranged at strategic places alongside these rivers or the streams and brooks that fed them. A common method was to build up a head of water behind a dam and divert the surplus flow around through a series of man-made channels, called races.

Watermills played important roles in the industrial revolution. Mills were used to grind corn into flour, but their wheels could also be used for industrial work such as rolling metal or grinding edge tools. Some were also adapted to provide the blast for smelting iron, forging iron or pounding rags for paper making. Watermills were a constant feature of Birmingham industry through to the early years of the twentieth century. Perhaps the most famous local watermill is Sarehole Mill, which was a corn mill built in the 1760s that worked through to 1919. It is well known because of its association with the author J.R.R. Tolkien.

Working with water had its drawbacks as supply was sometimes restricted and power of the mill was equally limited to the turning of the wheel, or wheels. The advent of the steam engine enabled factories to move away from the riverside and into the towns. Steam power did much to enhance the development of industry in Birmingham. Steam was a much more versatile means of driving machinery than the water mill. Engines could be placed close to the work and factory bosses were keen to exploit every new refinement in steam-engine technology. A feature of many nineteenth-century factories was the overhead or underfloor shafting that drove belting to dynamos, lathes and other machinery. Gas engines and oil engines added to the versatility of the power. But the most drastic change came through the adoption of electric power, which promoted the use of compact machinery and heavier presses.

In the eighteenth century various prospect views of Birmingham were published. The South East Prospect included the Heath (or Cooper’s) Mill, at Digbeth, which is shown in the centre of the enlarged section of the engraving. Heath Mill stood on the River Rea and used its waters to drive the water wheel. Water supply was controlled by floodgates that were aligned at the junction of the old river and the diverted course, which ran around the west side of the mill. The house (no. 17) belonged to Mr Cooper, the mill owner, while the two horsemen in the foreground are seen on Heath Mill Lane. (Local Studies Department, Birmingham Reference Library)

Birmingham is a town of hills and valleys. This feature was used to best advantage by the windmill builders. Although the Birmingham windmills have long since gone, Windmill Street, Holloway Head, is a reminder of Chapman’s Windmill, which formerly stood on the hillside nearby. This drawing of the Dog and Duck shows the windmill to the rear. (Birmingham Weekly Mercury, October 20 1895)

Tolkien drew his inspiration for his books from a variety of sources that included his childhood homes in Birmingham. Many other authors have also based fictional accounts around life in nineteenth- and twentieth-century Birmingham. There remains a host of untold stories and untold lives hidden in the rich industrial heritage of the district. Intertwined with the hard-working lives of many Birmingham people were the difficult working conditions that were common in the industrial towns and cities throughout Britain. Hardship had no boundaries whether people laboured in the factories and foundries of Birmingham, the mills of Manchester or the coalmines around Newcastle. Some employers, like Cadbury Brothers, adopted a benevolent attitude to their workers. The move from the smoke- and soot-laden atmosphere that prevailed around the city centre to the clean air and new factory site at Bournville was a caring move. Other factory owners shared similar views and made every attempt to improve the lot of their workers. Others did not. Workers’ pay was often low and employment sometimes irregular. There were those who even lived in poverty. Such people were caught in the trap where income barely paid for rent and pawned belongings were the only financial buffer for food.

Yet new industry continued to draw skilled and unskilled workers to the city. From their numbers was derived an entrepreneurial spirit where workers used their abilities to adapt and found further trades. Birmingham at this time supported a large number of small industries and a proportionate small workforce. It was only during the twentieth century that company mergers and takeovers created the large workforce employers. Family-run firms were particularly common where father and sons built up the business.

The simple hand press was the universal tool of many small firms. The basic concept of pressing parts by hand was used to best advantage by the button, gun and steel pen nib makers.(Birmingham Daily Post)

Time and again this pattern is repeated, and some went on to found large concerns. The names of Matthew Boulton and James Watt are frequently connected with the Birmingham engineering industry and their names head a long list of industrialists that were based in the town. Writers and historians have long praised Boulton and Watt as the industrial heroes that set Birmingham to commercial success, but there are many more who deserve a share of the credit and among their numbers the following deserve mention:

Herbert Austin, a pioneer of the automobile industry, set up the Longbridge Car Plant, where motor cars, commercial vehicles and aeroplanes were manufactured.

James Booth, engaged in the manufacture of Duralumin alloys, which assisted the manufacture of aircraft components.

Thomas Carlyle found fortune and success through the making of buttons.

Arthur Chamberlain may have been overshadowed by the political achievements of his brother, Joseph, but was a successful industrialist who turned around the fortunes of Kynochs. The firm founded by George Kynoch went on to be the keystone of the vast Imperial Metal Industries.

Benjamin Cook started as a jeweller and maker of steel toys, but then expanded his business to include the making of ornamental brassware and the first Birmingham-made metallic bedsteads.

Edward and Harry Crane set up a small bicycle-making business that developed into the massive Hercules Cycle Works in Aston.

Dudley, Ludford and William Docker started as retailers of black varnish and went on to manufacture varnishes and paints for automobiles, rail and road vehicles.

George and Henry Elkington brought the principles of electroplating to Birmingham and were integral to the foundation and development of this industry.

Henry Fulford brought new practice to the local brewery trade. Fulford was one of a number of brewers who established successful concerns and a pioneer in the use of up-to-date brewing methods at the Holt Brewery.

Joseph Gillott founded a successful business based on the making of steel pen nibs.

George Kynoch founded a business based on the making of percussion caps, that grew into a diverse group of occupations that included ammunition manufacture, metal working, cycle manufacture and soap-making.

Joseph Lucas began making oil lamps. He and his sons went on to found a multinational company that supplied parts to the automobile and aerospace industries.

Josiah Mason was a notable Birmingham entrepreneur who became a successful steel pen nib maker and was later a pioneer in the electroplate trade.

Alfred Morcam adapted his engineering skills to transform the business of G.E. Bellis into a successful marine engine and steam turbine manufacturing concern.

James Lansdown Norton started in business as a bicycle component maker during 1898 but went on to supply motors for bicycles and develop new motorcycles. He was the founder of Norton Motor Co., which gained an international reputation for the motorcycles produced at the Bracebridge Street factory.

William Priest helped to build up the reputation of the Quadrant Cycle Co. as a leading maker of quality bicycles and motorcycles.

Richard Prosser trained as a brass worker but studied engineering in his spare time. His work with tube manufacture helped to lay the foundation of the weldless tube industry.

John and Edmund Sturge came from Bewdley to establish a chemical works that produced citric acid and pure calcium carbonate.

James Webster came from Nottingham to work in Birmingham as an engineer and inventor. He devised an anti-fouling metallic paint, a method of steel making and a chemical means of extracting aluminium metal. His factory at Solihull Lodge was among the first in Britain to produce aluminium commercially.

Robert Walter Winfield founded an important brass foundry business that made gas fittings and ornamental brass work. He also deserves a share of the credit for the establishment of the metallic bedstead business in Birmingham.

John Wright came to Birmingham from his native Essex to found a gas stove business.

The nineteenth century proved important times for Birmingham industry. Out of the crucible of innovation came a host of new trades, which were developed alongside established business. Labour was constantly being drawn into the town from all parts of the country, bringing valued working skills with it.

In good or bad times, these people formed the reservoir for the many skills required to keep the wheels of industry in motion. There was a select group of common processes, which were adapted to suit the manufacturing trades. Many were related to the metal trades, where both ferrous and non-ferrous metals were worked into useful products. Any metal working begins with the basic metal, which was supplied to be worked up. Some metals, such as iron, were brought from the blast furnace to the foundry where the skills of the caster, moulder and pattern maker were employed to produce a rough casting. Metals were also mixed together to produce a particular alloy. Bronze and the many types of brass were produced at the foundry according to the finely honed skill of the caster’s art. A common aspect of Birmingham trade was for one place to make a rough article and another to take that article and finish it for a particular use.

Charles Purden Ltd factory, Lancaster Street. (Birmingham Daily Post)

In another part of the trade ingots of metal such as aluminium, brass, iron, nickel, phosphor bronze and steel were worked up by the extrusion machines and rolling mills to make bars, hoops, rails, sheets, tubes or wire. These, in turn, were worked up further by pressing, stamping, machining or lathe work into specific products that included buttons, buckles, nails and screws.

Through the working of iron lay the building blocks of a host of different industries. These ranged from cast holloware to the precision castings needed for the engineering trades. Foundries produced the shapes for others to work on and refine through hand filing, lathe work and drilling to the end product. Another method lay in the hands of the drop-forger, who through heat and hammering instilled strength into the metal.

Another aspect of metal work was the shaping and forming of metals by the die stamp and the press. Die stamping had a particular use in medal and medallion manufacture, but later came to be employed for the making of parts for the automotive and electrical industries. The humble hand press fulfilled many roles and was a familiar sight in the many workshops and factories across the city. Its uses ranged from stamping out pen nibs to making buttons. Some metals were easier to work up into a final product. Tin was brought into Birmingham for plating goods, but was also fashioned in finished articles known as pewter. Beer engine makers and bar fitters used pewter components.

A worker at a rolling mill. (Heartland Press Collection)

Heavy press work became an important Birmingham trade through the scientific application of hydraulic and later electrical engineering. Presses were capable of shaping and forming sheets of iron and steel that proved so necessary to car and commercial vehicle manufacture. The making of domestic appliances and railway rolling stock construction came to prominence in twentieth-century Birmingham and is still a staple trade.

George Morgan became noted among the Birmingham firms for quality forging for the car trade and was long associated with the Selly Oak factory that came to bear his name. He belonged to a select group of local businessmen who worked their way up to the level of company ownership. Components Ltd first employed George in 1910, when they were associated with the manufacture of cycle components and motor-cycles at the Dale Road Works. The group of factories in Dale Road included the Ariel Cycle Works and the Midland Tube and Forging Co. George Morgan became general manager for the tube works in 1919 and was still there as manager when, in 1926, the works became known as the Midland Forging Co. Ltd. They remained a Components Ltd subsidiary until 1932, when reorganisation separated the interests of Midland Forging and the Ariel Works, next door. George Morgan and two business associates purchased Midland Forging and set up George Morgan Ltd in 1933 and they continued to supply the needs of the local automotive industry until closure in 2000. (Archive Department, Birmingham Reference Library)

Tool making was just as important to Birmingham trade as press work. All presses were fitted with a ‘tool’, or ‘tools’, that shaped the metal when the press was closed. Each tool had to be made with precision and skill. Tool makers had to interpret engineering drawings and translate the dimensions to make the correct shape out of a piece of hard metal, frequently steel. A range of cutting, drilling and planing machines was utilised to produce the required form that often had to be accurate to a thousandth of an inch. Metal spinning was more than a skill, it was (and is) an art. Various metals, including aluminium and steel, were ‘spun’ on a lathe, working the metal against a wooden paddle that helped the spinner shape the piece into the form required.

The refining of precious metals and the cleaning of other metals such as steel encouraged the establishment of a local chemical industry. This industry diversified during the nineteenth century to include the production of fine chemicals for electroplating and colours for the paint trade. Once the making of town gas had been established a whole new range of chemical by-products became available for working up. Spent oxide from the gas works purifiers became a useful supply of sulphur for acid production.

Birmingham also became the centre of an important varnish industry. Varnishes were used to provide a protective coating for brassware and brought out the rich yellow colour of the different brasses, to enhance their ornamental qualities. All ingredients were imported from different parts of the globe and brought to Birmingham to be worked up as needed. Different formulations made to secret recipes formed the basis of the varnish trade. The local plastics industry developed out of the existing varnish industry, when synthetic resins came to be made in Birmingham.

Glass making was the result of mixing certain substances and heating in a furnace until molten. Sand and lead oxide were major ingredients in the process that made Flint Glass at the various glassworks in and around Birmingham. They produced fine examples of clear and coloured cut glass, while other firms concentrated on the supply of more mundane articles such as lenses for lamps or aspects for signals. Birmingham’s glassmakers were most prevalent during the nineteenth century, although some carried on the trade well into the twentieth century. Numbered among the glassmakers in Birmingham was the work sometimes referred to as a ‘Crib’, where a master worked with one or two small pots. These were small operations, which employed only a few men and boys and made common glassware, such as cruets. There appear to have been five or six similar works distributed across Birmingham who made this basic glassware.

Chunk Works, Coventry Road. The naming of these premises is attributed to the original owner, Thomas Morton Jones, whose association with inventor Dr William Church led to the building of the Chunk Engine Works. Originally devoted to making engine parts and boring cylinders, it is possible that the railway locomotive engine designed by Dr Church was assembled here. Church’s engine is remembered for the fatal boiler explosion at Bromsgrove in 1840, when two railway workers were killed. The Chunk Engine Works passed from Jones to Richard Prosser, who was a Birmingham-born engineer, and then to Alfred Lister. In Lister’s time the premises were adapted to making fenders, stove grates and other castings. (Cornish 1853Guide)

Birmingham engineering firms manufactured a diverse range of products. Heenan & Froude produced the Capel Fan at a factory in Aston before their move to Worcester. This fan was of particular use for underground ventilation in mines. (Kelly’s Directory)

Taylor & Challen advert. The making of steam engines in the Birmingham district is commonly associated with the firm of Boulton & Watt at the Soho Manufactory and the Soho Foundry (Smethwick). Demand for stationary engines for civil undertakings, factories and local collieries encouraged other firms to construct and supply machinery, engines and related parts. Joseph Taylor embarked on his engine-making career first in leased premises in Brasshouse Yard, Broad Street, before moving across the road to take charge of Peter Capper’s Broad Street Foundry. Another move took Taylor to Constitution Hill and a disused papier mâché factory, where the Derwent Foundry was established. (Heartland Press Collection)

The Austin car factory and munitions, Longbridge. Munition making during the First World War led to the building of several Midlands munitions factories. The Austin factory was considerably enlarged between 1915 and 1918 in order to deal with the amount of ammunition and ordnance vehicles produced there. (Mike Oliver)

Nineteenth-century industry presented many challenges for the makers of steam engines. Birmingham had its share of firms, which employed the skilled workforce that was required to produce precision-made parts so essential to the working of the engines. Birmingham cycle making was honed through the engineering skills developed in engine making, the gun trade and sewing machine manufacture. During the twentieth century, these skills were also adapted for the making of motorcycles, automobiles and aircraft components.

Billy Box set up the Electromagnets factory in Bond Street to make magnetic separation machines and electromagnets. (Archives Department, Birmingham Reference Library)

Another diverse use of engineering skills was the making of permanent and electro-magnets. The use of magnets as mineral and scrap separators or for lifting purposes developed during the twentieth century. Any list of the other diverse trades practised in Birmingham would be a lengthy one. The many aspects of the jewellery trade, gun making and the button trade are but some of those trades for which Birmingham is better known. Both metal- and wood-working skills were needed to make both upright and grand pianos, and local supplies of high quality steel wire assisted the establishment of piano making in the city. The skills of the wood worker were put to use in many other ways. Wood was fashioned and worked to make carriages and carts and formed the bodywork for early automobiles. It was used in the making of bedsteads, canal boats, furniture, looking glasses and railway wagons.

Shakespeare, Kirkland & Frost letterhead reproduced a photograph of the frontage of their cycle and motor works in Sampson Road North. Shakespeare & Co. were principally bicycle makers. (Edwards Brothers MS)

Bicycle and tricycle making came to be an important trade in Birmingham, where engineering skills were taken to a new level. Quadrant Cycles of Sheepcote Street were among the pioneers in this trade. (Heartland Press Collection)

Few people connect Birmingham with the leather trade, while many would associate leather working with nearby Walsall. Yet the town of Birmingham has hundreds of years of practice with the making of leather and leather goods. There were several tanneries in the Digbeth area that sent tanned hides to the Old Leather Hall, which was once located in New Street. Saddle making in Birmingham was still being carried on at the time of the Boer War and by 1910 some 80 firms still advertised as saddle and harness makers. These numbers gradually dwindled, but leather working has never left the city. Certain manufacturers came to specialise in the production of leather saddles for the cycle trade. Others produced leather upholstery for automobiles and carriages.

The sap of certain trees produced a type of latex known as Gutta-Percha, which found favour for certain uses in nineteenth-century Birmingham. Manufacturers would import this material to be worked up for footwear and related purposes. Another latex substance was rubber. The making of rubber goods flourished in twentieth-century Birmingham, when several tyre-making and rubber components firms were established in the town. These included international names like Dunlop, whose factories at Aston and later Erdington provided car tyres to customers across the globe.

Working conditions in factories changed during the early years of the twentieth century. Mess, washing and toilet facilities were improved and at larger factories staff were encouraged to take part in social and sporting events. The concessions all helped to ease the monotony of the many repetitive tasks that were the daily lot of the worker. Here tea ladies are seen at the Birmingham Small Arms factory, Small Heath, making their rounds of the cycle and arms factory providing refreshment for the staff. (Birmingham Museum & Art Galleries)

Those employed in the food and drink industries adapted their skills in many ways. Birmingham had its share of breweries (for both beer and vinegar), bakeries, biscuit factories, chocolate makers, crisp makers, mineral water suppliers, tea blenders and toffee makers. Some famous and household names have originated in the city, including Bird’s Custard Powder, Cadbury’s Dairy Milk Chocolate and Typhoo Tea.

Modern Birmingham is now a multicultural city and today there are factories established for the production and distribution of foods to suit many needs. Most notable are the various Asian food factories that have grown up around the city in recent years.

Railway links were essential to the manufacturers of Birmingham. The three major companies, the Great Western, London & North Western and Midland Railway, all had depots in the city where goods packed in open wagons and closed vans were received and sent out by the trainload. Manufacturers had the choice of railway company and dealt with those who could best serve their needs. For Scotland and the North East the LNWR or Midland might be preferred, while destinations in the South West and Wales would be placed with the Great Western. Hockley Goods was owned by the Great Western Railway and was their major depot for Birmingham. Horse-drawn and motor lorries and vans ferried goods and materials between Hockley and the business premises.

Tame Valley Canal, Deykins Avenue. (Black Country Living Musuem)

Hockley Goods station, looking north, 1939. (Heartland Press Collection)

Road cartage and carriage has changed over the years. An important trade across the city was the carter who carried for the different firms transporting manufactured goods and component parts. Many firms maintained a fleet of commercial vehicles for their trading needs. Until the 1920s carriage was principally horse-drawn throughout the town. Firms were put to the expense of buying horses and looking after their welfare. Stable blocks were provided and lucrative business for the carriage builder was maintained. In this photograph a pair of houses are linked up to a Davenports delivery wagon. Davenports were brewers in Bath Row, Birmingham, who set up a home delivery service for their beer and required an extensive fleet of delivery vehicles. (Davenports MSS, Birmingham Library Archives)

The canal network aided the development of the town of Birmingham, moving manufactured goods to destinations throughout Britain or abroad via the ports. Canal trade continued for nearly 200 years. In the illustration opposite a narrowboat is seen loading with parts destined for the Hardy Spicer Factory at Chester Road, Erdington. Other features in this view include the canal lock house, the GEC power station and the Birmingham Canal Navigations pumping station house.

CHAPTER 1

SEWING MACHINE MANUFACTURE

The invention of the mechanical sewing machine was a great asset to the clothing manufacturer. Production of garments was made possible on a far greater scale than was achieved through hand stitching. The basic concepts of the sewing machine, which included the shuttle mechanism and lock-stitch, were developed during the nineteenth century by American inventors, and it was in America that the manufacture of industrial sewing machines progressed. Elias Howe devised the lock-stitch method and took out a patent in the USA during 1846. Finding little interest in America, Howe sent his brother to Britain and found interest with William Thomas, a corset and bag maker from Cheapside, London. Thomas arranged for Elias Howe to come to London and work for him to produce a machine suitable for stitching corsets. Howe, on his return to America, found that several manufacturers had taken up sewing machine making and instituted a legal battle to recover his patent rights.

Early machines had an intermittent feed, but in 1849 Allen Benjamin Wilson improved the design with an automatic system. Two prominent American manufacturers that came to supply the British market were Wheeler & Wilson and the Singer Manufacturing Co. Both firms sent parts to Britain for assembly and sale. Wheeler & Wilson’s product was initially popular with some clothing manufacturers, building up stocks of hundreds of units. Gradually Singer, which was the first to cater for the family as well as the manufacturer, overtook Wheeler & Wilson’s sales.

British inventors were not idle during this period, and eventually new variations on the design were patented in Britain. William Frederick Thomas (the son of William Thomas) produced a range of sewing patents from 1853. An early maker of British sewing machines was the Bradbury factory in Oldham, Lancashire, but such was the number of foundries and press-working firms in the West Midlands that sewing machine manufacture was concentrated in Birmingham and Coventry.

Local trade directories published during the 1870s have a lengthy list of sewing machine makers, although a fair proportion were agents and suppliers for machines produced elsewhere. Thomas sewing machines were manufactured in Birmingham by Charles & William Harwood, who were die and press-tool makers at 54 New Summer Street. As trade increased premises were acquired in New Loveday Street, which became known as the Britannia Foundry.

Nottingham-born Arthur Maxfield was the owner of several sewing machine patents that led to the design and production of the Agenoria model. Together with Isaac Cole and Charles Fowke, Maxfield formed the Franklin Sewing Machine Co. in 1868. The Franklin Sewing Machine Works was set up on the corner of Musgrave Road and Park Road, Hockley and remained in their ownership until 1874. Isaac Cole left the firm to set up in business in Edinburgh. In January 1873 Cole signed an agreement with Maxfield for the supply of Agenoria sewing machines, whereby Maxfield would supply at least 18 machines each week to Cole. Isaac Cole was also given the rights to sell Agenoria machines in Scotland and elsewhere in the world, while Arthur Maxfield retained the rights to sell in England, Wales and the Channel Islands.

The resulting changes at the Franklin Works were accompanied by the takeover by Joseph Harris and John Judson. Joseph Harris had a variety of business interests and owned a steam-powered dyeing works in Birmingham. He also became an agent for the sale of different brands of sewing machines. Harris & Judson produced the Challenge and also supplied Agenoria sewing machines. They also changed the name of the factory to the Imperial Works. Arthur Maxfield moved to 71 and 72 Spencer Street, where the Agenoria machine continued to be made. Rights to make both the Agenoria and Challenge models were sold to the Royal Sewing Machine Co. in 1877, when the Imperial Works were closed.

The Franklin Sewing Machine Works, Park Road.

Another event of 1877 was the closing of the Breech Action Manufacturing Works at Small Heath. Known as the Regents Works, this factory had been established in 1871 and adjoined the Royal Sewing Machine Factory. It engaged in the varied trade of making Martini-Henry breech actions, sewing machines and roller skates.

Sewing machine making was a competitive trade, and works closures and bankruptcies were regular events within the industry. Names that came and went included the firms Thomas Barton (Lionel Street), The Birmingham Manufacturing Co. (36 Holloway Head), Greville, Harston & Co. and Thomas Slater (18 and 19 Edmund Street). Charles and William Harwood faced similar problems. They transferred their business to 101 Newtown Row, where Thomas machines continued to be made. Their new premises comprised upper and lower workshops complete with foundry and a smith’s shop. Harwoods formed the Harwoods London Machine Co. Ltd, which was quickly in financial trouble and suffered liquidation in 1875. The factory was then taken over by W.F. Thomas & Co., who continued sewing machine making there until about 1884. William Harwood carried on a separate business making and repairing sewing machines in a part of the Old Mill, Porchester Street, Aston, until April 1877.

Newton Wilson & Co. and the Royal Machine Manufacturing Co. Ltd were numbered among the more successful and longer-lived companies. The Royal Machine Manufacturing Co. (of Herberts Road, Small Heath) was formed in 1868 and was associated with Thomas Shakespear & Co., who sold their products through their depot at 32 Union Street. Shakespear had been agents in Birmingham for Wheeler & Wilson’s models since 1860, but lost the agency about the time the Royal was established. Shakespear then started to advertise Wheeler & Wilson machines made at the Herbert Road Works. It was a situation which the Wheeler & Wilson Manufacturing Co. of Broadway, New York, contested. In 1869 Wheeler & Wilson published advertisements in the Birmingham papers that Shakespear had no authority to sell their sewing machines, represent them or use their name. Wheeler & Wilson models were sold through an office in the Exchange Buildings, Stephenson Place in Birmingham. Shakespear, at the time, advertised Wheeler and Wilson models alongside the Shakespeare Lock-Stitch hand machine. They continued to run their advertisements for a time using the term ‘Royal’ Wheeler & Wilson but eventually withdrew all mention of the Wheeler & Wilson name and simply called this model of machines the Royal.

The Royal Sewing Machine factory comprised a range of two- and three-storey shops that included show rooms, packing rooms, machine shops, fitting shops, screw making shops, wheel shop, rim shop, smithies and stoves. They produced a range of different brands that had been devised by themselves or acquired from other manufacturers: the Shakespear, Windsor, Times, Challenge and Agenoria were numbered among their product lines in 1878.

The firm of Newton Wilson and Co. owed its origin principally to William Newton Wilson, whose patents of the early 1860s included several improvements to the basic sewing machine design. Wilson, who traded from 144 High Holborn in London, had previously patented a washing machine in 1858. In 1860 William Wilson described himself as manufacturer of sewing machines when some improvements were suggested in his next patent petition that incorporated information supplied by Lucius Bijeleur of Boston, USA. Wilson set up a factory in Birmingham, first in Floodgate Street and subsequently at 52 Pope Street, in the Jewellery Quarter. The St George’s Foundry was established at the Pope Street works and it was here that Princess of Wales brand of machine was produced.

One of the trademarks of the Royal Sewing Machine Co.

Mechanical sewing machines had a ready market among garment makers and the leather trade. One local tailor contributed to the pool of invention through devising an improved machine for making buttonholes. James Moore Clements had a tailor’s shop in Livery Street when, in 1862, he was granted a patent for a new arrangement of stitching the hole. The success of the design enabled him to set up his own works.

Some firms chose to specialise in the making of components, rather than make complete machines. William Bown (of 308 Summer Lane) was one who founded a business for the supply of sewing machine components such as shuttles, shuttle reels, springs, binders, hemmers and tuckers. Bown’s business had been established in 1860, and he prospered by selling sewing machine parts and components for bicycles and tricycles. A notable achievement on its part was the purchase of the licence for hill-climbing gearing for velocipedes, which was to prove to be an important benefit for cyclists. Bown’s involvement with sewing machines continued to diversify as new ideas and concepts evolved. During 1885 and 1886 the firm became associated with the Moldacot Pocket Sewing Machine Co. of London for the supply of 50,000 pocket sewing machines.

The demand for bicycles created a new industry for the Midlands and led to the sewing machine makers adapting their business to cycle manufacture. The Royal Machine Manufacturing Co., of Small Heath, added the making of bicycles and tricycles to their range and gradually ran down their sewing machine trade, while William Bown also concentrated on the making of cycle components. Newton Wilson & Co. changed their name to the St George’s Engineering Co. They made the New Rapid bicycles and tricycles and came to concentrate on this aspect of the trade during the 1880s. Sewing machine making ceased at Pope Street in 1887, when the foundry plant, with cupola, crane, sand mill, moulding boxes, ladles, patterns and pig and scrap iron used for making sewing machines, was offered for sale.

A few firms still traded as manufacturers, such as the Two Reel Sewing Machine Co. Ltd (Albion Street) and the Ernest Street Sewing Machine Works (Holloway Head), but only one, Smith, North & Priestman (Ellis Street), remained in the trade after 1900. Agents continued to deal in the sale of machines assembled elsewhere, but the large-scale production of sewing machines was now left to factories in other locations. Most notable perhaps was the Singer factory at Kilbowie on the River Clyde, near Glasgow.

CHAPTER TWO

WIRE & NAILS

The method of wire drawing was briefly discussed in Birmingham’s Industrial Heritage (Sutton Publishing, 2002). Wire made from ferrous and non-ferrous metals was worked up to a variety of products that included crinolines, fish-hooks, nails, needles, pins, screws, springs and umbrella frames. Steel and iron wire was employed in the making cables, hawsers and ropes, while special quality steel wire proved suitable for piano wire. Wire was fashioned to make chains for lamps, chandeliers or scales. It also was an essential component for fenders, fire guards, meat safes, rat traps and window blinds.

Thick wires were generally used for fencing and telegraph purposes, while finer wires were required for hooks and eyes, needles and pins. The firm of Sharp & Brown, Fazeley Street, established in 1853, adopted a process that changed little with the years. Their mill was capable of producing nearly 100 tons of wire per week. Iron was delivered by canal boat from the Stourbridge iron manufacturers in bars 20ft long by 2in square. These were then cut into shorter lengths, of about 3ft long, and heated in a furnace until red hot. Each bar was drawn into a rod, some fifty times its original length. The rod was then cooled and coiled up on a wheel. The coils were then pickled in acid, and left for the attentions of the wire drawer, who reduced the diameter of the rods to wire of the required thickness.

WIRE DRAWERS

Not every manufacturer had the equipment or skills to draw the wire down to the necessary widths, and demand for specific diameters of metal wire sustained a number of firms which acted as middlemen working up wire to suit the needs of specific customers. Frederick A. Power supplied bright drawn steel wires of different thicknesses to a number of customers. This firm was established in about 1877 on vacant land beside Metropolitan Road, Saltley, that became known as the Midland Mills. It later moved to the Adderley Park Mills, which had been vacated by the Birmingham Metals & Munitions Co. during 1919. These works were subsequently enlarged when Power’s came to occupy the adjacent Union Paper Mills when Smith, Stone & Knight concentrated their business at Catells Grove.

Wire drawing was a particular skill, as wire had to be drawn with accuracy, often to a thousandth of an inch. Drawing was also a team effort where a drawer and loader worked together for each machine. The loader put the wire onto the machine, while the drawer set the process in motion and was responsible for the successive die settings that reduced the wire to the required diameter.

Power owned several different types of drawing machines. One type was known as the ‘Longholer’, where a coil of steel wire was drawn through a die box onto a ‘Diablo’ shaped drum. This drum then fed through another die box to a second drum and so the process was repeated with dies and take-up drums until the required thickness was achieved. Every pass through the die reduced the diameter of the wire by degree, and banks of five or eight ‘Diablos’ and die boxes were arranged in each Longholer. With every pass through the die, the wire was lubricated by soapy water. Each batch of wire was pointed before being set through the die, and subsequent lengths of wire were soldered onto the preceding one, so that a continuous process was set up. This was a physically demanding job, with workers constantly handling heavy coils of steel, but once a pattern had been established skilled loaders and drawers could process up to 24 tons of wire a day.

Firms like Power produced rolls of wire to a range of thicknesses and these were sold for a variety of uses. Some were exported, others found use in the local mattress, nail and screw factories.

WIRE WEAVING

The firm of G. Baker & Co., Birmingham Wiremills & Wireworks, Chester Street, received wire from the wire makers in rough coils. Iron, copper and brass wire were purchased in different lengths and delivered to the Chester Street Works for weaving into mesh and netting or making into chandelier chains. Wire was ‘pickled’ in long troughs containing a special mixture of acid and lime before being reduced to required thickness through drawing.

Baker’s business as described in 1880 reveals a factory capable of working wire into many forms. Baker’s own patent chain-making machines were devised in about 1848. These machines were capable of taking brass wire and forming it into lengths of double-link brass chain, each link having its circles neatly bent, ends turned in and hanging around the next link. In another part of the factory upholsterers’ nails and staples were turned out.

Wire netting was made by the aid of bobbins and a frame, but during the 1850s a new development copied the process used in the Nottingham lace-netting machine and Baker & Sons purchased a machine based on these principles for their Aston factory. The partnership that comprised the firm of George Baker & Co. was dissolved during November 1883 and the plant at the Birmingham Wiremills & Wireworks, Chester Street was offered by sale by auction on Monday 17 December 1883. Baker then transferred his business to premises in 68 Cecil Street, where the business of wire working and weaving was continued through to the twentieth century. George Baker died in 1895, but members of the Baker family continued to run Cecil Street Works.

Other adaptations of the wire weaving trade included mattress manufacture, which became a staple trade in Birmingham alongside the metallic bedstead trade and wire grid work for paper manufacture.

Newey Factory, 54 Brearley Street. Hooks and eyes were produced at the original three-storey factory near the corner of Summer Lane and Brearley Street. (Kelly’s Trade Directory)

HOOK AND EYE MANUFACTURE

Laces, pins and buckles were commonly used to hold garments in place. Another more specialist type of fastening was the hook and eye arrangement. Thin wire was fashioned into hooks and eyes for the clothing industry, where they were used on certain types of undergarments. Birmingham became an important centre for the trade, which developed during the early years of the nineteenth century. Over twenty different firms included hook and eyes as part of their trade, but one, owned by the Newey family, deserves the lion’s share of the credit for the establishment of the hook and eye in Birmingham.

Newey’s former factory in Brearley Street, May 2000. The Newey family owned a group of adjoining buildings in Brearley Street and Summer Lane. In addition to the original factory there were shops and houses, which were eventually incorporated into the factory site. The original factory building still has the stone plaque advertising its royal patronage. (Ray Shill)

A 1960s advertisement showing the range of fasteners supplied by Newey’s. (Birmingham Chamber of Commerce Journal)

The frontages of buildings in Brearley Street still comprise a mixture of industrial properties, May 2000. (Ray Shill)

Richard Newey began the family business making steel toys in Birmingham during the latter half of the eighteenth century. These included shoe-buckles, whip mounts and watch keys which were made by stamping and pressing at a factory in Loveday Street. Richard Newey died in 1798 and the business passed to his son James. In 1804 the business was moved to Summer Lane, where hook and eye fasteners were first made. James George Newey joined the firm in 1820 and later succeeded his father in the business. He patented a new design of hook and eye, called the Swan Bill Hook, in 1846. It proved to be a practical design and generated many sales for Newey. A new factory was constructed in Brearley Street in 1850, which still stands. Some of the toy range, which included split rings for ale and gas taps, also continued to be made at Brearley Street.

During the First World War Newey’s made fastenings for many clothing items, ranging for greycoats to gun belts. Newey’s continued to specialise in the fastener trade after the war, and retained a separate existence until merging with pin makers D.F. Tayler in 1934.

PIN MAKING

Pins were commonly made from brass wire cut to length, headed, and dipped in tin. Several pin-making firms were established in Birmingham. They sold their produce to the wholesale drapers and to haberdashers or for export through Birmingham-based export merchants.

The making of a simple pin required several processes. It was once a very labour-intensive trade, but was mechanised in the Victorian era through the development of machines that made pins directly from wire. Thorpe, Latham & Kilminster had a pin works in Lancaster Street, which originally made pins by the old method. A description of pin making at their works was published in West’s Warwickshire Directory that was published in 1830. Some twelve separate processes were evidently needed to make a pin.

Thorpe, Latham & Kilminster’s factory at 5 Lancaster Street was taken over by the firm of Palmer & Holt. During 1840 an inspection was made by R.D. Grainger to examine the conditions in which children were employed at the two Birmingham pin factories belonging to Palmer & Holt and to Thomas Phipson & Son, which provides graphic details of the way children were treated. Boys and girls as young as seven years were employed in the heading shops from 8 a.m till 7 or 8 p.m.

Thomas Phipson & Son had a long history of pin making in Birmingham and could trace their firm back to start of the trade in the town. Samuel Ryland had commenced wire drawing and pin making there during the middle of the eighteenth century. Ryland established a pin factory in New Street, which passed into the ownership of his nephew, Thomas Phipson Jnr. Thomas Phipson & Son remained at New Street until the mid-1830s, when they transferred to a canal-side factory at 12 Broad Street. They occupied these premises for some ten years before moving again to Mott Street.

A description of the pin manufactory of Messr Thorpe, Latham, and Kilminster near to the Birmingham and Fazeley Canal (West’s Directory 1830, p. 223)

We were highly gratified in viewing with what celerity the twelve different processes were gone through, in forming and completing an article, of which four times that number of the manufactured article are disposed of for one half penny. The 1st process, is that of cleaning the wire when received from the mill.

2nd The wire drawer

3rd The straightener

4th The pointer, who cuts the wire into six lengths, in 400 or 500 in one handful, although the shears will only admit of the wire being laid flat, and every pin cut distinctly.

5th The pointer holds and points about forty at a time, in almost an instant.

6th The header

7th The head drawer; this part of the process requires peculiarly fine tools.

8th The twister of the wire, which form the heads

9th The head cutter, who cuts about fourteen at one stroke

10th The whitener, under whom the pin goes through several processes

11th The sticker on the papers, in which a small scored frame is used, as a guide to fix a row instantaneously

12th The making them up in packets for the market