Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The History Press

- Kategorie: Sachliteratur, Reportagen, Biografien

- Sprache: Englisch

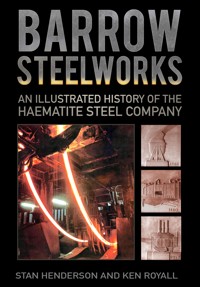

During the second half of the nineteenth century, Barrow-in-Furness became a pioneer in iron and steel production. It went on to grow astronomically – owning collieries in three counties and ore mines in two – and became the largest integrated steelworks in north Lancashire and Cumberland and, at one time, the largest steelworks in the world. Its success was due, in part, to having the prestige of three dukes as directors, as well as to being only 2 miles away from one of the largest and richest iron ore mines in the country. Written by two former employees of the works, Barrow Steelworks chronicles the company's past from the early empire through the inter-war and post-war years, the development of continuous casting in the 1950s, which revolutionised steelmaking, and, finally, the struggles and ultimate demise from the 1960s onwards of this once prominent industry.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 130

Veröffentlichungsjahr: 2015

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Bessemer steelmaking. (Geoff Berry)

Authors’ Note

Limitations of space, and thereby cost, have mitigated against the inclusion of all information collated about the works and processes of the British Haematite Steel Company (BHS). More so regarding the Open Hearth process (chapter 6). It is hoped to correct this by the publication of another book – a companion to this current work – at some point in the future.

Acknowledgements

This book relies on references to and quotations from several publications. A bibliography of works consulted is included to allow the reader the opportunity for further reading.

I wish to acknowledge the invaluable assistance given by so many who directly or indirectly contributed. I am indebted to my late friend and colleague, George Hurley of the Ship Drawing Office of Vickers, Barrow. George provided my copy of the Iron and Coal Trades Review, which has been the main reference source for the early years of the works. He also related many amusing anecdotes – which could easily become the subject of another book.

In particular, I would like to thank Julie Bromley of Corus Rail, Workington who facilitated a visit to the Workington No.1 rail mill in 2002. Also Matthew Roylance for his editing skills, and all that such necessitated.

Grateful thanks to ex-Barrow steelworkers Derek Barnes, Albert Brennan, Jim Ducie, Tony Frankowski, Jim McGlennon, Peter Keenan, Ken Law, Ray Millard, Billy Miller, Bill Pearson, and Jim Walton, who between them have over 300 years’ experience on which to draw.

Acknowledgements are made to the staff of Cumbria Archives and Local Studies Centre (Barrow), Bill Myers and the Barrow Evening Mail and Sabine Skae of the Dock Museum. The Barrow coat of arms is used under open data from Barrow Borough Council, 19 May 2011.

All photographs used in this book, unless stated otherwise, were taken by K.E. Royall, manager of the Fuel and Instrument Department (also the work’s photographer from 1957), or sourced from his extensive collection. Every attempt has been made to contact copyright holders. Plate negatives (12x10) now reside at the Dock Museum.

Contents

Title

Authors’ Note

Acknowledgements

Introduction

1 Hindpool

2 The Hindpool Blast Furnaces

3 The Birth of Bulk Steelmaking

4 Rolling Mills and Soaking Pits

5 The Hoop and Bar Mills

6 Open-Hearth Plant and Steel Foundries

7 Boilers, Engines and Transport

8 The Development of High-Speed Continuous Casting

9 Barcon

10 Fuel and Instrument Department

11 Sport and Leisure

12 Subsidiaries

13 Hoop Works Rundown and Closure

14 Steelworks Closure and Demolition

Epilogue

Glossary

Appendices

Appendix I

Appendix II

Appendix III

Bibliography

About the Authors

Copyright

Introduction

This book is an attempt to write a local industrial history, at grass-roots level, which may be of value to a new generation of students. It is not about the founding fathers or the rich mine owners of whom much has already been adequately documented. Neither is it an economic history. The book is about the buildings, plant and machinery that collectively comprised the once-mighty Haematite Steel Company at Hindpool. It is also about the men and women with brains and ingenuity and the men whose sweat and aching muscles ran the mills and furnaces of this once colossal works. The project has been an undertaking pursued by the authors in an attempt to preserve the memory of the once prominent local iron and steelworks, and the lives of some of the many who contributed to the works having the unique distinction of twice being a world leader in steelmaking technology nearly 100 years apart. The Iron and Coal Trades Review of 4 August 1899 noted:

Barrow works of the first magnitude were erected to stand or fall by the manufacture of Bessemer steel, and primarily of the rolling of that steel into rails, which had been done nowhere else. It was a bold experiment. The conditions under which the rail manufacture was carried on were hardly sufficiently fixed to determine whether it would be entirely successful. The only rails previously made in England had been treated as cast steel and hammered from ingots 7 or 8 inches square and 4 feet long in four heats. It was some time later before the size of the ingot was raised to a sufficient size to make two thirty feet rails. By the 1870s ingots at Barrow are produced of 5 and 2-tons in weight, and the mills are capable of rolling rails 250 feet in length. The only limiting factor being the amount of metal the Hindpool furnaces could deliver.

Many years later, during the 1950s, the aforementioned ingots would be tossed onto the proverbial scrapheap when Barrow works developed a high-speed process for the continuous casting of steel billets and slabs. This high-speed process consigned several steps of orthodox steelmaking to the history books. Barrow once again played host to the world’s steelmaking fraternity as delegates from steelworks as far away as Japan came to the town, in much the same way as they had in 1874 when Andrew Carnegie and the Iron and Steel Institute came to Barrow. The unfortunate thing was the achievement did nothing to boost the town’s economy, or for jobs locally. Taking the broader view, the successful development work in Barrow was part of the biggest improvement in steelmaking since the Bessemer process itself. It may be of interest to note that the casting speeds achieved at Barrow during the 1950s are still an unbroken record.

The idea for this book was hatched in 1984, after having salvaged various items from a skip on the demolition site, which would be visited almost daily. I suppose that like many others I found it hard to accept that it would soon be gone, having grown up in the shadows of its tall chimneys, rumblings, screaming furnaces and general daily commotion. It was assumed that, like Black Combe in the background, it would stand forever.

There are still several gaps in our knowledge with regard to the early history of the works and then the interwar years. Unlike Workington Iron and Steel Company, very little has been recorded – or survived for posterity. By far the best reference source is the Iron and Coal Trades Review of 4 August 1899, the narrative of which was copied verbatim in the report of the Iron and Steel Institute visit to the town in 1903, then again in the 1937 book Barrow Steel. The reasons for the production of the latter publication have always been a mystery. This book, which makes reference to being a modern steelworks (which it certainly wasn’t), was issued just two years before it was poised to close down – but for the onset of the Second World War it most certainly would have. Was this book, then, intended to stand as something of a memorial to a glorious past?

It is not possible in this type of book to give an account of all plant and machinery, which for a period of over 100 years was being constantly upgraded, replaced or rearranged; such a book would take on encyclopaedic proportions, or become just one large engineering inventory. The authors therefore have focused on items, hopefully, of historical significance.

During the thirty years spent collecting information it has not been possible to ascertain the location of the metal mixer, details of the slitting mill, tin bar mill or tyre mill. We do not know precisely when steelmaking by the Bessemer process ceased. It is a fact that whilst the place was an integrated steelworks it was not designed that way. The steelmaking side, east of the Furness Railway main line, was in fact a bolt-on, being laid down six years after the ironworks was established. This meant that the transporting of molten iron between blast furnaces and converters was not ergonomically sound, a journey of over 1 mile being involved for the ladle cars. At Moss Bay, Workington the same journey for the ladles was about 150yds.

S. Henderson, 2014

1

Hindpool

Queen Victoria died on 22 January 1901 and she had reigned as Queen of the United Kingdom since 1837 when she succeeded William IV. During her reign massive advances were made in technology and there was a worldwide expansion of boundaries due to the development of railways, heavy engineering and telegraphic communication. Her long reign spanned the second part of the Industrial Revolution and locally the period of what was Barrow’s greatest development. The most significant early effects of this progress were in the areas of the Strand and Hindpool. Hindpool became home to many local industries, and by far the largest and most significant was the iron and steelworks, aided in no small measure by the Furness Railway Company. From the excellent 1958 work of Dr J.D. Marshall we learn that the land at Hindpool, which became the site of the iron and steelworks, was bought by the Furness Railway Company from the Cranke family of Urswick.

The site was leased to Messrs Schneider and Hannay for the erection of blast furnaces. The first two were laid down in 1857 and put into service in 1859. By 1860 there were four, seven by 1862 and ten by 1866. With the forming of the Barrow Haematite Steel Company in 1864, Schneider and Hannay’s partnership was dissolved, with their assets at Hindpool, together with the mining interests in Furness, incorporated into the new company, of which they became directors.

By 1870 there were fourteen blast furnaces and eighteen Bessemer converters deployed in iron and steel production. The steelworks, which occupied the site to the east of the Furness Railway’s main line, had a frontage on Walney Road of almost 1 mile and covered a vast area.

To cater for the rapid expansion of the town and the influx of workers, Hindpool became like one large building site. A London firm was contracted to build an estate of terraced houses. The steel company engaged a Scottish firm, Smith and Caird, to build a block of flats using local sandstone on a triangular piece of land adjacent to the works. These flats, because of their resemblance to Glasgow tenements, became known as the Scotch Buildings. They housed about 950 people – more if they were well acquainted. Although an eyesore latterly, upon completion they must have looked quite impressive with their wide pavements of Coniston green slate around the external perimeter. These pavements were to survive for a few years after the original buildings disappeared. Demolition work began in May 1956 by John Binnell of Cameron Street, Barrow Island although the last vestiges managed to survive into early 1960.

The area known as Lower Hindpool had the largest concentration of ironworkers. These were the streets between Duke Street and Hindpool Road and in the early days of the works were occupied mainly by migrant workers. As iron and steelmaking was thirsty work this area boasted the most pubs and alehouses. The main watering hole of the ironworkers was the Hindpool Hotel, found on the corner of Hindpool Road and Blake Street and said to have the longest bar in the town. Steelworkers tended to favour the Queens Hotel, another large establishment with twelve bedrooms and stables to the rear, on the corner of Blake Street and Duke Street. Another popular venue was the Hammer and Pincers (later the New Inn) on the corner of Franklin and Steel Streets. Built by William Gradwell, this pub used to supply ‘near beer’ to the mill workers who, in those early days, could be working up to sixty hours per week. In later years the Wheatsheaf, on Hindpool Road, assumed the mantle of the area’s best pub and was regularly frequented by steelworkers. Never before had there been such a coming together of wit, talent and characters, the pub could have easily been the last bastion of the Anacreontic Society in its celebration of wine, women and song!

Hindpool people referred to the flats as simply ‘the buildings’. In 1933 the steelworks sold them to a housing association for £18,000.

View of the Scotch Buildings from the south c. 1955. Looking up Blake Street, St James’s church and school can be seen in the distance; most of the construction costs, as well as the land, were paid for by the steelworks’ directors. Just visible to the left, along Walney Road, is the entrance to Tay Street.

The Duke Street elevation. The Steelworks Club, which was on the corner of Duke Street and Walney Road, is to the right of the photo. (James Melville, courtesy of Alice Leach)

Demolition of the Scotch Buildings on 22 May 1956. Binnell’s lorry is at the junction of Duke Street and Walney Road tugging at a section of roofing.

Two views of the Walney Road facade under the British Steel Corporation banner, 1970s.

Map of Hindpool, extract from O.S. Map sheet 21, 1874.

2

The Hindpool Blast Furnaces

As originally constructed, the blast furnaces were 45ft in height, being raised in 1871 to 62ft. They were open-topped, allowing the hot gases produced to escape to atmosphere. The boshes of the larger furnaces were 21ft and the smaller ones 17ft in diameter. Each furnace was fitted with six tuyères.The blast, heated partly by Cowper and partly by Gjers stoves, (later upgraded to Whitwell) was originally 900°F, raised in 1890 to 1,270°F. The hoists were inclined planes, and fourteen furnaces were fitted with six inclines, each with a separate pair of engines (referred to later) and winding drums driven by friction gear and fitted with steam brakes. A high-level platform allowed the charge to be conveyed to each furnace by men known as ‘barrow-wheelers’. The average weekly output of the furnaces was gradually increased as mechanical improvements were made, from a capacity of 500 tons in 1875 to 600 tons in 1890 and to 720 tons in 1898. The Hindpool furnaces were more than successful.

Later, the furnaces were modified by Josiah Smith, general manager, for collecting and utilising the waste gases. The furnace tops were closed off by incorporating the bell-and-hopper system invented in 1850 by George Parry of Ebbw Vale. The gas take-off was just below the hopper at what was called the furnace throat, and from here large pipes called down-comers directed the gases to ground level. Initially these gases were directed back to the foot of the furnaces to heat the blasts. Further developments saw these gases distributed to the steam-raising plant around the works – recycling before the term had been coined! From the mid-1870s the Hindpool blast furnace plant was deemed the finest and most modern in the country.

Initially the coke for use in the blast furnaces was brought in from Durham, 130 miles away, by wagons of the Furness Railway. The costs associated with this were more than compensated for by the benefit of having the richest of haematite ore on the doorstep. Years later, when the local ores became depleted and the basic method of steelmaking became established, these carriage costs became significant.